Nano gold/graphene oxide composite material and preparation method thereof

A composite material and graphene technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve problems such as poor electrical conductivity, and achieve the effects of stable state, simple experimental conditions and simple operation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of nano gold / graphene oxide, comprising the following steps:

[0016] 1) Weigh 1mg GO, dissolve it in 1mL double distilled water, and prepare 1mg / mL GO solution,

[0017] 2) Weigh 1g HAuCl 4 , dissolved in a 100mL volumetric flask, and prepared with 1% HAuCl 4 solution,

[0018] 3) In a round bottom flask containing 20 mL of distilled water, add 0.2 mL of 1 mg / mL GO solution, stir for 10 minutes, then quickly add 0.1 mL of 1% HAuCl 4 Solution, continue to stir vigorously for 10 minutes, add 0.035mg NaBH 4 . Finally, it was stirred for 20 minutes to obtain a composite material with gold nanoparticles modified on GO.

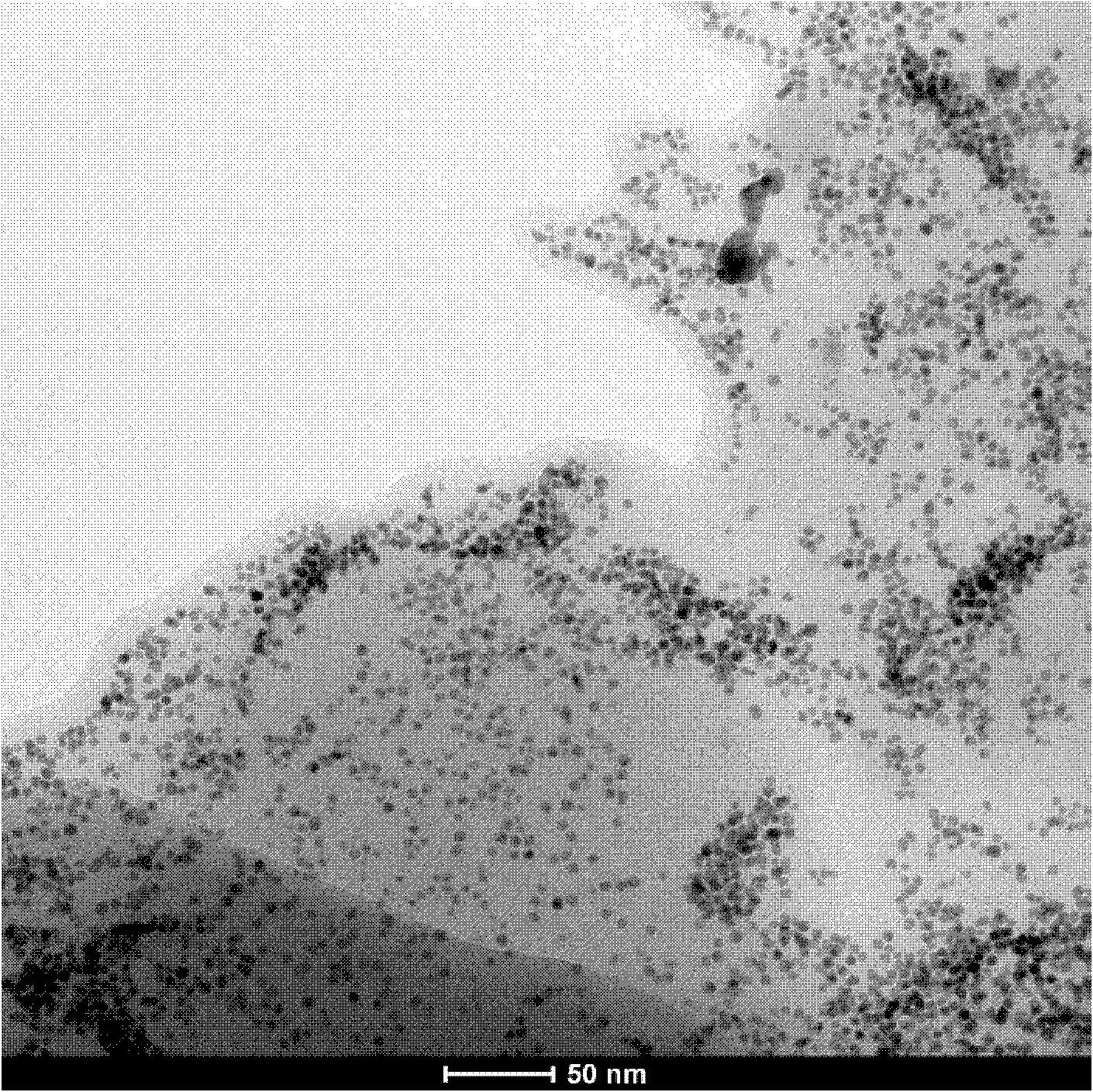

