Preparation method of LiFeXCo1-XPO4/N-C/CC composite material

A technology of composite materials and mixed solutions, which is applied in the preparation/purification of carbon, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of low electronic conductivity hindering development, low energy density, and affecting performance, so as to improve electrocatalysis Performance, simple processing method, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

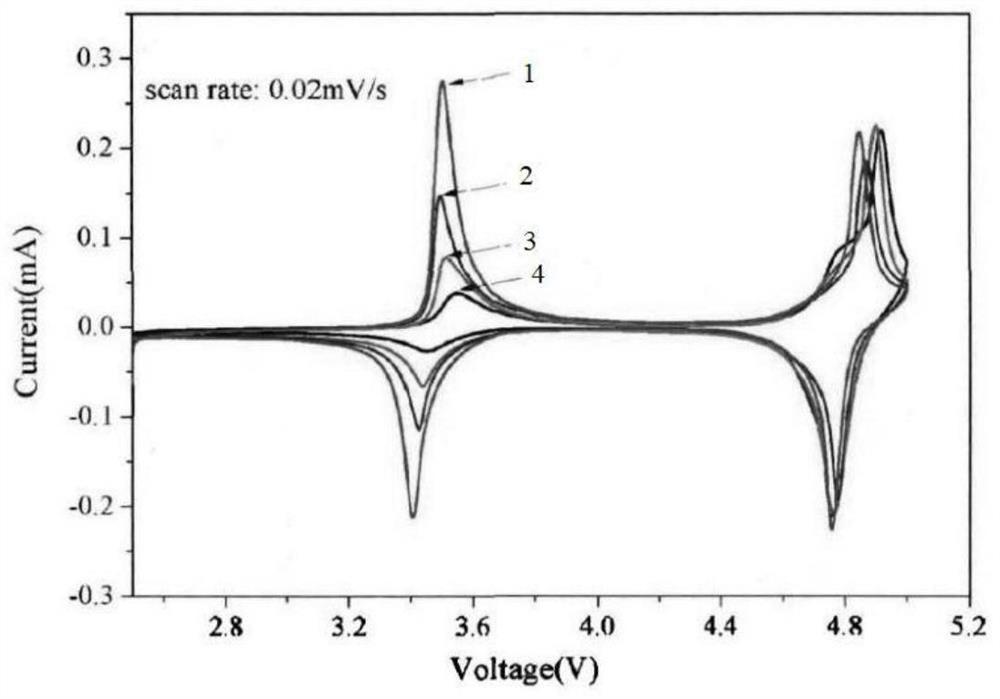

Embodiment 1

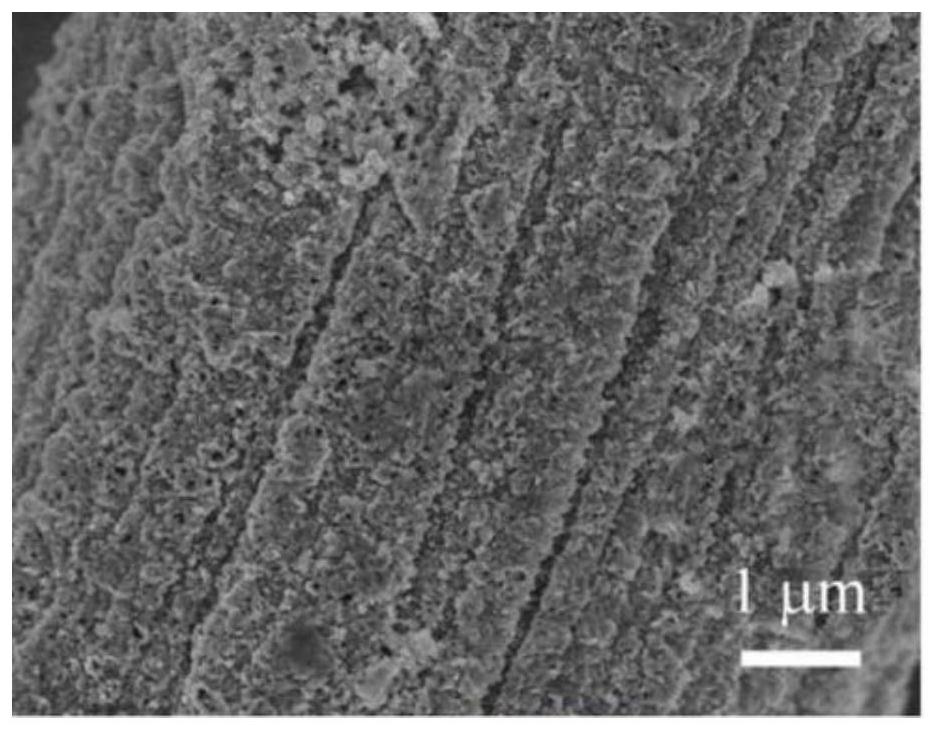

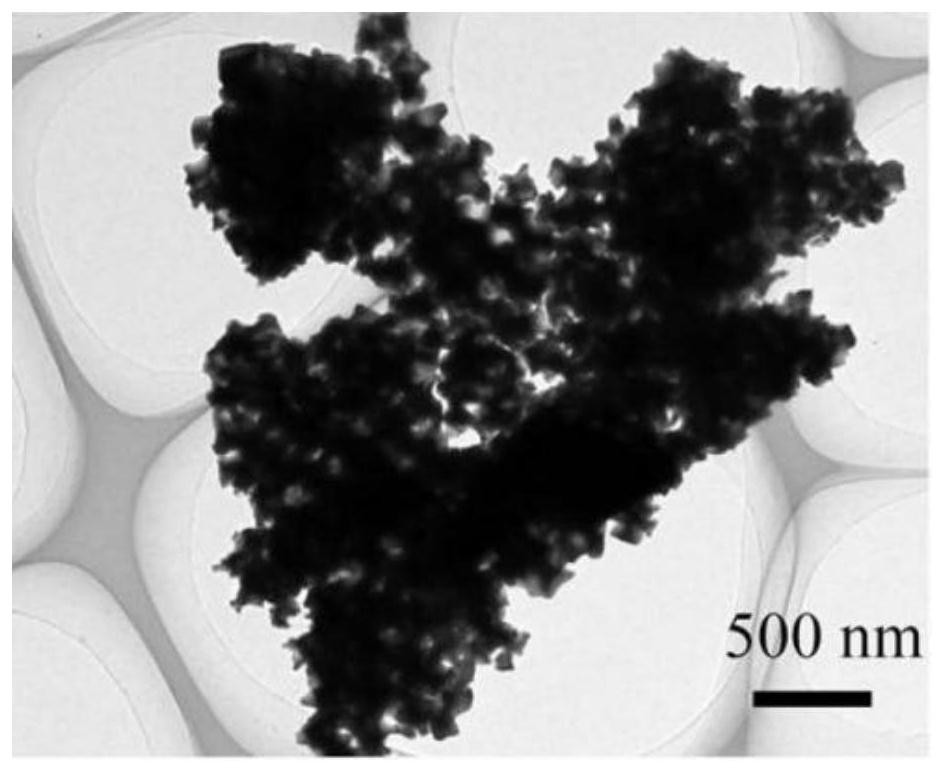

[0026] a LiFe X co 1-X PO 4 / N-C / CC composite material, specifically including the following preparation steps:

[0027] (1) Pretreatment of carbon cloth: put a carbon cloth with a side length of 2×3 into a mixed solution of 100ml of nitric acid and water with a volume ratio of 1:3, and conduct a hydrothermal reaction at 90°C for 2 hours;

[0028] (2) Add 0.03mol lithium acetate, 0.015mol ferric nitrate, 0.015mol cobalt nitrate and 0.03mol ammonium dihydrogen phosphate into 60ml deionized water, stir magnetically for 1 hour, transfer the above solution into a polytetrafluoroethylene reactor, put Carbon cloth, hydrothermally reacted at 190°C for 12h, then washed with deionized water;

[0029] (3) Put 5ml of ethylene glycol and 1ml of aniline into a beaker, add 55ml of deionized water, stir for 1 hour, add 1.5g of hexadecyltrimethylammonium bromide, continue to stir for 11 hours, and then age for 5 hours. After the reaction, Wash the product with deionized water and ethanol,...

Embodiment 2

[0040] a LiFe X co 1-X PO 4 / N-C / CC composite material, specifically including the following preparation steps:

[0041] (1) Pretreatment of carbon cloth: put a carbon cloth with a side length of 2×3 into a mixed solution of 100ml of nitric acid and water with a volume ratio of 1:3, and conduct a hydrothermal reaction at 80°C for 2 hours;

[0042] (2) Add 0.03mol lithium acetate, 0.01mol ferric nitrate, 0.02mol cobalt nitrate and 0.03mol ammonium dihydrogen phosphate into 60ml deionized water, stir magnetically for 1 hour, transfer the above solution into a polytetrafluoroethylene reactor, put Carbon cloth, hydrothermally reacted at 160°C for 10h, then washed with deionized water;

[0043] (3) Put 4ml of ethylene glycol and 1ml of aniline into a beaker, add 50ml of deionized water, stir for 1h, add 1g of cetyltrimethylammonium bromide, continue stirring for 10h, and then age for 4h. After the reaction, use Wash the product with deionized water and ethanol, and put it into ...

Embodiment 3

[0048] a LiFe X co 1-X PO 4 / N-C / CC composite material, specifically including the following preparation steps:

[0049] (1) Pretreatment of carbon cloth: put a carbon cloth with a side length of 2×3 into a mixed solution of 100ml of nitric acid and water with a volume ratio of 1:3, and conduct a hydrothermal reaction at 100°C for 2 hours;

[0050] (2) Add 0.03mol lithium acetate, 0.015mol ferric nitrate, 0.015mol cobalt nitrate and 0.03mol ammonium dihydrogen phosphate into 60ml deionized water, stir magnetically for 1 hour, transfer the above solution into a polytetrafluoroethylene reactor, put Carbon cloth, hydrothermally reacted at 190°C for 12h, then washed with deionized water;

[0051] (3) Put 5ml of ethylene glycol and 1ml of aniline into a beaker, add 60ml of deionized water, stir for 1 hour, add 2g of cetyltrimethylammonium bromide, continue to stir for 12 hours, and then age for 6 hours. After the reaction, use Wash the product with deionized water and ethanol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com