Cationic metal phthalocyanine/carbon nano-tube self-assembled membrane electrode and preparation method thereof

A metal phthalocyanine and carbon nanotube technology, which is applied in the field of cationic metal phthalocyanine/carbon nanotube self-assembled membrane electrodes and their preparation, can solve the problems of unstable electrochemical properties, low surface coverage, complex process and the like , to achieve the effect of improving electrocatalytic activity, firm membrane material, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

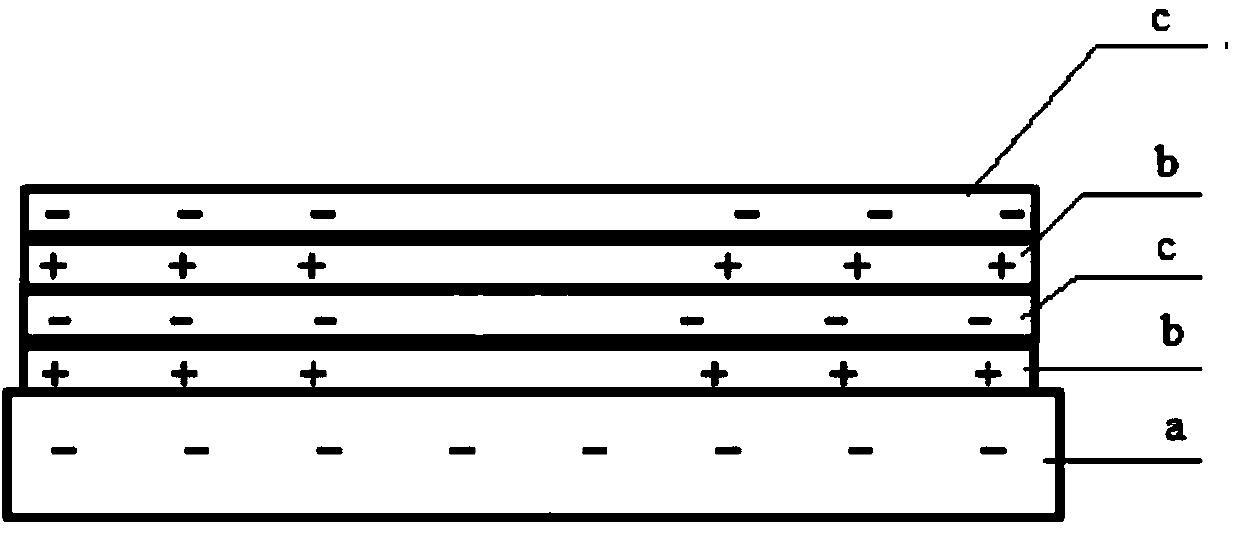

[0024] Embodiment 1: A cationic metal phthalocyanine / carbon nanotube self-assembled film electrode of this embodiment is to alternately assemble positively charged cationic metal phthalocyanine layers and negatively charged carbon nanotubes on a negatively charged substrate layers to form a multilayer film electrode with alternating cationic metal phthalocyanine layers and carbon nanotube layers.

[0025] ① The surface molecules of the cationic metal phthalocyanine / carbon nanotube self-assembled membrane electrode prepared in this embodiment are arranged uniformly and orderly, and grow layer by layer with equal thickness.

