Polycrystal high-nickel positive electrode material used for lithium ion battery and preparation method for polycrystal high-nickel positive electrode material

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of reducing the first discharge capacity and first charge and discharge efficiency, lithium ion conductor compounds do not exert capacity, and are unfavorable for lithium ions and electron migration To achieve the effect of improving the first charge and discharge efficiency, ensuring structural stability and electrochemical performance, and high first charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

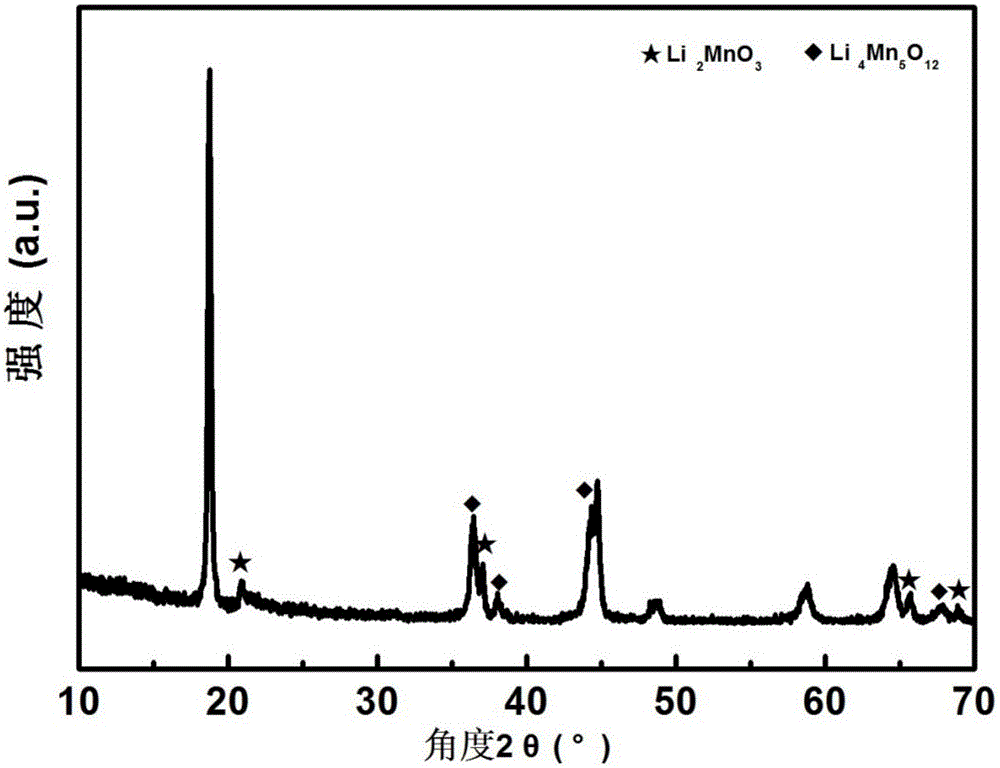

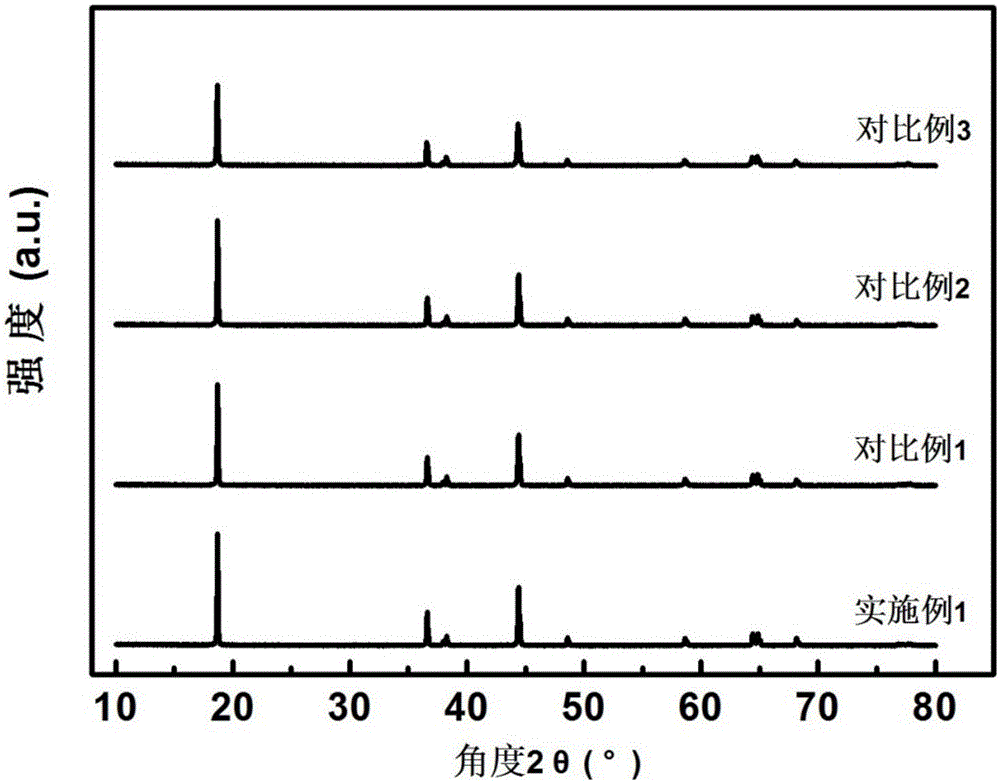

[0037] A polycrystalline high-nickel positive electrode material for a lithium secondary battery of the present invention, comprising a substrate of a layered structure and a coating layer of a spinel structure outside the substrate, and the substrate is a positive electrode material Li 1.05 Ni 0.8 co 0.1 mn 0.1 o 2 ; The coating layer uniformly coated on the outer surface of the substrate is Li 2 MnO 3 and Li 4 mn 5 o 12 mixture.

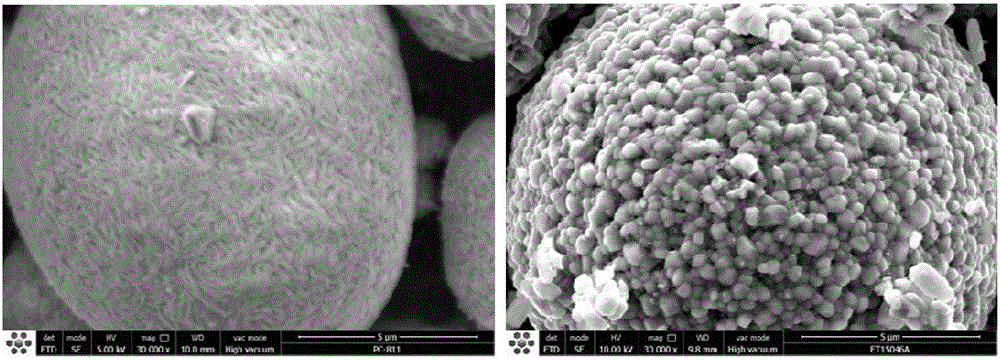

[0038] The pH of the surface-modified polycrystalline high-nickel positive electrode material in this embodiment is 11.65, the secondary particle size is 12.8 μm, and the primary particle size is 450 nm.

[0039] The preparation method of the polycrystalline high-nickel positive electrode material for the lithium secondary battery of the above-mentioned present embodiment specifically includes the following steps:

[0040] (1) Substrate preparation: weigh the compound Ni 0.8 co 0.1 mn 0.1 (OH) 2 Represented nickel cobalt manganese comp...

Embodiment 2

