Method for raising surface plasma resonance sensor sensitivity by using nano gold grain catalytic growing

A surface plasmon and resonance sensor technology, applied in the field of improving the sensitivity of biosensors, can solve the problems of difficult and effective signal extraction, background increase, etc., and achieve the effect of low cost, high sensitivity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

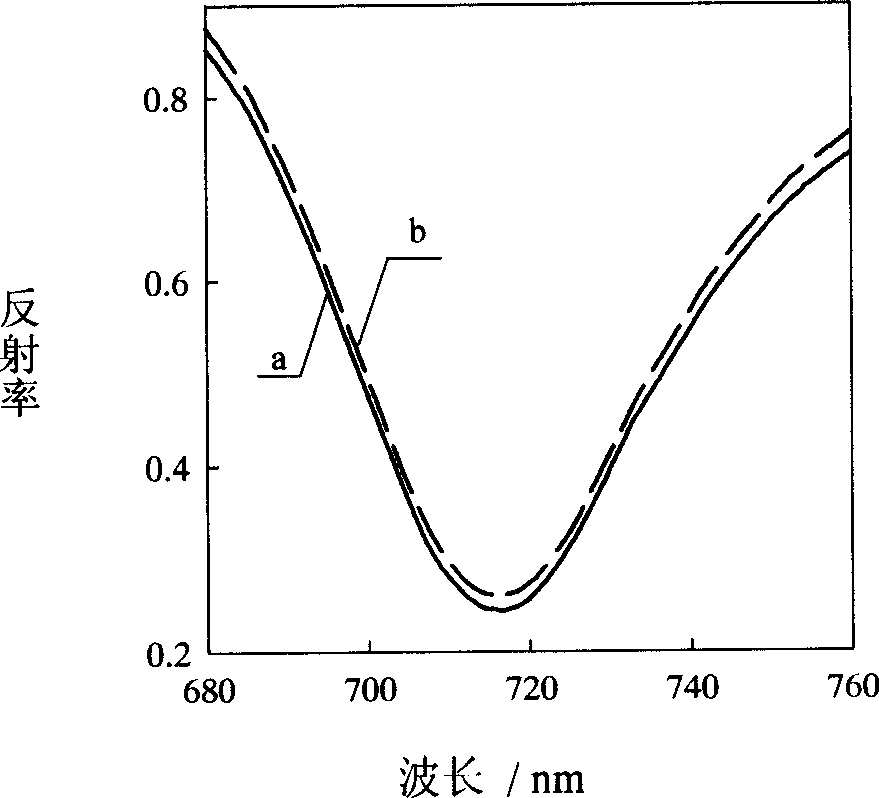

[0028] The surface plasmon resonance (SPR) sensor enhanced by nano-gold catalytic growth was used to detect 33nmol / L target DNA.

