Stainless steel dry-resistant running magnetic pump

A stainless steel, magnetic pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of sliding bearing wear, internal magnetic rotor and isolation sleeve damage, leakage, etc., to ensure the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

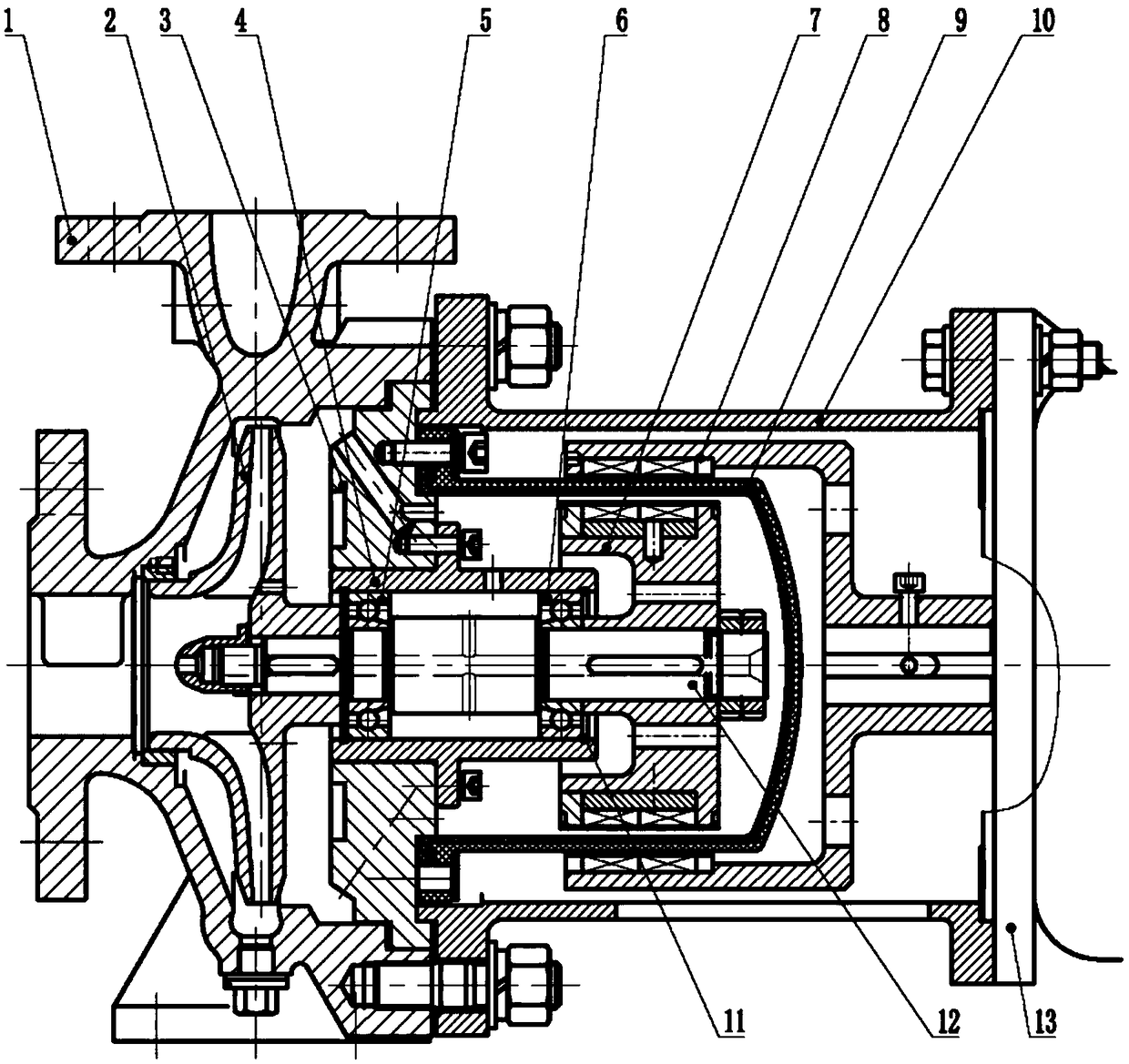

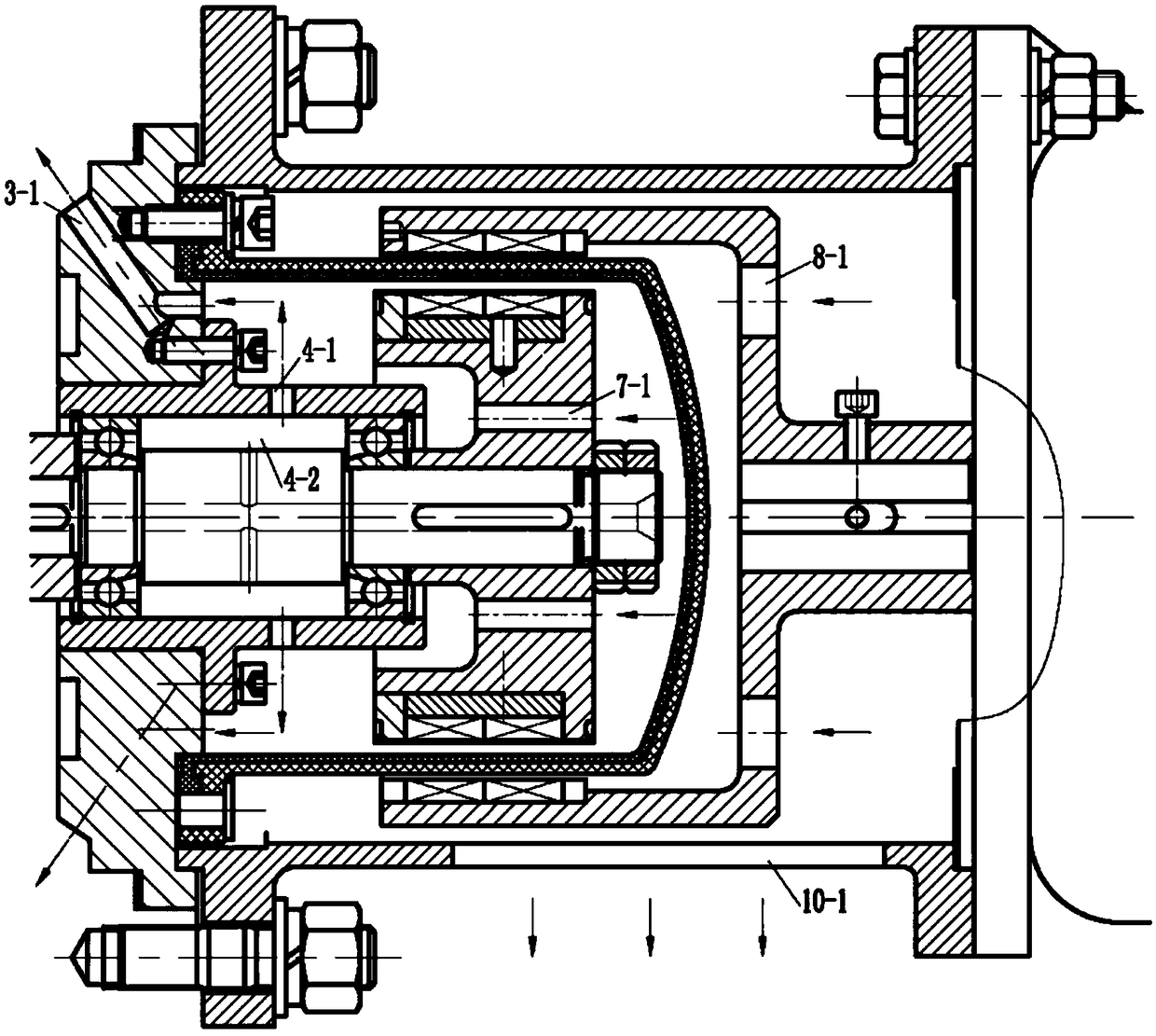

[0030] A stainless steel dry-running magnetic pump, comprising a pump body 1, an impeller 2, a pump cover 3, a bearing seat 4, a first ceramic bearing 5, a second ceramic bearing 6, an inner magnetic rotor 7, an outer magnetic rotor 8, and a spacer sleeve 9 , Coupling frame 10, circlip 11 for holes, pump shaft 12 and motor 13.

[0031] The motor 13 is connected to the pump body 1 through the coupling frame 10, and the coupling frame 10 is cylindrical. In the coupling frame 10, the outer magnetic rotor 8, the spacer sleeve 9, the inner magnetic rotor 7 and the pump body 1 are arranged in sequence from the motor 13 to the pump body 1. Shaft 12, the other end of the pump shaft 12 passes through the pump cover 3 and is provided with the impeller 2.