[0019] In this example, GO and HAuCl 4 The mass ratio is 1:5. The product perspective electron microscope picture is as follows figure 1 shown. The shape of gold nanoparticles on GO is a regular spherical shape with a diameter of about 5nm, the state is stable, and the particle size distribution is uniform.

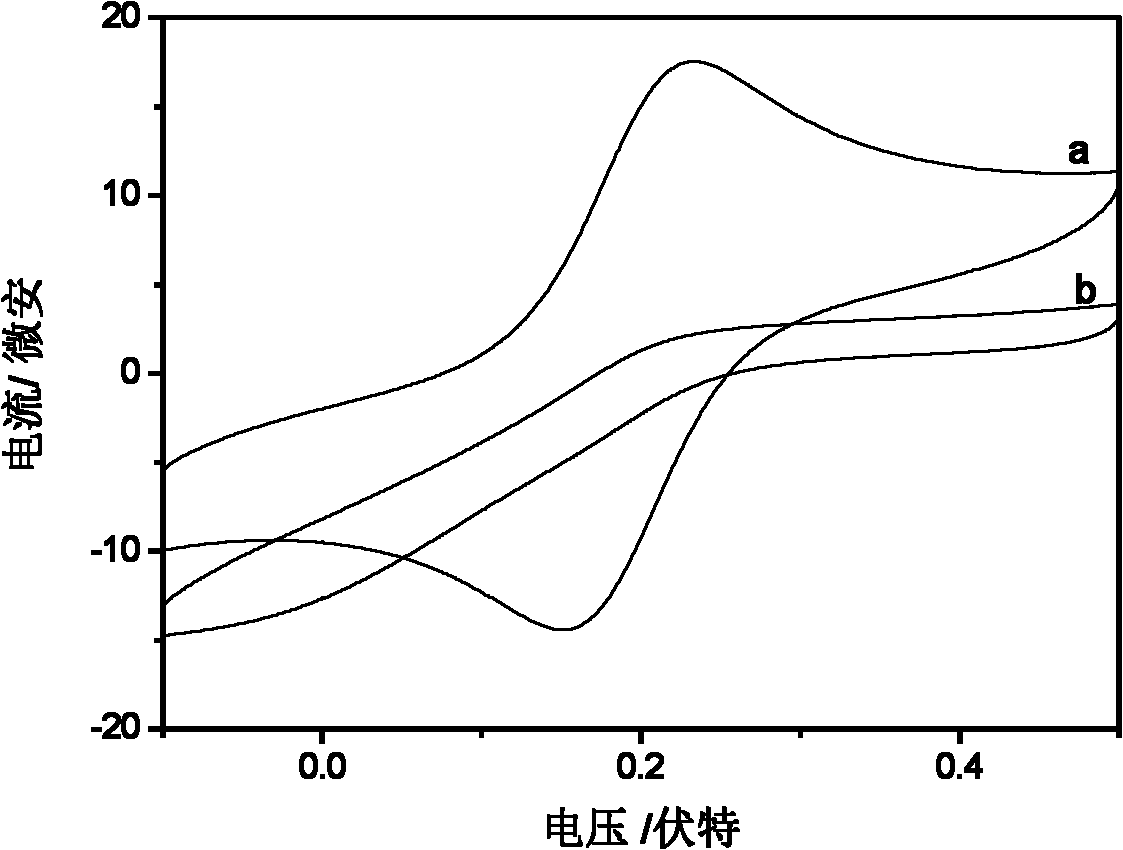

[0020] figure 2...

Embodiment 2

[0024] A preparation method of nano gold / graphene oxide, comprising the following steps:

[0025] 1) Weigh 1mg GO, dissolve it in 1mL double distilled water, and prepare 1mg / mL GO solution,

[0026] 2) Weigh 1g HAuCl 4 , dissolved in a 100mL volumetric flask, and prepared with 1% HAuCl 4 solution,

[0027] 3) In a round bottom flask containing 20 mL of distilled water, add 0.2 mL of 1 mg / mL GO solution, stir for 10 minutes, then quickly add 0.2 mL of 1% HAuCl 4 Solution, continue to stir vigorously for 10 minutes, 0.07mg NaBH 4 . Finally, it was stirred for 20 minutes to obtain a composite material with gold nanoparticles modified on GO.

