Three-dimensional nanometer tricobalt tetraoxide, preparation method and application

A technology of cobalt tetroxide and three-dimensional nanometer, which is applied in the field of preparation of electrochemical catalytic materials, can solve the problems of slow application development and low conductivity of cobalt-based materials, and achieve the effects of good electrocatalytic performance, high catalytic performance and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

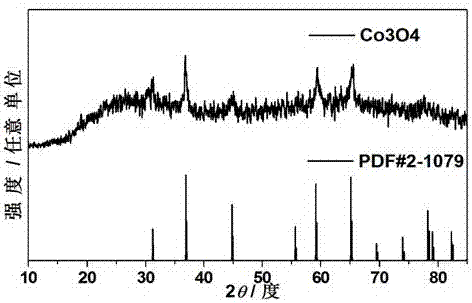

[0026] 1. The preparation process and verification of three-dimensional nano-cobalt tetroxide.

[0027] (1) Add 1 g of cobalt acetate and 1 to 5 g of α-alanine to 100 mL of deionized water, stir and dissolve at room temperature, add 0.5 to 1 L of absolute ethanol to the solution, and centrifuge the above system after stirring to obtain a solid Dry naturally in the air to obtain the Co-MOF precursor.

[0028] figure 1 Scanning electron microscopy images of the Co-MOF precursors are shown.

[0029] It can be seen that the Co-MOF precursor obtained by simple room temperature stirring reaction has a uniform olive-shaped morphology, the particle length is about 500 nm, and the diameter is about 300 nm. And it can be observed that the surface of olive-shaped Co-MOF particles is not smooth, but has spiral sheet folds.

[0030] (2) The Co-MOF precursor is calcined in a tube furnace at an air atmosphere at a rate of 0.2-5°C / min to 300-800°C for 0.5-2 hours, and after natural cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com