Organogel polymer electrolytic solution, preparation method, application, sodium-based dual-ion battery and preparation method thereof

An organic electrolyte and organic gel technology, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problems of liquid organic electrolyte leakage, limited application occasions, affecting battery performance, etc., to improve electrochemical performance, The effect of a wide range of applications, improved service life and safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] In a second aspect, in at least one embodiment, a method for preparing an organogel polymer electrolyte is provided, comprising the following steps:

[0084] Mix organic polymers, inorganic additives and solvents and heat to obtain a solid polymer matrix; mix sodium salts with organic solvents to obtain organic electrolytes;

[0085] Putting the solid polymer matrix into the organic electrolyte to obtain the organogel polymer electrolyte.

[0086] The above preparation method is simple to operate, easy to realize, and low in cost, and the prepared organogel polymer electrolyte has excellent performance.

[0087] Preferably, the solvent includes at least one of water, alcohols, ketones, acids, sulfones, benzene, halides, ammonia or liquid oxides, preferably the solvent includes ethanol, acetone, dimethyl Sulfoxide, acetonitrile, chloroform, N-methylpyrrolidone, ethylenediamine, water, methanol, formic acid, sulfuric acid, benzene, carbon disulfide, carbon tetrachloride,...

Embodiment 1

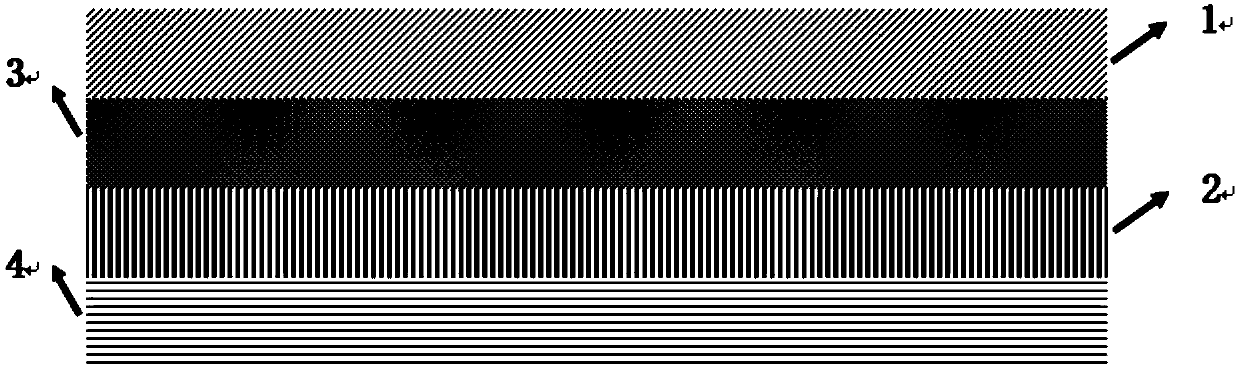

[0153] A sodium-based double-ion battery includes a positive electrode, a negative electrode, and an organic gel polymer electrolyte between the positive electrode and the negative electrode.

[0154] The preparation method of sodium-based double ion battery comprises:

[0155] Preparation of the negative electrode of the battery: cutting the tin sheet into discs with a diameter of 12 mm, cleaning the discs with ethanol, and putting them into a vacuum drying oven for vacuum drying.

[0156]Prepare battery positive electrode: Add 0.8g carbon material, 0.1g conductive carbon black, and 0.1g polytetrafluoroethylene into 2ml nitrogen methyl pyrrolidone solution, grind thoroughly to obtain a uniform slurry; then evenly coat the slurry on carbon-coated aluminum foil surface (ie, positive current collector) and vacuum-dried. The electrode sheet obtained by drying was cut into a disc with a diameter of 10 mm, and was used as a positive electrode after compaction.

[0157] Preparatio...