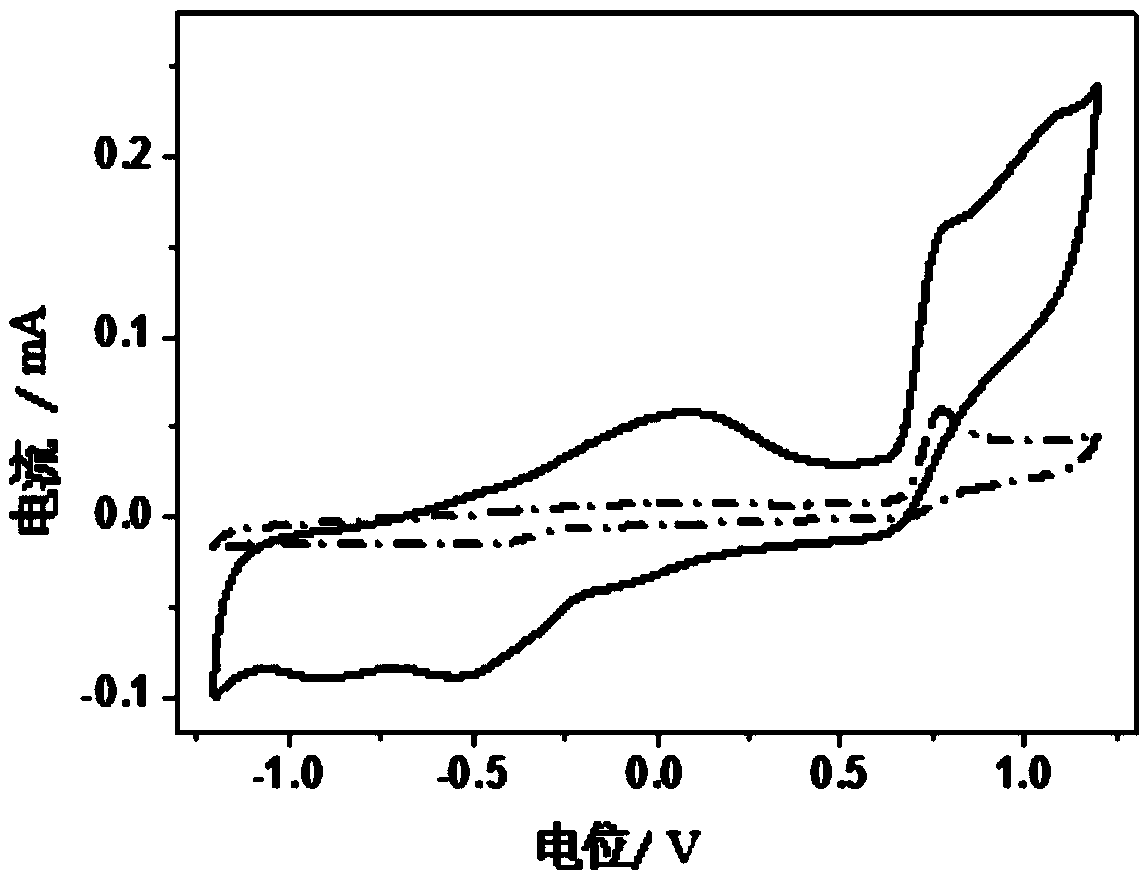

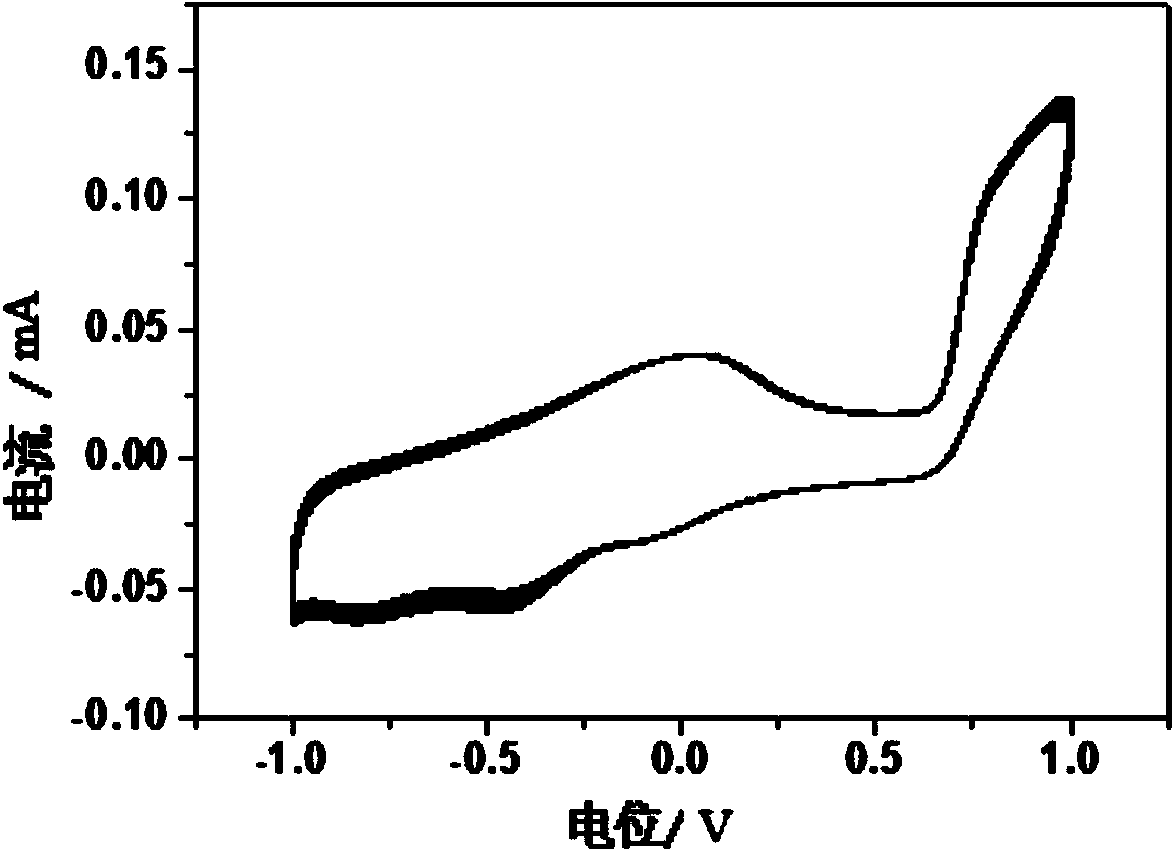

[0026] ② The cationic metal phthalocyanine / carbon nanotube self-assembled film electrode prepared in this embodiment has excellent electrocatalytic performance, and its linear range is as wide as 0.1-10 mmol L -1 , the detection limit is as low as 10μmol L -1 , the sensitivity is 0.051mA·L·mol-1 .

[0027] ③ The cationic metal phthalocyanine / carbon nanotu...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the positively charged cationic metal phthalocyanine layer and the negatively charged carbon nanotubes in the cationic metal phthalocyanine / carbon nanotube self-assembled film electrode The number of layers is the same, 4 to 30 layers. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the general structural formula of the cationic metal phthalocyanine in the positively charged cationic metal phthalocyanine layer is as follows:

[0032] where M is Co 2+ , Fe 2+ 、Ni 2+ 、Cu 2+ , Zn 2+ , Pd 2+ , Pb 2+ or Mn 2+ . Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com