Hole filling method by blasting

A technology of explosion method and detonation method, which is applied in the field of blasting, can solve the problems of limited improvement of water hole plugging effect, limited effect of increase, and limited length of the device, so as to improve the effect of single-hole blasting, increase the amount of charge, reduce The effect of plugging length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

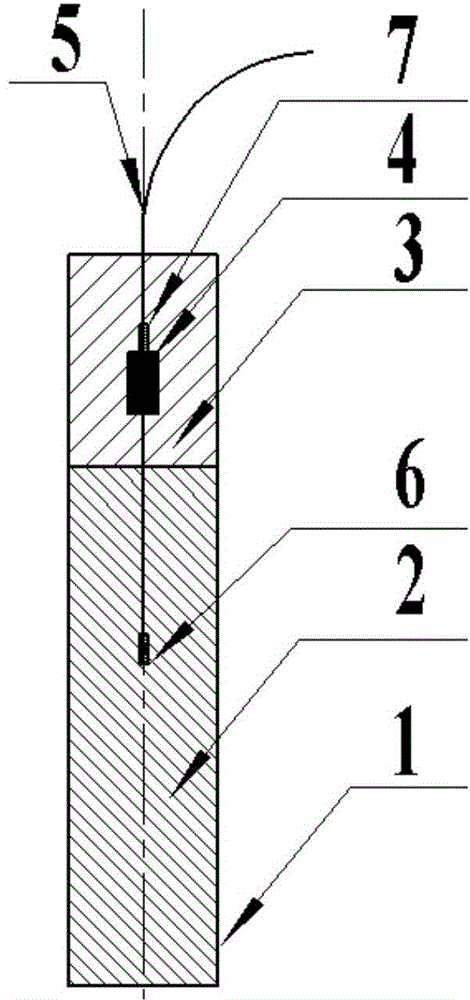

[0018] Such as figure 1 As shown, blasthole 1 is a dry hole with a diameter of 90mm and a depth of 8.0m. The charge 2 at the bottom of the blast hole uses powdered ammonium nitrate explosive, coupled with the charge. The plugging section 3 uses a mixture of rock, soil and sand. According to the conventional plugging method, the plugging length of the plugging section 3 is 4.0m, and the charging length of the charging section 2 is 4.0m. After using the explosion method to plug the hole, the plugging length can be reduced to 2.0m, and the charge length is 6.0m. Blocking charge pack 4 uses a roll of 32mm, 150g emulsion explosive. The distance between the center of the plugging cartridge 4 and the orifice is 1.3m, that is, it is located at the lower part of the middle part of the plugging section. Charge section 2 and plugging charge package 4 are detonated by electric delay detonators 6 and 7 respectively, and the sections of detonators 6 and 7 are respectively MS5 (110ms) and...

Embodiment 2

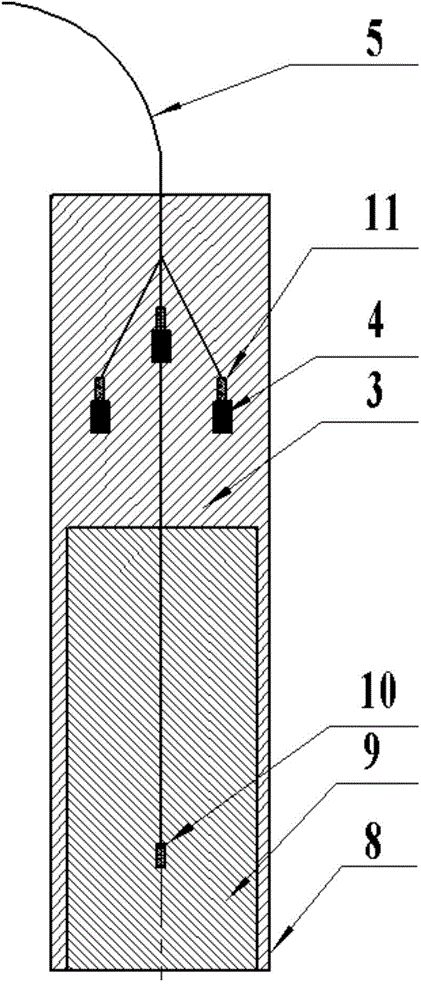

[0021] Such as figure 2 As shown, the blasthole 8 is a water hole with a diameter of Φ135mm and a depth of 15.0m. The charge 9 at the bottom of the blast hole uses a strip-packed emulsion explosive with a diameter of Φ110mm and a weight of 4kg, which is not coupled to the charge. The plugging section 3 uses a mixture of rock, soil and sand. According to the conventional plugging method, the plugging length of the plugging section 3 should be 6.0m. Due to the existence of water, it is difficult for the plugging section to achieve the plugging effect in the dry hole. The charge length of charge section 9 is 9.0m. When using the explosion method to plug holes, set 3 plugging charges 4 in the packing section, all of which use Φ32mmΦ150g emulsified explosives, the plugging length is 3.0m, and the 3 plugging charges are as follows: figure 2 The layout is 1.5m, 2.3m, and 2.3m from the orifice in the vertical direction, and the two blocking charges below are symmetrically distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com