Patents

Literature

61results about How to "Interdiffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

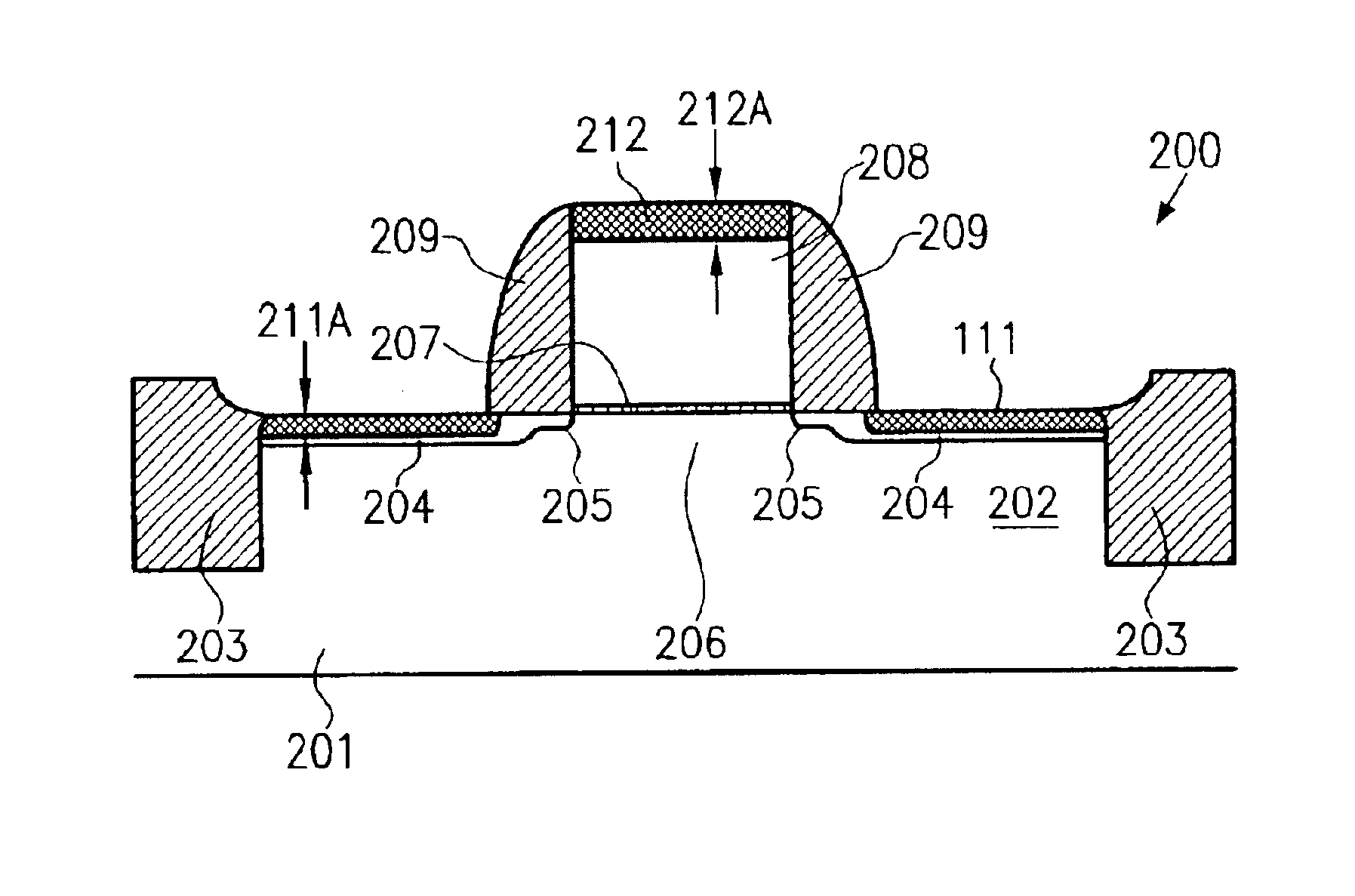

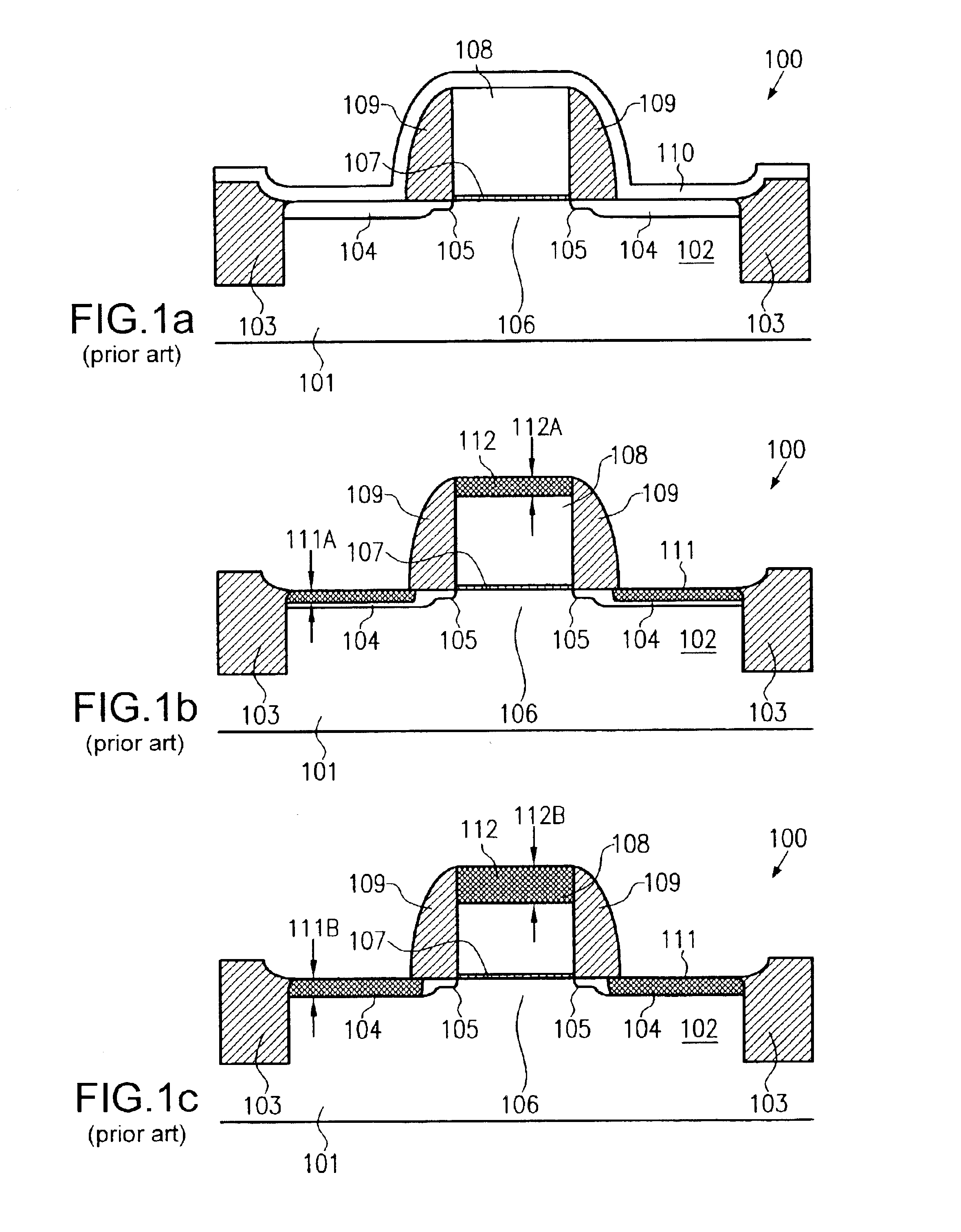

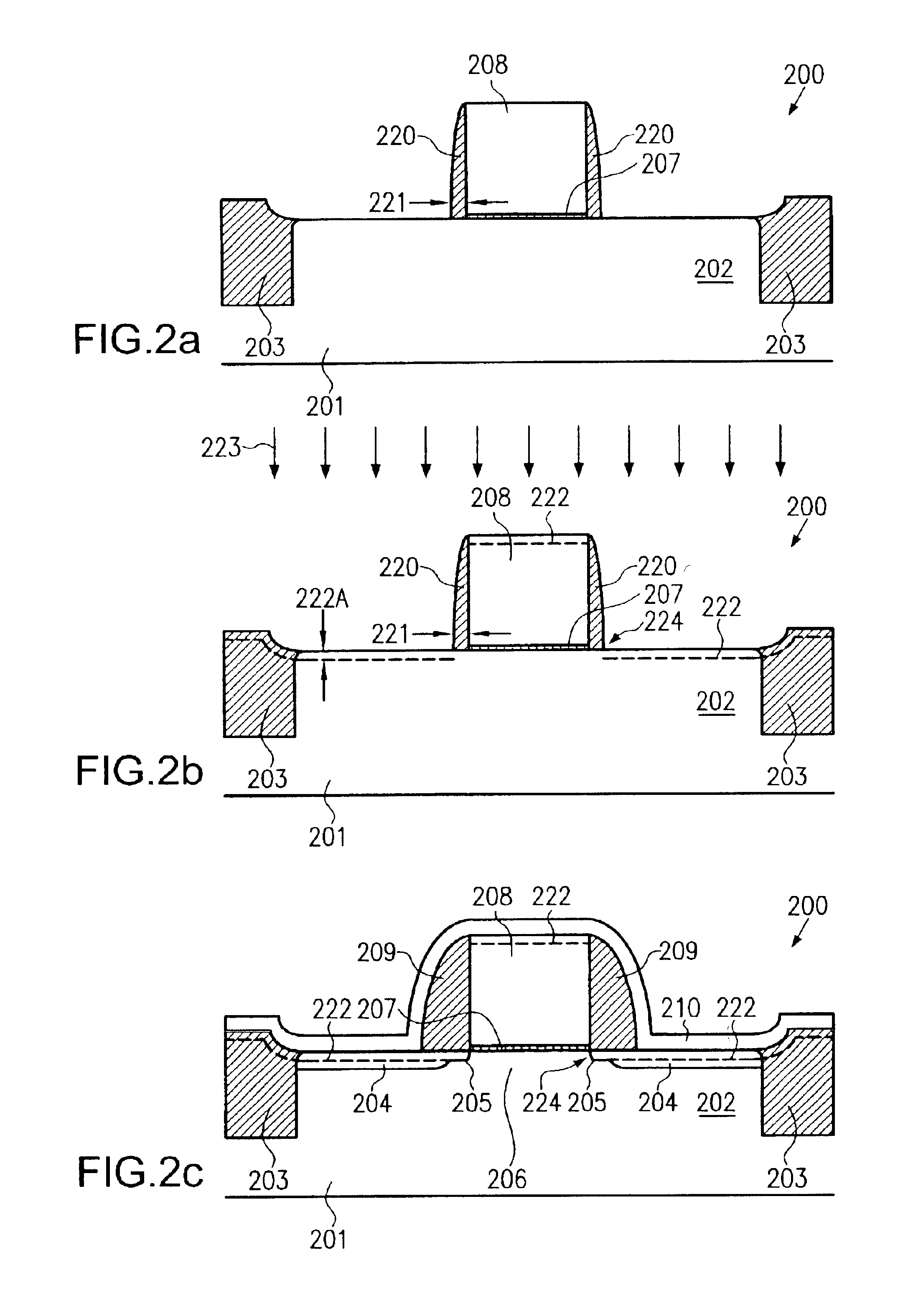

Circuit element having a metal silicide region thermally stabilized by a barrier diffusion material