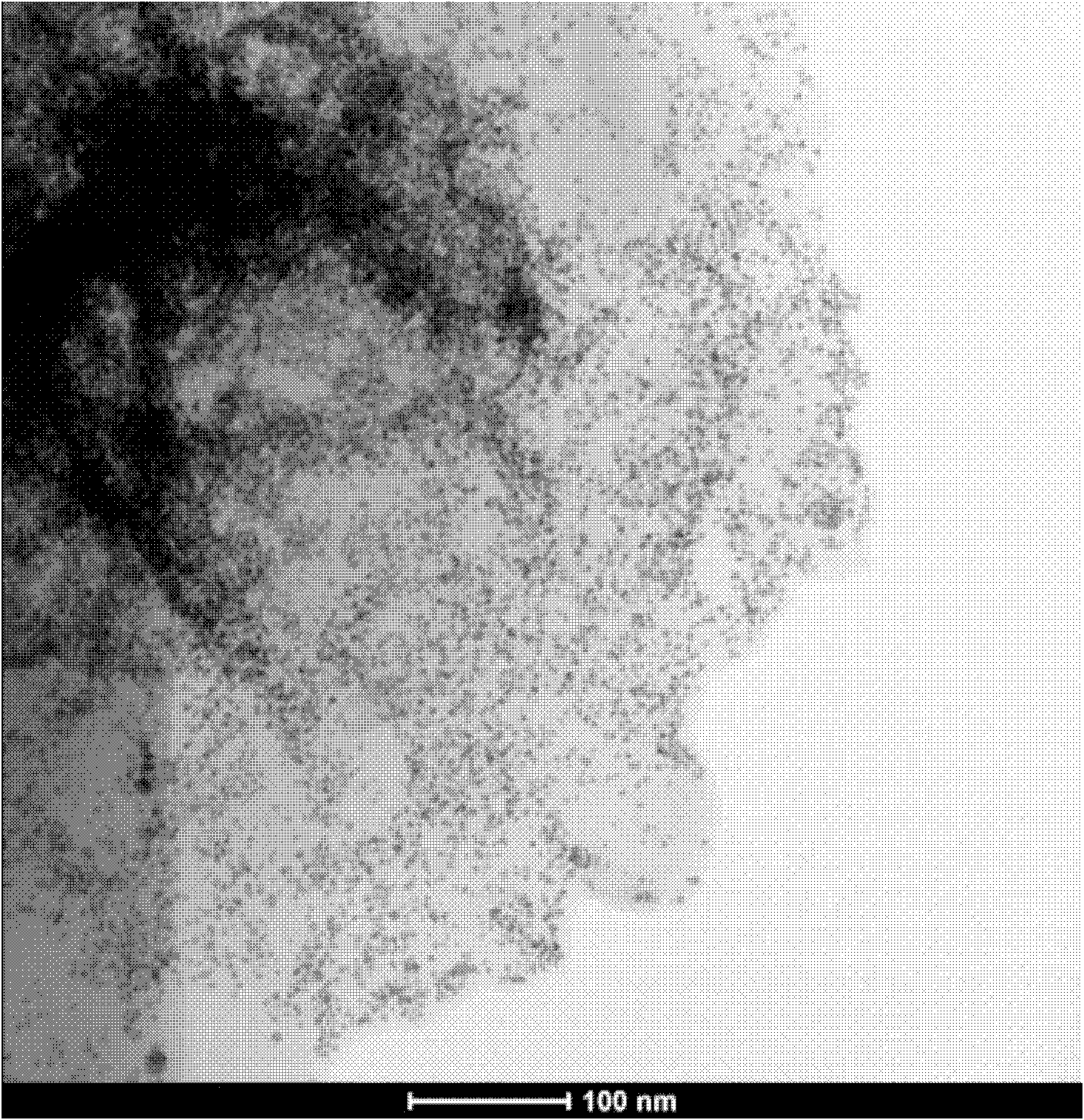

[0028] In this example, the GO and HAuCl used 4 The mass ratio is 1:10. The product perspective electron microscope picture is as follows figure 2 shown. The shape of gold nanoparticles on GO is a regular spherical shape with a diameter of about 5nm, the state is stable, and the particle size distribution is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com