Nitrogen-doped carbon-coated manganese sulfide composite negative electrode material and preparation method and application thereof

A nitrogen-doped carbon and negative electrode material technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of industrial application, environmental pollution, and price Expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

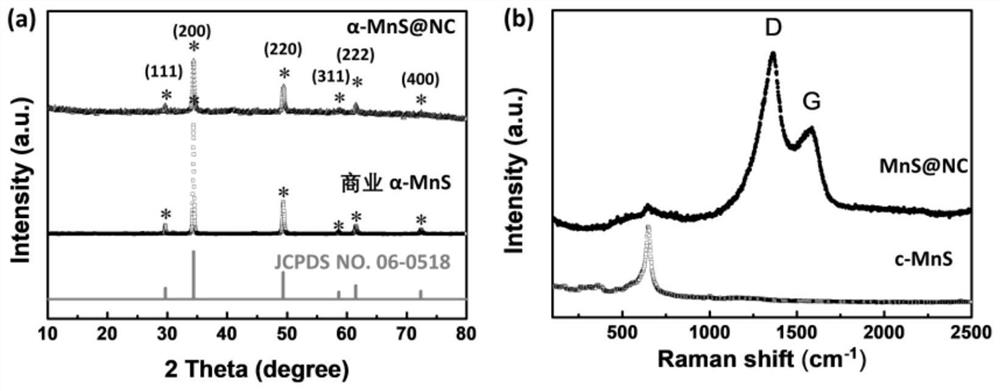

[0026] The invention provides a method for preparing a nitrogen-doped carbon-coated manganese sulfide composite negative electrode material, comprising the following steps:

[0027] (1) micron manganese sulfide is ball milled to obtain nanometer manganese sulfide;

[0028] (2) the nano-manganese sulfide obtained in the step (1) is mixed with a nitrogen-containing polymer and a solvent, and then dried to obtain a precursor;

[0029] (3) Calcining the precursor obtained in the step (2) to obtain a nitrogen-doped carbon-coated manganese sulfide composite negative electrode material.

[0030] Unless otherwise specified, the present invention has no special limitation on the source of each component, and commercially available products or products prepared by conventional preparation methods well known to those skilled in the art can be used.

[0031] In the invention, the micron manganese sulfide is ball-milled to obtain nanometer manganese sulfide.

[0032] In the present inven...

