A tubular casting and welding device

A casting-welding and tube-type technology is applied in the field of battery pole lug casting and welding devices, which can solve the problems of cumbersome battery production process and easy detachment of the pole group, and achieve the effects of avoiding difficulty in disassembly, facilitating fastening, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

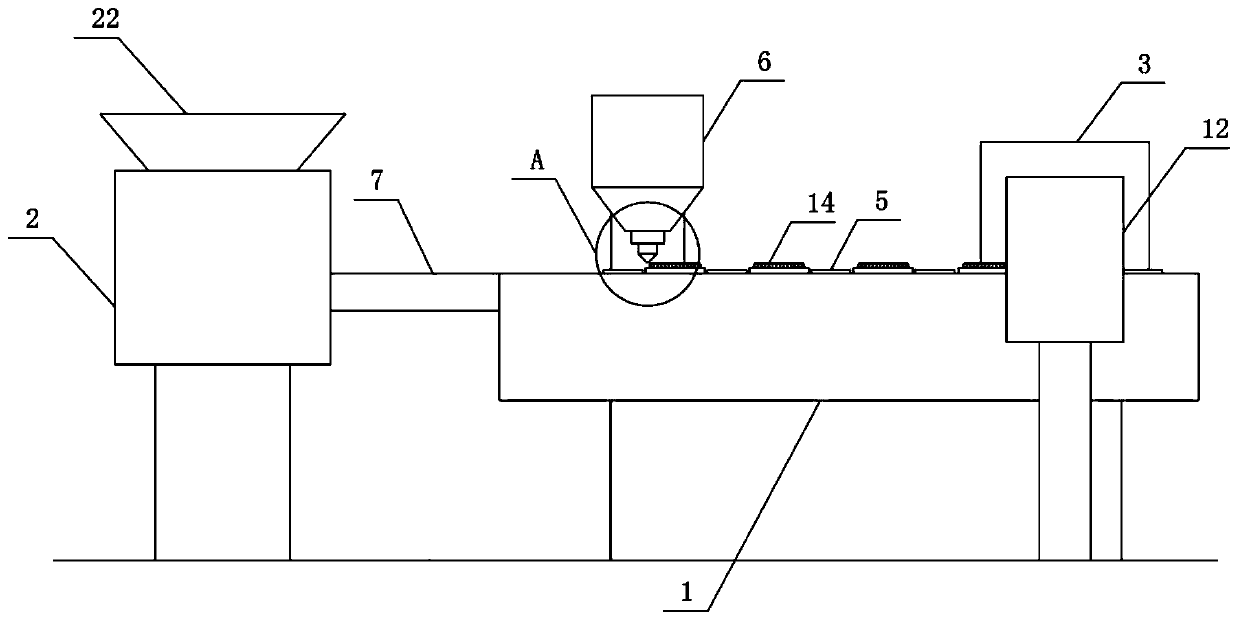

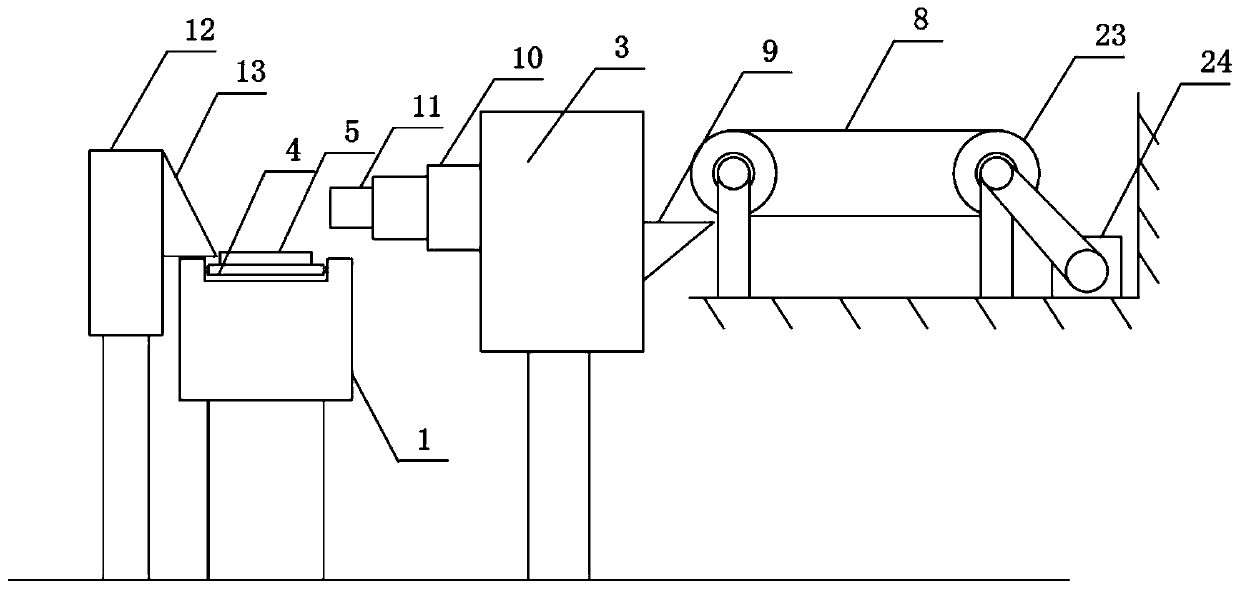

[0024] according to figure 1 A tubular casting and welding device shown includes a casting and welding station 1, a mold feeding device 2 and a tab feeding device 3. The setting of the mold feeding device 2 and the tab feeding device 3 is beneficial to the tab casting and welding mold 14 and the tabs are transported and sorted, so that the chaotically arranged tab casting molds 14 and the tabs are integrated, the mold feeding device 2 is set at one end of the casting station 1, and the tab feeding device 3 is set at the casting On one side of the other end of the soldering station 1, a liquid lead tank 6 is provided on one side of the casting and soldering station 1. The setting of the liquid lead tank 6 facilitates accurate measurement of the lead solution by a meter 19 and then transports it to the lug casting mold 14, compared with the traditional method of utilizing lead wire to melt, the lead liquid in the lead liquid tank 17 can be fully filled, avoiding the inconsistenc...

