Lithium ion battery ceramic diaphragm paste

A technology of lithium-ion batteries and ceramic diaphragms, which is applied to battery pack components, separators/films/diaphragms/spacer components, circuits, etc., can solve the electrochemical performance of battery space, unfavorable energy and power density, coating, etc. Problems such as poor layer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

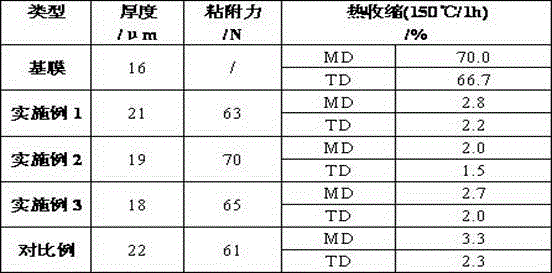

[0014] Example 1: Weigh 7.5g of ethylene-vinyl acetate copolymer, 15g of polyvinyl alcohol aqueous solution, 140g of nano-alumina (average particle size: 200nm) powder, and 60g of alumina whisker (average aspect ratio 1:20) , polyacrylamide 2.5g, deionized water 270g, dispersant 5g. Mix in a sand mill for 30 minutes to obtain a uniform suspension; apply the suspension to a PE film with a thickness of 16 μm on both sides, dry it at 60°C, and measure the coating thickness, adhesion and heat shrinkage properties. The results are shown in Table 1.

Embodiment 2

[0015] Example 2: Weigh 7.5g of ethylene-vinyl acetate copolymer, 15g of polyvinyl alcohol aqueous solution, 120g of nano-alumina (average particle size: 200nm) powder, and 80g of alumina whisker (average aspect ratio 1:20) , polyacrylamide 2.5g, dispersant 5g, deionized water 270g. Mix in a sand mill for 30 minutes to obtain a uniform suspension; apply the suspension to a PE film with a thickness of 16 μm on both sides, dry it at 60°C, and measure the coating thickness, adhesion and heat shrinkage properties. The results are shown in Table 1.

Embodiment 3

[0016] Example 3: Weigh 7.5g of ethylene-vinyl acetate copolymer, 15g of polyvinyl alcohol aqueous solution, 75g of nano-alumina (average particle size: 200nm) powder, 125g of alumina whiskers (average aspect ratio 1:20), Polyacrylamide 2.5g, dispersant 5g, deionized water 270g. Mix in a sand mill for 30 minutes to obtain a uniform suspension; apply the suspension to a PE film with a thickness of 16 μm on both sides, dry it at 60°C, and measure the coating thickness, adhesion and heat shrinkage properties. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com