Dry method selective non-catalytic reduction method and device

A selective, non-catalytic technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of energy waste, water wall corrosion, increase in fly ash carbon content, etc., and achieve simple, reliable and economical processes. The effect of low heat and running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

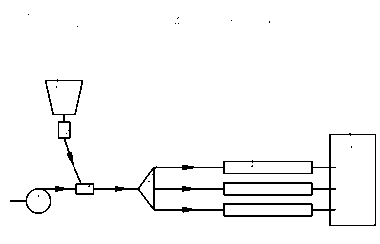

[0025] Example 1: figure 1 It is a dry selective non-catalytic reduction (Dry SNCR) method in which the reducing agent is urea powder in the present invention.

[0026] The dry selective non-catalytic reduction method in which the reductant is urea powder is: The urea granules are ground into urea powder and loaded into the silo; The urea powder is conveyed into the mixer through the feeder; The air from the conveying air source and the urea powder conveyed from the feeder are mixed in the mixer to form a mixed gas; The mixed gas is transported to the distributor through the pipeline, and the mixed gas is divided into multiple strands in the distributor; The mixed gas from the distributor is sent into the spray gun through the pipeline; The mixed gas is sprayed into the flue through the spray gun; The mixed gas participates in the denitrification reaction in the flue.

[0027] The device for realizing the present invention includes: a feed bin, a feeder, a conveyi...

Embodiment 2

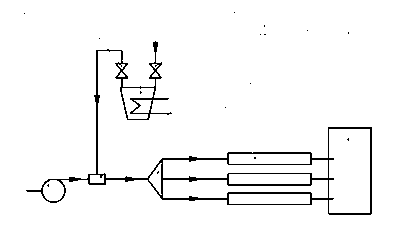

[0038] Example 2: figure 2It is a dry selective non-catalytic reduction (Dry SNCR) method in which the reducing agent of the present invention is ammonia gas, urea gas or urea melt. This dry selective non-catalytic reduction method is:

[0039] Liquid ammonia and urea are loaded into the heater through the feed valve to be heated and vaporized into ammonia gas and urea gas (or liquefied into urea melt); Ammonia gas, urea gas or urea melt enters the mixer through the discharge valve; The steam from the delivery gas source and the ammonia gas, urea gas or urea melt from the discharge valve are mixed in the mixer to form a mixed gas; The mixed gas is transported to the distributor through the pipeline, and the mixed gas is divided into multiple strands in the distributor; The mixed gas from the distributor is sent into the spray gun through the pipeline; The mixed gas is sprayed into the flue through the spray gun; The mixed gas participates in the denitrification r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com