Embodiment 2

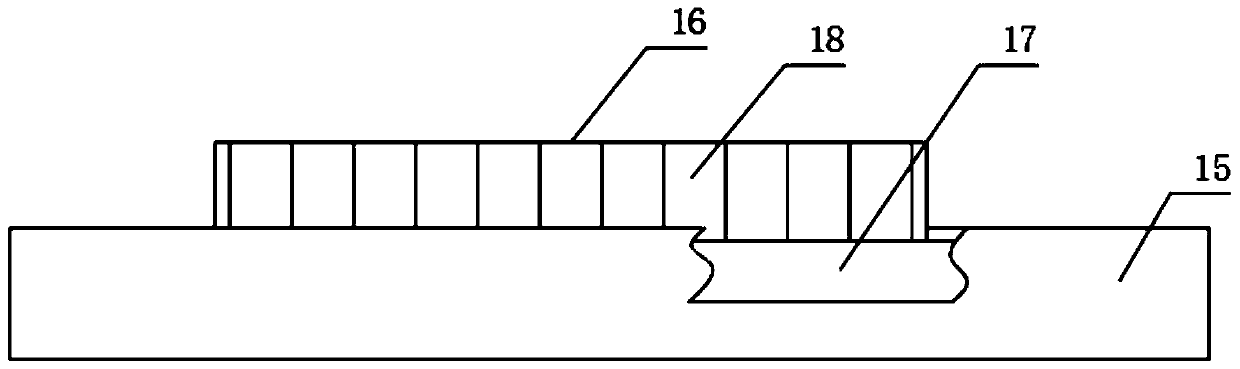

[0030] The difference from Example 1 is that the two side walls of the groove 21 are set at an inclination angle of 45° to 60°, which is conducive to the inclined setting of the vertically placed lug casting mold 14, and avoids the lead liquid tank 17. The lead liquid in the interior is not solidified, so that the bottom end of the tab falls into the bottom of the lead liquid tank 17, and the other end of the tab is exposed, resulting in low product quality.

[0031]The working principle of the present invention: start the machine, each part starts to work, and the tab casting and welding mold 14 is transported from the mold feed port 22 to the mold feeding device 2, and the mold feeding device 2 carries out the process of receiving the chaotic tab casting and welding mold 14. Regularly transported to the conveying line 4 through the mold conveying platform 7 after sorting, and each tab casting mold 14 is arranged between adjacent partitions 5, and the tab is placed on the tab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com