Method for continuously preparing graphene

A technology of graphene and graphite, which is applied in the field of rapid and continuous preparation of graphene by electrochemical method, can solve the problems of restricting the mass production and application of graphene, the thickness of graphite flakes is not uniform enough, and the treatment of strong acid waste liquid is difficult, and it is suitable for large batches The effect of rapid continuous production, low cost and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

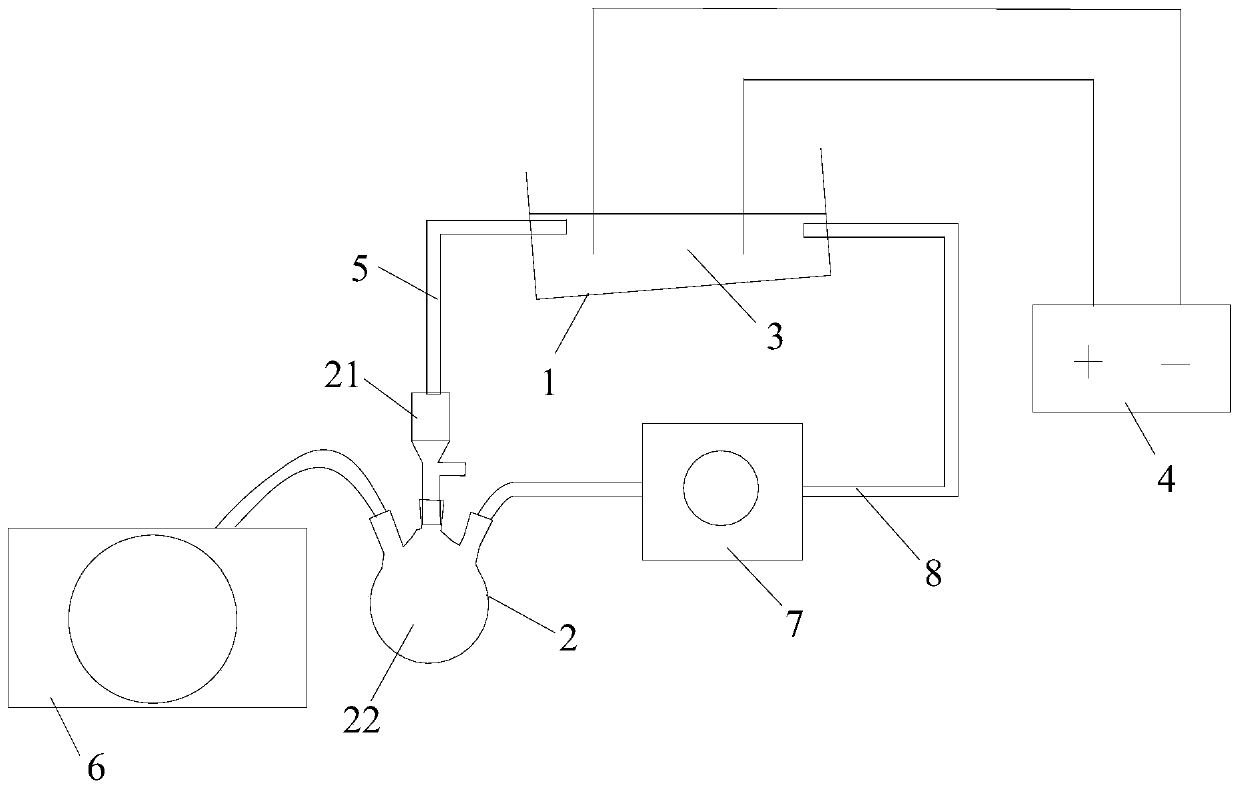

[0034] 1) device

[0035] Such as figure 1 As shown, the present embodiment provides a device for continuously preparing graphene, comprising a rectangular electrolytic cell 1 and a solid-liquid separator 2, an electrolytic solution 3 is housed in the rectangular electrolytic cell 1, and a commercial graphite material is used as an anode, a metal sheet or The graphite electrode is the cathode, which is inserted into the electrolyte 3, the anode and the cathode are connected to a DC stabilized power supply 4, a certain current and voltage are applied between the anode and the cathode, and an electrochemical reaction is performed to strip the graphite electrode to form graphene, which is dispersed in the electrolyte.

[0036] A liquid outlet is provided on one side wall of the rectangular electrolytic cell 1 near the liquid surface of the electrolyte, the rectangular electrolytic cell 1 is inclined 5° to the side where the liquid outlet is provided, and the liquid outlet passes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com