Preparation method of MoS2/S-NiCoCr-LDH composite material

A composite material and product technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of reducing the Faraday efficiency of the reaction, difficult to catalyze the reaction, poor conductivity, etc., to improve the performance of electrocatalytic nitrogen reduction, simple process, easy to use The effect obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

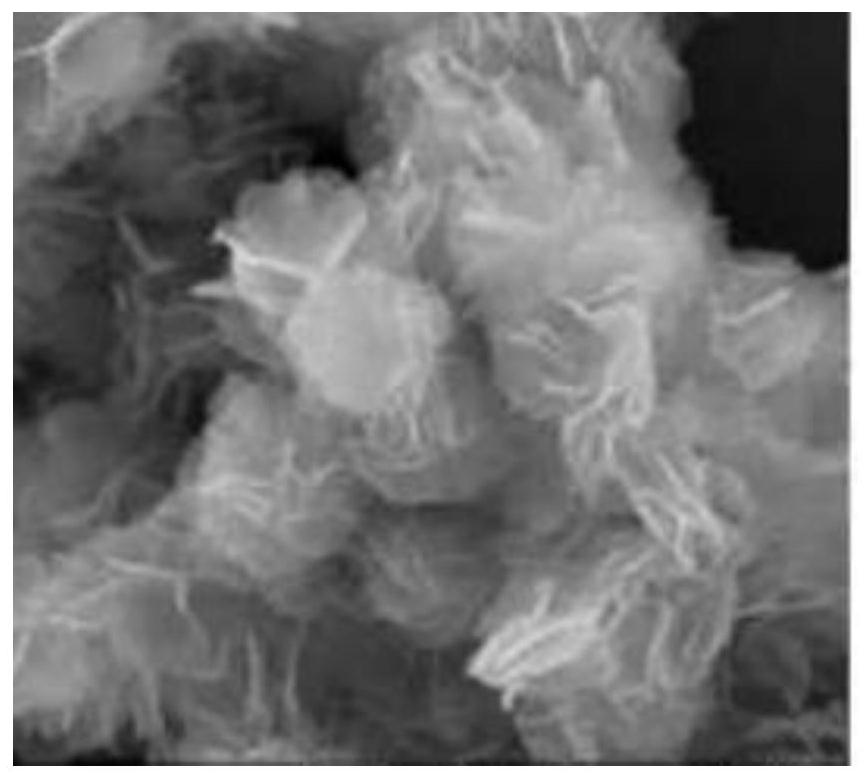

[0031] A kind of MoS 2 / S-NiCoCr-LDH composite material specifically includes the following preparation steps:

[0032] (1) Add 1mmol chromium nitrate, 1.5mmol cobalt nitrate, 1.5mmol nickel nitrate and 2mmol urea into 200ml deionized water, stir magnetically for 30min, then add 1mol / L NaOH solution dropwise, adjust the pH of the solution to 10, and then in 100℃ Stir in an oil bath for 24 hours, then wash with deionized water until neutral, and dry at a constant temperature of 80°C;

[0033] (2) Add 200 mg of the product of step (1) into 50 ml of deionized water, add 100 mg of Na 2 S, stirred for 30 minutes, transferred to a polytetrafluoroethylene reactor, hydrothermally reacted at 120°C for 24h, after the reaction was completed, washed with deionized water, and vacuum-dried at 60°C;

[0034](3) Add 200 mg of the product of step (2) into 100 ml of deionized water, add 300 mg of sodium molybdate, 200 mg of thioacetamide and 100 mg of cetyltrimethylammonium bromide, ultrasoni...

Embodiment 2

[0039] A kind of MoS 2 / S-NiCoCr-LDH composite material specifically includes the following preparation steps:

[0040] (1) Add 1mmol chromium nitrate, 0.5mmol cobalt nitrate, 2.5mmol nickel nitrate and 1.5mmol urea into 200ml deionized water, stir magnetically for 30min, then add 1mol / L NaOH solution dropwise, adjust the pH of the solution to 10, and then Stir in an oil bath for 18 hours, then wash with deionized water until neutral, and dry at a constant temperature of 80°C;

[0041] (2) Add 200 mg of the product of step (1) into 50 ml of deionized water, add 50 mg of Na 2 S, stirred for 30 minutes, transferred to a polytetrafluoroethylene reactor, hydrothermally reacted at 100°C for 16h, after the reaction was completed, washed with deionized water, and vacuum-dried at 60°C;

[0042] (3) Add 200 mg of the product of step (2) to 100 ml of deionized water, add 200 mg of sodium molybdate, 100 mg of thioacetamide and 40 mg of hexadecyltrimethylammonium bromide, ultrasonicate ...

Embodiment 3

[0045] A kind of MoS 2 / S-NiCoCr-LDH composite material specifically includes the following preparation steps:

[0046] (1) Add 1mmol chromium nitrate, 2.5mmol cobalt nitrate, 0.5mmol nickel nitrate and 3mmol urea into 200ml deionized water, stir magnetically for 30min, then add 1mol / L NaOH solution dropwise, adjust the pH of the solution to 10, and then set the solution at 120°C Stir in an oil bath for 32 hours, then wash with deionized water until neutral, and dry at a constant temperature of 80°C;

[0047] (2) Add 200 mg of the product of step (1) to 50 ml of deionized water, add 200 mg of Na 2 S, stirred for 30 minutes, transferred to a polytetrafluoroethylene reactor, hydrothermally reacted at 150°C for 36h, after the reaction was completed, washed with deionized water, and vacuum-dried at 60°C;

[0048] (3) Add 200 mg of the product of step (2) to 100 ml of deionized water, add 400 mg of sodium molybdate, 300 mg of thioacetamide and 150 mg of cetyltrimethylammonium bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com