Method for preparing cathode material of lithium iron phosphate lithium-ion battery

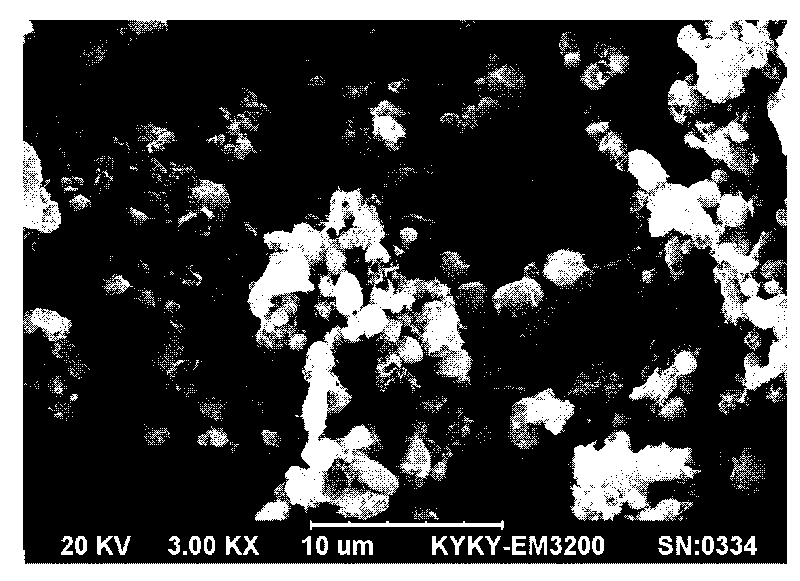

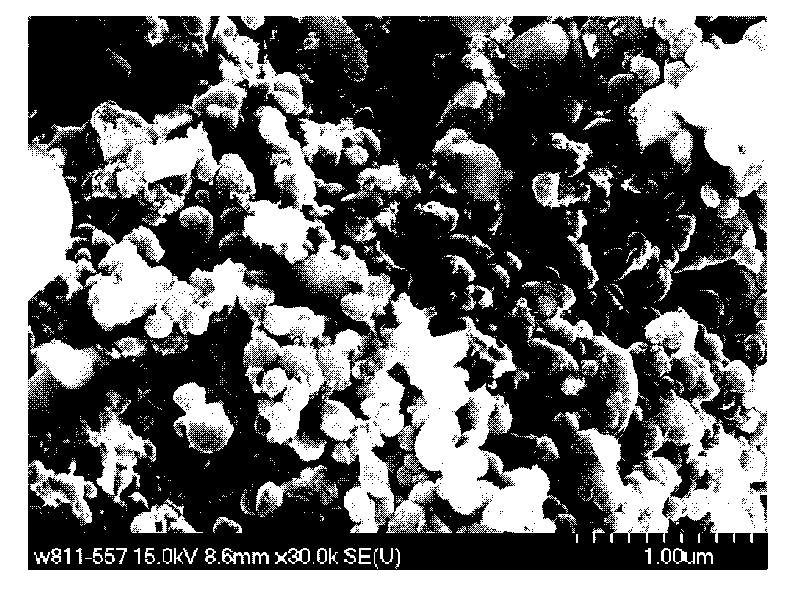

A lithium-ion battery and lithium iron phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of poor cycle stability, high cost, and low specific capacity, and achieve good crystallization, uniform composition, and Uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: the preparation method of lithium ferrous phosphate lithium ion battery cathode material of the present embodiment is carried out according to the following steps: one, by lithium hydroxide: ferrous oxalate: the mol ratio of ammonium dihydrogen phosphate=1: 1: 1 Weigh lithium hydroxide powder, ferrous oxalate powder and ammonium dihydrogen phosphate powder and mix them evenly, then add conductive agent and lithium hydroxide of 0.3% to 2% of the total mass of lithium hydroxide, ferrous oxalate and ammonium dihydrogen phosphate , ferrous oxalate and ammonium dihydrogen phosphate total mass 3% ~ 25% of the dispersant to obtain the mixture; 2, the mixture obtained through step 1 is rolled through a double roller mill with a gap of 0.8mm ~ 1.2mm uniform, and then crushed into a powder with a fineness of 30 mesh to 50 mesh, and then repeat the extrusion and crushing process three times to obtain a uniformly mixed powder; 3. Put the powder obtained in s...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that the conductive agent described in step 1 is one of acetylene black, earthy graphite, carbon fiber or graphite emulsion or a combination of several of them. Others are the same as in the first embodiment.

[0016] When the conductive agent of this embodiment is a composition, each conductive agent is mixed in an arbitrary ratio.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the dispersant in Step 1 is one of kerosene, diesel or gasoline or a combination of several of them. Others are the same as in the first or second embodiment.

[0018] When the dispersant of this embodiment is a composition, each dispersant is mixed in an arbitrary ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com