Case net type floating breakwater based on FRP material

A floating breakwater and box net technology, used in breakwaters, jetties, embankments, etc., can solve problems such as crack water seepage and loss of workability, and achieve high corrosion resistance, convenient transportation, prefabrication, and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments.

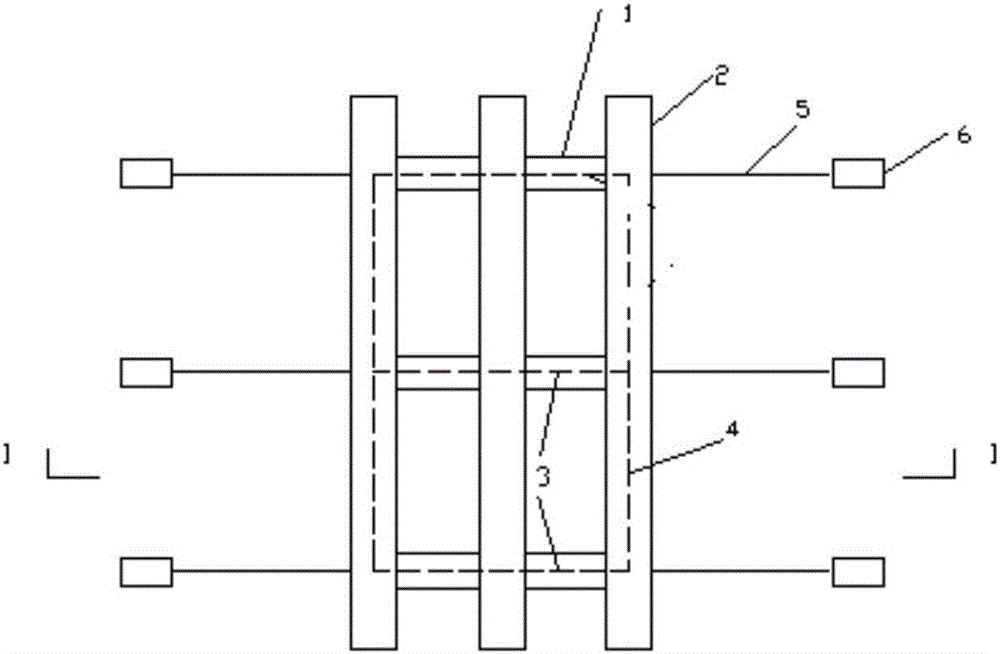

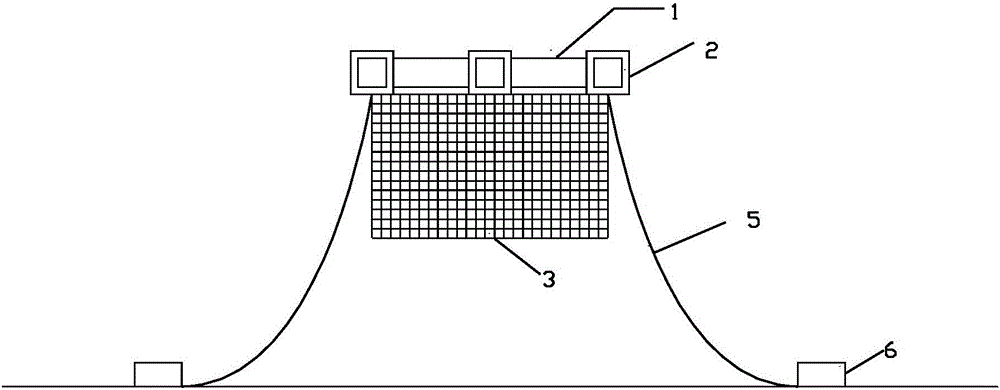

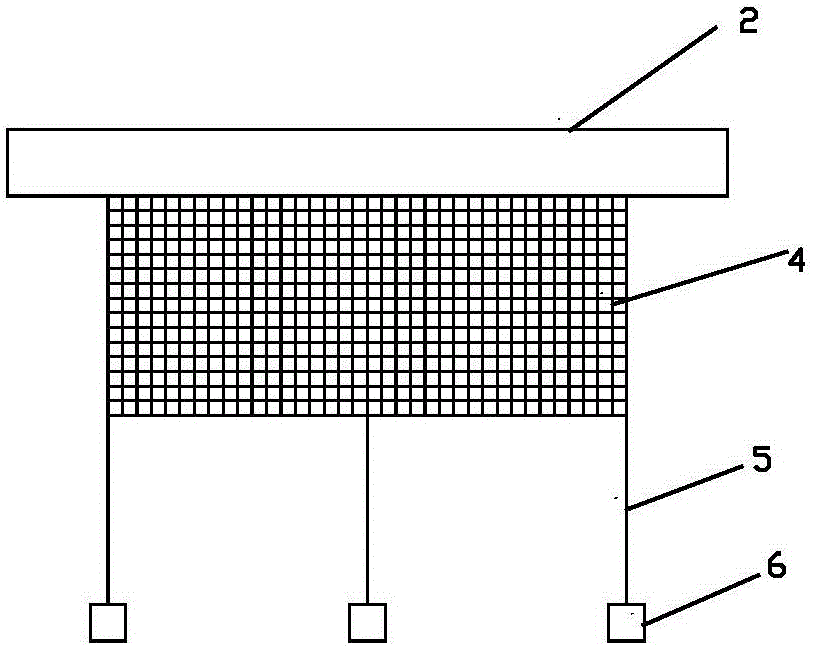

[0026] combine Figure 1 to Figure 5 , the present invention is a box net type floating breakwater based on FRP material, including a buoyant box, a grid connected under the buoyant box, and anchor chains 5 and anchor spindles 6 . The pontoon is composed of vertical and vertical rectangular concrete pontoon girders 2 and horizontal and vertical rectangular concrete pontoon girders 1. The vertical and horizontal rectangular concrete pontoon girders are prefabricated by concrete. FRP grids 4 and 3 are arranged under the vertical rectangular concrete pontoon girder and the horizontal rectangular concrete pontoon girder, and each FRP grid is connected to form a grid cage structure. FRP bars are arranged in the vertical and horizontal rectangular concrete pontoon box girders, and the FRP grid is cast into one body with the vertical and horizontal rectangular concrete pontoon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com