Reserved electricity box hole mould and using method thereof

A technology of molds and electrical boxes, which is applied in the field of formwork/formwork/work frame, construction components on-site preparation, construction, etc., which can solve the problem of waste materials and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

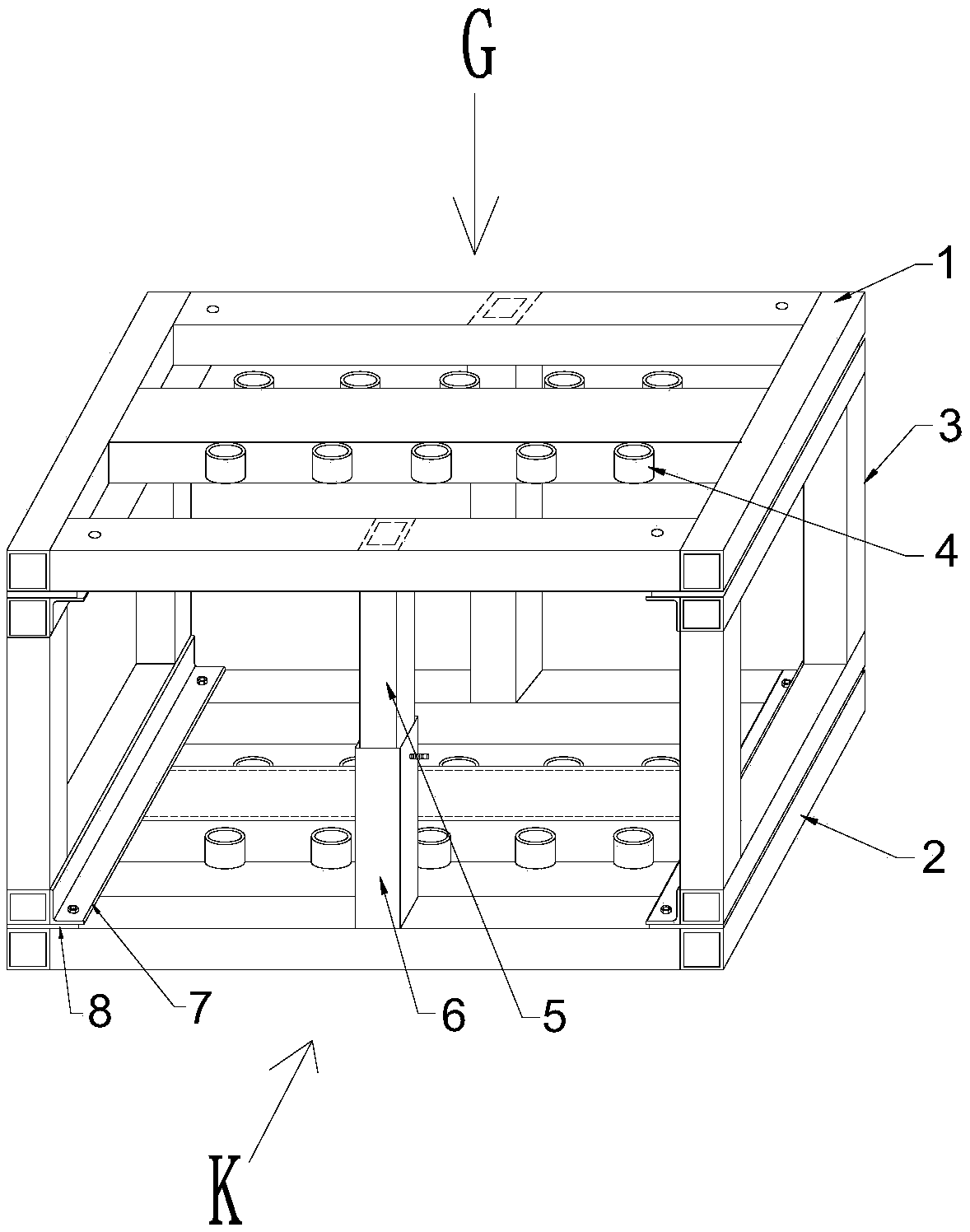

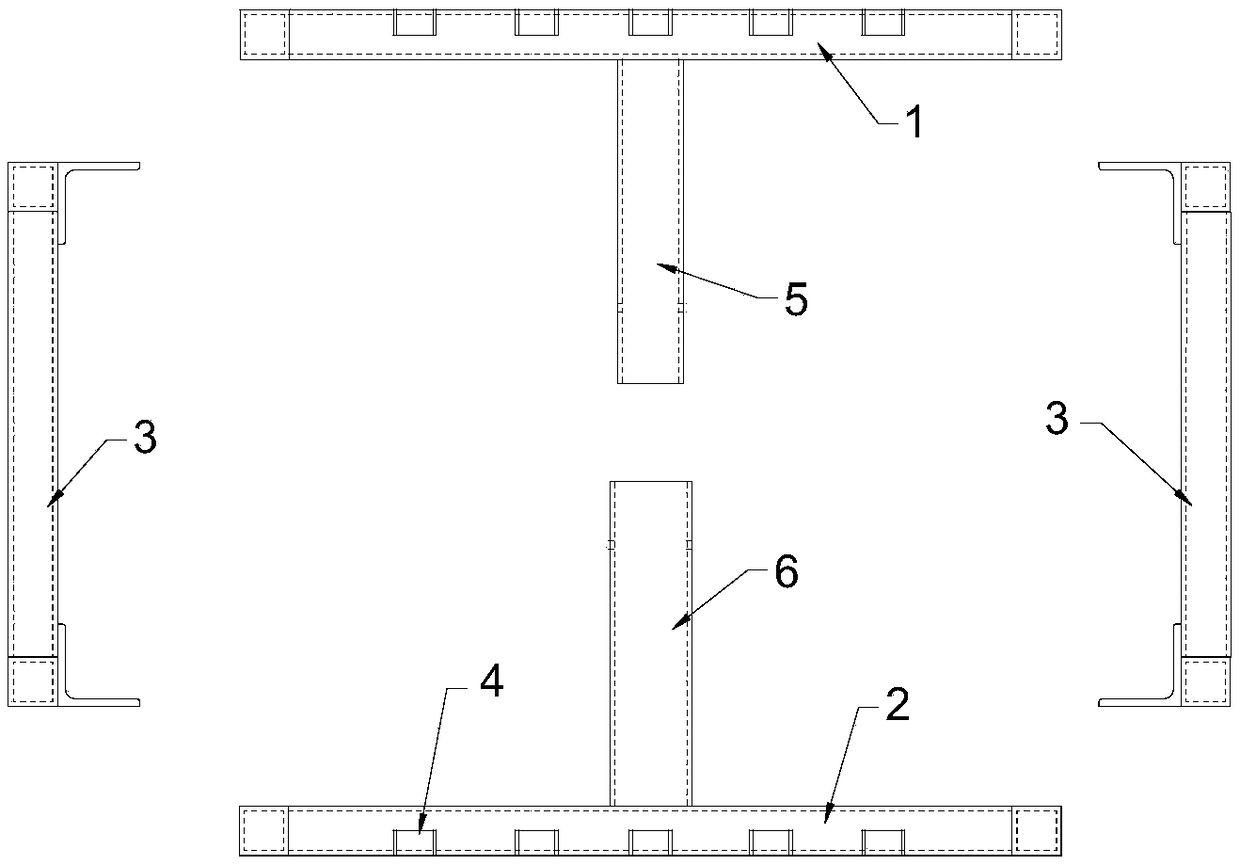

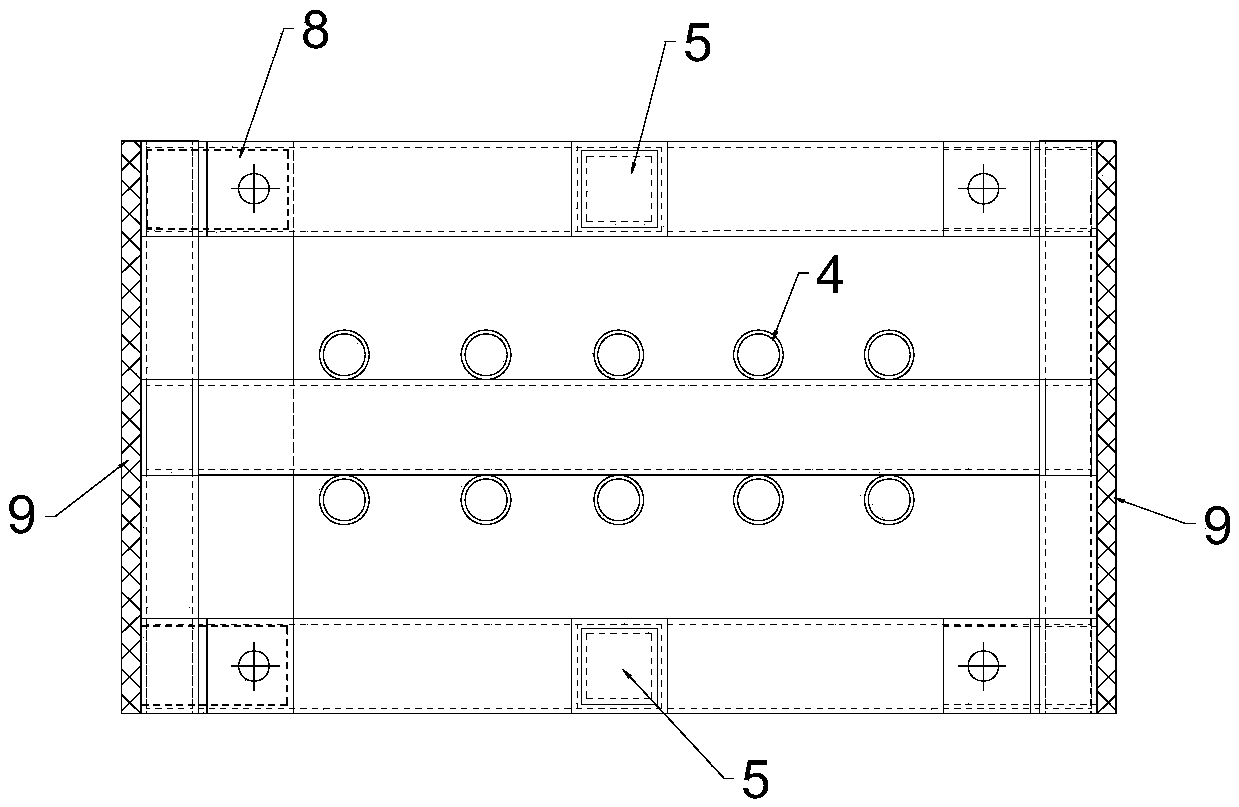

[0029] The mold for the reserved opening of the electric box provided by the invention is made of a steel structure frame outsourcing and a rubber plate that cannot be combined with concrete. The steel structure frame provided by the present invention is composed of two plane frames and two vertical frames, and rubber interlayer pads are arranged between the plane frames and the vertical frames.

[0030] Concrete structure of the present invention is: as Figure 1-5 As shown, a mold for the reserved opening of the electric box includes a square frame structure assembled from square tubes. The frame structure includes an upper plane frame 1 and a lower plane frame 2. Vertical frame 3 is installed, upper plane frame 1, four corners of lower plane frame 2 are provided with bolt holes, and vertical frame 3 upper side, lower side are fixedly connected with connecting angle steel 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com