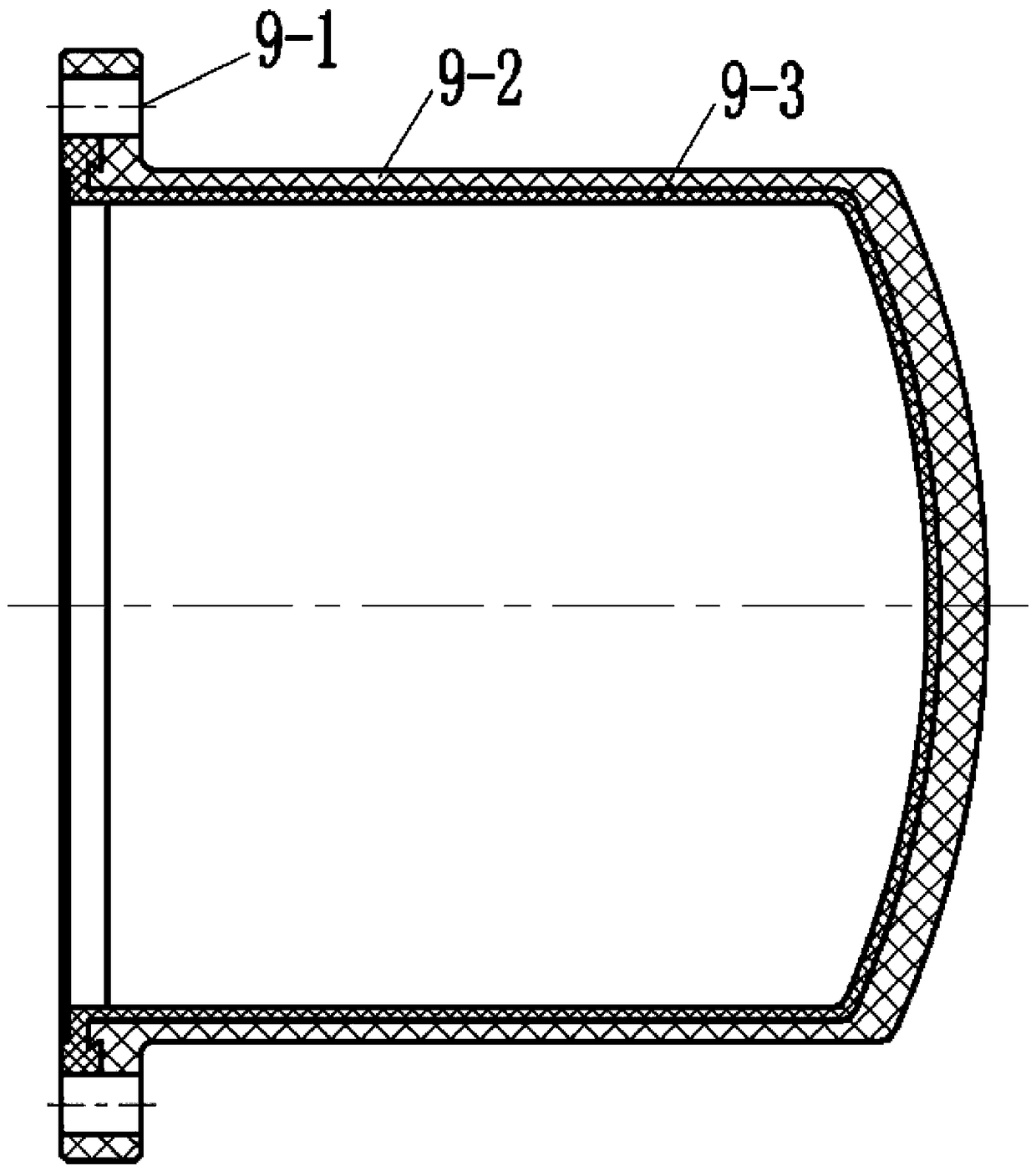

[0032] The spacer 9 is arranged between the inner magnetic rotor 7 and the outer magnetic rotor 8, the outer magnetic rotor 8 is installed on the shaft of the motor 13, and the spacer 9 is a non-metallic double-layer spacer.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com