Grinding wheel with split dovetail groove structure

A dovetail groove and split technology, which is applied in the field of grinding tools, can solve the problems of difficult control of die pressing and sintering, increase the cost of use, and different quality of grinding wheels, and achieve the effects of easy replacement, material saving and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

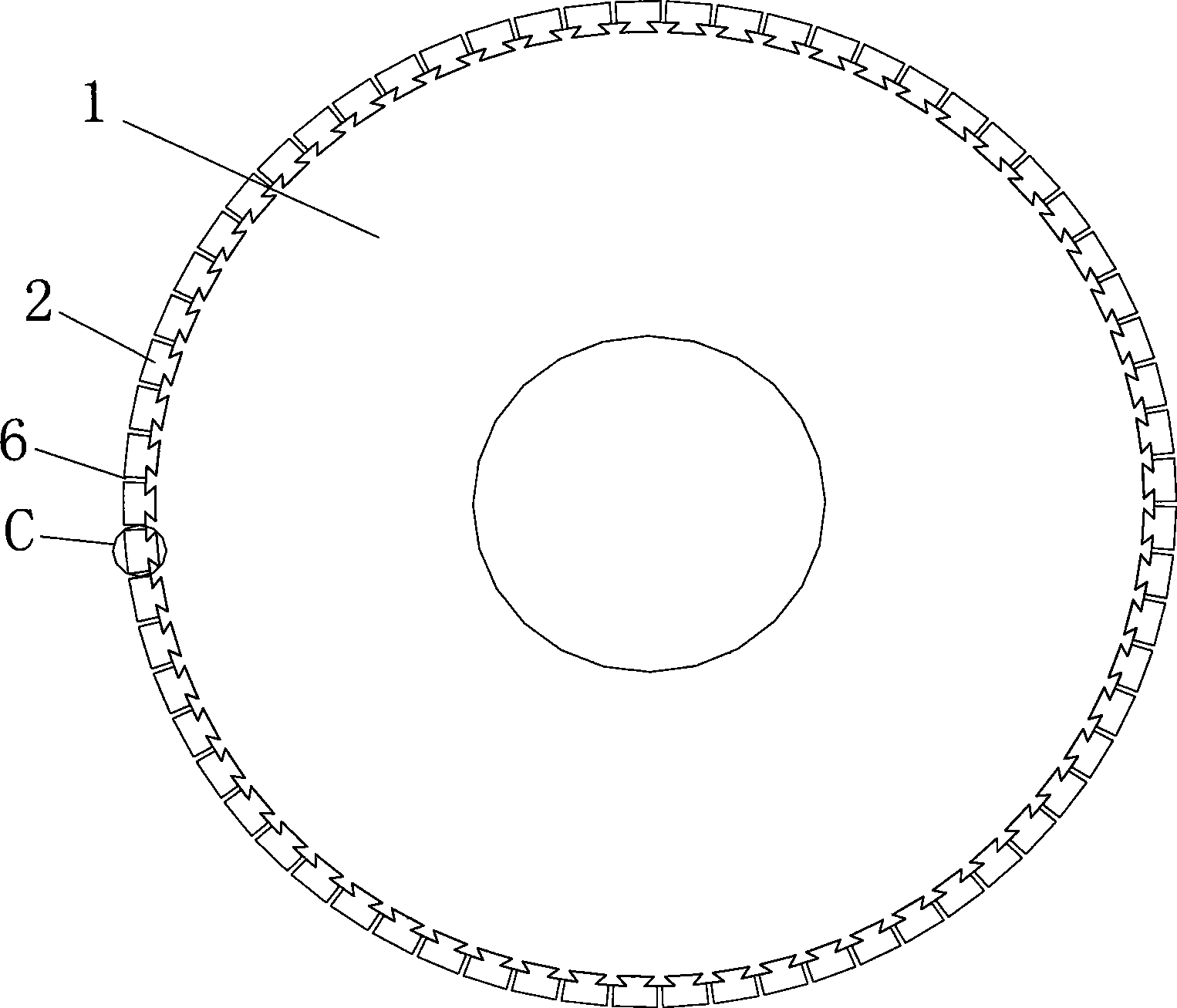

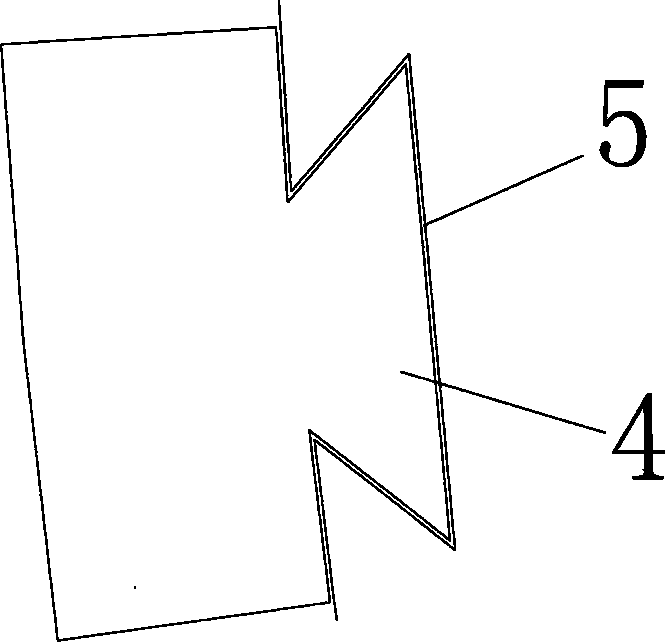

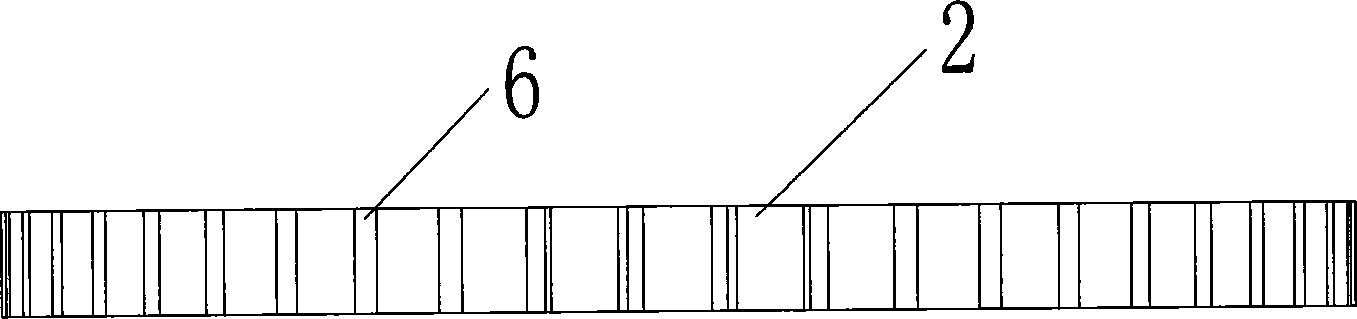

[0018] Example 1. like figure 1 , 3 As shown, it includes an annular metal substrate 1 and a grinding wheel grinding layer fixed on the outer peripheral surface of the metal substrate 1. The grinding wheel grinding layer is formed by splicing a plurality of grinding wheel grinding blocks 2, and the grinding wheel grinding block 2 is made of diamond and bonded The agent is made by mixing, granulating, pressing, drying, pre-sintering, sintering (nucleation, crystallization, sintering), heat preservation, cooling and other processes. Crystal glass is the basic glass, and titanium dioxide is used as a nucleating agent. The chemical composition of the basic glass is as follows: K 2 O 5~10%, MgO 10~18%, Al 2 o 3 10-20%, B 2 o 3 2-5%, TiO 2 1~4%, ZrO 2 1~4%, Na 2 O+K 2 O 3%, KF 5~12%, ZnO 4~8%, the rest is SiO 2 . During production, according to the above basic glass formula, use analytically pure raw materials, and mix according to the composition, put the batches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com