Hole bottom energy gathering and dissipating device suitable for inclined blast hole and capable of improving blasting excavation flatness of foundation surface

An energy-dissipating device and foundation surface technology, which is applied in the field of rock and soil blasting, can solve the problems of limited blasting shock wave buffering effect, limited energy gathering effect of the device, and large fluctuation difference of the foundation surface, so as to improve efficiency, good blasting effect, Ease of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

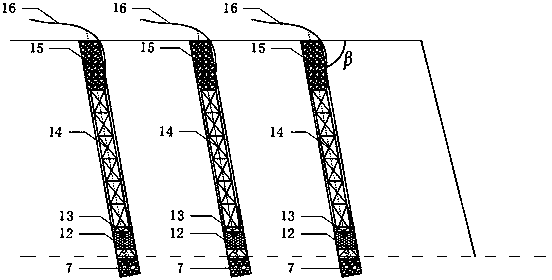

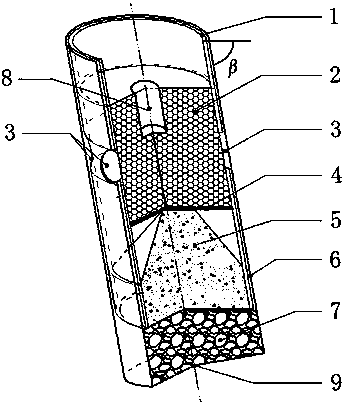

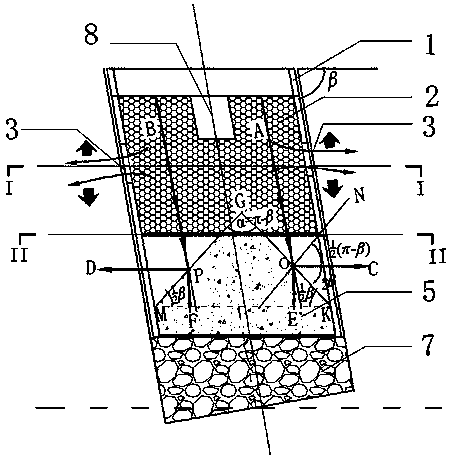

[0026] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 1-5 As shown in the figure, a hole bottom energy-dissipating device suitable for improving the flatness of foundation surface blasting excavation for inclined blastholes includes: polyvinyl chloride pipe 1, which is arranged in sequence from bottom to top in the polyvinyl chloride pipe 1 There are sand and gravel layer 7, energy-gathering-energy-dissipating seat 5, kraft paper pad 4, and shaped explosive layer 2. The pipe wall of the polyvinyl chloride pipe 1 is provided with an energy-gathering hole 3, and the center of the shaped explosive layer 2 is A cylindrical groove 8 is provided.

[0027] The relevant parameters of the polyvinyl chloride pipe 1 are as follows:

[0028] ① Outer diameter of PVC pipe: In the formula, is the hole diameter. The diameter of the polyvinyl chloride pipe is 15-20mm smaller than the diameter of the blast hole so that the device can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com