Ion sieve cathode for electrolytic cell used for extracting lithium from lithium-containing aqueous solution and method for producing same

A manufacturing method and technology of aqueous solution, applied in chemical instruments and methods, improvement of process efficiency, water/sewage treatment, etc., can solve the problem that the lithium ion conductivity of solid electrolyte cannot be fully exerted, the surface load of current collector cannot be effectively improved, and the Alkali metal electrochemical intercalation and other problems, to achieve the effect of excellent practicability, widening use types, and large loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

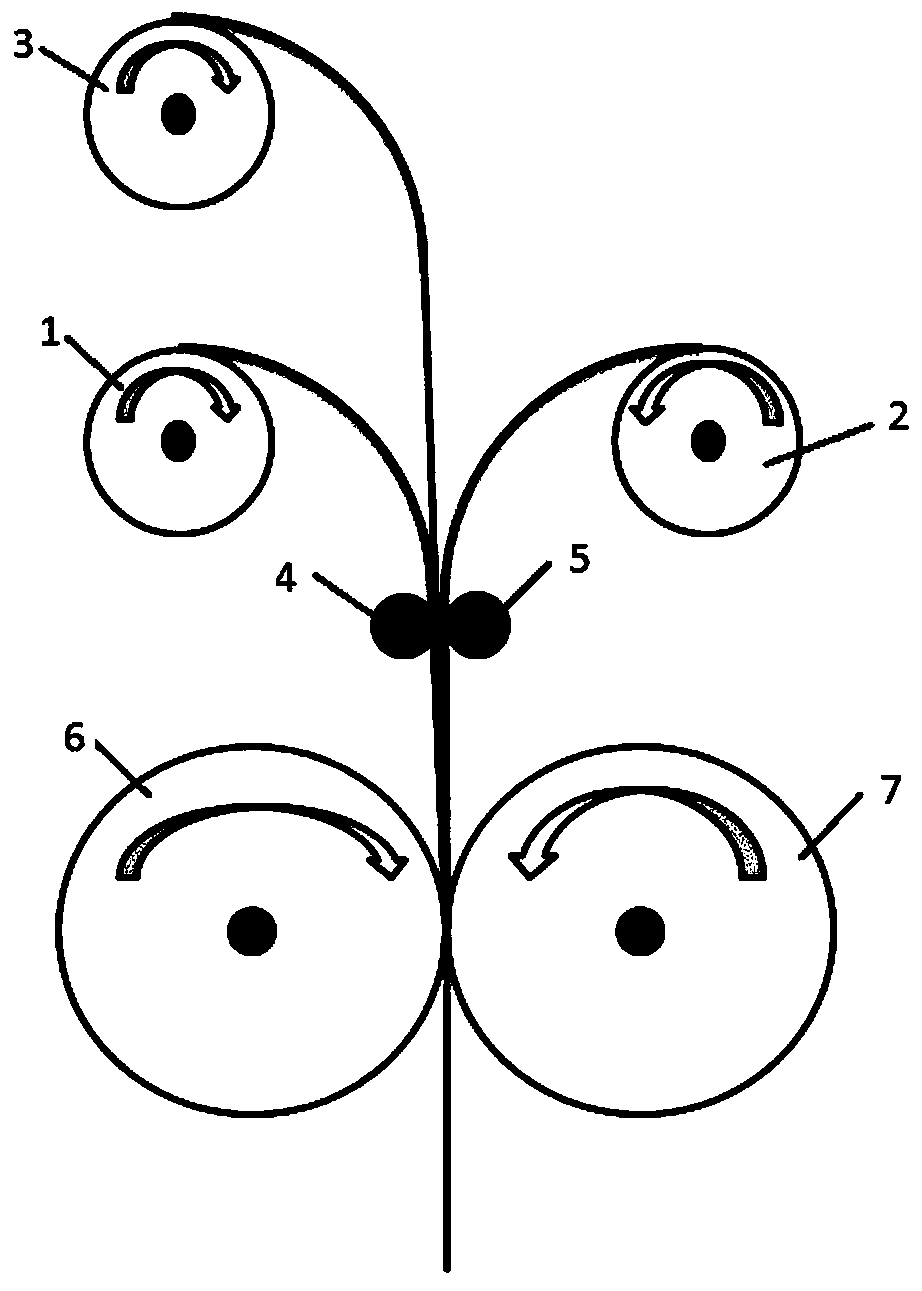

Method used

Image

Examples

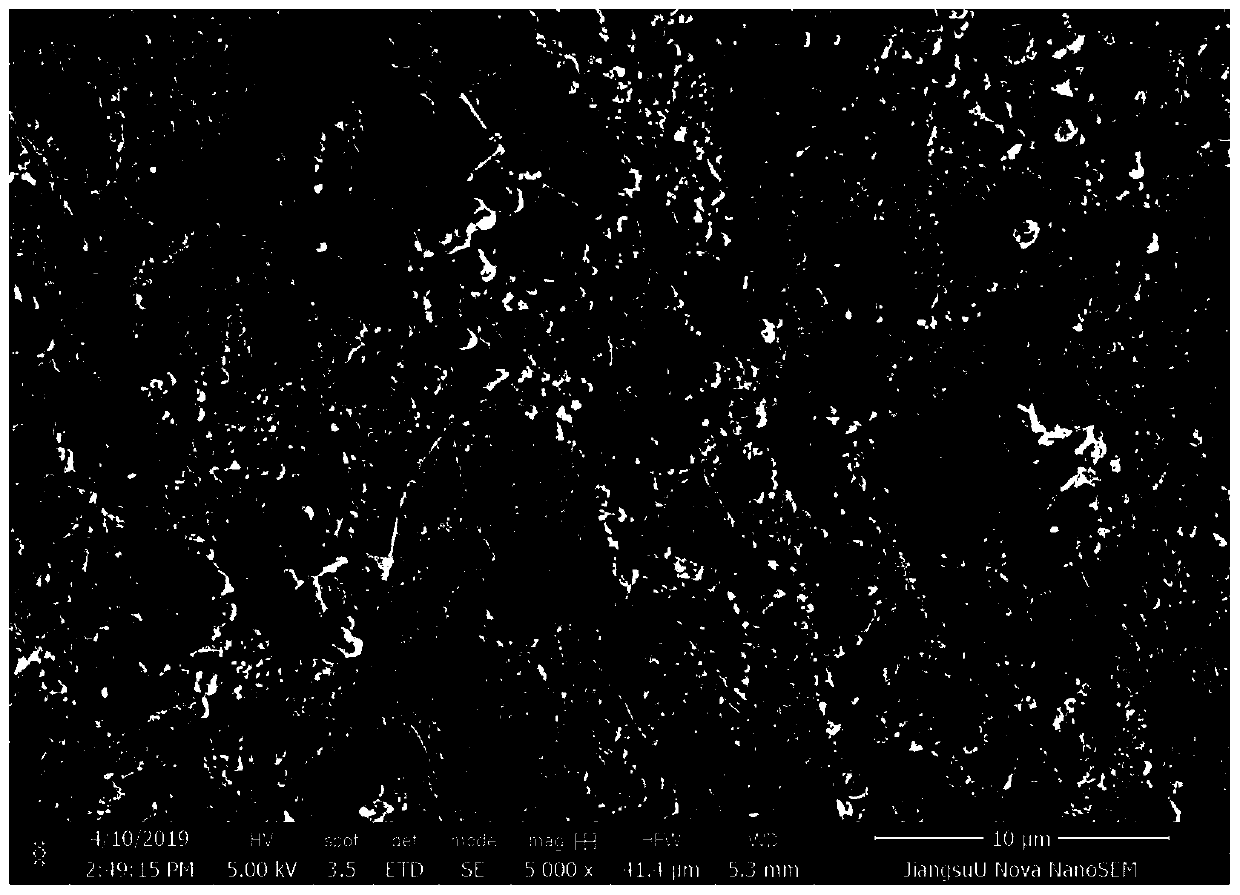

Embodiment 1

[0042] Will Li 4 Ti 5 o 12 , pre-lithiated polyphenylene sulfide and Super-P according to the weight percentage of 79%: 10%: 5%, mixed uniformly in a VC type high-efficiency asymmetric mixer to obtain powder A, in the structure of pre-lithiated polyphenylene sulfide The crystalline state and the cross-linked state each accounted for 50%. In a low-temperature freezer at 5°C, use a V-type mixer to mix the polytetrafluoroethylene particle powder and powder A according to the weight percentage of 6%:94% for 2 hours to obtain powder B uniformly; use the gas flow rate to reach super Dry compressed air at the speed of sound grinds powder B in a closed stainless steel chamber to obtain mixed powder C. The ground mixed powder C is discharged and collected with the airflow; mixed powder C is rolled twice by a hot roller press to form a film , the hot pressing temperature is 180°C, the thickness after the first rolling is about 700 microns, and the thickness after the second rolling i...

Embodiment 2