Embodiment 2-11

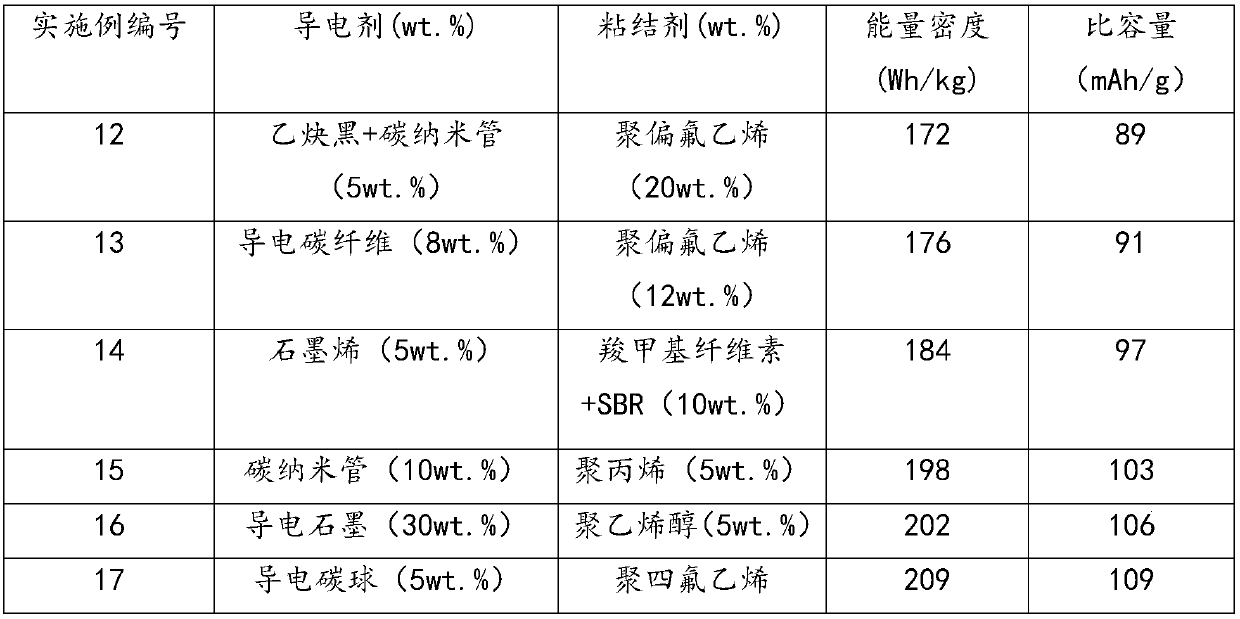

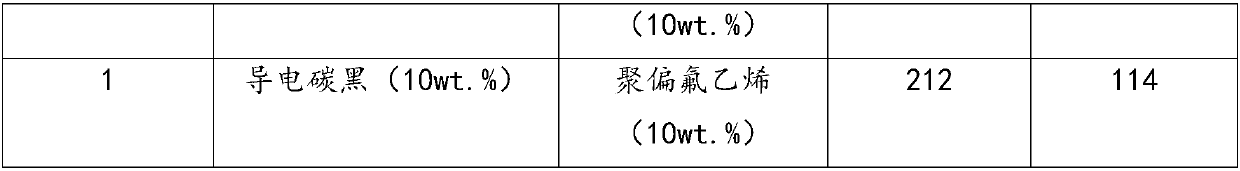

[0160] Example 2-11 is the same as the preparation process of the sodium-based double-ion battery of Example 1, except that the carbon material in the positive electrode active material used when preparing the positive electrode is different, and all other steps and materials used are the same. The energy storage performance of the sodium-based double-ion battery is tested, and compared with the performance of Example 1 of the present invention, the positive electrode material used in Example 1 and Example 2-11 and its energy storage performance based on the battery. For details, see Table 1.

[0161] Table 1: Performance parameter table of the sodium-based double-ion battery of Examples 1-11

[0162] Example number

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com