Rapid and low-energy-consumption preparation method of self-supporting nanostructure electrocatalyst

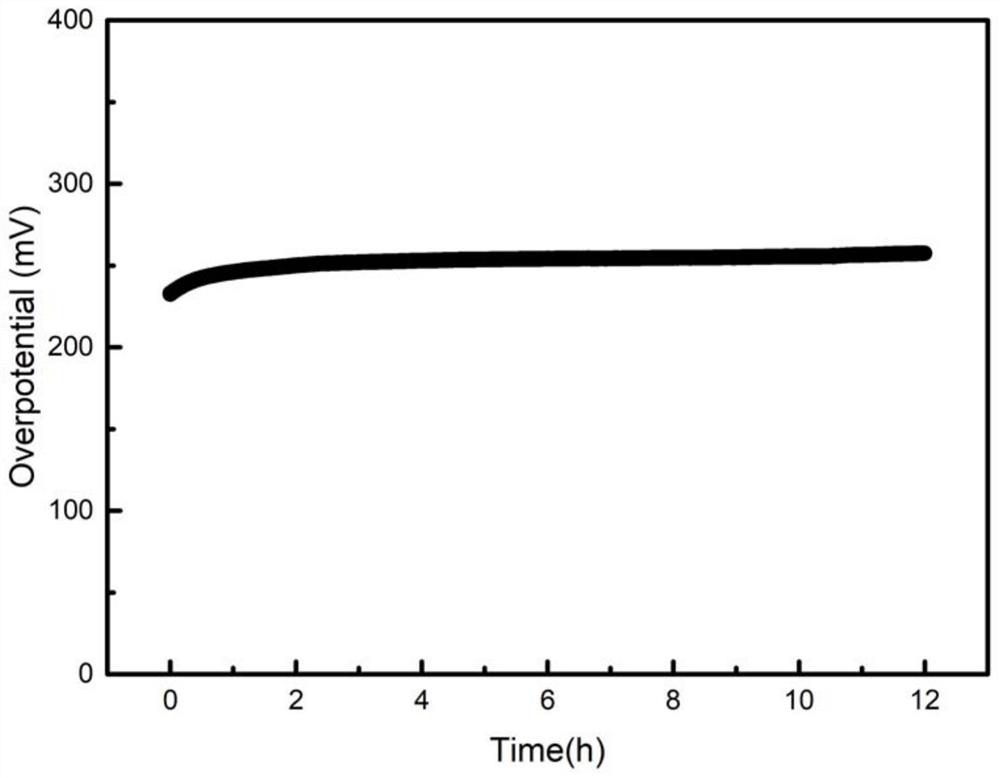

A nanostructure, electrocatalyst technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor electrocatalytic activity and stability, long synthesis cycle, complex process, etc., achieve excellent electrocatalytic performance, shorten synthesis The effect of shortening the cycle and shortening the corrosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