InactiveUS6838363B2InterdiffusionReduce formationSemiconductor/solid-state device detailsSolid-state devicesSalicideMetal silicide

The introduction of a barrier diffusion material, such as nitrogen, into a silicon-containing conductive region, for example the drain and source regions and the gate electrode of a field effect transistor, allows the formation of nickel silicide, which is substantially thermally stable up to temperatures of 500° C. Thus, the device performance may significantly improve as the sheet resistance of nickel silicide is significantly less than that of nickel disilicide.

Owner:GLOBALFOUNDRIES US INC

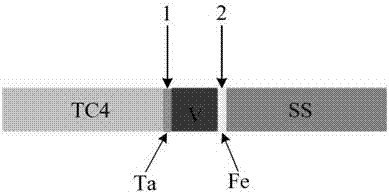

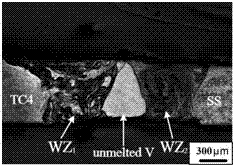

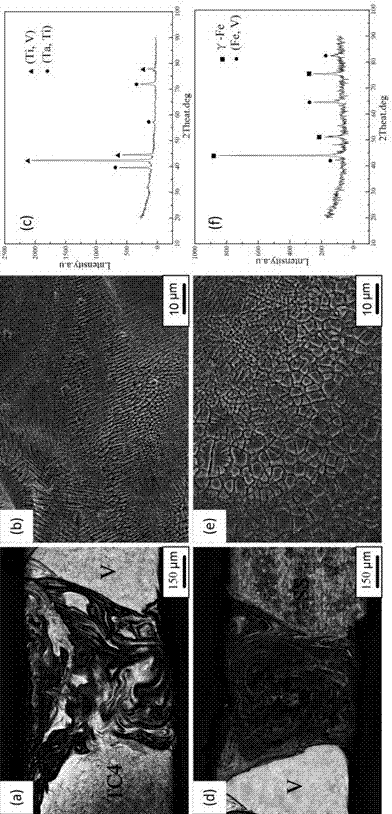

Laser welding method of titanium alloy-stainless steel dissimilar metal by adopting composite intermediate layer

ActiveCN107127454AEasy to shapeAvoid unfusedWelding/soldering/cutting articlesLaser beam welding apparatusOmegaTitanium alloy

The invention relates to a laser welding method of a titanium alloy-stainless steel dissimilar metal by adopting a composite intermediate layer, and belongs to the technical field of material welding (connection). According to the method, laser is adopted as a welding heat source, and a Ta / V / Fe composite layer is used as an intermediate layer material, so that formation of an omega brittle phase in a titanium alloy-vanadium welding line and an alpha brittle phase in a vanadium-stainless steel welding line can be controlled, the joint brittleness can be reduced, and the joint performance can be improved; by adopting the two welding, a high-quality high-efficiency welding joint which is made of a dissimilar metal material and contains a titanium alloy-vanadium welding line, an unmolten vanadium layer and a vanadium-stainless steel welding line can be obtained. The process comprises the steps of plate assembling and clamping, preload adjustment of a titanium alloy-intermediate layer-stainless steel contact face, and laser welding along the center line of a Ta intermediate layer and the center line of a Fe intermediate layer, so that connection of the titanium alloy-stainless steel dissimilar metal can be realized. The method has the advantages of stable welding process, attracted welding line formation, no welding defects including crack, pore, undercutting, uncomplete welding, incomplete fusion and the like, and good welding process performance.

Owner:JILIN UNIV

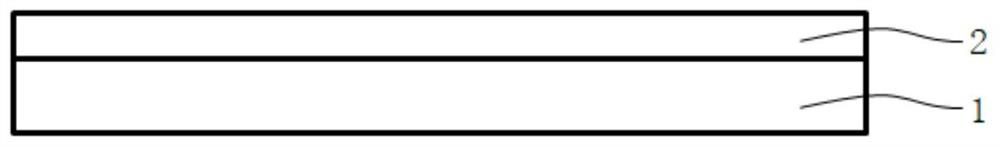

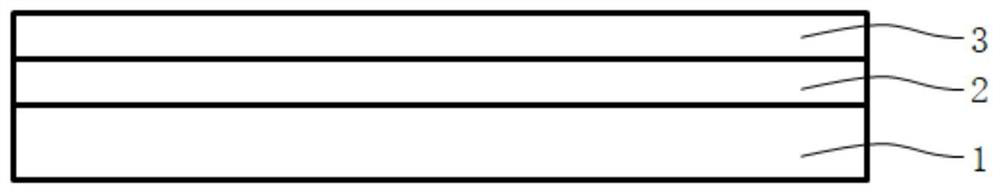

Method for producing titanium-steel composite plate taking nickel as interlayer

InactiveCN104907332AInterdiffusionEasy to shapeAuxillary arrangementsMetal rolling arrangementsSheet steelTitanium

The invention relates to the manufacturing and processing field of titanium-steel composite plates, in particular to a method for producing a titanium-steel composite plate taking nickel as an interlayer. The method includes the following steps that a steel plate, a titanium plate, nickel foil and a steel plate are symmetrically assembled into a blank in sequence, the periphery of the blank is welded, vacuumizing is conducted in the blank, and a combined blank is obtained; the combined blank is heated for 120 min-360 min at the temperature of 780 DEG C-850 DEG C; the heated combined blank is rolled, and the titanium-steel composite plate is obtained. The titanium-steel composite plate obtained according to the method has a good shape, no obvious defects are formed on the surface, no titanium / iron compound is generated on the combination interface, the combination effect is good, and the combination strength is greater than 190 MPa and is much higher than that of similar titanium-steel composite plates manufactured according to national standards.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

