Aldehyde-free face decorating all-bamboo or bamboo-wood composite oriented strand board and manufacturing method thereof

A technology of oriented strand board and manufacturing method, applied in the direction of manufacturing tools, flat products, other household appliances, etc., can solve the problems of poor surface forming, sticking to steel belts on the board surface, and inability to convey, so as to reduce production costs and solve the problems of board surface sticking. Steel strips, the effect of increasing the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

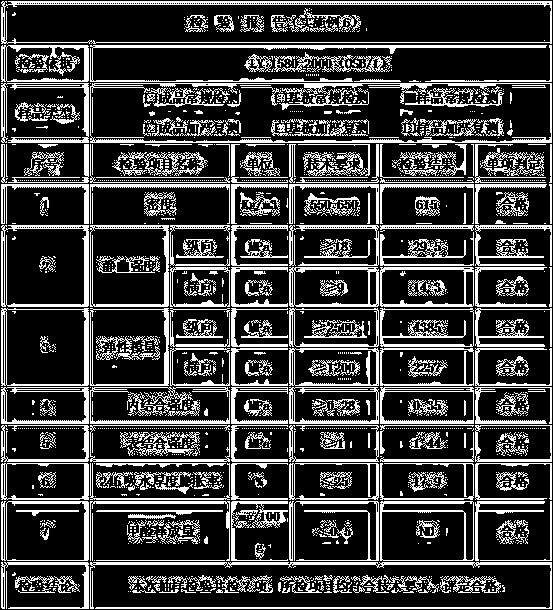

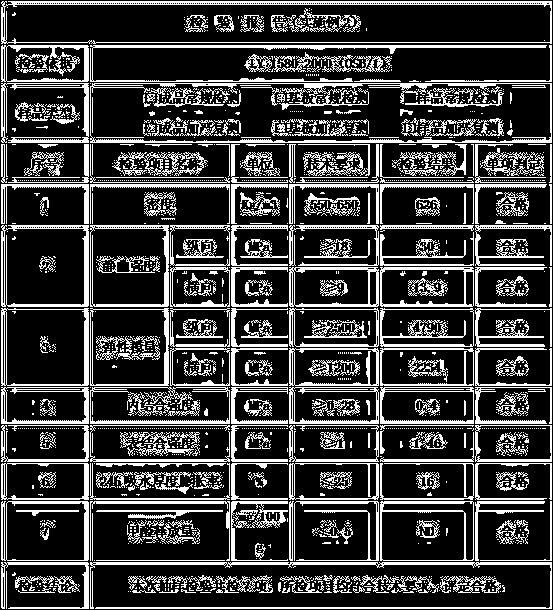

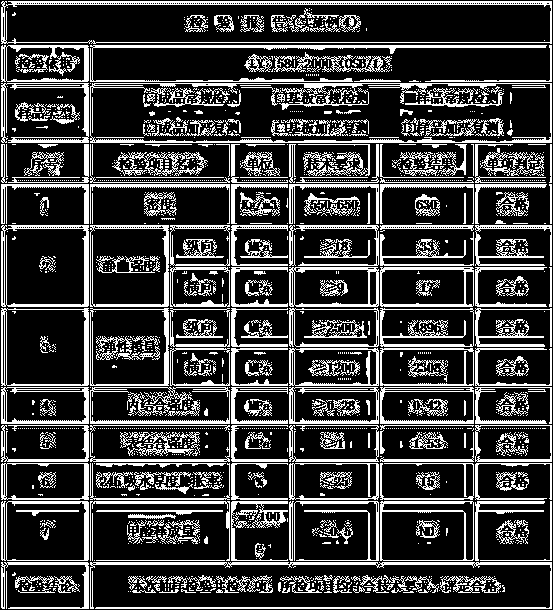

Image

Examples

Embodiment 1

[0028] The steps of the production method of the aldehyde-free veneerable bamboo-wood composite oriented strand board of the present invention are as follows:

[0029] (1) Cut the bamboo into 150mm length bamboo chips, cut the wood into 100mm length wood chips, and screen out the bamboo chips and wood chips with a length less than 50mm;

[0030] (2) Slicing the bamboo chips and wood chips greater than 50 mm obtained in step (1) into bamboo and wood chips with a thickness of 0.5 mm;

[0031] (3) Slicing the bamboo chips and wood chips less than 50mm screened out in step (1) into bamboo and wood shavings with a thickness of 0.5mm;

[0032] (4) Bamboo, wood flakes and shavings obtained in steps (2) and (3) are dried to a relative moisture content of 3.5% through a single-channel flue gas dryer;

[0033] (5) The dried material in step (4) is screened in a vibrating screen and a pneumatic air separation system, and divided into four parts: oversized material, large piece material,...

Embodiment 2

[0039] The steps of the production method of the whole bamboo oriented strand board without aldehydes of the present invention that can be decorated are as follows:

[0040] (1) Cut the bamboo into pieces with a length of 100mm, and screen out the pieces with a length of less than 50mm;

[0041] (2) Slicing the bamboo slices greater than 50mm obtained in step (1) into bamboo flakes with a thickness of 1mm;

[0042] (3) Slicing the bamboo flakes less than 50mm screened out in step (1) into bamboo shavings with a thickness of 1mm;

[0043] (4) The large bamboo flakes and shavings obtained in steps (2) and (3) are dried to a relative moisture content of 4% through a single-channel flue gas dryer;

[0044] (5) Screen the dried materials in step (4) according to the number of meshes, and divide them into four parts: oversized material, large piece material, fine material and dust;

[0045] (6) Break up 250 g of the oversized material obtained in step (5) as the surface material; ...

Embodiment 3

[0050] The steps of the production method of the aldehyde-free veneerable bamboo-wood composite oriented strand board of the present invention are as follows:

[0051] (1) Cut the bamboo into 80mm length bamboo chips, cut the wood into 120mm length wood chips, and screen out the bamboo chips and wood chips whose length is less than 50mm;

[0052] (2) Slicing the bamboo chips and wood chips greater than 50 mm obtained in step (1) into bamboo and wood chips with a thickness of 0.8 mm;

[0053] (3) Slicing the bamboo chips and wood chips less than 50mm screened out in step (1) into bamboo and wood shavings with a thickness of 0.8mm;

[0054] (4) Bamboo, wood flakes and shavings obtained in steps (2) and (3) are dried to a relative moisture content of 2% through a single-channel flue gas dryer;

[0055] (5) Screen the dried materials in step (4) according to the number of meshes in the vibrating screen and pneumatic air separation system, and divide them into four parts: oversize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com