[0046] The delithiated lithium iron phosphate powder, pre-lithiated polyphenylene sulfide sulfone, and reduced graphene are mixed uniformly in a VC type high-efficiency asymmetric mixer according to a weight percentage of 75%: 12%: 5% to obtain a powder. In the structure of pre-lithiated polyphenylene sulfide sulfone, the proportion of crystalline state and cross-linked state is 40%: 60%. Mix the polytetrafluoroethylene particle powder and powder A according to the weight percentage of 8%:92% in a V-type mixer in a low-temperature freezer at 5°C for 2 hours to obtain powder B uniformly; use the gas flow rate to reach Supersonic dry compressed air grinds powder B in a closed stainless steel chamber to obtain mixed powder C. The ground mixed powder C is discharged and collected with the airflow; mixed powder C is rolled twice by a hot roller press to form For the film, the hot-pressing temperature is 180°C, the thickness after the first rolling is about 800 microns, and the thic...

Embodiment 3

[0050] The delithiated lithium manganate powder, pre-lithiated polyphenylene sulfide ketone, and activated carbon are mixed uniformly in a VC type high-efficiency asymmetric mixer to obtain powder according to the weight percentage of 76%: 10%: 8%. In the structure of lithiated polyphenylene sulfide ketone, the proportion of crystalline state and crosslinked state is 60%: 40%. Mix the polytetrafluoroethylene particle powder and powder A according to the weight percentage of 6%:94% in a V-type mixer in a low-temperature cold storage at 5°C for 2 hours until uniformly obtained powder B; use the gas flow rate to reach Supersonic dry compressed air grinds powder B in a closed stainless steel chamber to obtain mixed powder C. The ground mixed powder C is discharged and collected with the airflow; mixed powder C is rolled twice by a hot roller press to form For the film, the hot-pressing temperature is 200°C, the thickness after the first rolling is about 500 microns, and the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com