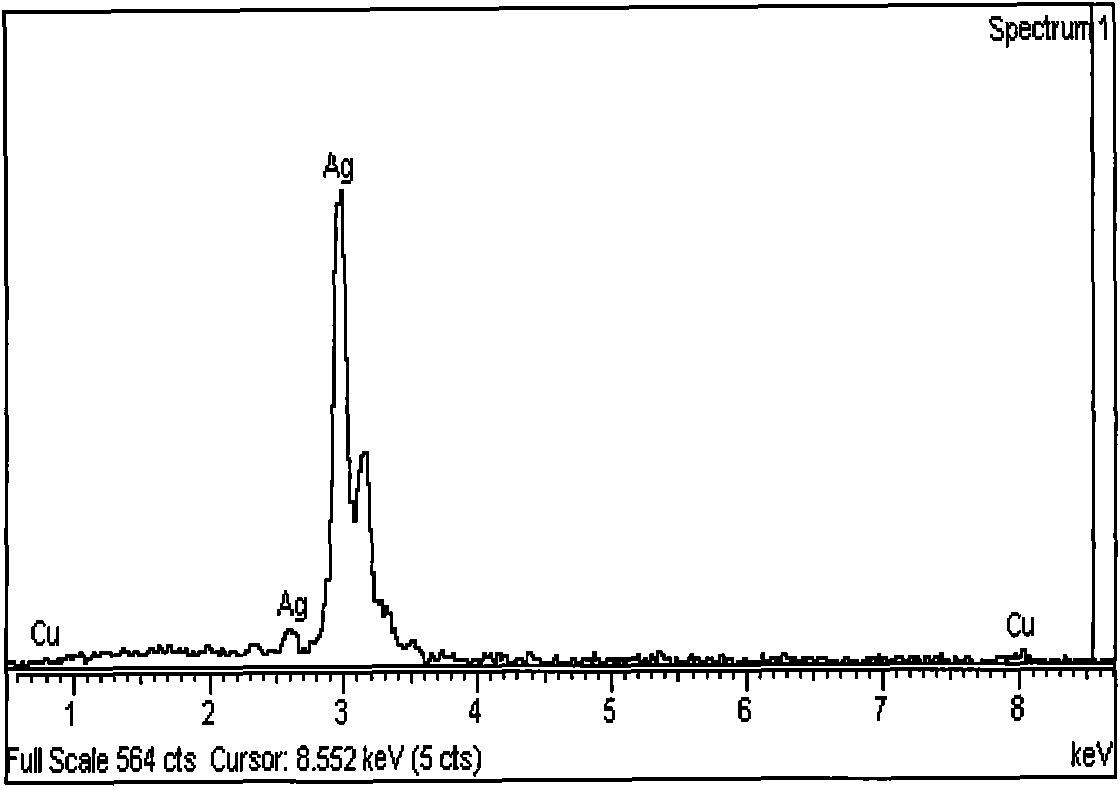

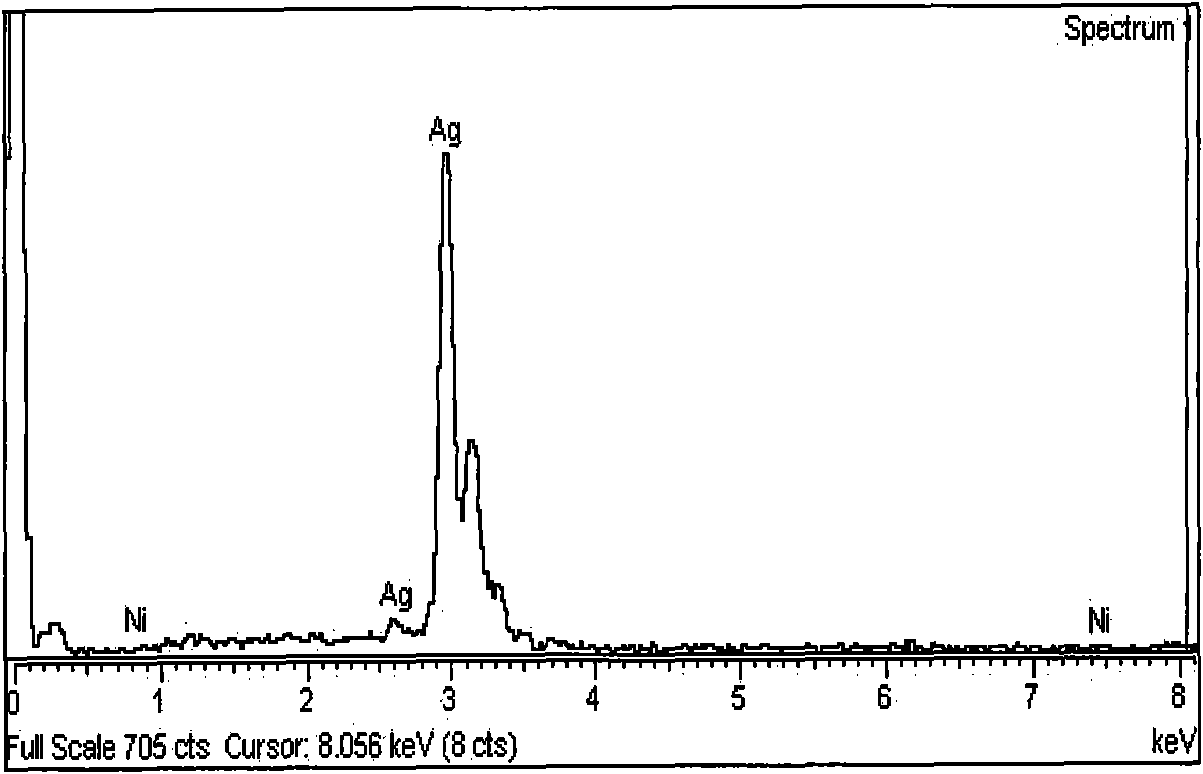

Preparation method of stainless steel surface copper-silver diffusion coating layer

InactiveCN101880860AAvoid the pitfalls of consuming too muchSolve the problem that it is not easy to precipitate uniformly on the surface of the substrateVacuum evaporation coatingSputtering coatingChemical platingCopper

The invention relates to a preparation method of a stainless steel surface copper-silver diffusion coating layer, which is characterized in that: a double-layer glow ion metal cementation method is utilized to infiltrate copper on the surface of a stainless steel base material, and an oxidized layer and a copper film on the surface of the stainless steel base material are removed; then a chemical plating method is utilized to plate silver on the surface of the stainless steel base material; and finally thermal diffusion treatment on the stainless steel base material after being plated with silver is carried out, so an antibacterial sterilization film layer with graded distribution of copper and silver on the surface of the stainless steel base material is formed. The antibacterial stainless steel can greatly improve the antibacterial and sterilization effect under the common effect of the copper and the silver, can reduce the production cost, and can solve the problem of the great consumption of the energy and the raw material caused by the integral smelting method. The method has good repeatability, can easily control the quality, is simple to operate, and can be widely applicable to the production of the antibacterial stainless steel product.

