An efficient two-dimensional nitrogen heterocarbon material, a preparation method thereof and an application thereof in the field of energy conversion

An aza-carbon, high-temperature carbonization technology, applied in nanotechnology, electrical components, battery electrodes, etc. for materials and surface science, can solve problems such as the arrival of unfavorable active substances, and achieve high specific surface area, conducive to transmission, excellent The effect of electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

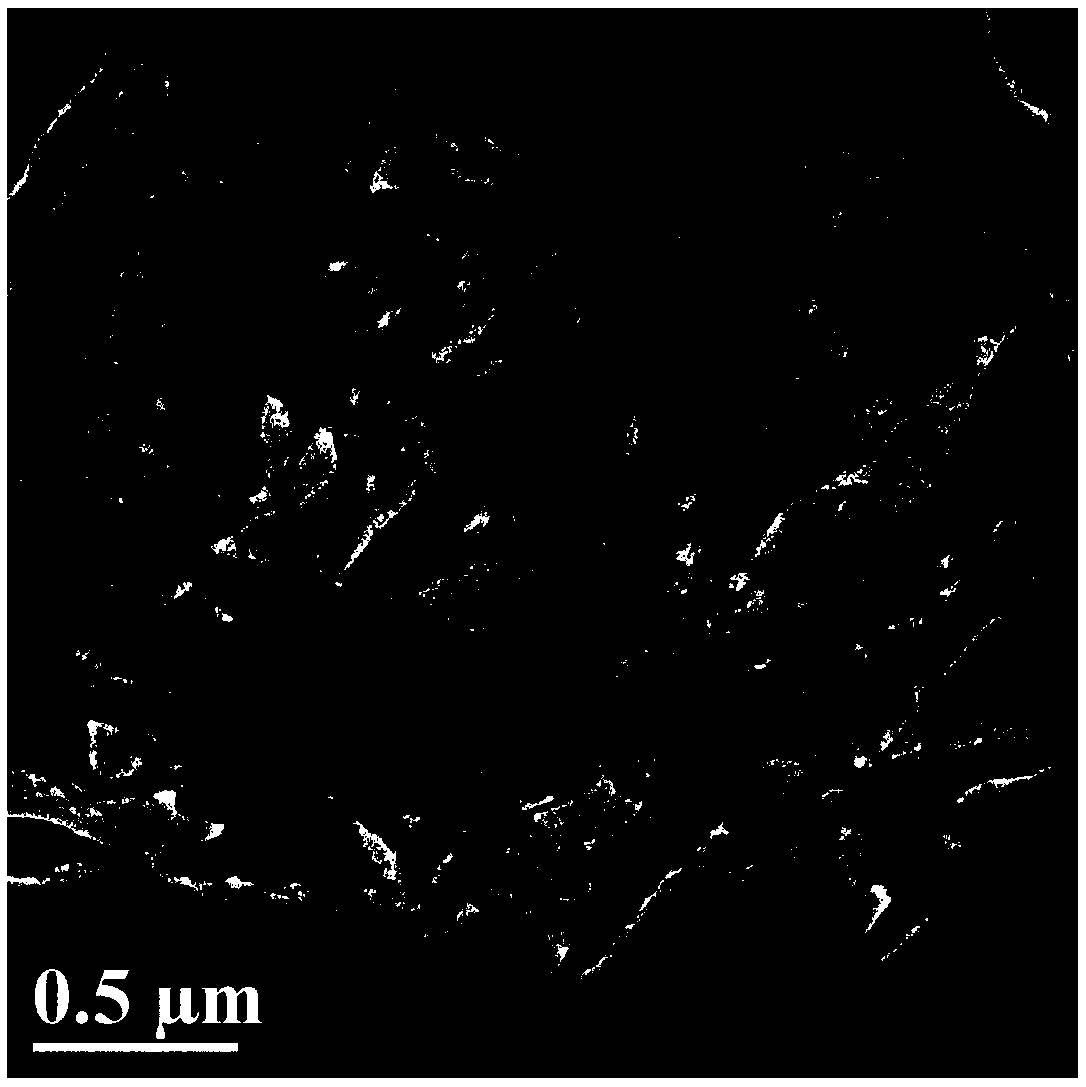

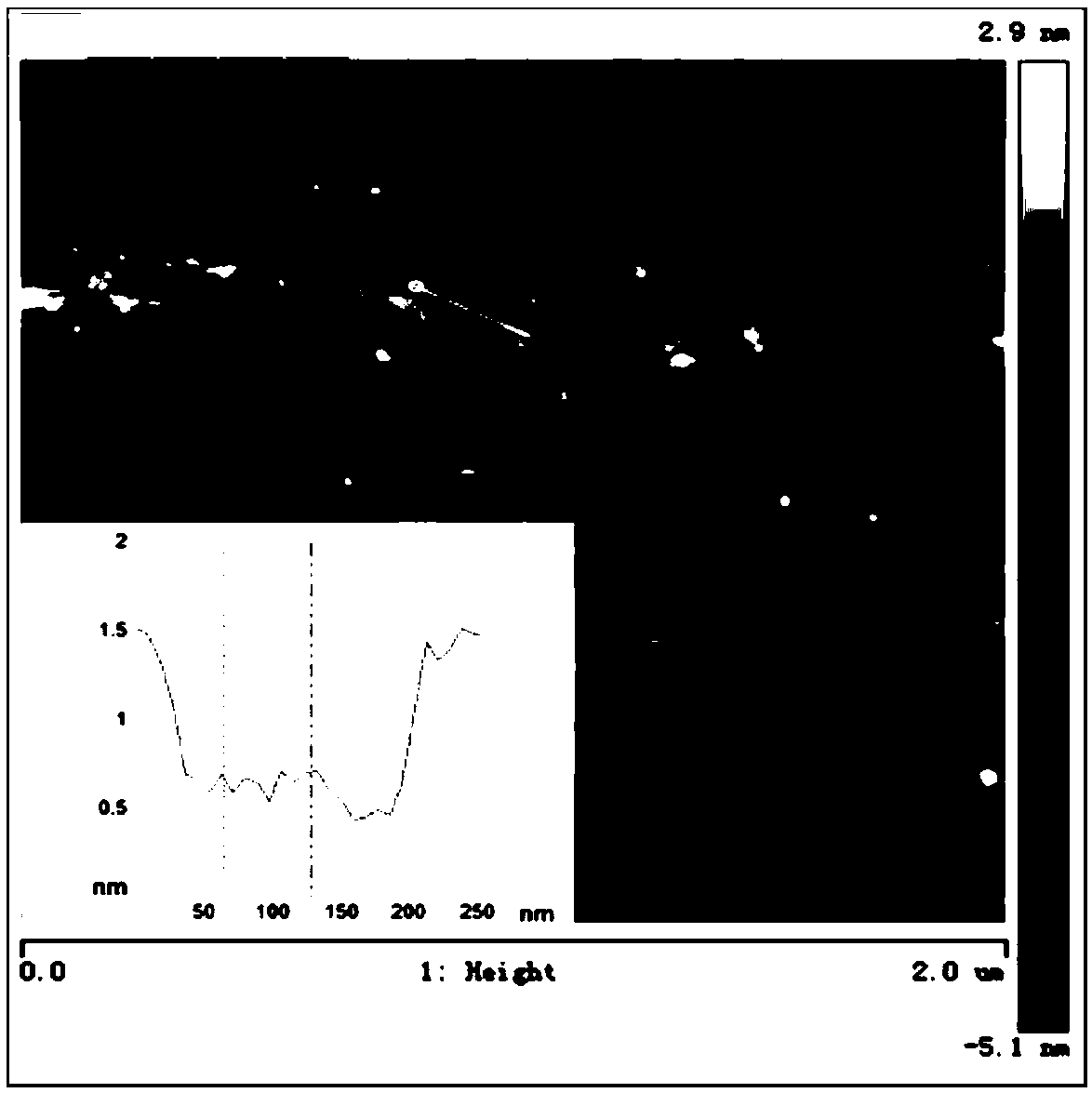

[0033] (1) Synthesis of two-dimensional silica materials

[0034] Weigh 4.6 parts by mass of P123 and add it to 116 parts by volume of an aqueous solution containing 0.522 parts by mass of graphene oxide, stir at room temperature until P123 is completely dissolved, then add 22.5 parts by volume of concentrated hydrochloric acid with a mass fraction of 37%, and continue stirring in a water bath at 37°C 2.5h, slowly add 9.4 parts by volume of tetraethyl orthosilicate dropwise, continue to stir vigorously for 25h, transfer to the reaction kettle, crystallize at 110°C for 20h, filter, wash, dry, and then roast at 550°C for 5h to remove the template agent, A two-dimensional silica material is obtained.

