Formation and validation method capable of improving cycle performance of lithium iron phosphate battery

A lithium iron phosphate battery, cycle performance technology, applied in the field of lithium ion batteries, can solve problems such as failure to achieve effective formation or verification, uneven and dense SEI film formation, affecting battery liquid retention, etc., to achieve good performance of lithium batteries , Improving the first discharge efficiency and reducing the effect of the unformed dead zone area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

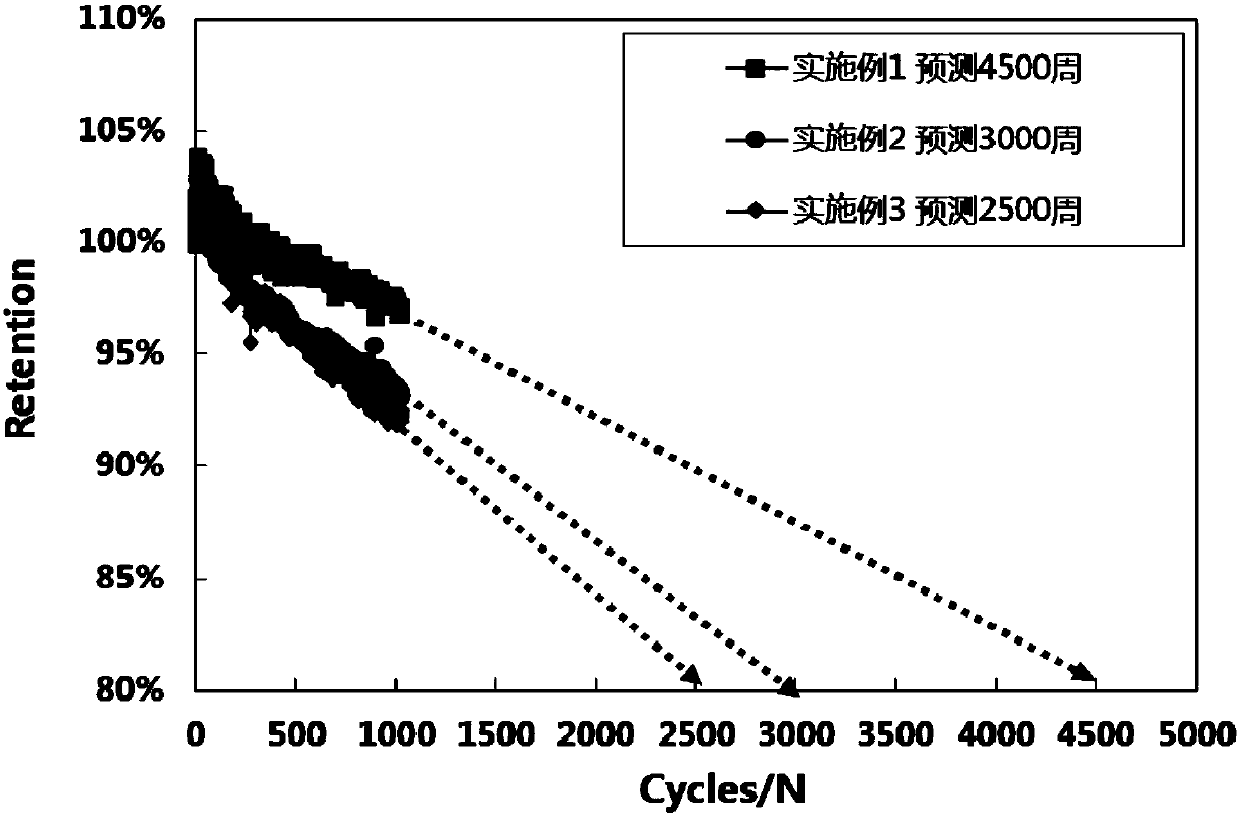

Embodiment 1

[0045] The model of the prepared square soft pack battery is 90161227-25Ah; the positive electrode active material powder is lithium iron phosphate; the negative electrode active material is graphite; the electrolyte is 1mol / L LiPF 6 / (EC+DMC+DEC) (volume ratio 1:1:1). Positive electrode: LFP, conductive agent and binder are prepared according to the ratio (mass ratio) of 92.5:4:3.5; the ratio of negative electrode is: graphite, conductive agent, CMC and binder (SBR) according to 94.5:2:1:2.5 Ratio (mass ratio) for preparation. In the early stage, the positive and negative electrode powders are mixed, coated, rolled, sheeted, assembled, and baked. After baking, the moisture content is ≤300ppm; the weight of the excess electrolyte injected is 260±3g; it is placed in a dry place at 45°C for 24 hours; then the battery is subjected to hot pressing at 80°C and cold at 20°C through the main board pressure of 0.3Mpa. pressure treatment.

[0046] The obtained square pouch battery i...

Embodiment 2

[0050] The specific process is with reference to embodiment 1, and difference with embodiment 1 is:

[0051] The obtained square pouch battery is preformed in stages at room temperature, and the specific process is as follows:

[0052] S1: Charge the battery with a constant current of 0.01C for 2 hours, and the upper limit voltage is 3.4V; S2: Charge the battery with a constant current of 0.04C for 5 hours, and the upper limit voltage is 3.5V; S3: Finally, charge the battery with a constant current of 0.1C for 5 hours, The upper limit voltage is 3.65V.

Embodiment 3

[0054] The specific process is with reference to embodiment 1, and difference with embodiment 1 is:

[0055] The obtained square pouch battery is preformed in stages at room temperature, and the specific process is as follows:

[0056] S1: Charge the battery with a constant current of 0.02C for 1 hour, and the upper limit voltage is 3.4V; S2: Charge the battery with a constant current of 0.04C for 5 hours, and the upper limit voltage is 3.5V; S3: Finally, charge the battery with a constant current of 0.1C for 6 hours, The upper limit voltage is 3.65V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com