Lithium-rich multi-element positive electrode material, preparation method thereof, positive electrode and lithium ion power battery

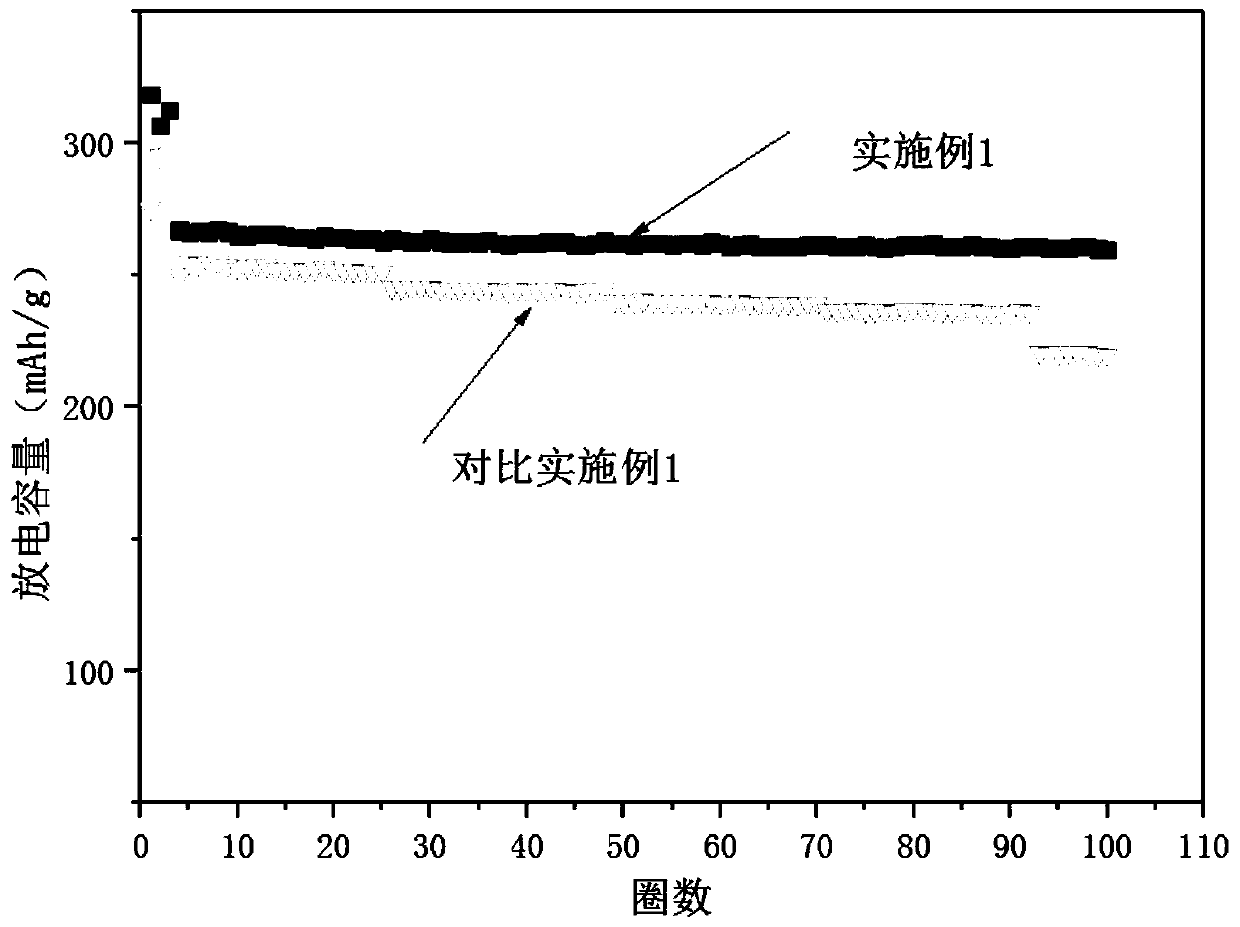

A positive electrode material and multi-component technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of precursor tap density, low compaction density, unstable electrochemical properties of materials, and unfavorable processing performance of positive electrode materials. Achieve the effects of reducing energy consumption, benefiting discharge capacity, and high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a preparation method of a lithium-rich multi-element positive electrode material, comprising the following steps:

[0042] A) After mixing the nickel-containing multi-element precursor with the primary lithium source, pre-sintering is carried out to obtain an intermediate;

[0043] The primary lithium source is one or more of lithium carbonate, lithium hydroxide, lithium fluoride and lithium nitrate;

[0044] B) mixing the intermediate, the secondary lithium source and the additive, and performing secondary sintering to obtain a lithium-rich multi-element positive electrode material;

[0045] The secondary lithium source is one or more of lithium carbonate, lithium hydroxide, lithium fluoride and lithium nitrate;

[0046] The ratio of the amount of the total substance of the primary lithium source and the secondary lithium source to the amount of the nickel-containing multi-element precursor is (1-2): 1; the molar ratio of the primary lithium sou...

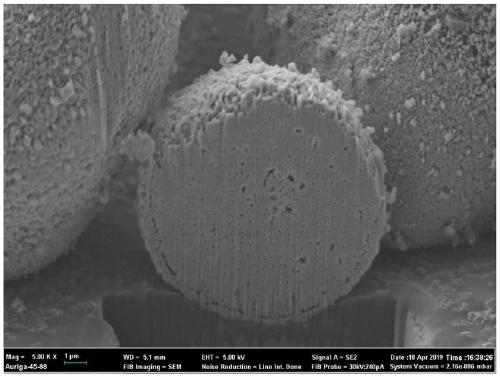

Embodiment 1

[0091] (1) configure the mixed solution of nickel sulfate, cobalt sulfate, manganese sulfate, the mol ratio of described nickel sulfate, cobalt sulfate, manganese sulfate is 1:1:4, the total concentration of nickel sulfate, cobalt sulfate, manganese sulfate in the mixed solution It is 2mol / L.

[0092] (2) Configure a sodium carbonate precipitant solution with a concentration of 4mol / L.

[0093] (3) Prepare an ammonia solution with a concentration of 0.2 mol / L.

[0094] (4) above-mentioned three kinds of solutions are continuously added in the reaction kettle with stirring, and the ammoniacal liquor addition of control is (complexing agent: nickel-cobalt-manganese mol ratio=1:2), regulates the flow rate of sodium carbonate precipitating agent solution to control pH The value is 8.1, and after 20 hours of reaction, it starts to discharge continuously to obtain the nickel-cobalt-manganese carbonate precursor, which is separated and washed to obtain the general formula Ni 0.1665...

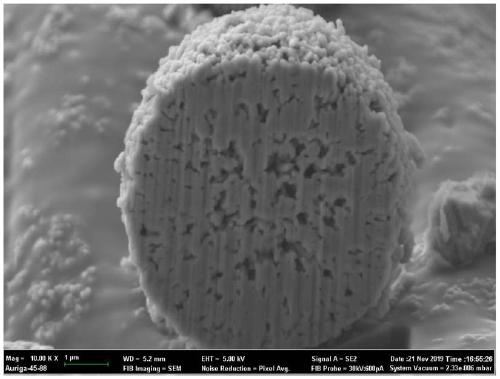

Embodiment 2

[0100] (1) configure the mixed solution of nickel sulfate, cobalt sulfate, manganese sulfate, the mol ratio of described nickel sulfate, cobalt sulfate, manganese sulfate is 1:1:4, the total concentration of nickel sulfate, cobalt sulfate, manganese sulfate in the mixed solution It is 2mol / L.

[0101] (2) Configure a sodium hydroxide precipitant solution with a concentration of 4mol / L.

[0102] (3) Prepare an ammonia solution with a concentration of 0.2 mol / L.

[0103] (4) above-mentioned three kinds of solutions are continuously added in the reaction kettle with stirring, and the ammoniacal liquor addition of control is (complexing agent: nickel-cobalt-manganese mol ratio=1:2), regulates the flow rate of sodium carbonate precipitating agent solution to control pH The value is 10.50, and after 20 hours of reaction, the continuous discharge starts to obtain the nickel-cobalt-manganese carbonate precursor, which is separated and washed to obtain the general formula Ni 0.222 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com