Preparation method of fluorine ion doped lithium iron phosphate material

A technology of lithium iron phosphate and fluorine ions, which is applied in nanotechnology for materials and surface science, active material electrodes, electrical components, etc. It can solve the problems of increasing the difficulty of mixing, the loss of fluorine ions, and affecting the uniformity of mixing. , to achieve the effect of ensuring electrochemical performance, high tap density and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention discloses a preparation method of a fluoride-doped lithium iron phosphate material. Include the following steps:

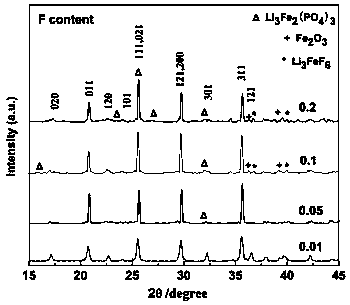

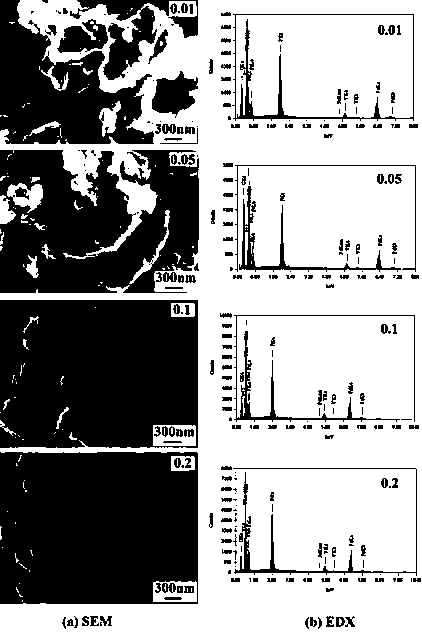

[0033] S1. Preparation of precursor mixed solution: mix soluble lithium source, iron source, phosphorus source, and fluoride according to the molar ratio of ions Li + :(Fe 3+ or Fe 2+ ): PO 4 3- :F - =0.97~1.05:1:1-x:3x is dissolved in deionized water, wherein x is 0.01 to 0.2, and a water-soluble carbon source and a water-soluble additive are added at the same time, and stirred to dissolve to obtain a precursor mixed solution;

[0034] S2. Gelation treatment: heat the precursor mixed solution obtained in step S1 in an oil bath, and control the heating temperature at 50-100° C. to obtain a viscous precursor gel;

[0035] S3, self-propagating combustion treatment: heating the precursor gel in step S2 to 200-300°C, making it fully react and decomposing by self-propagating combustion to obtain combustion products;

[0036] S4. Ball milling...

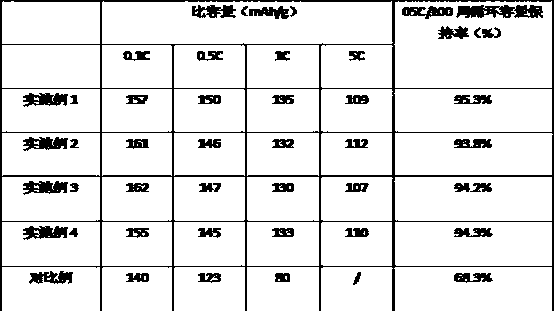

Embodiment 1

[0048] The invention discloses a preparation method of a fluoride-doped lithium iron phosphate material. Include the following steps:

[0049] S1. Preparation of precursor mixed solution: mix soluble lithium source, iron source, phosphorus source, and fluoride according to the molar ratio of ions Li + :(Fe 3+ or Fe 2+ ): PO 4 3- :F - = 1.05: 1: 1-x: 3x is dissolved in deionized water, wherein x is 0.1, and a water-soluble carbon source and a water-soluble additive are added at the same time, and stirred to dissolve to obtain a precursor mixed solution;

[0050] S2. Gelation treatment: heat the precursor mixed solution obtained in step S1 in an oil bath, and control the heating temperature at 50° C. to obtain a viscous precursor gel;

[0051] S3, self-propagating combustion treatment: heating the precursor gel in step S2 to 300°C to make it fully react and undergo self-propagating combustion decomposition to obtain combustion products;

[0052] S4, ball milling treatment...

Embodiment 2

[0056] The invention discloses a preparation method of a fluoride-doped lithium iron phosphate material. Include the following steps:

[0057] S1. Preparation of precursor mixed solution: mix soluble lithium source, iron source, phosphorus source, and fluoride according to the molar ratio of ions Li + :(Fe 3+ or Fe 2+ ): PO 4 3- :F - = 1.01: 1: 1-x: 3x is dissolved in deionized water, where x is 0.01, while adding a water-soluble carbon source and a water-soluble additive, stirring to dissolve to obtain a precursor mixed solution;

[0058] S2. Gelation treatment: heat the precursor mixed solution obtained in step S1 in an oil bath, and control the heating temperature at 100° C. to obtain a viscous precursor gel;

[0059] S3. Self-propagating combustion treatment: heating the precursor gel in step S2 to 250° C. to make it fully react and undergo self-propagating combustion decomposition to obtain combustion products;

[0060] S4, ball milling treatment: transfer the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com