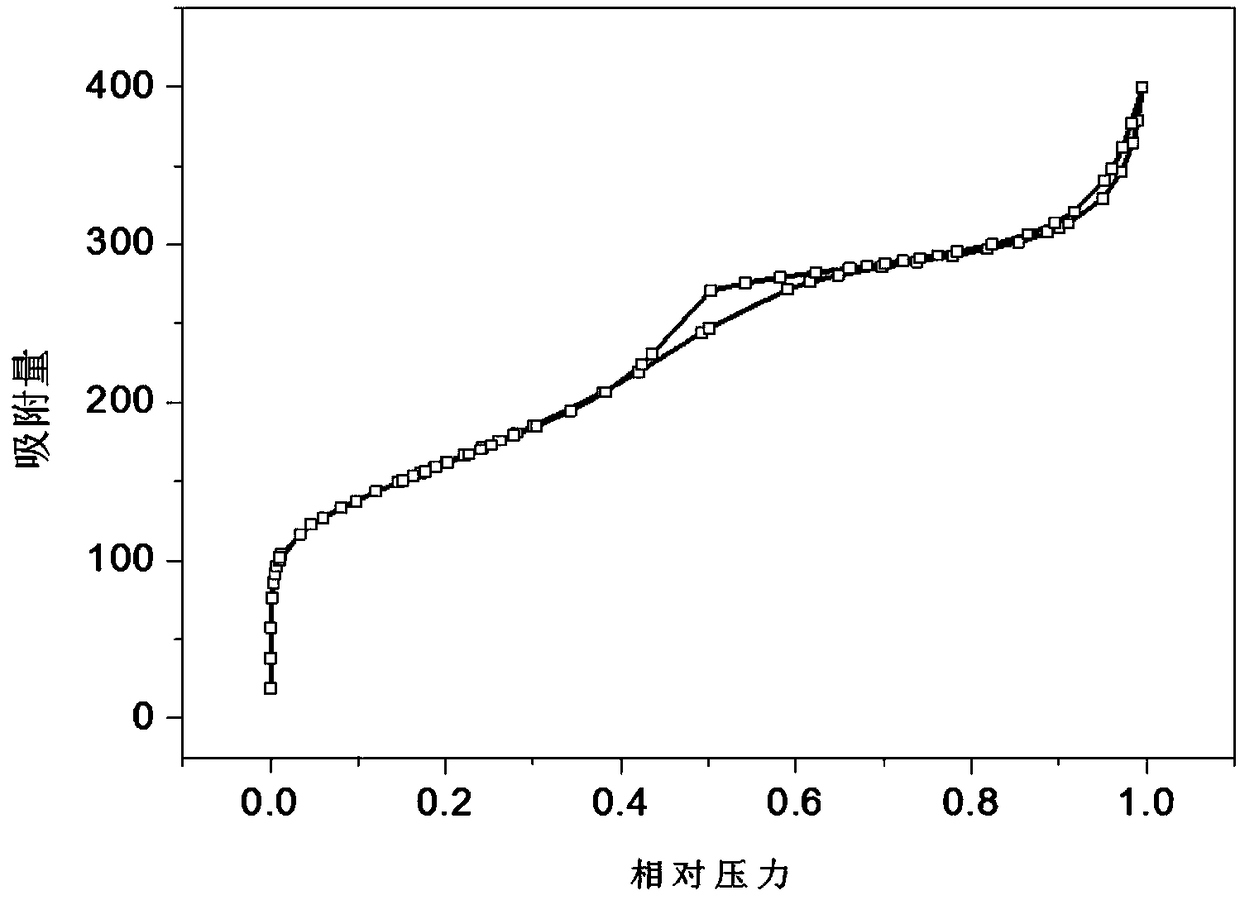

[0035] (2) Preparation of nitrogen-doped carbon catalyst

[0036] Weigh 3.2 parts by mass of o-phenanthroline dissolved in 25.0 parts by volume of ethanol and 25.0 parts by volume of 0.2M FeCl 2 Into the solution, 2.85 parts by mass of the above-mentioned two-dimensional silica w...

Embodiment 2

[0042] (1) Synthesis of two-dimensional silica materials

[0043] Weigh 4.6 parts by mass of P123 and add it to 116 parts by volume of an aqueous solution containing 0.261 parts by mass of graphene oxide, stir at room temperature until P123 is completely dissolved, then add 22.5 parts by volume of concentrated hydrochloric acid with a mass fraction of 37%, and continue stirring in a water bath at 37°C 2.5h, slowly add 9.4 parts by volume of tetraethyl orthosilicate dropwise, continue to stir vigorously for 25h, transfer to the reaction kettle, crystallize at 110°C for 20h, filter, wash, dry, and then roast at 550°C for 5h to remove the template agent, A two-dimensional silica material is obtained.

[0044] (2) Preparation of nitrogen-doped carbon catalyst

[0045] The method for preparing the nitrogen-doped carbon catalyst is the same as step (2) of Example 1.

[0046] The material characterization and electrochemical performance testing methods of the catalyst are the same ...

Embodiment 3

[0048] (1) Synthesis of two-dimensional silica materials

[0049] Weigh 2.3 parts by mass of P123 and add it to 116 parts by volume of an aqueous solution containing 0.522 parts by mass of graphene oxide, stir at room temperature until P123 is completely dissolved, then add 22.5 parts by volume of concentrated hydrochloric acid with a mass fraction of 37%, and continue stirring in a water bath at 37°C 2.5h, slowly add 9.4 parts by volume of tetraethyl orthosilicate dropwise, continue to stir vigorously for 25h, transfer to the reaction kettle, crystallize at 110°C for 20h, filter, wash, dry, and then roast at 550°C for 5h to remove the template agent, A two-dimensional silica material is obtained.

[0050] (2) Preparation of nitrogen-doped carbon catalyst

[0051] Weigh 2.5 parts by mass of o-phenanthroline dissolved in 20.0 parts by volume of ethanol and 20.0 parts by volume of 0.1M FeCl 2 Into the solution, 1.75 parts by mass of the above-mentioned two-dimensional silica w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com