Anti-fingerprint TPU protective film for 3D curved screen and preparation method of anti-fingerprint TPU protective film

A protective film and anti-fingerprint technology, which is applied in the direction of pressure-sensitive film/sheet, film/sheet-like adhesive, coating, etc. It can solve the problem of rebound warping of the curved surface of the mobile phone screen, low adhesion, and bending of the 3D curved screen Large radian and other problems, to achieve the effect of good uniformity of film thickness, adjustable film hardness, and good self-expelling foam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

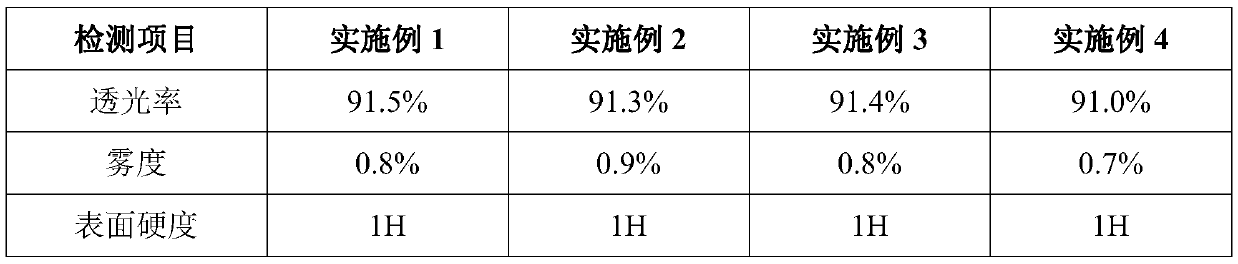

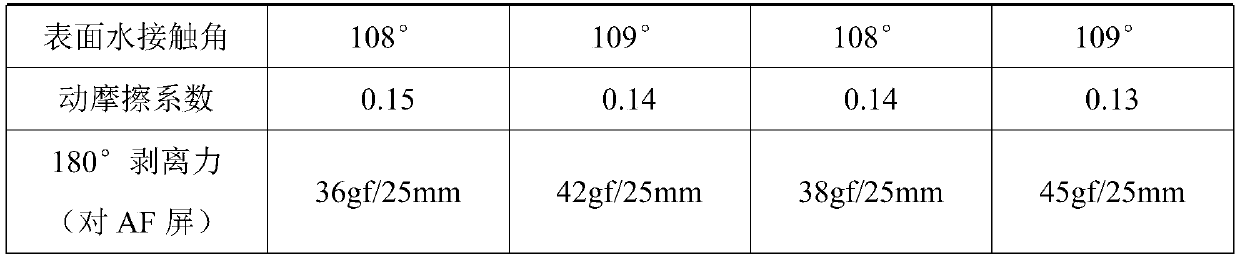

Examples

Embodiment 1

[0031] Composed of 100 parts by weight of polyurethane acrylate, 5 parts by weight of isooctyl acrylate, 1 part by weight of 1-hydroxy-cyclohexyl benzophenone, 1 part by weight of fluorine-containing acrylate, and 100 parts by weight of ethyl acetate. Fingerprint UV hardening paint;

[0032] Optical grade hard TPU is formed by mixing hexamethylene diisocyanate, polycaprolactone polyol, and ethylene glycol at a molar ratio of 1:0.8:0.2 and polymerizing in ethyl acetate solvent through the catalysis of dibutyltin dilaurate glue;

[0033] Optical-grade high-viscosity silicone pressure-sensitive adhesive is composed of 100 parts by weight of MQ methyl silicone resin, 0.1 parts by weight of hydrogen-based silicone oil, 0.1 parts by weight of silane coupling agent, and 0.1 parts by weight of platinum catalyst with a concentration of 5000ppm;

[0034] Coat the optical-grade hard TPU glue on the PET release film with a coating thickness of 50 μm, dry it at 90-120°C and cure to form a...

Embodiment 2

[0039] 100 parts by weight of urethane acrylate, 40 parts by weight of lauryl acrylate, 5 parts by weight of 2-hydroxyl-2-methyl-phenylacetone-1, 10 parts by weight of silicon-containing acrylate, 180 parts by weight of propylene glycol Anti-fingerprint UV hardening coating composed of methyl ether acetate;

[0040]It is composed of isophorone diisocyanate, polycarbonate diol, and 1,4-butanediol in a molar ratio of 1:0.85:0.15 and polymerized in toluene solvent through the catalysis of dibutyltin dilaurate to form optical grade hard TPU glue;

[0041] Optical-grade high-viscosity silicone pressure-sensitive adhesive is composed of 100 parts by weight of polydimethylsiloxane, 2 parts by weight of hydrogen-based silicone oil, 1 part by weight of silane coupling agent, and 3 parts by weight of a platinum catalyst with a concentration of 5000ppm;

[0042] Coat the optical-grade hard TPU glue on the PET release film with a coating thickness of 50 μm, dry it at 90-120°C and cure to...

Embodiment 3

[0047] Composed of 100 parts by weight of polyurethane acrylate, 5 parts by weight of isooctyl acrylate, 1 part by weight of 1-hydroxy-cyclohexyl benzophenone, 1 part by weight of fluorine-containing acrylate, and 100 parts by weight of ethyl acetate. Fingerprint UV hardening paint;

[0048] Optical grade hard TPU is formed by mixing hexamethylene diisocyanate, polycaprolactone polyol, and ethylene glycol at a molar ratio of 1:0.9:0.1 and polymerizing in ethyl acetate solvent through the catalysis of dibutyltin dilaurate glue;

[0049] Optical-grade high-viscosity silicone pressure-sensitive adhesive is composed of 100 parts by weight of MQ methyl silicone resin, 0.1 parts by weight of hydrogen-based silicone oil, 0.1 parts by weight of silane coupling agent, and 0.1 parts by weight of platinum catalyst with a concentration of 5000ppm;

[0050] Coat the optical-grade hard TPU glue on the PET release film with a coating thickness of 200 μm, dry it at 90-120°C and cure to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com