Leakage repairing rod for stopping slurry leakage of cast-in-situ bored pile on riprap embankment in complex sea area

A technology for drilling cast-in-place piles and leak repair, which is applied in the field of leak repair rods, can solve the problems of difficult control, leakage of slurry in the deep coarse sand layer, and poor leakage plugging effect, and achieves the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

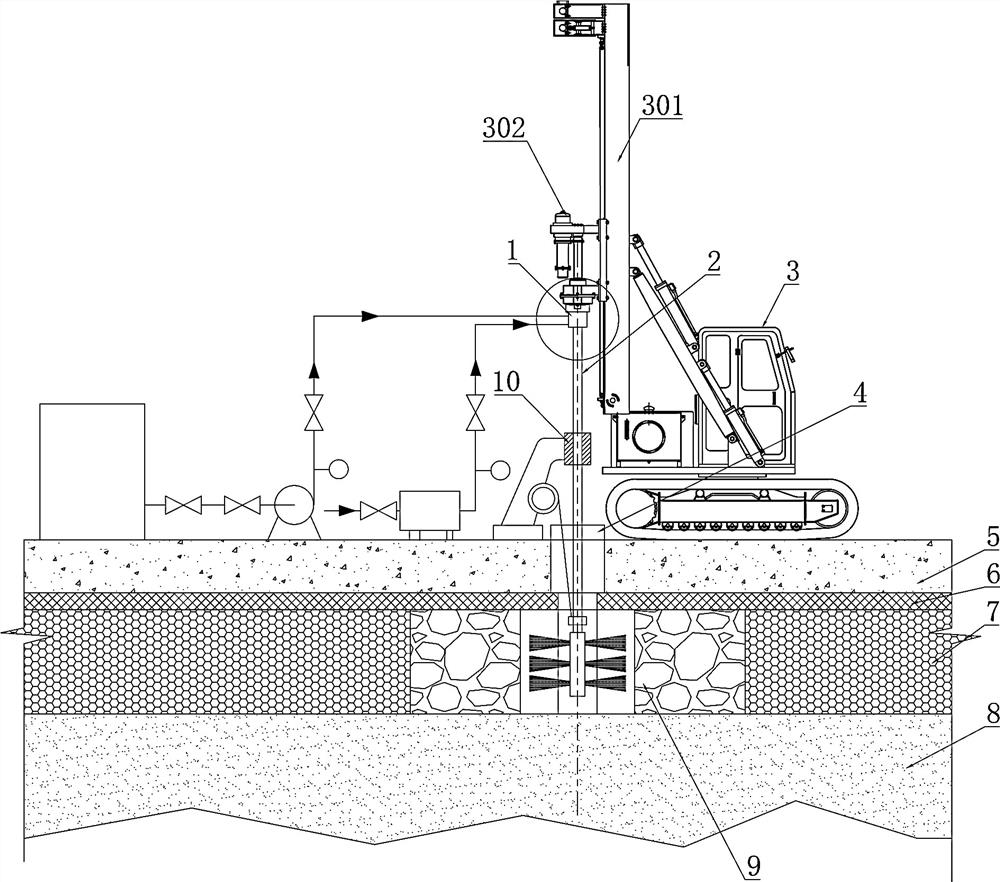

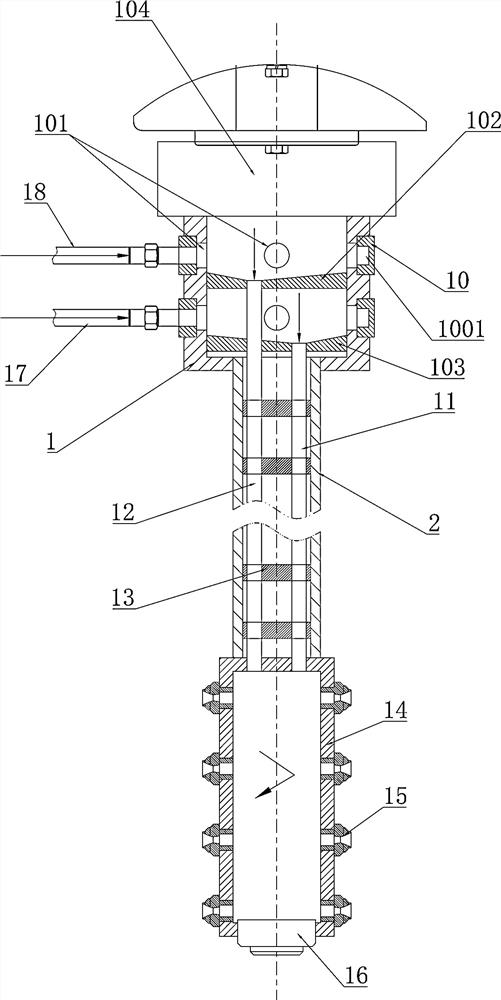

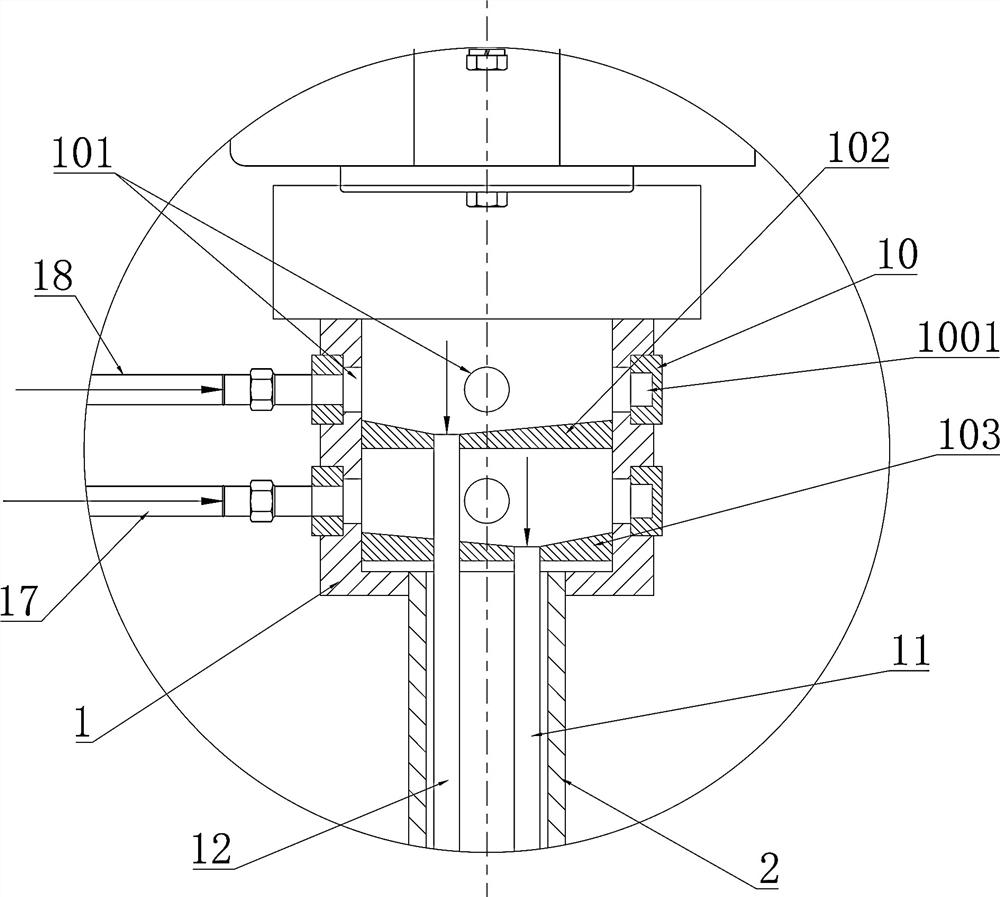

[0023] like Figures 1~4 As shown in the figure, a leakage repair rod used for the leakage of grouting of bored piles on riprap embankments in complex sea areas is provided. A plurality of nozzles 15, the grouting rotating ring 1 at the upper end of the leak repair rod 2 is connected to the driving rotating seat 302 of the bolting rig 3, the air pressure pipe 17 and the grouting pipe 18 are respectively connected with the grouting rotating ring 1, and the air pressure pipe 17 and the injection pipe are respectively connected. The slurry pipe 18 is in rotational sealing communication with the grouting rotary ring 1 , and the leak repair rod 2 is provided with an air pressure standpipe 11 and a solution standpipe 12 . The air pressure pipeline 17 and the grouting pipeline 18 are connected to the inside of the grouting rotary ring 1 . The gas injection pipeline 17 and the grouting pipeline 18 are merged into the grouting rotary ring 1 , and the grouting rotary ring 1 conveys gas...

Embodiment 2

[0032] Further illustrate in conjunction with embodiment 1, as Figure 1-4 As shown, the bolt on the bolt drilling rig 3 is disassembled from the driving rotating base 302 , and the leak trap 2 is installed on the rotating base 302 of the bolt drilling rig 3 , and the rotating base 302 can slide up and down on the sliding table 801 .

[0033] The bolting rig 3 extends the leakage repair rod 2 through the steel casing 12 to the slurry leakage position.

[0034] The position of the spray seat 14 at the lower end of the leak trap 2 is adjusted by sliding the rotating seat 302 on the sliding table 301 by the driving of the bolt drilling machine 3 .

[0035] After the position of the nozzle seat 14 is adjusted accurately, the grouting pump and the air compressor are turned on, and the slurry is mixed with the air to form a strong impact force.

[0036] Mix cement (PC42.5) and quick-setting agent in the dispensing container, the water-cement ratio is 1:1, the cement slurry pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com