Owner:TAIYUAN UNIV OF TECH

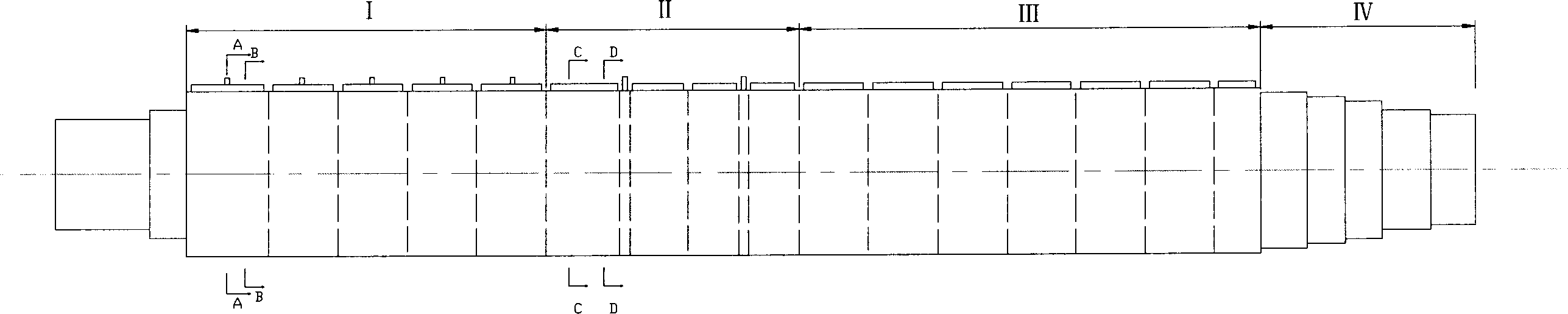

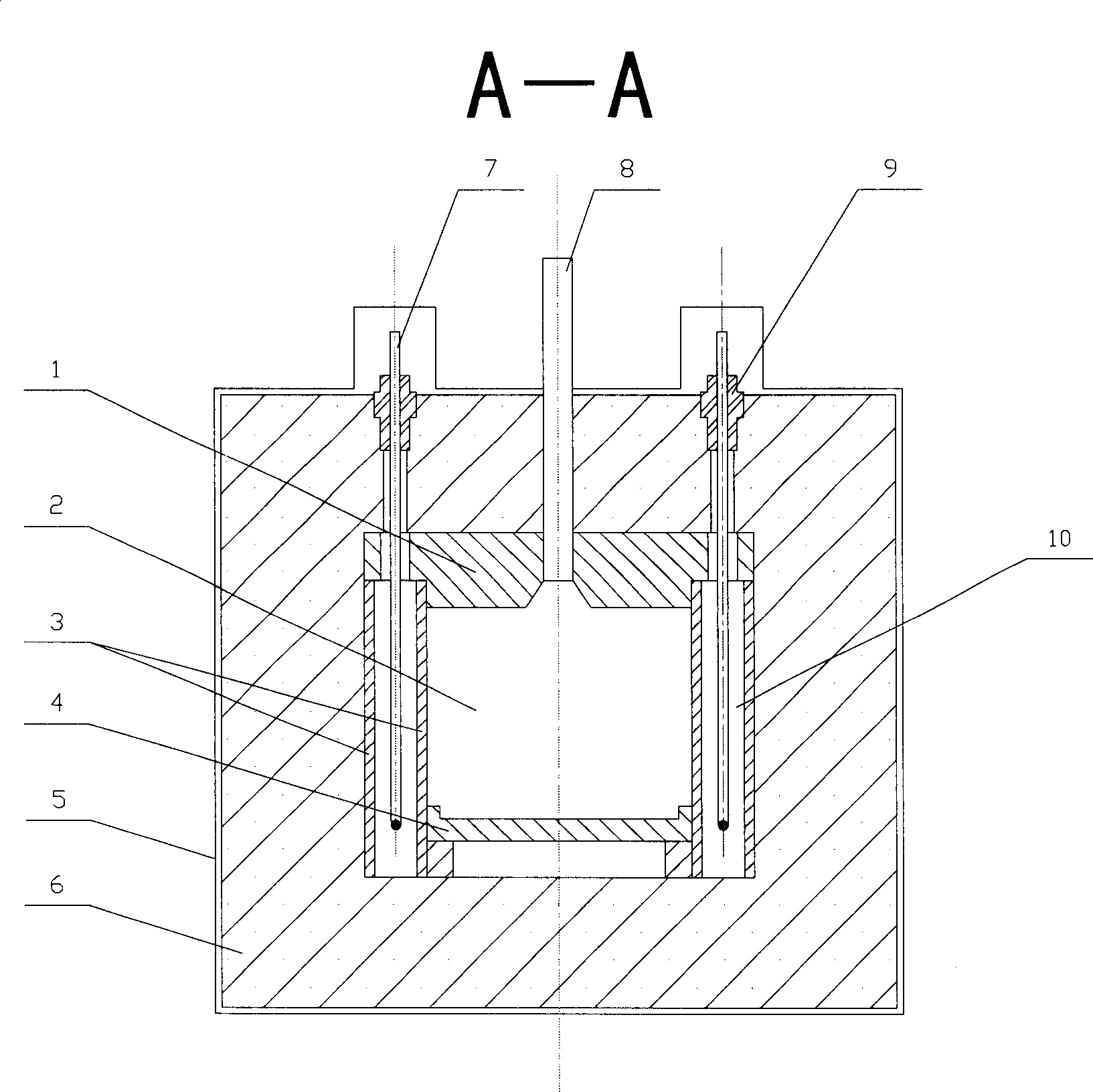

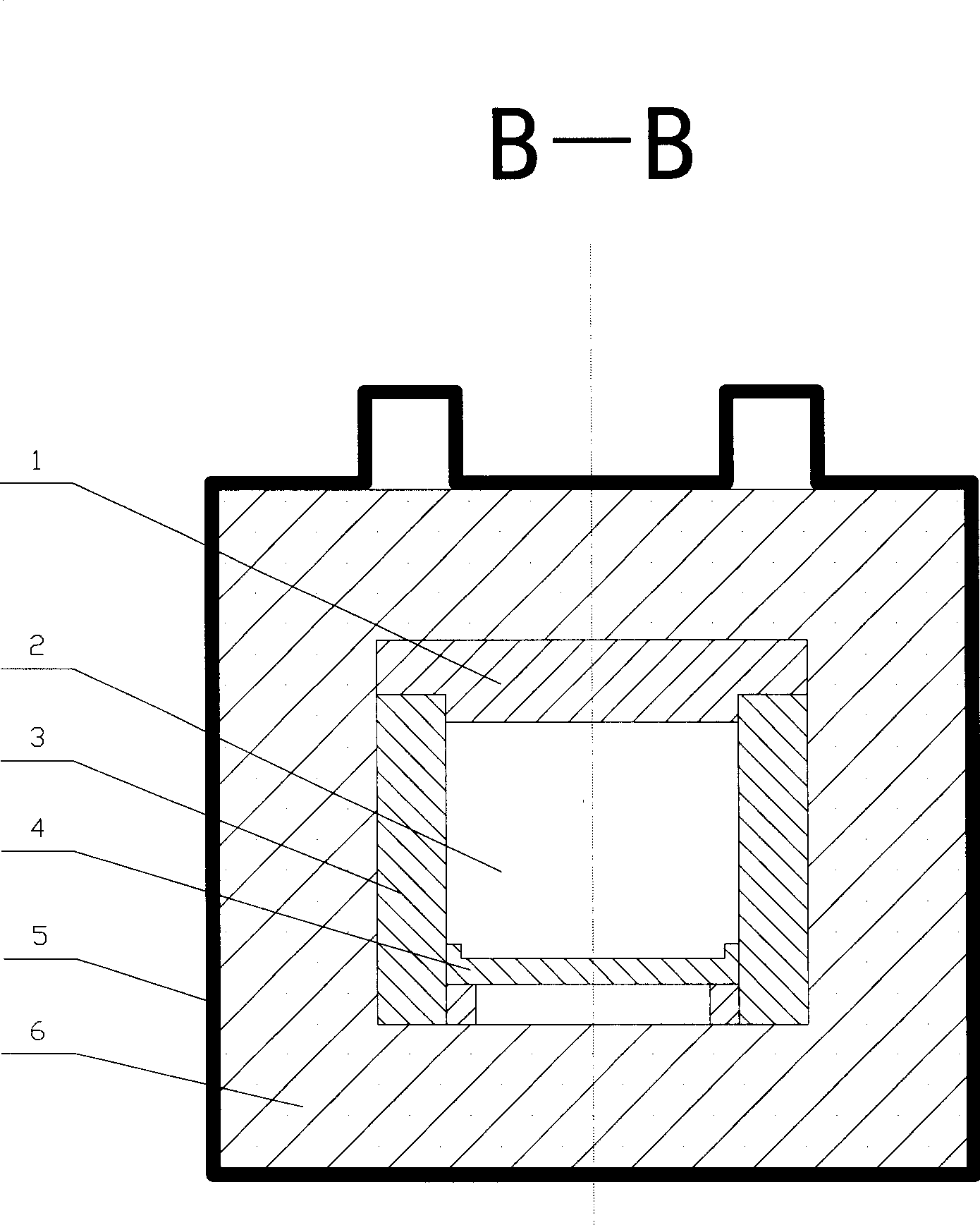

Firebox structure of pusher plate kiln in calcining apparatuses for preparing alloy of vanadium-nitrogen continously

ActiveCN1760120AAvoid corrosionExtended service lifeNitrogen-metal/silicon/boron binary compoundsFurnace typesInternal cavityMagnesium

An internal cavity structure of the push bar kiln used for preparing VN alloy is composed of internal cavity, cover plate, side wall and tracks. A push bar kiln is longitudinally and sequentially composed of the low-temp segment with 5 temp regions, the transition segment with 4 temp regions, the high-temp segment with 7 temp regions, and the cooling segment consisting of natural cooling region and forced cooling region. It features that different but proper refractories are chosen for different temp regions. Its internal cavity has 3 separated channels. The central channel is the kiln cavity and two side channels are isolated heating element ones.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

High-temperature manufacturing method for titanium-steel composite plate taking titanium as interlayer

The invention relates to the manufacturing and processing field of titanium-steel composite plates, in particular to a high-temperature manufacturing method for a titanium-steel composite plate taking titanium as an interlayer. The method includes the following steps that a steel plate, a titanium plate, nickel foil and a steel plate are symmetrically assembled into a blank in sequence, the periphery of the blank is welded, vacuumizing is conducted in the blank, and a combined blank is obtained; the combined blank is heated for 120 min-360 min at the temperature of 950 DEG C-1000 DEG C; the heated combined blank is rolled, and the titanium-steel composite plate is obtained. The titanium-steel composite plate obtained according to the method has a good shape, no obvious defects are formed on the surface, no titanium / iron compound is generated on the combination interface, the combination effect is good, and the combination strength is greater than 195 MPa and is much higher than that of similar titanium-steel composite plates manufactured according to national standards.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

