TiB2-based coating with multicycle structure and preparation method and application thereof

A titanium diboride, periodic structure technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problem of poor thermal stability and toughness, high residual stress, low self-diffusion coefficient of elemental film, etc. problem, to achieve the effect of low brittleness, good bonding force, and improved high temperature oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation:

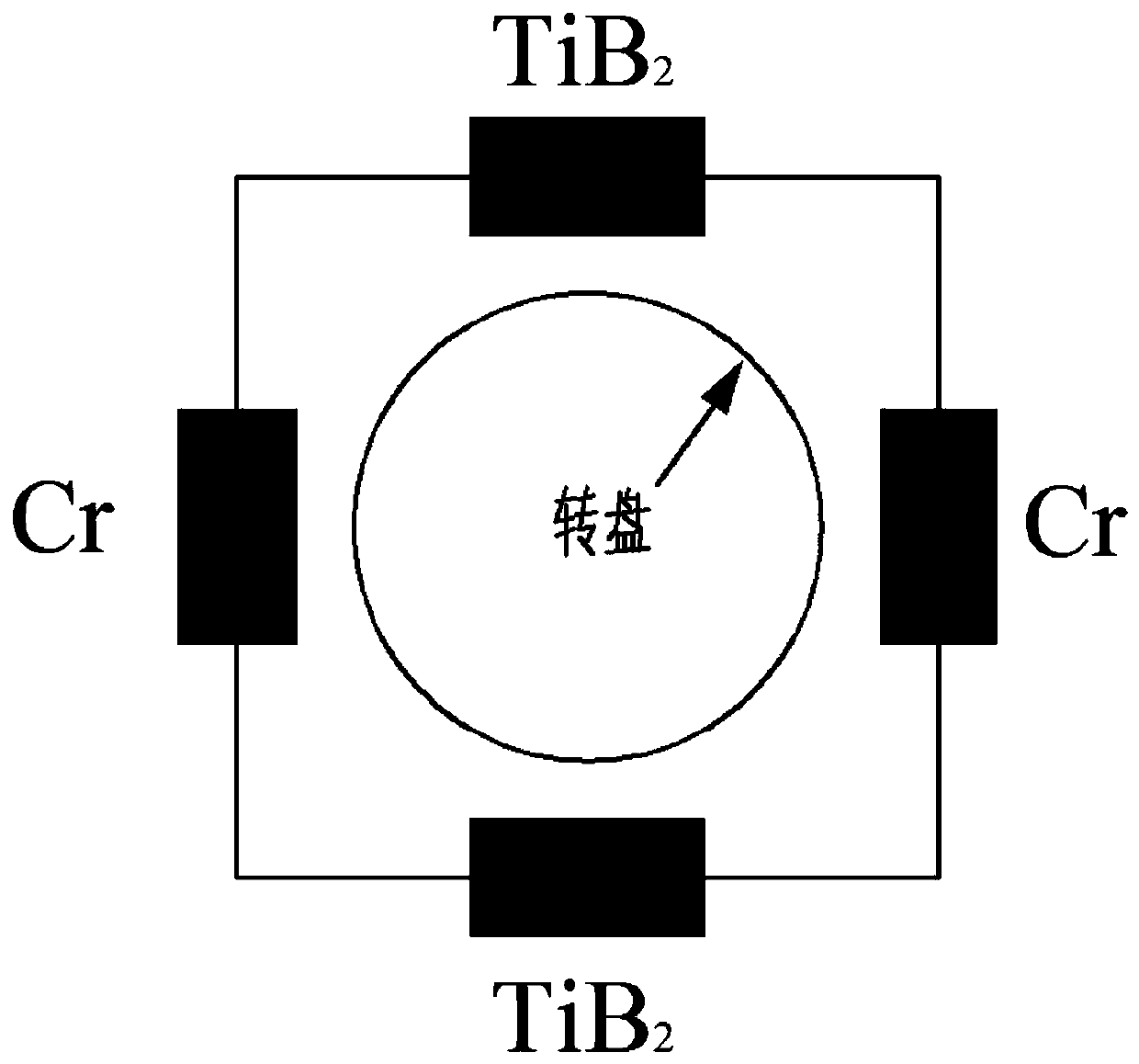

[0036] S1. Two TiBs are symmetrically installed on the ion coating machine 2 target and two metal targets, TiB 2 The target is a planar target, the atomic ratio of Ti and B is 1:2, and the purity is 99.99%; the metal target is a chromium (Cr) planar target, the purity is 99.99%, and the workpiece support is installed in the middle of the vacuum chamber.

[0037] S2. Cleaning the substrate: send the polished (100) oriented single crystal silicon substrate into an ultrasonic cleaning machine, and perform ultrasonic cleaning with acetone and absolute ethanol for 30 minutes respectively, and then clean it with deionized water, and then wash it with a purity ≥ 99.5% nitrogen blow dry.

[0038] S3. Vacuuming and ion beam etching cleaning chamber: two TiBs are symmetrically installed on the ion coating machine 2 Target and two Cr metal targets, clean the coating chamber with a high-power vacuum cleaner; place the substrate after ultrasonic cleaning on the ...

Embodiment 2

[0044] 1. Preparation:

[0045] S1. Two TiBs are symmetrically installed on the ion coating machine 2 target and two metal targets, TiB 2 The target is a planar target, the atomic ratio of Ti and B is 1:2, and the purity is 99.99%; the metal target is a chromium (Cr) planar target, the purity is 99.99%, and the workpiece support is installed in the middle of the vacuum chamber.

[0046] S2. Clean the substrate: send the polished WC-Co cemented carbide substrate to the ultrasonic cleaning machine, and use acetone and absolute ethanol to conduct ultrasonic waves at 30kHz respectively. Clean for 30 minutes, then rinse with deionized water, and dry with nitrogen with a purity of ≥99.5%.

[0047] S3. Vacuuming and ion beam etching cleaning chamber: clean the coating chamber with a high-power vacuum cleaner; place the substrate after ultrasonic cleaning on the workpiece support in the vacuum chamber, and vacuum the vacuum chamber to a vacuum of 5.0×10 -3 Below Pa, then turn on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com