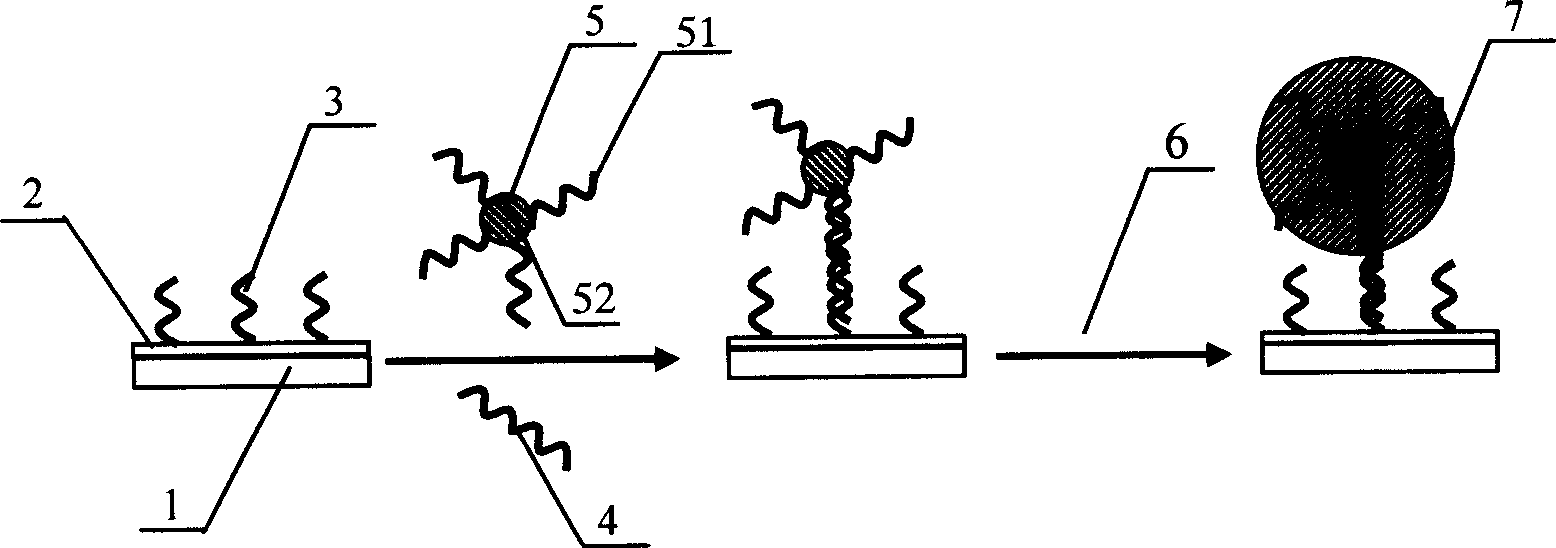

[0029] like figure 2 Shown, concrete steps of the present invention are:

[0030]1) Evaporate or sputter a layer of silicon dioxide (SiO2) with a thickness of 25 nm on the surface of the gold film 1 2 ) thin layer 2, made of silicon dioxide (SiO 2 ) The gold film 1 coated with the thin layer 2 is used as the metal film of the surface plasmon resonance (SPR) sensor, and the following reaction process is monitored with the surface plasmon resonance (SPR) sensor.

[0031] 2) By physical adsorption method, on silicon dioxide (SiO 2 ) thin layer 2 coated gold film 1 surface adsorption biotinylated bovine serum albumin (BSA), then add avidin and biotinylated bovine serum albumin (BSA) in combination to obtain a surface rich in avidin Silicon dioxide (SiO 2 ) gold film coated with a thin layer; through the binding between biotin-avidin, the biotin-l...

Embodiment 2

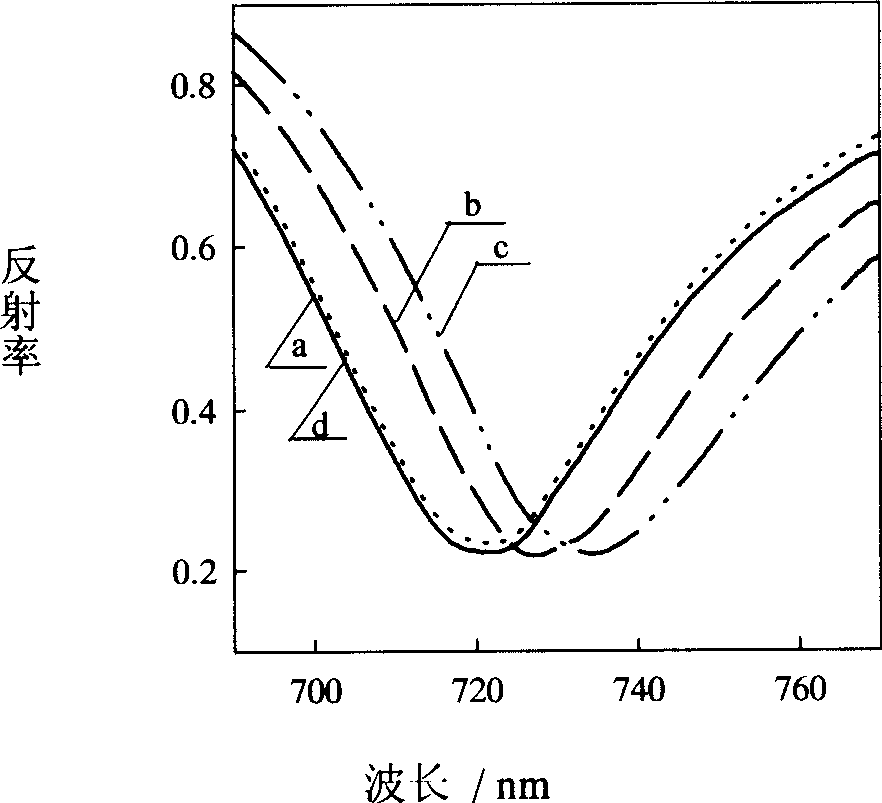

[0034] A surface plasmon resonance (SPR) sensor enhanced by catalytic growth of gold nanoparticles was used to detect different concentrations of target DNA.

[0035] The specific steps are:

[0036] 1), adopt the method for vacuum coating, in gold film 1 (referring to figure 2 ) surface evaporated or sputtered a layer of 25nm thick silicon dioxide (SiO 2 ) thin layer 2, which consists of silicon dioxide SiO 2 The gold film 1 coated with a thin layer is used as the metal film of the surface plasmon resonance SPR sensor.

[0037] 2), through the method of physical adsorption, in silicon dioxide (SiO 2 ) thin layer 2 coated gold film 1 surface adsorption biotinylated bovine serum albumin (BSA), then add avidin and biotinylated bovine serum albumin (BSA) in combination to obtain a surface rich in avidin Silicon dioxide (SiO 2 ) gold film coated with a thin layer; through the binding between biotin-avidin, the biotin-labeled DNA probe A3 was immobilized on the metal film of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com