Embodiment 1

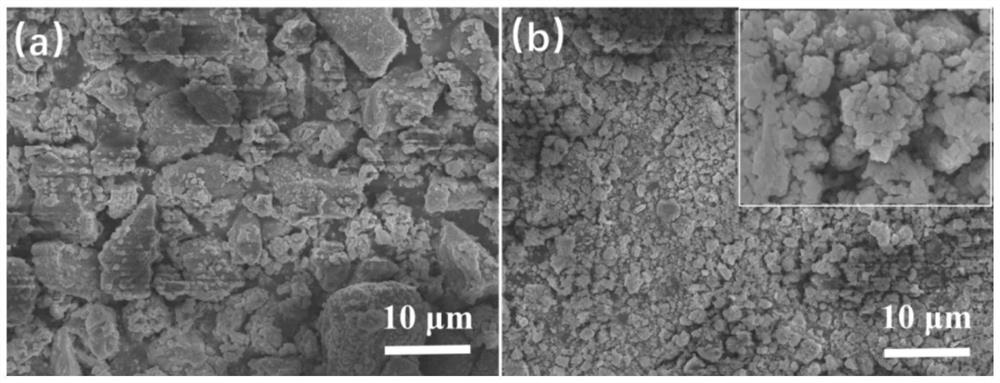

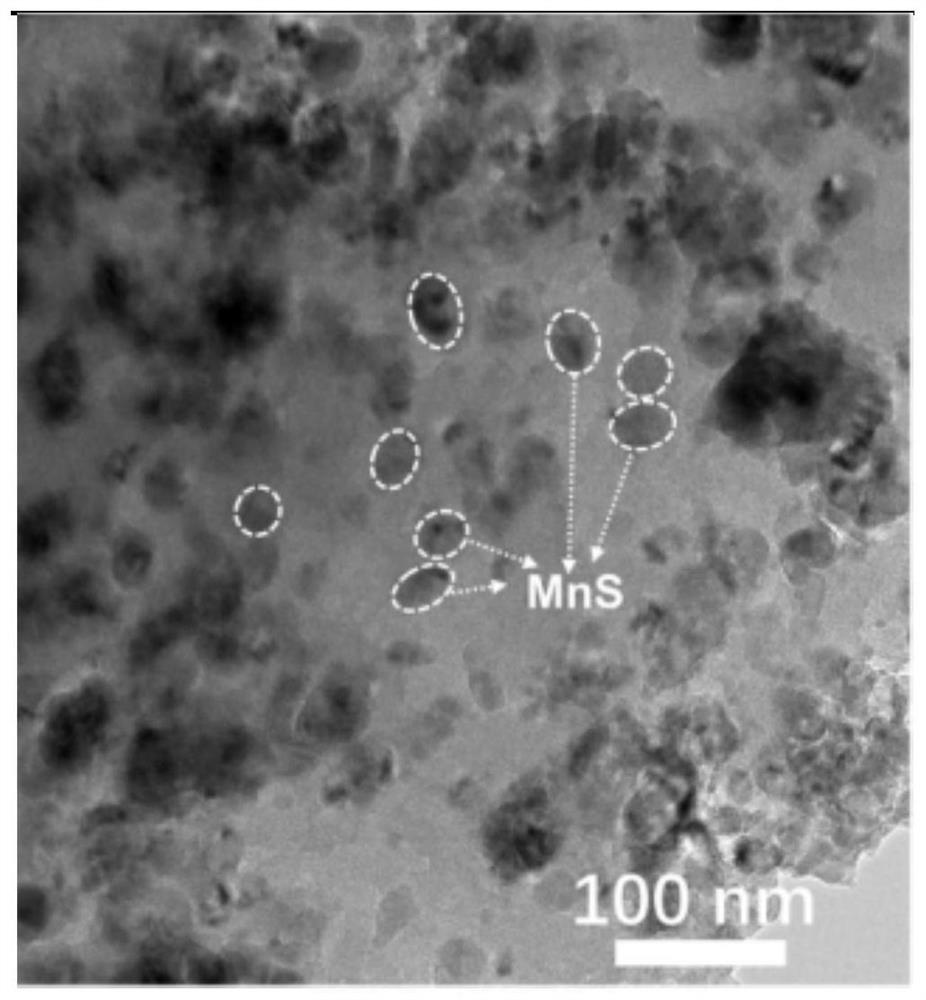

[0053] (1) Put 2g of micron manganese sulfide c-MnS (particle size 1~10 μm) in a zirconia ball mill tank (ball-to-material ratio is 20:1), and ball mill for 2 hours at a speed of 400rpm to obtain nanometer manganese sulfide (primary particle size 30~200nm), denoted as MnS-BM;

[0054] (2) Dissolve 0.3g of polyacrylonitrile PAN in 10mL of N,N-dimethylformamide (the volume ratio of polyacrylonitrile to N,N-dimethylformamide is 0.03g:1mL), and then add 0.7g of nano-manganese sulfide after ball milling in step (1) (the mass ratio of nano-manganese sulfide and polyacrylonitrile is 2.33:1), and after magnetic stirring in an oil bath at 80°C for 20 hours, the precursor was obtained;

[0055] (3) Place the precursor obtained in step (2) in a tube furnace, heat to 200°C for 1 h under the protection of Ar gas, then heat to 500°C for 2 h, and cool naturally to room temperature to obtain a nitrogen-doped carbon package The manganese sulfide-coated composite anode material is denoted as M...

Embodiment 2

[0057] (1) Put 3g of micron manganese sulfide c-MnS (particle size 1~10 μm) in a zirconia ball mill jar (ball-to-material ratio is 25:1), and ball mill for 2 hours at a speed of 450rpm to obtain nanometer manganese sulfide (primary particle size 30~200nm);

[0058] (2) Dissolve 0.4g polyacrylonitrile PAN in 10mL N,N-dimethylformamide (the volume ratio of polyacrylonitrile to N,N-dimethylformamide is 0.04g:1mL), and then add 0.6g of nano-manganese sulfide after ball milling in step (1) (the mass ratio of nano-manganese sulfide and polyacrylonitrile is 1.5:1), and after magnetic stirring in an oil bath at 85°C for 25 hours, the precursor is obtained;

[0059] (3) Put the precursor obtained in step (2) in a tube furnace, heat to 180°C for 1 h under the protection of Ar gas, then heat to 550°C for 2 h, and cool naturally to room temperature to obtain nitrogen-doped carbon package manganese sulfide-coated composite anode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com