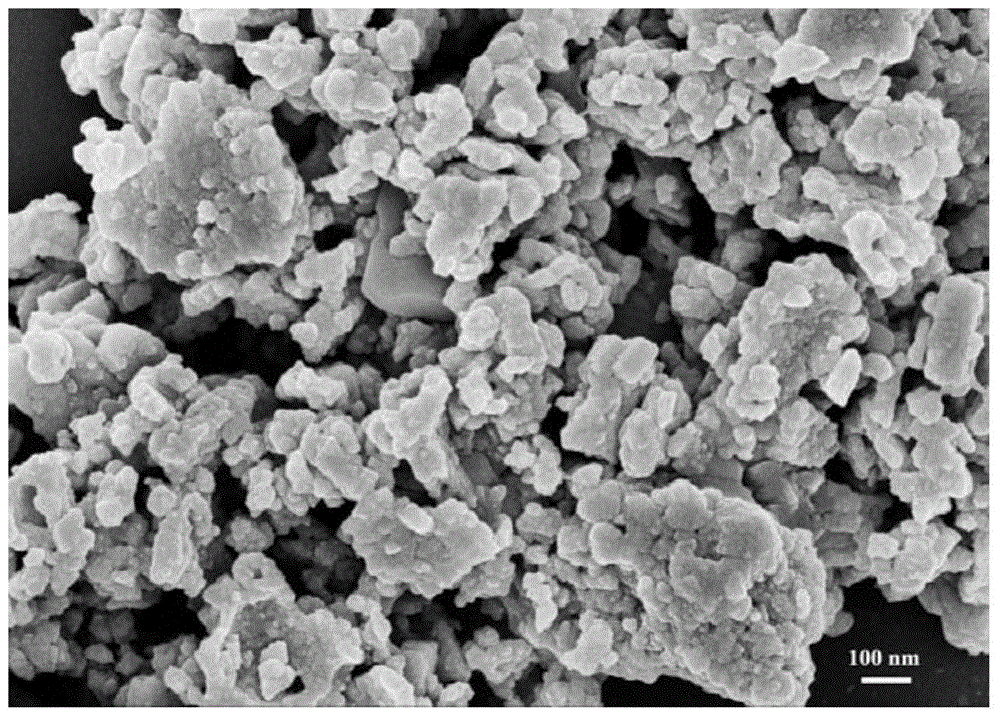

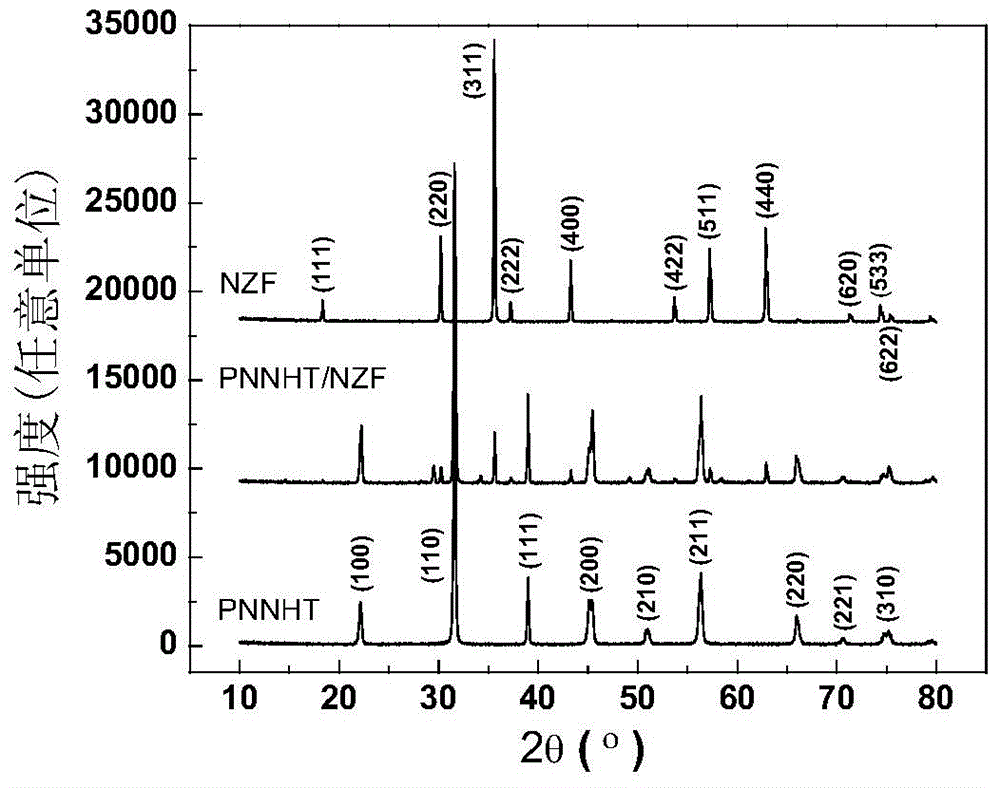

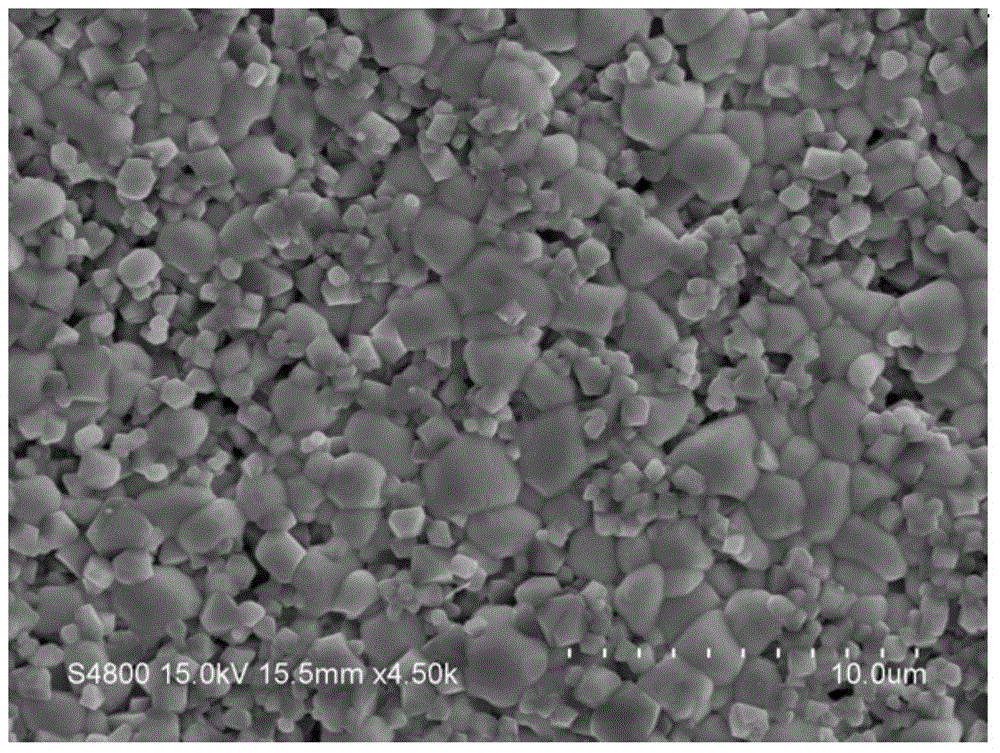

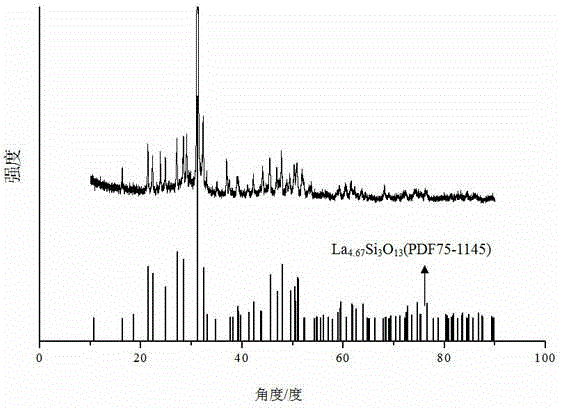

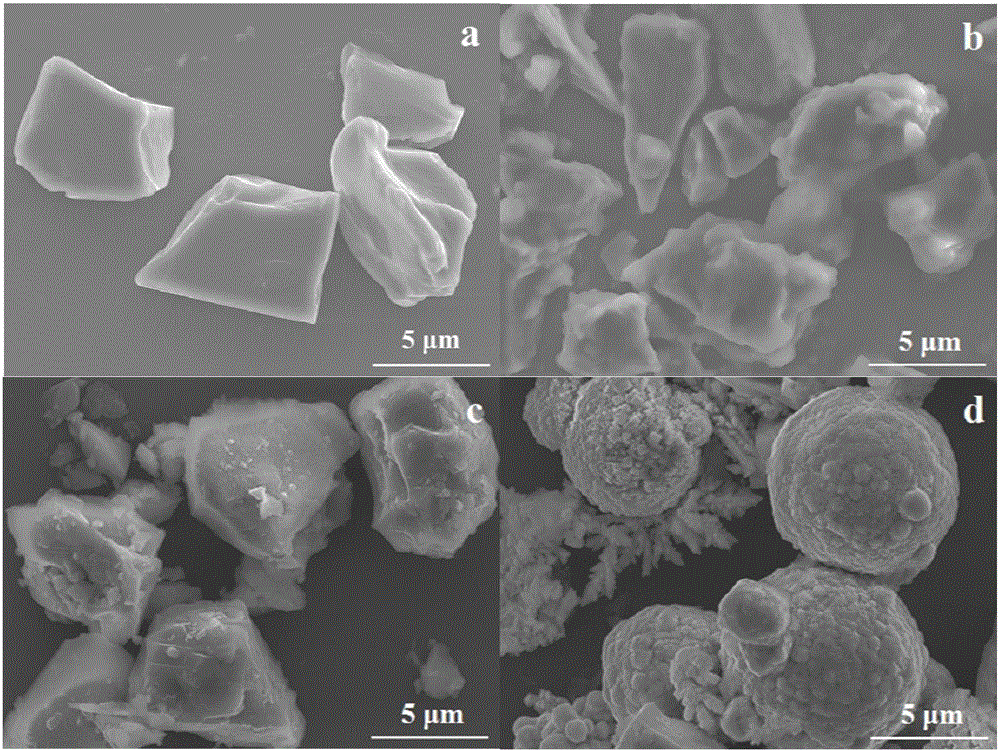

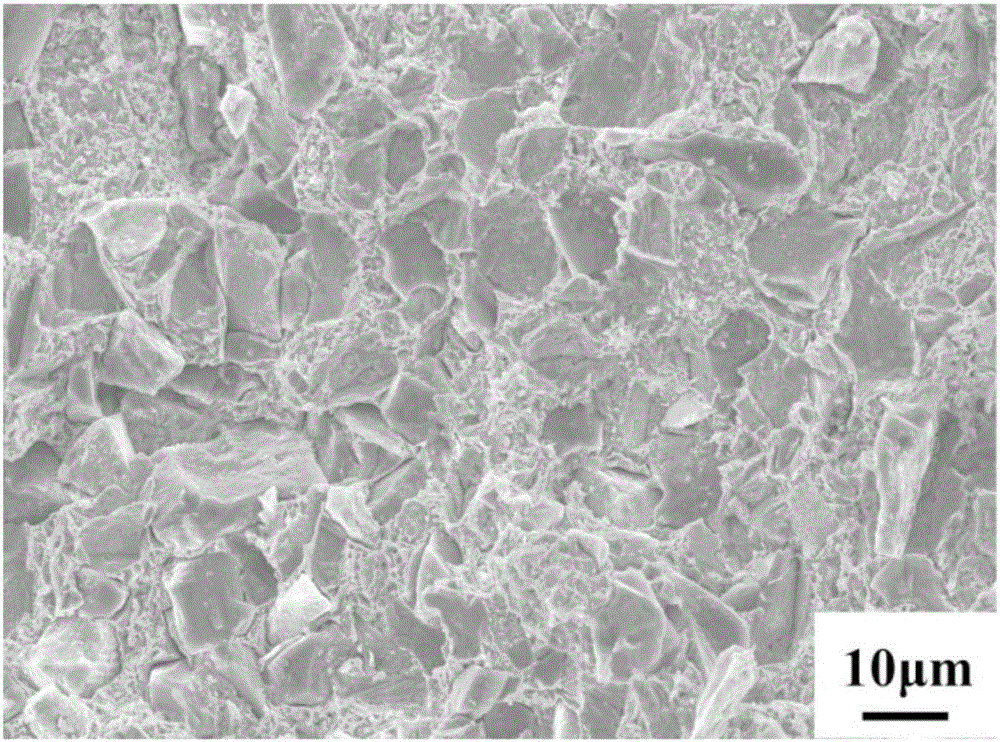

Method for preparing 0-3 magnetic-electricity composite ceramic through low-temperature sintering realized by induction of nanometer sintering additive through self-propagating

ActiveCN104609859AHigh magnetoelectric coupling effectLarge magnetoelectric coupling coefficientElectricityHigh density

The invention belongs to the field of magnetic-electricity composite materials and provides a method for preparing 0-3 magnetic-electricity composite ceramic through low-temperature sintering realized by induction of a nanometer sintering additive through self-propagating. Surfaces of a ferroelectric-phase particle and a ferromagnetic-phase particle are coated with nanometer WO3 and CuO respectively through a self-propagating process, then the coated ferroelectric-phase particle and the ferromagnetic-phase particle are uniformly mixed and subjected to solid-phase sintering, and the magnetic-electricity composite ceramic is prepared. The method has the advantages that (1), due to the introduction of the nanometer sintering additive, 0-3 particle composite ceramic with high density can be prepared through low-temperature sintering; (2), mutual diffusion of a ferroelectric-phase body and a ferromagnetic-phase body is effectively prevented, and the prepared 0-3 particle magnetic-electricity composite ceramic presents a high magneto-electricity coupling effect and has a large electro-electricity coupling coefficient; (3), a technological process is simple, the cost is low, and the method is applicable to preparation of other kinds of 0-3 particle magnetic-electricity composite ceramic.

Owner:江阴智产汇知识产权运营有限公司

Method for high-temperature rolling of titanium steel composite board with nickel as interlayer

InactiveCN104826866AInterdiffusionPrevent penetrationMetal rolling arrangementsTitaniumNational standard

The invention relates to the field of manufacturing and machining of titanium steel composite boards, in particular to a method for high-temperature rolling of a titanium steel composite board with nickel as an interlayer. The method for high-temperature rolling of the titanium steel composite board with nickel as the interlayer comprises the following steps that symmetrical assembly is conducted in the steel plate-titanium plate-nickel foil-steel plate sequence, the periphery of black is welded, vacuumizing is conducted in the interior of the blank, and thus a blank combination is obtained; the blank combination is heated for over 120 minutes, wherein the heating temperature ranges from 980 DEG C to 1050 DEG C; the titanium steel composite board is obtained by rolling the heated blank combination. According to the titanium steel composite board obtained through the method, the plate shape is good, no obvious defect exists on the surface, no titanium / iron compound is generated on a combined interface, the combining effect is good, and the combining strength is higher than 1200 MPa and is far higher than the combining strength of similar titanium steel composite boards meeting the national standard.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

