Sodium iron chlorophyllin-chitosan/sodium alginate microcapsules and preparation method thereof

A technology of sodium iron chlorophyllide and sodium alginate, which is applied in the field of preparation of medicinal and food pigments, can solve the problems such as microcapsules of sodium iron chlorophyllide that have not yet been seen, and achieve improved drug efficacy and bioavailability, and enhanced stability The effects of safety and preparation process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Sodium ferric chlorophyllin was dissolved in 1.5 times of 1.5% sodium alginate solution, and the resulting solution was placed in vegetable oil containing 1.0 g of Span-60, stirred at 600 r / min, and emulsified for 20 min. Aqueous acetic acid solution containing 2.0% chitosan and calcium chloride was added dropwise, stirring was continued for 30 min, and the mixture was allowed to stand for 2 h to remove the oil phase. The microcapsules were washed three times with petroleum ether and isopropanol respectively, filtered with suction, and dried at room temperature to obtain iron sodium chlorophyllinate-chitosan / sodium alginate microcapsules.

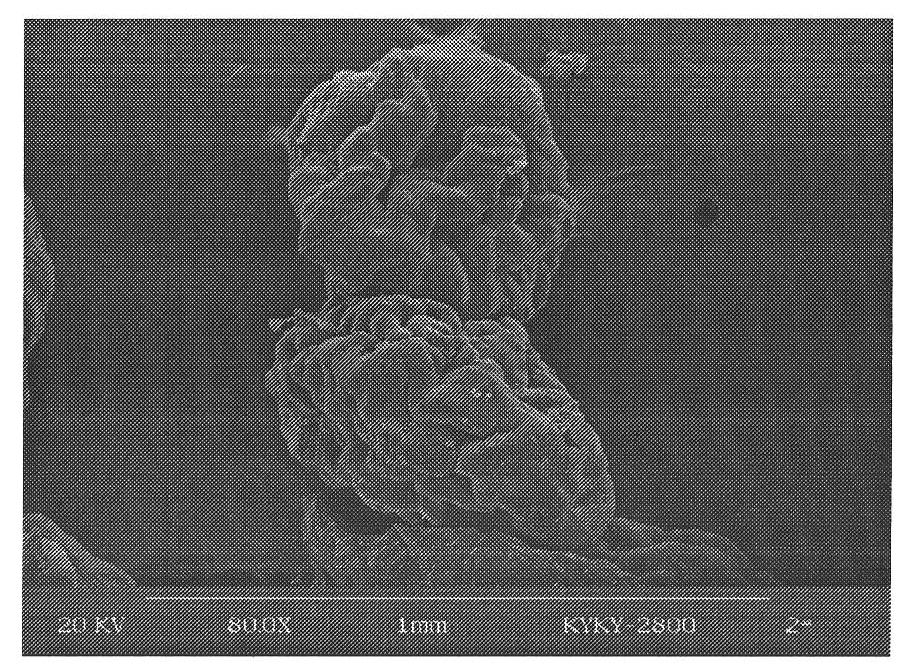

[0023] Carry out microcapsule evaluation: its appearance is a uniform ellipsoid see figure 1 , evenly dispersed; the particle size distribution reaches 70% in the range of 75 μm to 100 μm; the release rate of the microcapsules in vitro is 50% within 4 hours.

Embodiment 2

[0025] Sodium ferric chlorophyllin was dissolved in 1.5 times of 1.8% sodium alginate solution, and the resulting solution was placed in vegetable oil containing 1.0 g of Span-60, stirred at 700 r / min, and emulsified for 20 min. Aqueous acetic acid solution containing 2.0% chitosan and calcium chloride was added dropwise, stirring was continued for 30 min, and the mixture was allowed to stand for 2 h to remove the oil phase. The microcapsules were washed three times with petroleum ether and isopropanol respectively, filtered with suction, and dried at room temperature to obtain iron sodium chlorophyllinate-chitosan / sodium alginate microcapsules.

[0026] Carry out microcapsule evaluation: its appearance is a uniform ellipsoid see figure 1 ; The particle size distribution reaches 60% in the range of 100±0.65μm; the release rate of microcapsules in vitro is 40% within 4 hours.

Embodiment 3

[0028] Sodium ferric chlorophyllin was dissolved in 1.5 times of 2.0% sodium alginate solution, and the resulting solution was placed in vegetable oil containing 1.0 g of Span-60, stirred at 900 r / min, and emulsified for 20 min. Aqueous acetic acid solution containing 2.0% chitosan and calcium chloride was added dropwise, stirring was continued for 30 min, and the mixture was allowed to stand for 2 h to remove the oil phase. The microcapsules were washed three times with petroleum ether and isopropanol respectively, filtered with suction, and dried at room temperature to obtain iron sodium chlorophyllinate-chitosan / sodium alginate microcapsules.

[0029] The microcapsules were evaluated: the appearance was uniform ellipsoid and broken capsule, resulting in irregular capsule shape; the particle size reached 70% in the range of 75±0.74 μm; the release rate of microcapsules in vitro was 60% in 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com