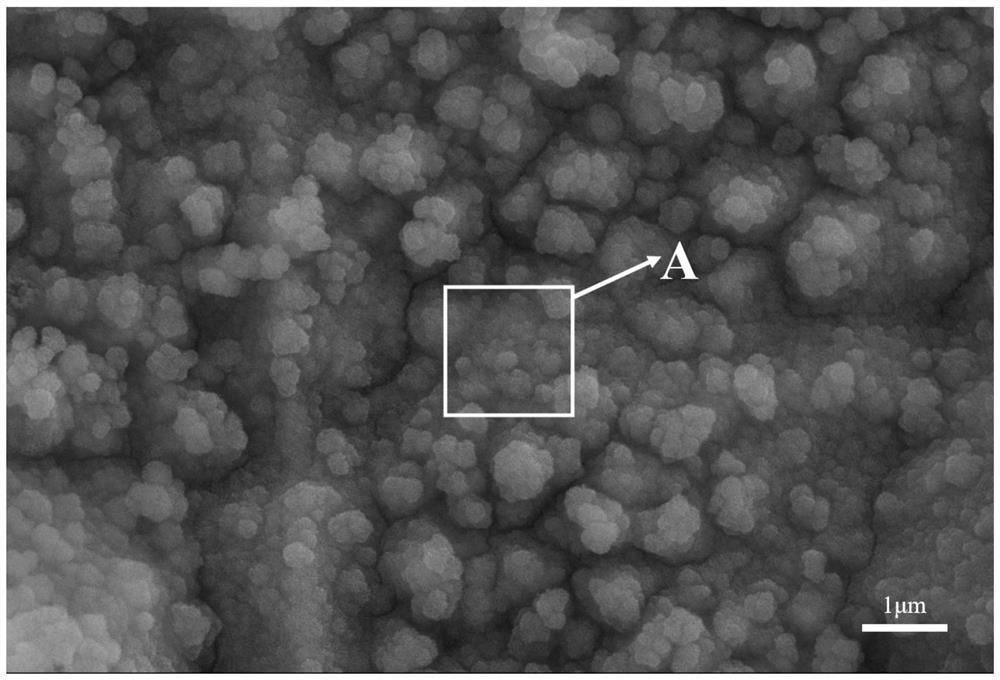

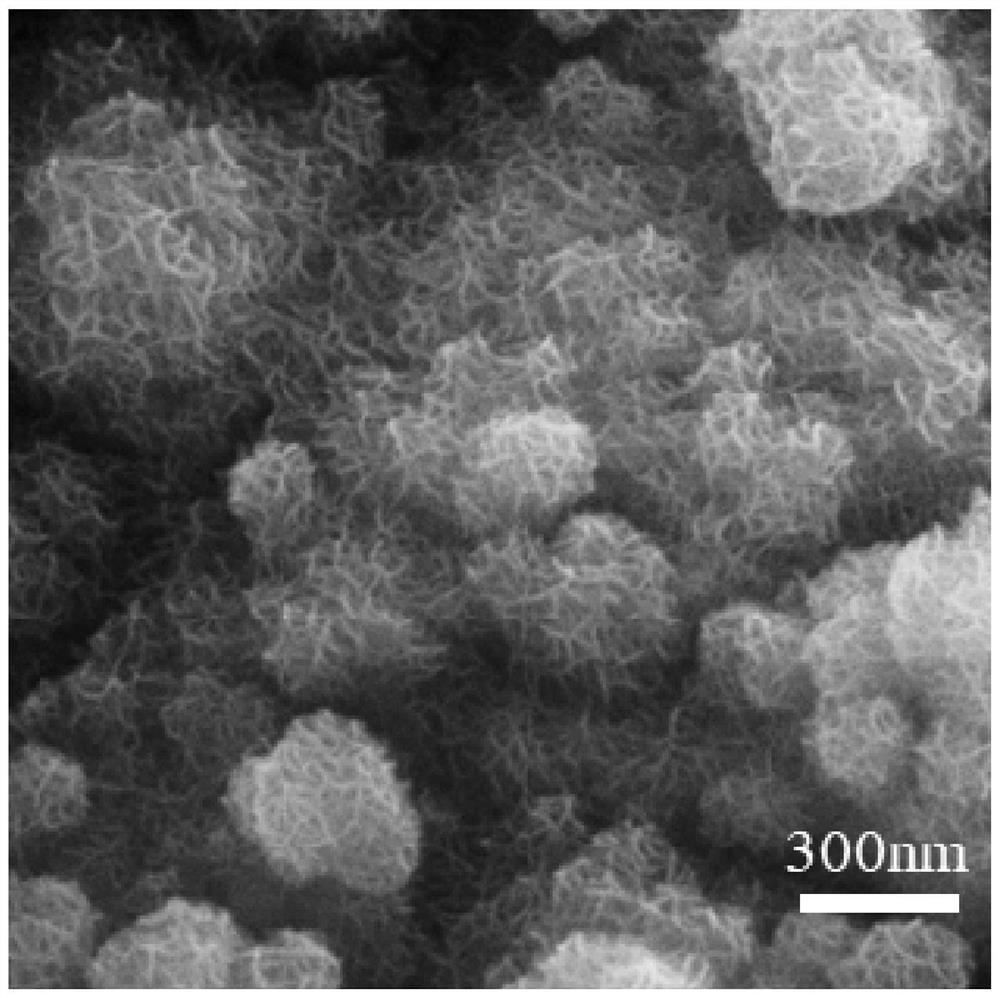

[0026] Specific embodiment one: present embodiment a kind of preparation method of self-supporting nanostructure electrocatalyst of fast low energy consumption, it is to carry out according to the following steps:

[0027] 1. Pretreatment of active substances:

[0028] The active substance is mixed with water to obtain a mixed solution, and then the mixed solution is ultrasonically vibrated to obtain an active substance solution;

[0029] The concentration of the mixed solution is 0.005mol / L~0.8mol / L;

[0030] Second, the formation of liquid film:

[0031] Evenly drop the active material solution on the pretreated precursor, so that the active material solution forms a liquid film on the surface of the precursor, and obtain a precursor with a liquid film on the surface;

[0032] 3. Apply an atmosphere to the precursor:

[0033] ①. Place the precursor covered with a liquid film in the hearth of the tube furnace;

[0034] ②. At room temperature, close the intake valve, open ...

specific Embodiment approach 2

[0046] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the pretreated precursor described in step 2 is specifically prepared according to the following steps: the precursor is sequentially used with 0.1mol / L~5mol / L HCl solution, deionized water and absolute ethanol for 0.5min to 5min each time. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0047] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the precursor is a transition metal material. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com