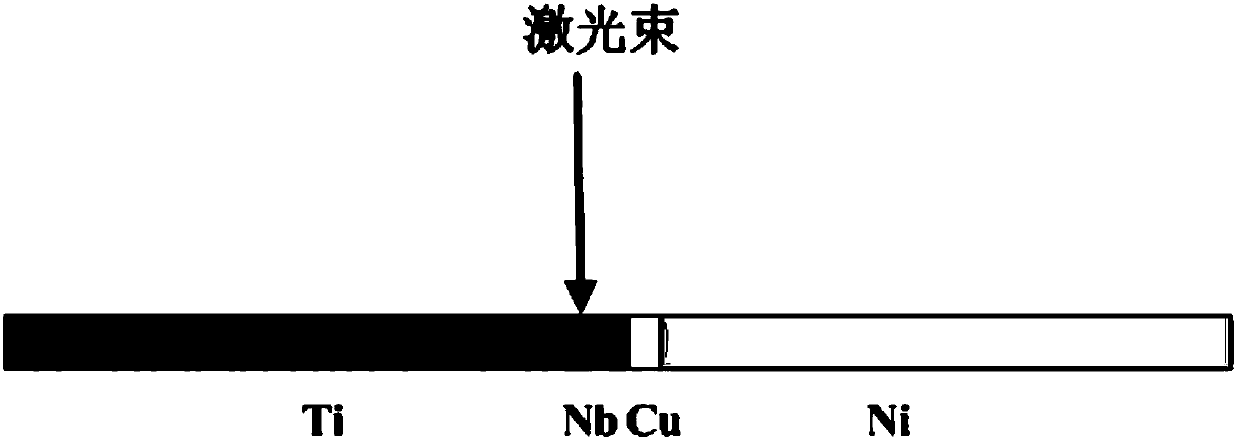

Laser-induced monotectic and isomorphous reaction welding method for titanium-nickel heterogenic joint

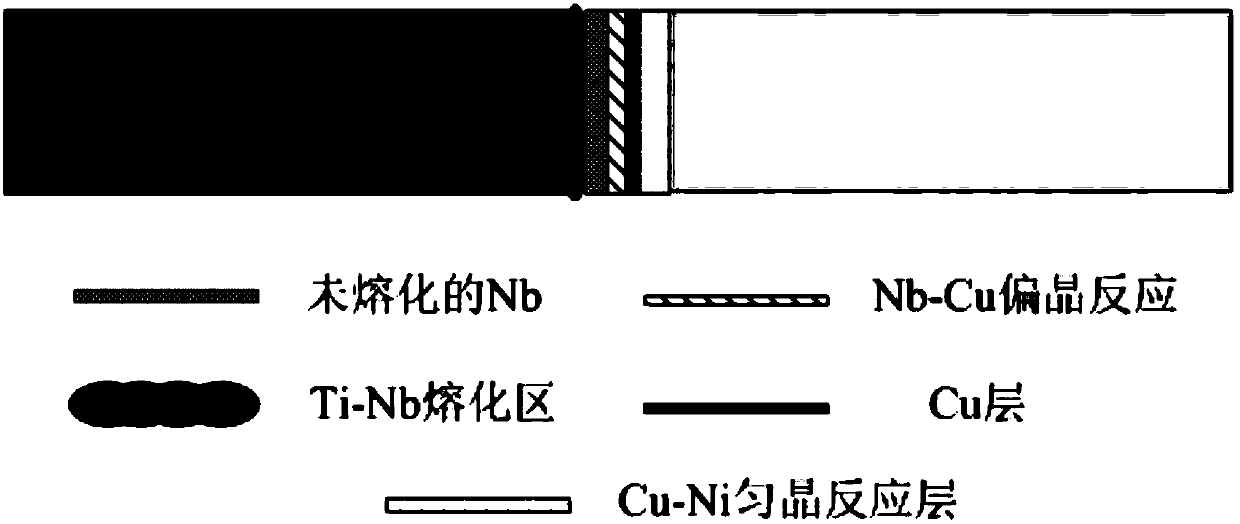

ActiveCN107931840AHigh strengthImprove plasticityWelding/soldering/cutting articlesLaser beam welding apparatusBond interfaceNiobium

The invention discloses a laser-induced monotectic and isomorphous reaction welding method for a titanium-nickel heterogenic joint. According to the method, two layers of composite interlayer solder are added between a titanium material and a nickel material, niobium metal serves as the first layer of composite interlayer solder, copper metal serves as the second layer of composite interlayer solder, the bonding interface of the niobium metal and the titanium material is the interface 1, the bonding interface of the niobium metal and the copper metal is the interface 2, the bonding interface of the copper metal and the nickel material is the interface 3, and the focal point of a welding heat source is located near the interface 1; and in the welding process, heat generated by the welding heat source forms a fusion welding mode on the bonding interface of the first layer of composite interlayer solder and the titanium, and the heat is higher than the melting point of the second layer ofcomposite interlayer solder when transmitted to the interface 2 and the interface 3 through the first layer of composite interlayer solder. By means of the welding method, formation of titanium-nickel intermetallic compounds is avoided, a fusion welding seam is formed at the interface 1, soldered seams are formed at the interface 2 and the interface 3 at the same time, and the obtained titanium-nickel heterogenic metal joint achieves the tensile strength of 200-230 MPa and the elongation percentage of 2-4%.