[0076] A polycrystalline high-nickel positive electrode material for a lithium secondary battery of the present invention, comprising a substrate of a layered structure and a coating layer of a spinel structure outside the substrate, and the substrate is a ternary positive electrode material Li 1.05 (Ni 0.8 co 0.1 mn 0.1 ) 0.98 al 0.02 o 2 ; The spinel-type cladding layer uniformly coated on the outer surface of the substrate is a mixture of Li 2 MnO 3 and Li 4 mn 5 o 12 .

[0077] The pH of the surface-modified polycrystalline high-nickel positive electrode material in this embodiment is 11.68, the secondary particle size is 13.5 μm, and the primary particle size is 480 nm.

[0078] The preparation method of the polycrystalline high-nickel positive electrode material for the lithium secondary battery of the above-mentioned present embodiment specifically includes the following steps:

[0079] (1) Substrate preparation: weigh the compound Ni 0.8 co 0.1 mn 0.1 (OH...

Embodiment 3

[0083] A polycrystalline high-nickel positive electrode material for a lithium secondary battery of the present invention, comprising a substrate of a layered structure and a coating layer of a spinel structure outside the substrate, and the substrate is a ternary positive electrode material Li 1.04 Ni 0.8 co 0.2 o 2 ; The spinel-type cladding layer uniformly coated on the outer surface of the substrate is a mixture of Li 2 MnO 3 and Li 4 mn 5 o 12 .

[0084] The pH of the surface-modified polycrystalline high-nickel positive electrode material in this embodiment is 11.64, the secondary particle size is 14.2 μm, and the primary particle size is 450 nm.

[0085] The preparation method of the polycrystalline high-nickel positive electrode material for the lithium secondary battery of the above-mentioned present embodiment specifically includes the following steps:

[0086] (1) Substrate preparation: weigh the compound Ni 0.8 co 0.2 (OH) 2 The indicated nickel-cobalt c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com