3D porous bracket with mesoporous biological glass coating and preparation method thereof

A bioglass, three-dimensional porous technology, applied in coatings, medical science, prostheses, etc., can solve problems such as unfavorable cell adhesion, poor hydrophilicity, and slightly weak mechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

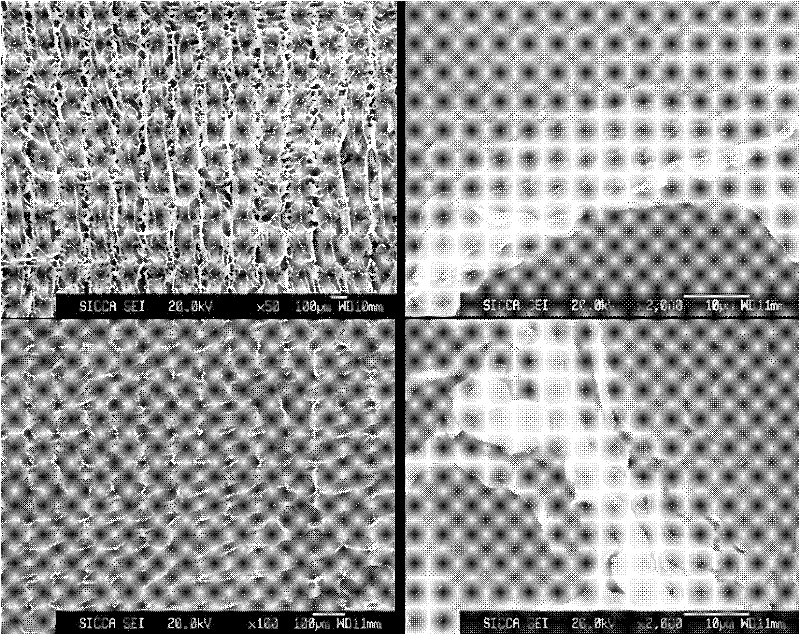

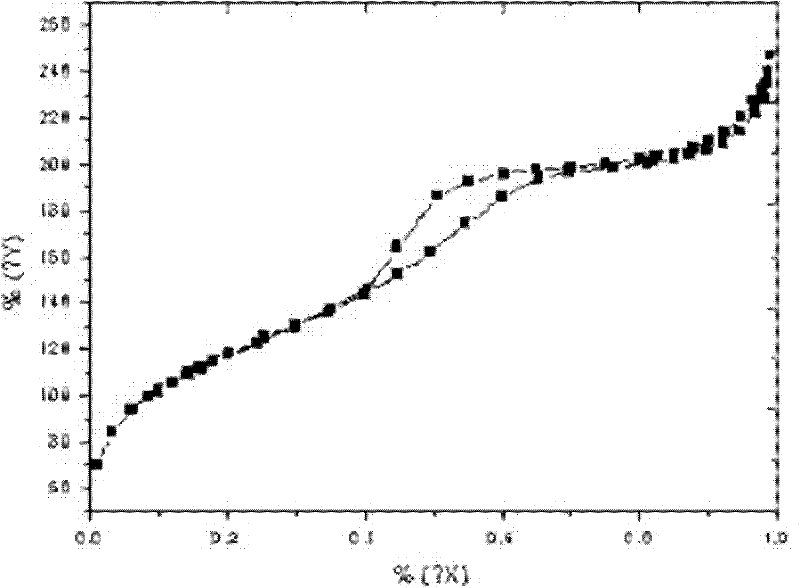

[0027] Example 1: Preparation of polylactic acid scaffold PM-3 coated with mesoporous bioactive glass M80S

[0028] 0.3 g of polylactic acid (PLLA) was dissolved in 10 ml of 1,4-dioxane to make a transparent solution with a mass fraction of 3%. The solution was poured into polytetrafluoroethylene molds, and immediately placed in a refrigerator at -20°C for 24 hours. The mold was submerged in 80% ethanol aqueous solution at -20°C, extracted for 3 days, and the liquid was changed every 8 hours. After the extraction is complete, remove the mold, put it in a fume hood, dry it at room temperature for 1 day, and then dry it under vacuum at room temperature overnight.

[0029] Add 4.0 grams of triblock copolymer P123 to 1 gram of 0.5M hydrochloric acid and 60 grams of absolute ethanol. After completely dissolving, add 6.7 grams of TEOS, 1.4 gram of Ca(NO3)2·4H2O and 0.73 gram of TEP, and stirred at room temperature for one day to obtain the precursor sol of the mesoporous bioactive...

Embodiment 2

[0032] Example 2: Preparation of polylactic acid scaffold PM-6 coated with mesoporous bioactive glass M80S

[0033] The polylactic acid scaffold was prepared according to the steps and raw material ratio of Example 1, and the precursor sol of M80S was prepared. The dipping and volatilization self-assembly process of polylactic acid scaffolds was repeated 6 times, followed by extraction and drying. The ordered hexagonal structure of the mesoporous glass coating remained unchanged, the mass fraction of inorganic components in the composite scaffold increased to 40%, and the porosity of the scaffold decreased to 63.7±1.2% (Table 1).

[0034] Bioactivity detection of mesoporous bioactive glass M80S coated polylactic acid scaffold PM-6:

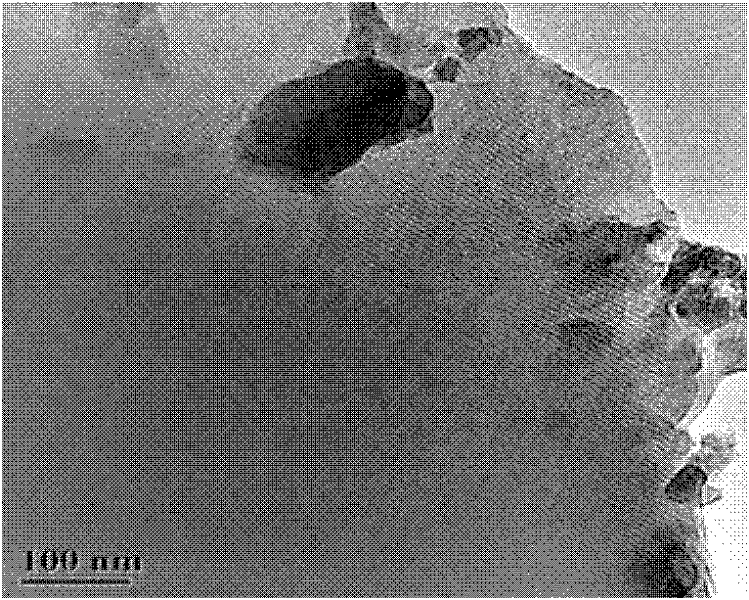

[0035] Freshly prepared simulated body fluid SBF has similar ion concentrations to human plasma. Take a certain volume of SBF and put it into a polyethylene container, dip the stent into the SBF, keep at 37°C for 6 hours, 1 day, and 3 days respe...

Embodiment 3

[0040] Example 3: Preparation of polylactic acid scaffold PM-9 coated with mesoporous bioactive glass M80S

[0041] The polylactic acid scaffold was prepared according to the steps and raw material ratio of Example 1, and the precursor sol of M80S was prepared. The dipping and volatilization self-assembly process of PLA scaffolds was repeated 9 times, followed by extraction and drying. The ordered hexagonal structure of the mesoporous glass coating remained unchanged, the mass fraction of inorganic components in the composite scaffold increased to 50%, and the porosity of the scaffold decreased to 52.4% (Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com