Owner:BAOJI UNIV OF ARTS & SCI

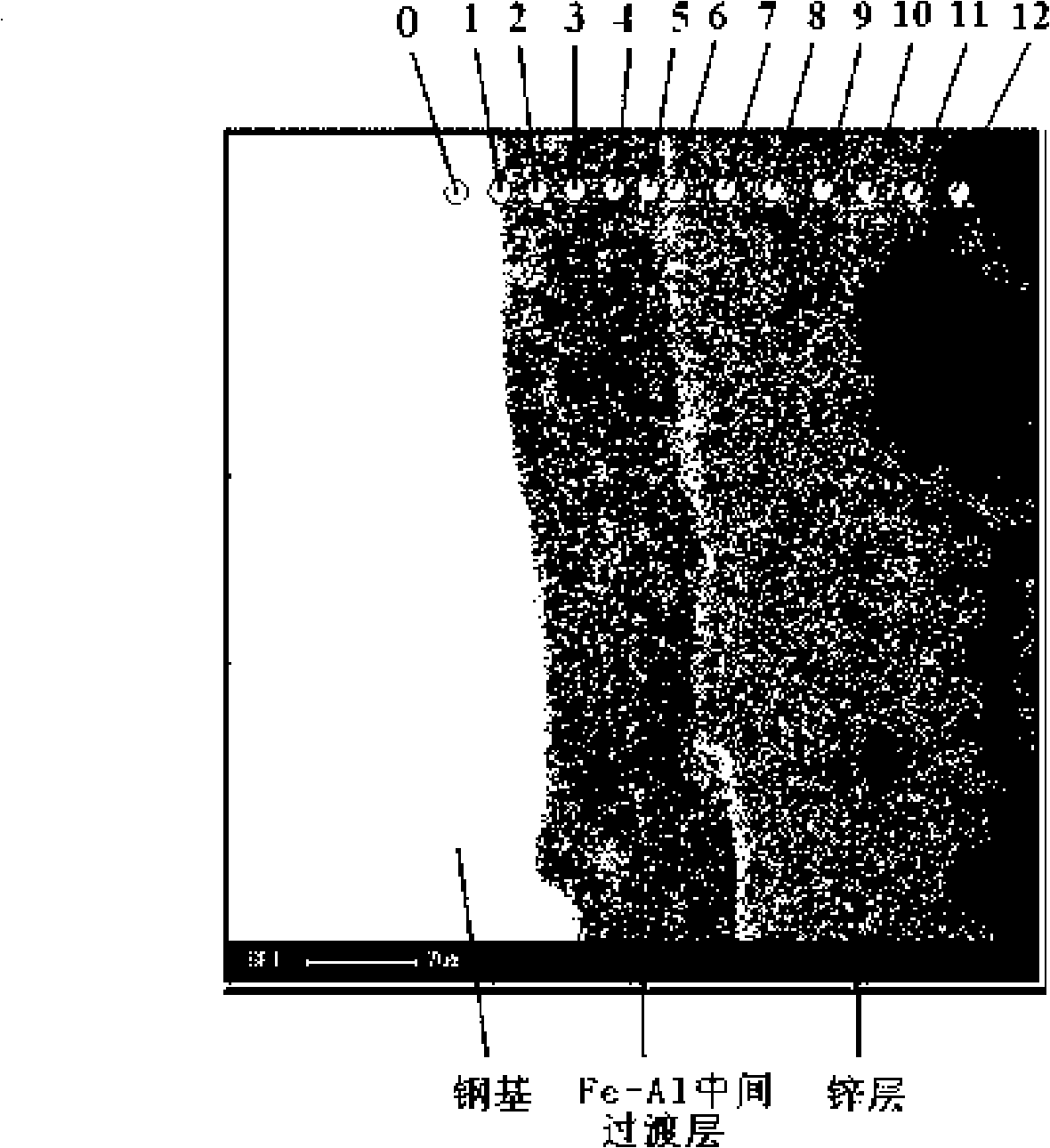

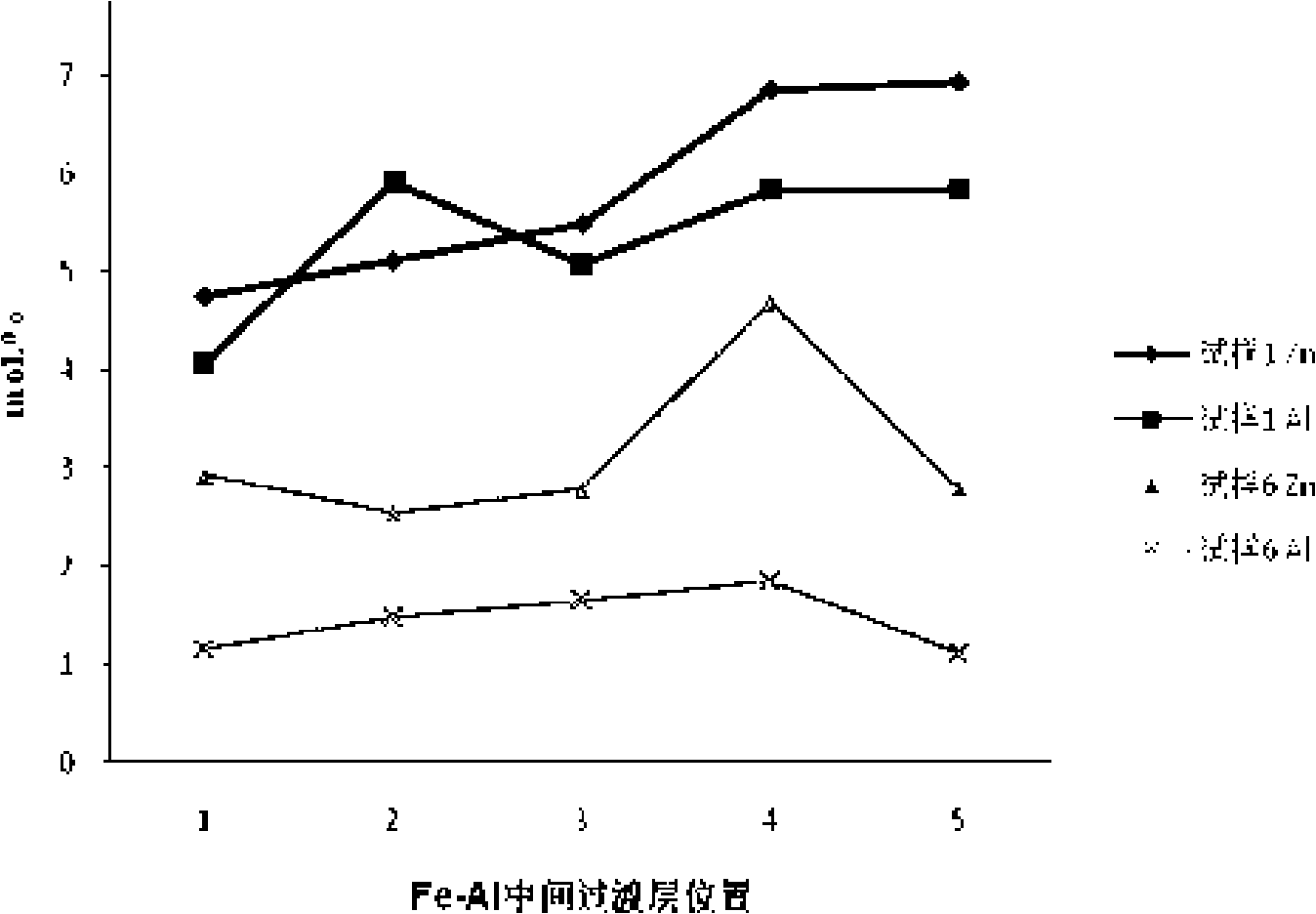

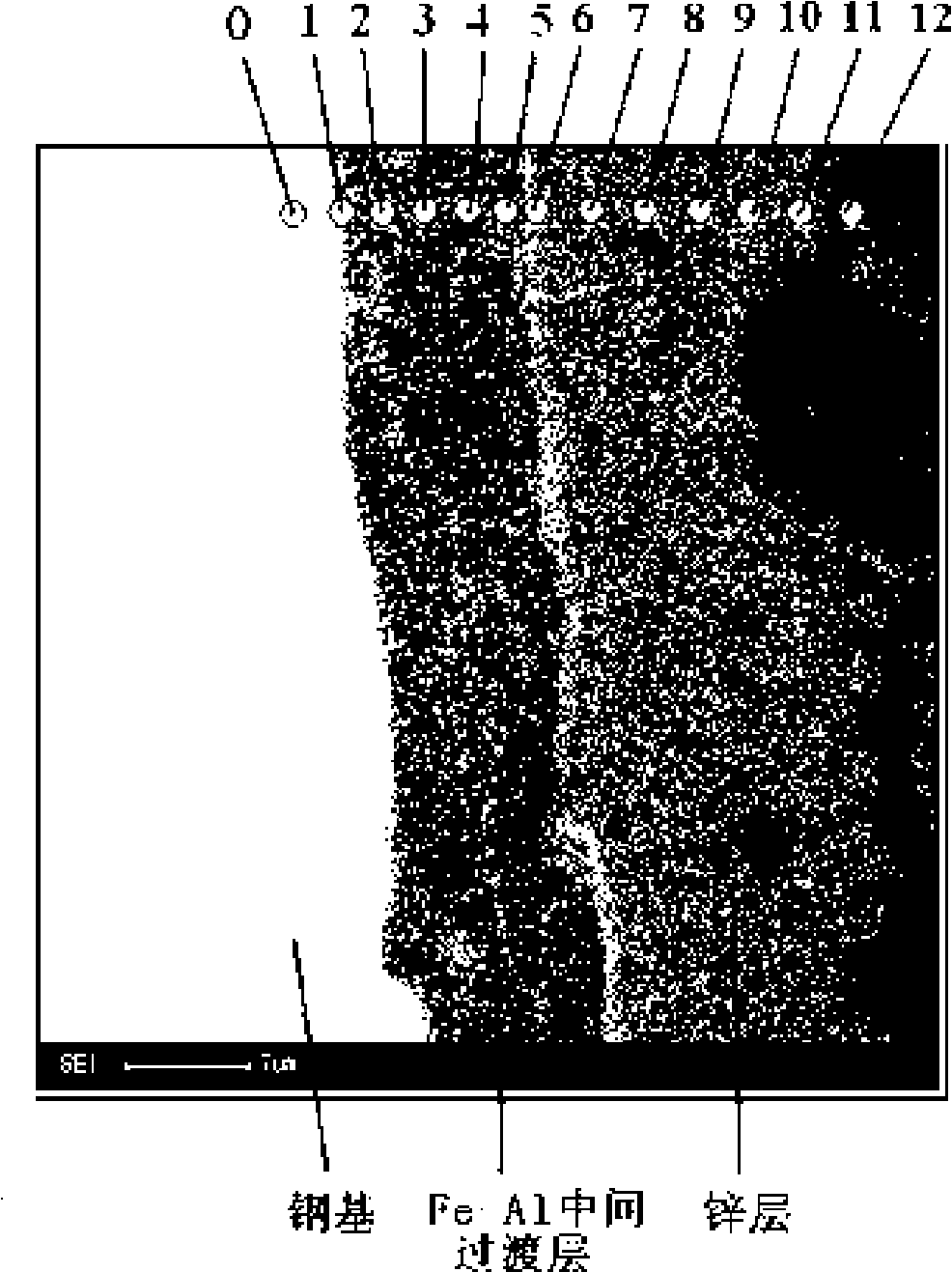

