Preparation method of lithium ion battery formed at normal pressure and sealed at negative pressure

A lithium-ion battery and sealing technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and final product manufacturing, etc., can solve the problem of high cost of gas production equipment, and achieve the advantages of ensuring electrochemical performance, reducing internal pressure, and increasing battery costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing a negative pressure sealed lithium-ion battery by normal pressure formation, the specific steps are as follows:

[0018] (1) Put the injected lithium-ion battery into the battery formation cabinet, and the formation cabinet is in the dew point environment of -25~-45°C;

[0019] (2) Then conduct battery formation, the formation current is 0.05-0.15C, and the charging time is 60-360min;

[0020] (3) After the battery is formed, put the battery in a vacuum box to exhaust, and keep it at -50~-90Kpa for 5~15min;

[0021] (4) After the battery is exhausted, put steel balls into the seal under the condition of -50 ~ -90Kpa to complete the preparation of the battery.

[0022] Feasible, the dew point of the environment where the chemical formation cabinet is located in step (1) is controlled at -25 to -35°C.

[0023] Feasible, the formation current in step (2) is 0.05-0.1C, and the charging time is 150-300min.

[0024] Feasible, the pressure in the vacu...

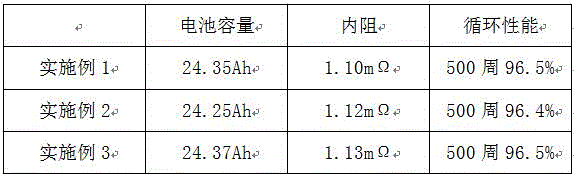

Embodiment 1

[0027] A kind of normal pressure into negative pressure sealing lithium-ion battery preparation method, it comprises the steps:

[0028] (1) Put the liquid-injected lithium-ion battery into the battery formation cabinet, and the formation cabinet is in a dew point environment of -25°C;

[0029] (2) For battery formation, use 0.05C current and charge for 300min;

[0030] (3) After the battery is formed, put the battery in a vacuum box to exhaust, and keep it at -50Kpa for 15 minutes;

[0031] (4) After the battery is exhausted, seal it with steel balls at -60Kpa to complete the preparation of the battery.

Embodiment 2

[0033] A kind of normal pressure into negative pressure sealing lithium-ion battery preparation method, it comprises the steps:

[0034] (1) Put the injected lithium-ion battery into the battery formation cabinet, and the formation cabinet is in a dew point environment of -35°C;

[0035] (2) For battery formation, use 0.1C current and charge for 150 minutes;

[0036] (3) After the battery is formed, put the battery in a vacuum box to exhaust, and keep it at -80Kpa for 10 minutes;

[0037] (4) After the battery is exhausted, seal it with steel balls at -80Kpa to complete the preparation of the battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com