High-performance recycled concrete and preparation process thereof

A technology of recycled concrete and preparation technology, which is applied in construction, construction material processing, building construction, etc., and can solve problems such as low apparent density, poor durability, and large crushing index, so as to improve compactness and work performance , the effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

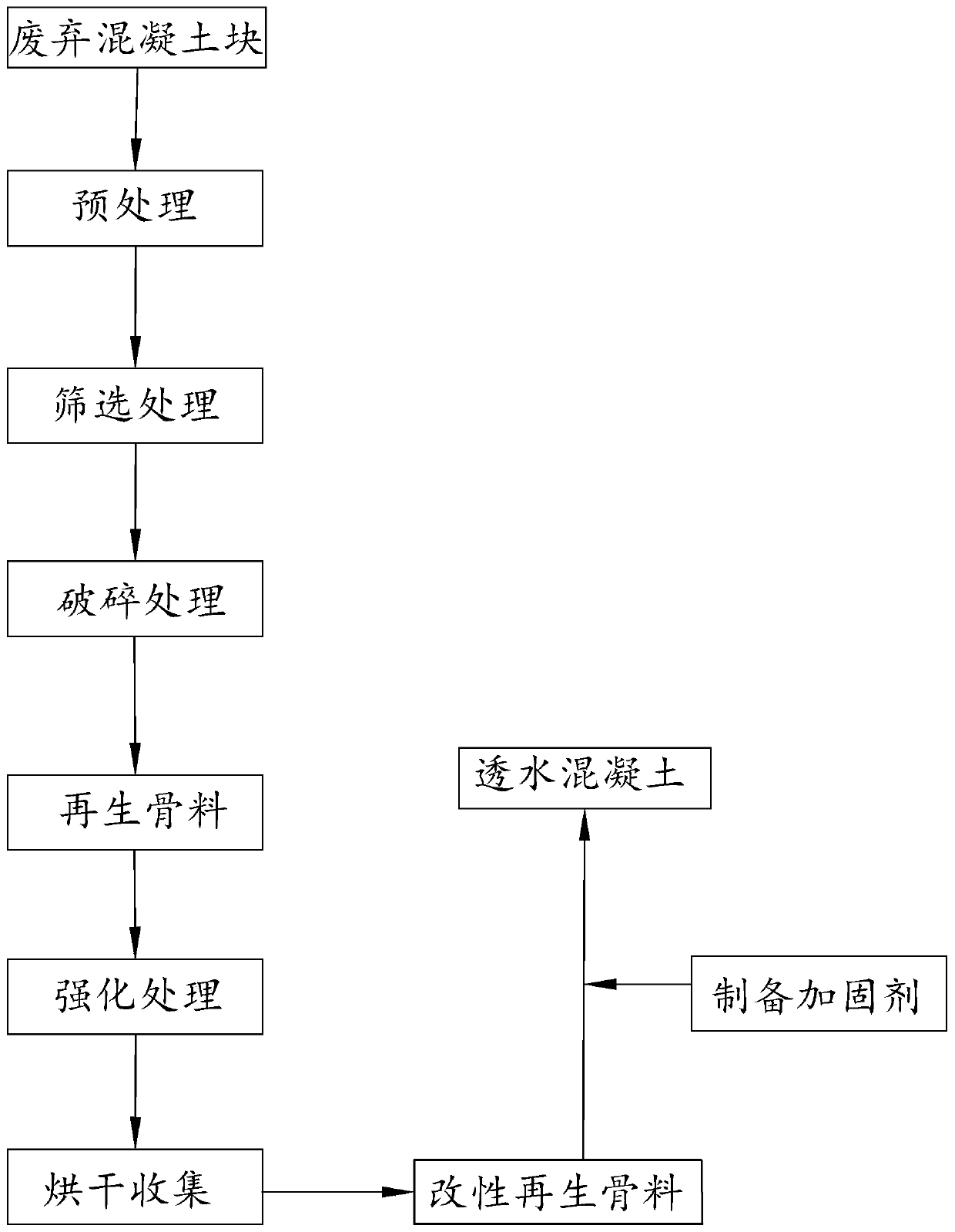

Method used

Image

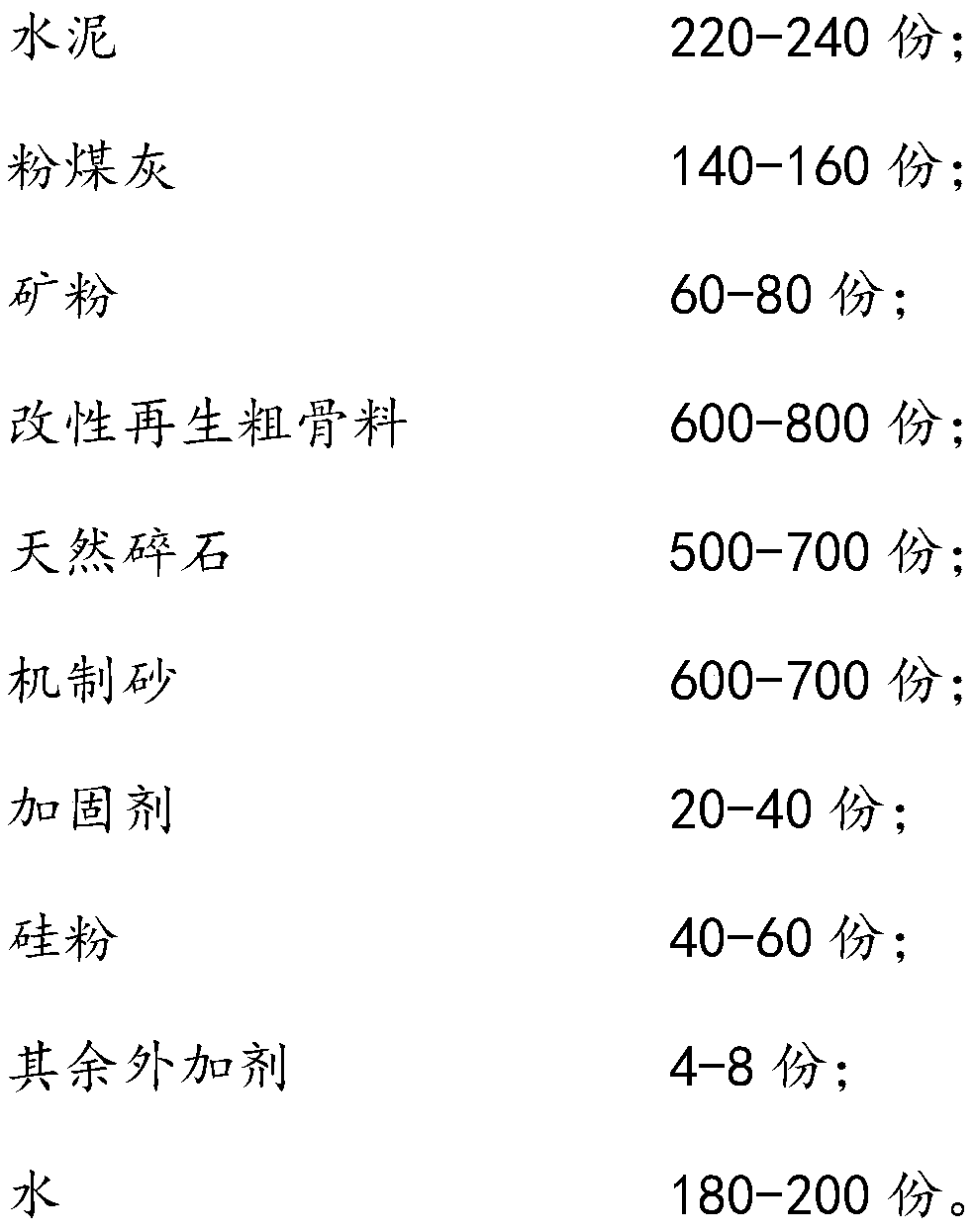

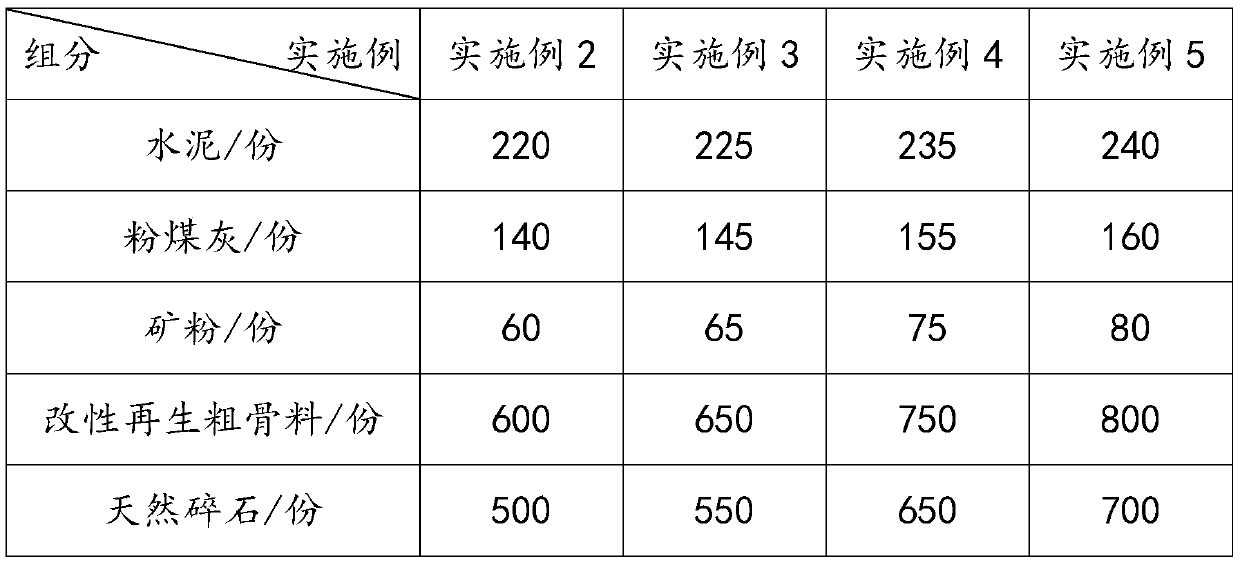

Examples

Embodiment 1

[0134] The difference between Embodiment 10-13 and Embodiment 1 is that the nutrient solution comprises the following raw materials in weight percentage:

[0135]

[0136]

[0137] The difference between Embodiment 14-17 and Embodiment 1 is that the first auxiliary agent includes the following raw materials in weight percentage:

[0138]

[0139] The difference between Embodiment 18-21 and Embodiment 1 is that the second auxiliary agent includes the following raw materials in weight percentage:

[0140]

[0141] The difference between Embodiment 22-25 and Embodiment 1 is that the reinforcing agent includes the following raw materials in weight percentage:

[0142]

[0143]

[0144] The difference between Embodiment 26-29 and Embodiment 1 is that the fibrous filler comprises the following raw materials in weight percent:

[0145]

[0146] The difference between Embodiment 30-33 and Embodiment 1 is that all the other admixtures include the following raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com