Preparation method of salt-tolerance controlled-release high-water-absorption resin with hydrophobic chain segments

A technology of superabsorbent resin and hydrophobic segment, which is applied in the field of preparation of salt-resistant slow-release superabsorbent resin to achieve excellent performance, improved water retention rate, and reduced sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

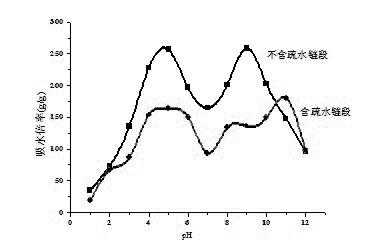

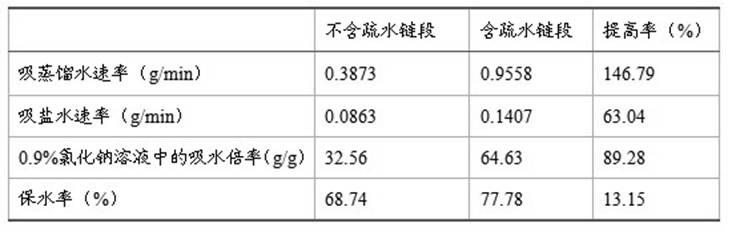

Image

Examples

Embodiment 1

[0014] Slowly add 2.0 g of carboxymethyl cellulose powder into a 250 mL three-necked flask filled with 120 g of distilled water under stirring conditions to form a carboxymethyl cellulose solution. Add 0.32g of initiator potassium persulfate, stir at 40°C for 10 minutes, then add 4.04g of acrylic acid, 11.96g of acrylamide, 0.22g of acrylic hydrophobic monomer lauryl methacrylate and 0.11g of crosslinking agent α-ring Add dextrin into a three-necked flask, adjust the pH of the system to 2.3 with sodium hydroxide, stir at a high speed to make it evenly dispersed, raise the temperature to 70°C, and keep the reaction for 2.5 hours. After the reaction, the product was taken out and dried at low temperature to constant weight.

Embodiment 2

[0016] Slowly add 2.5 g of carboxymethyl cellulose powder into a 250 mL three-neck flask containing 130 g of distilled water under stirring to form a carboxymethyl cellulose solution. Add 0.4g of initiator ammonium persulfate, stir at 40°C for 10 minutes, then add 6.45g of acrylic acid, 9.55g of acrylamide, 0.48g of acrylic hydrophobic monomer octadecyl methacrylate and 0.16g of crosslinking agent N-hydroxy Add methacrylamide into a three-necked flask, adjust the pH of the system to 2.0 with sodium hydroxide, stir at high speed to make it evenly dispersed, raise the temperature to 65°C, and keep the reaction for 2 hours. After the reaction, the product was taken out and dried at low temperature to constant weight.

Embodiment 3

[0018] Slowly add 2.3g of carboxymethylcellulose powder into a 250mL three-neck flask containing 125g of distilled water under stirring to form a carboxymethylcellulose solution. Add 0.3g of initiator potassium persulfate, stir at 40°C for 10 minutes, then shrink 5.25g of acrylic acid, 10.75g of acrylamide, 0.16g of acrylic hydrophobic monomer tetradecyl methacrylate and 0.08g of crosslinking agent polypropylene glycol Glyceryl ether was added into a three-necked flask, the pH of the system was adjusted to 2.5 with sodium hydroxide, the mixture was stirred at high speed to make it evenly dispersed, the temperature was raised to 75°C, and the reaction was kept for 3 hours. After the reaction, the product was taken out and dried at low temperature to constant weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com