Preparation method for carbon-coated ferroferric oxide nano-shell-loaded nano gold particles

A technology of carbon-coated ferric oxide and nano-gold particles, which is applied in the field of nanomaterials, can solve the problems of low drug loading, poor controlled release effect, and limited application fields, and achieve appropriate gold loading and high drug loading. rate, the effect of increasing the drug loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

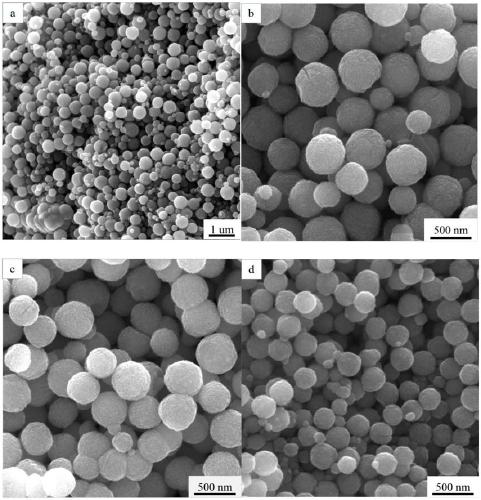

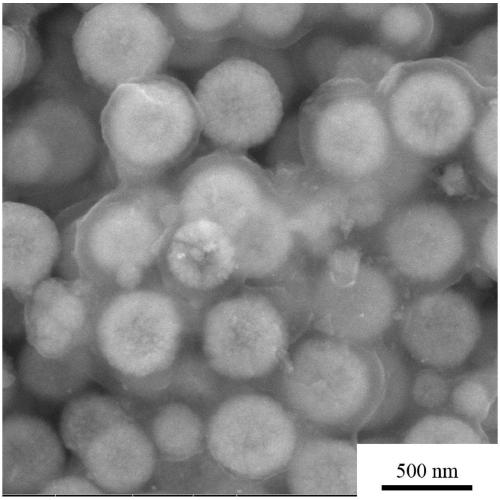

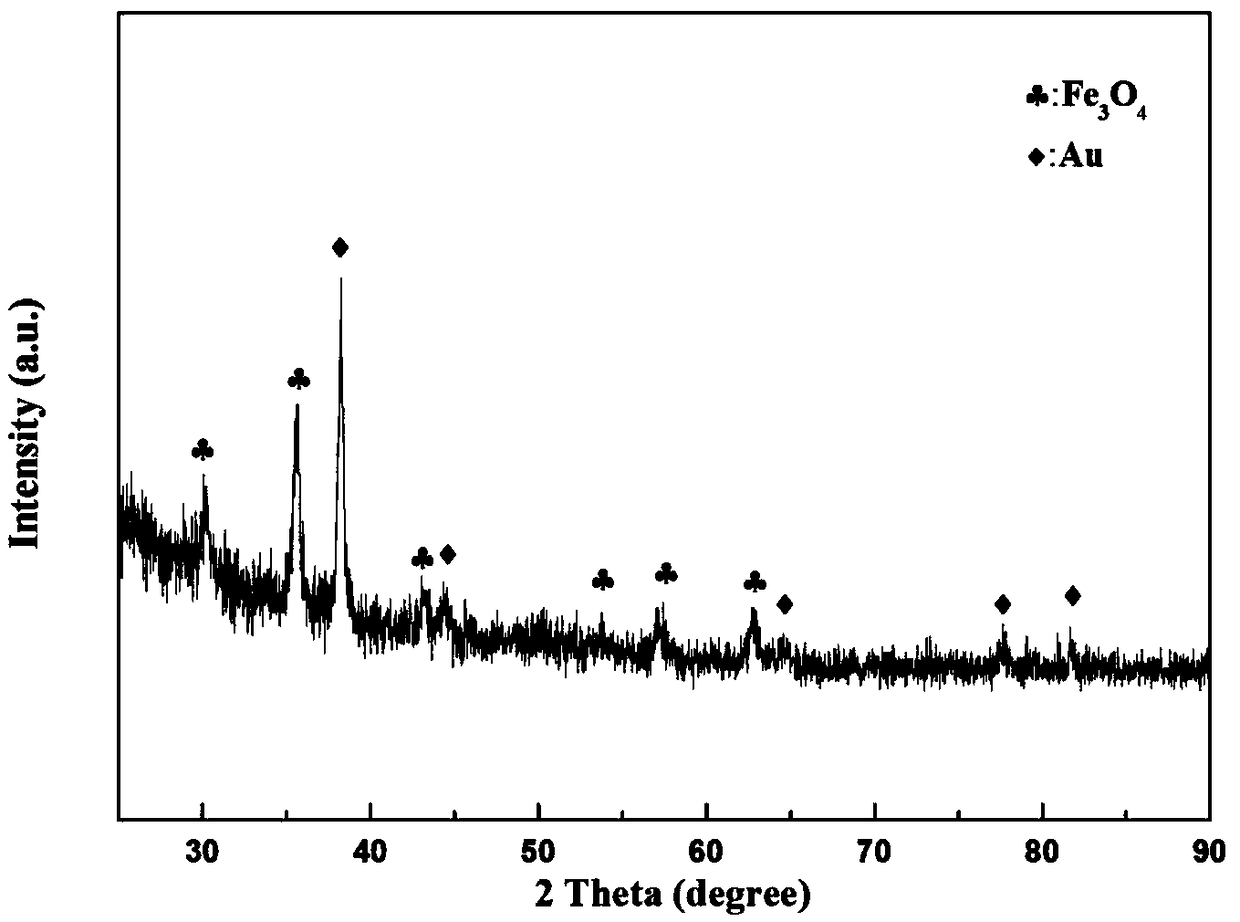

[0029] First step, Fe 3 o 4 Preparation of nanoshells:

[0030] (1) Weigh 0.8g of sodium dodecylbenzenesulfonate (SDBS) and dissolve it in 80mL of ethylene glycol (EG), stir magnetically for 30min until dissolved.

[0031] (2), weigh 2.7g ferric trichloride hexahydrate (FeCl 3 ·6H 2O) Dissolve in the above solution and stir magnetically for 30 min.

[0032] (3) Dissolve 4.65 g of sodium acetate (NaAc) in the above solution and stir for 1 h.

[0033] (4) Pour the above solution into a 100mL polytetrafluoroethylene-lined reactor, put it into a resistance oven at 180°C to react for 12 hours, and cool naturally.

[0034] (5) The black precipitate was collected by centrifugation, washed 3 times with deionized water, and then washed 3 times with absolute ethanol, dried in a vacuum oven at 60°C, ground and collected for later use. During the washing process, the centrifugation speed is 6000r / min, and the time is 8min.

[0035] The second step, carbon coated Fe 3 o 4 Preparat...

Embodiment 2

[0046] The difference from Example 1 is that the amount of sodium acetate (NaAc) is 5.65 g.

Embodiment 3

[0048] The difference from Example 1 is that the amount of sodium acetate (NaAc) is 6.65g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com