Lithium-ion battery and preparation method for same

A lithium-ion battery, liquid electrolyte technology, applied in the direction of electrolyte battery manufacturing, secondary battery, battery pack components, etc., can solve the problems affecting the electrochemical performance of the battery, electrolyte leakage, poor safety performance, etc. performance, reduce leakage, overcome the effect of electrolyte leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

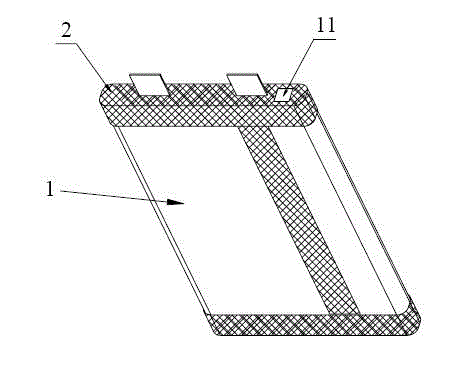

[0028] Accordingly, the present invention provides a lithium ion battery and a preparation method thereof, which can better avoid the influence of monomers and initiators on the negative electrode SEI film, and have better safety performance. The lithium ion battery provided by the present invention includes: a casing, a pole core accommodated in the casing, the pole core includes a positive pole, a negative pole, and a diaphragm between the positive pole and the negative pole, and a liquid electrolyte is contained in the pole core. Gel is filled between the pole core and the shell.

[0029] The pole core structure of the lithium ion battery of the present invention can be similar to that of the existing liquid lithium ion battery, and the liquid electrolyte is accommodated in the diaphragm.

[0030] The gel contains or does not contain conductive lithium ions, preferably, the gel does not contain conductive lithium ions, so the gel is not used as a gel-state electrolyte, and it...

Embodiment 1

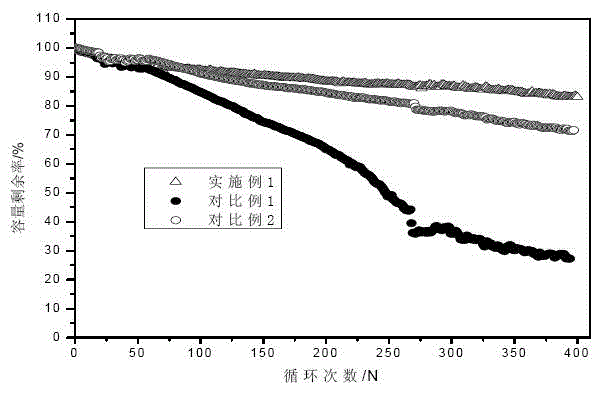

[0055] The separator and positive and negative electrode materials (LiCoO 2 Positive electrode / diaphragm / graphite negative electrode), wound into a battery pole core; paste tape on the bottom of the pole core and the winding end, reserve the first liquid injection port on the top of the pole core, and paste tape on the rest of the position; from the first Injection port containing LiPF 6 and the first solution of EC-EMC-DEC-VC organic solvent, wherein, LiPF 6 The concentration is 1mol / L, and the weight ratio of EC:EMC:DEC:VC is 4:3:2.5:0.5. After aging, precharge the battery; The position where the core is wrapped by the tape is injected with a second solution containing 9 wt% tetraethylene glycol dimethacrylate, 1 wt% dibenzoyl peroxide and 90 wt% EC-EMC-DEC-VC mixed solvent, Among them, the weight ratio of EC:EMC:DEC:VC is 4:3:2.5:0.5; heating at 80°C for 60min, heating triggers the polymerization of the second solution to form a gel, and the lithium ion battery A1 is obt...

Embodiment 2

[0065] The separator and positive and negative electrode materials (for example: LiCoO 2 Positive electrode / diaphragm / graphite negative electrode), wound into a battery pole core; paste transparent tape on the bottom of the pole core and the winding end, and after the first liquid injection port area is reserved on the top of the pole core, the rest of the position is pasted with transparent tape. Inject 1M containing LiPF from the first injection port 6 and the first solution of EC-EMC-VC, where LiPF 6 The concentration of the battery is 0.6mol / L, and the weight ratio of EC:EMC:VC is 3:6.5:0.5. After aging, the battery is precharged; Inject the second solution containing 20 wt% of methyl methacrylate monomer, 0.5 wt% of dibenzoyl peroxide and 79.5 wt% of EC and DMC mixed solvent at the position covered by the tape, where EC: the weight of DMC The ratio is = 1:1; heating at 60°C for 180 minutes, heating triggers the polymerization of the second solution to form a gel, and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com