Positive plate of lithium-ion battery with high safety performance and fabrication method of positive plate

A lithium-ion battery, safety performance technology, applied in the direction of battery electrodes, electrode manufacturing, non-aqueous electrolyte storage battery electrodes, etc., can solve the problems of affecting the electrochemical performance of the battery, coating material powder falling, and the inability to effectively improve the safety performance of the battery, etc. , to achieve the effect of reducing the battery interface impedance, preventing micro shedding, and reducing battery short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

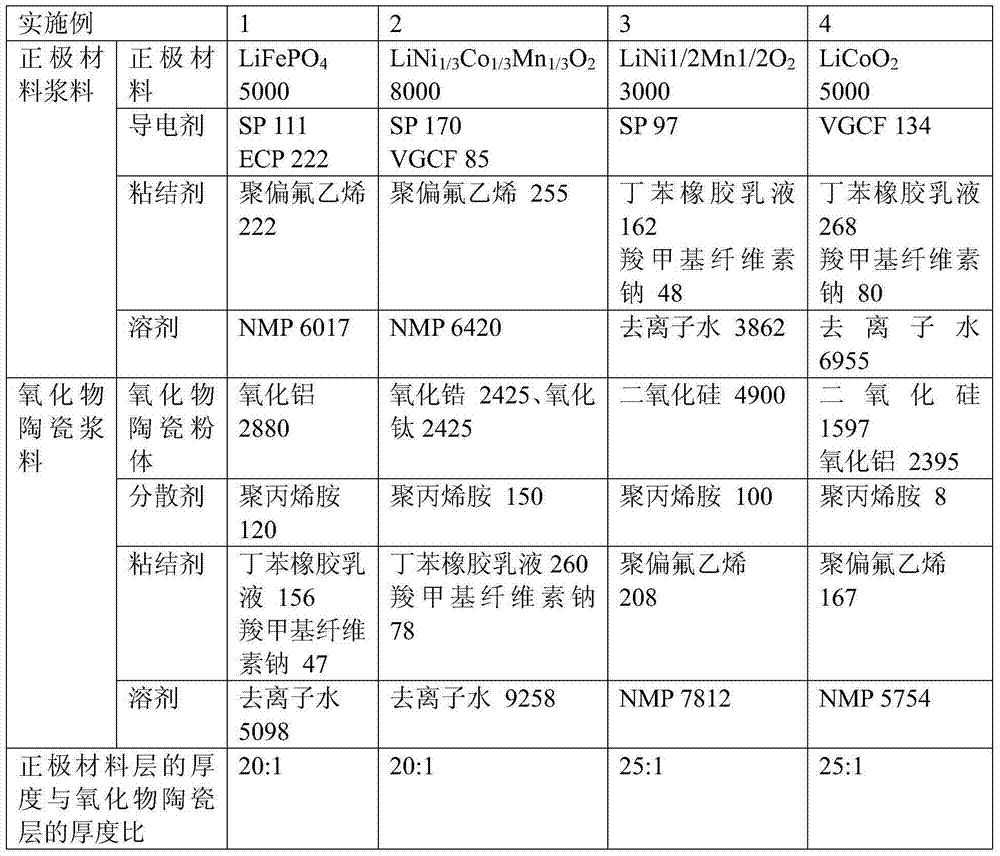

Embodiment 1-4

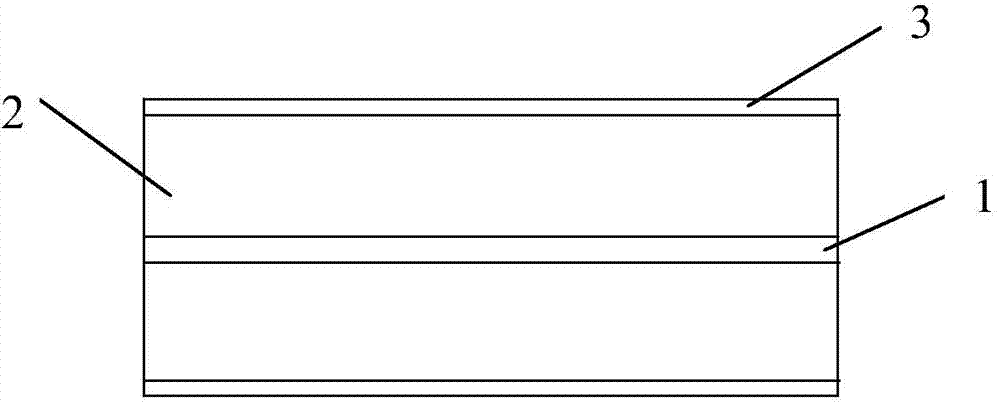

[0021] A method for making the positive electrode sheet of a lithium ion battery, the method is to uniformly coat the positive electrode material slurry on the current collector to obtain the current collector 1 with the positive electrode material layer 2 on the surface, and then apply the oxide ceramic slurry Evenly coated on the positive electrode material layer to form an oxide ceramic layer 3, the structure is specifically shown in figure 1 , wherein the coating method steps of the oxide ceramic layer are as follows:

[0022] 1) Mix the oxide ceramic powder with a mass percentage of 96-99.8% and 0.2-4% dispersant evenly, and then pulverize it so that the D50 of the powder is controlled between 0.1-0.8 μm, and then add deionized water to carry out Disperse, stir for 2-3 hours and then stand still for 2 hours, extract the upper and middle layer slurry, filter and then dry to obtain ultra-fine ceramic oxide powder with D50<600nm;

[0023] 2) Mix and stir the solvent and the...

Embodiment 5

[0028] Add 90% LiNi by mass percentage in 2514gNMP 1 / 3 co 1 / 3 mn 1 / 3 o 2 2880g and 6% conductive agent VGCF192g, 4% binder PVDF128g were mixed and dispersed to obtain a positive electrode slurry with a solid content of 56% and a viscosity of 10000mPa·s, and then evenly coated the positive electrode slurry on the aluminum foil. The thickness of the positive electrode material layer was 210 μm.

[0029] Mix 5kg of high-purity alumina powder and 102g of dispersant evenly and pulverize it to obtain a powder with a D50 of 0.7μm. Disperse the powder in deionized water and stir for 2 hours, then let it stand for 2 hours, and deposit it on the upper part 70% of the slurry was taken out, filtered, and dried to obtain ultrafine alumina powder with a D50 of 0.54 μm.

[0030] Disperse 10g of binder CMC with 235g of deionized water, stir for 3 hours, add 250g of ultrafine alumina powder, stir and disperse for 2 hours, add 10g of styrene-butadiene rubber SBR emulsion, the solid content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com