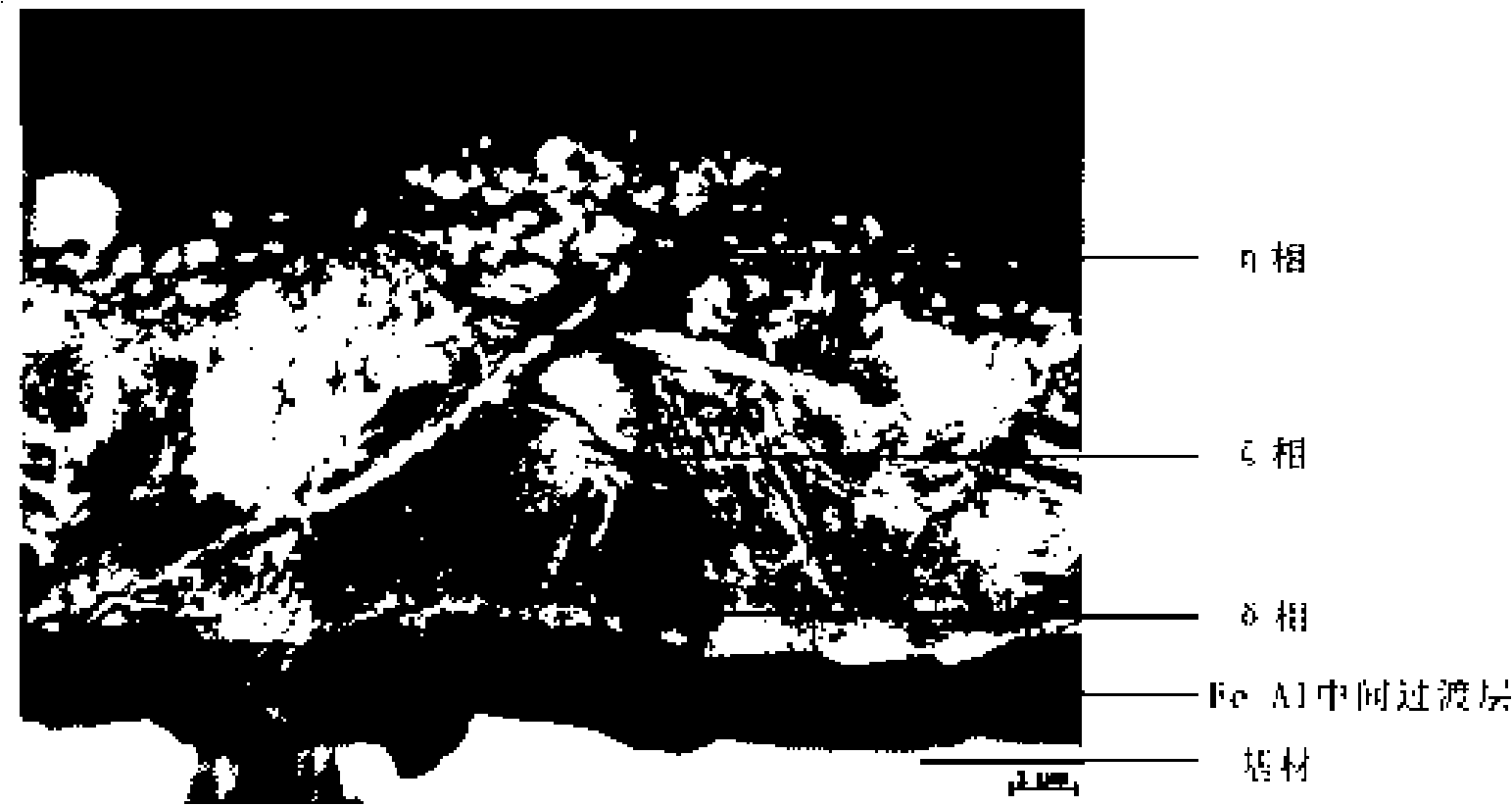

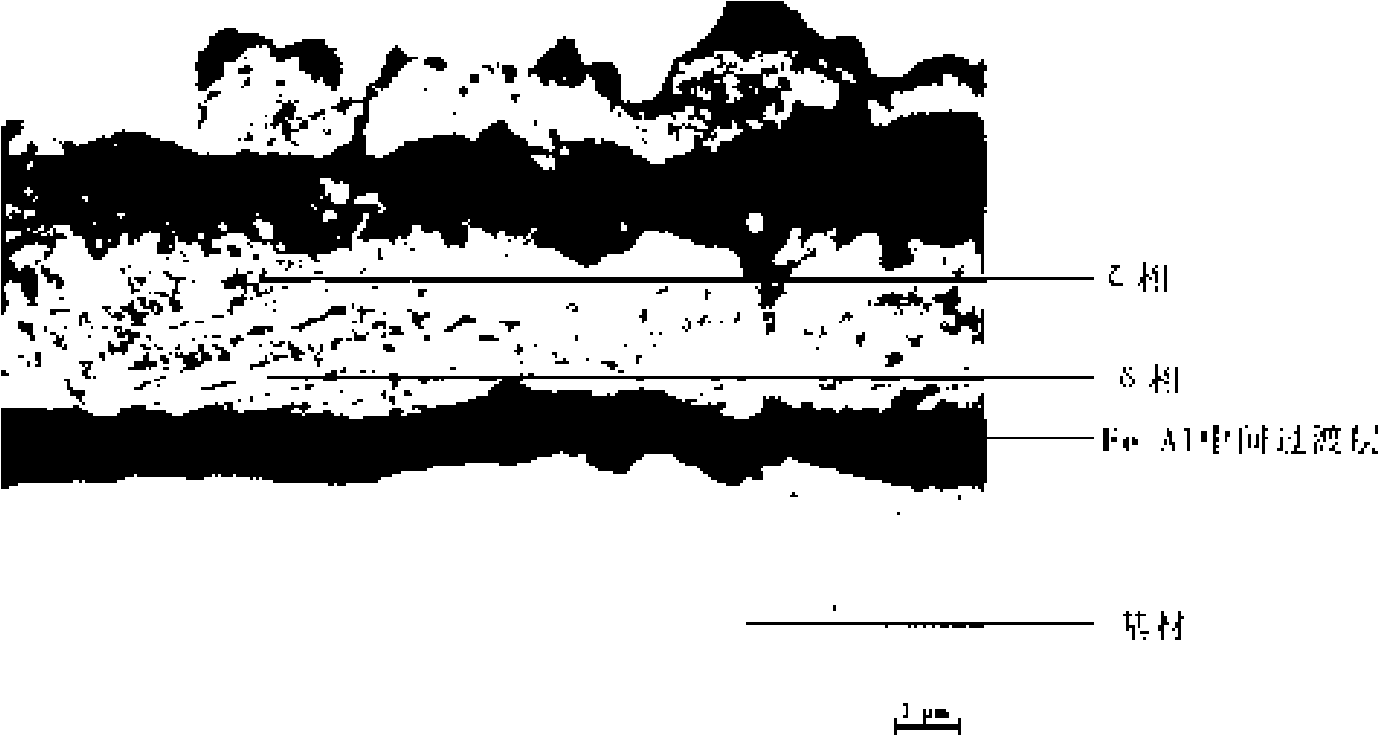

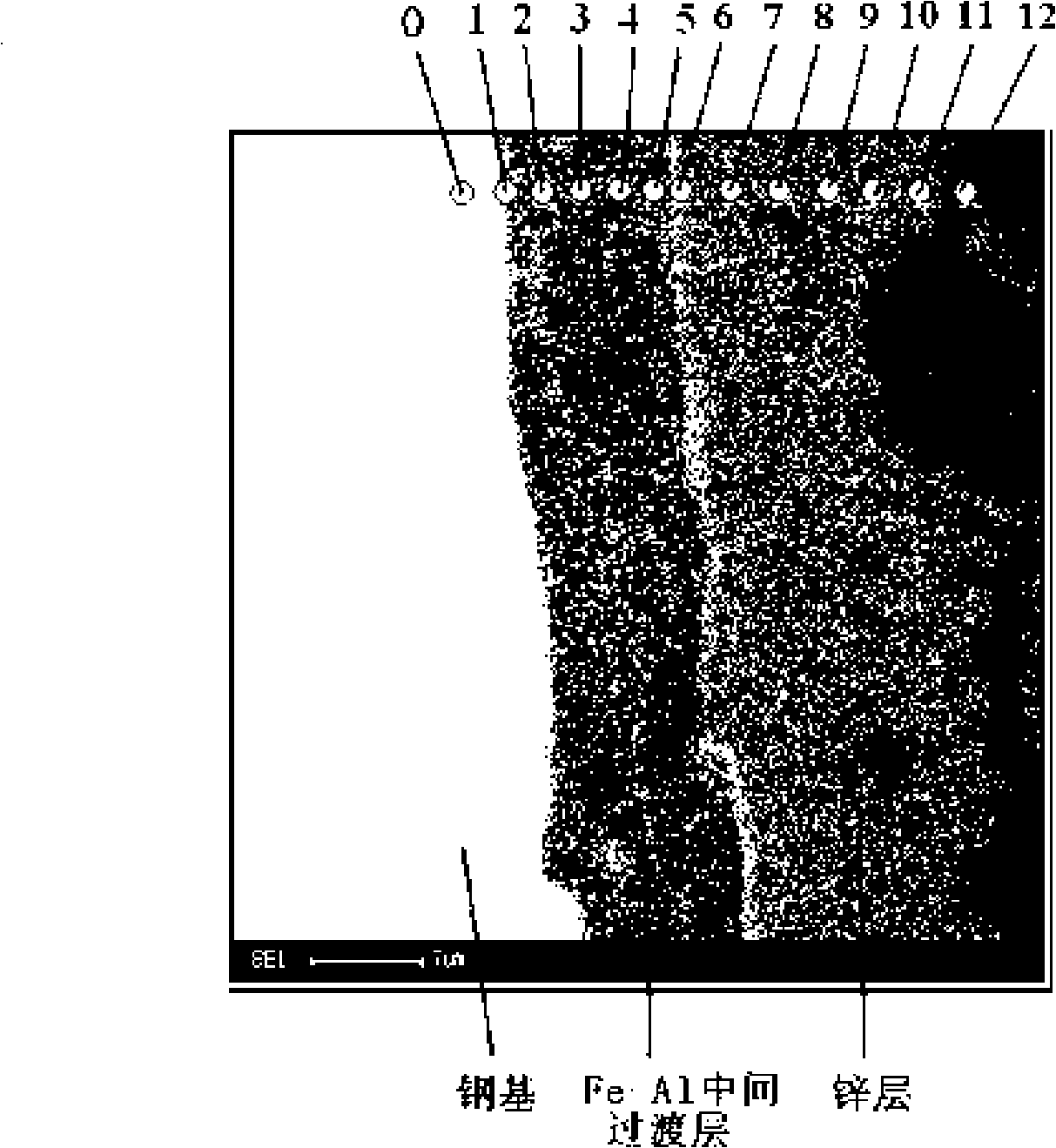

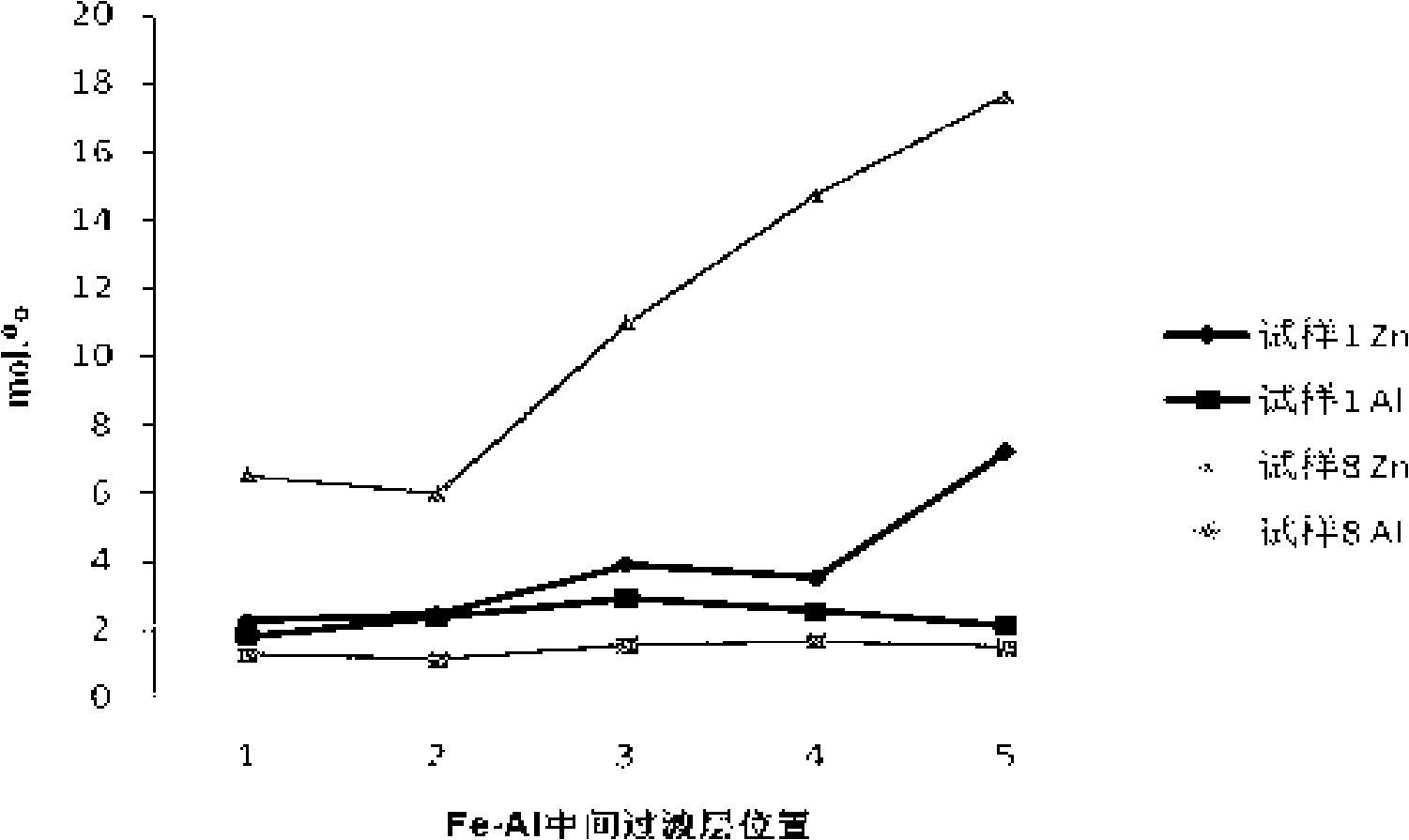

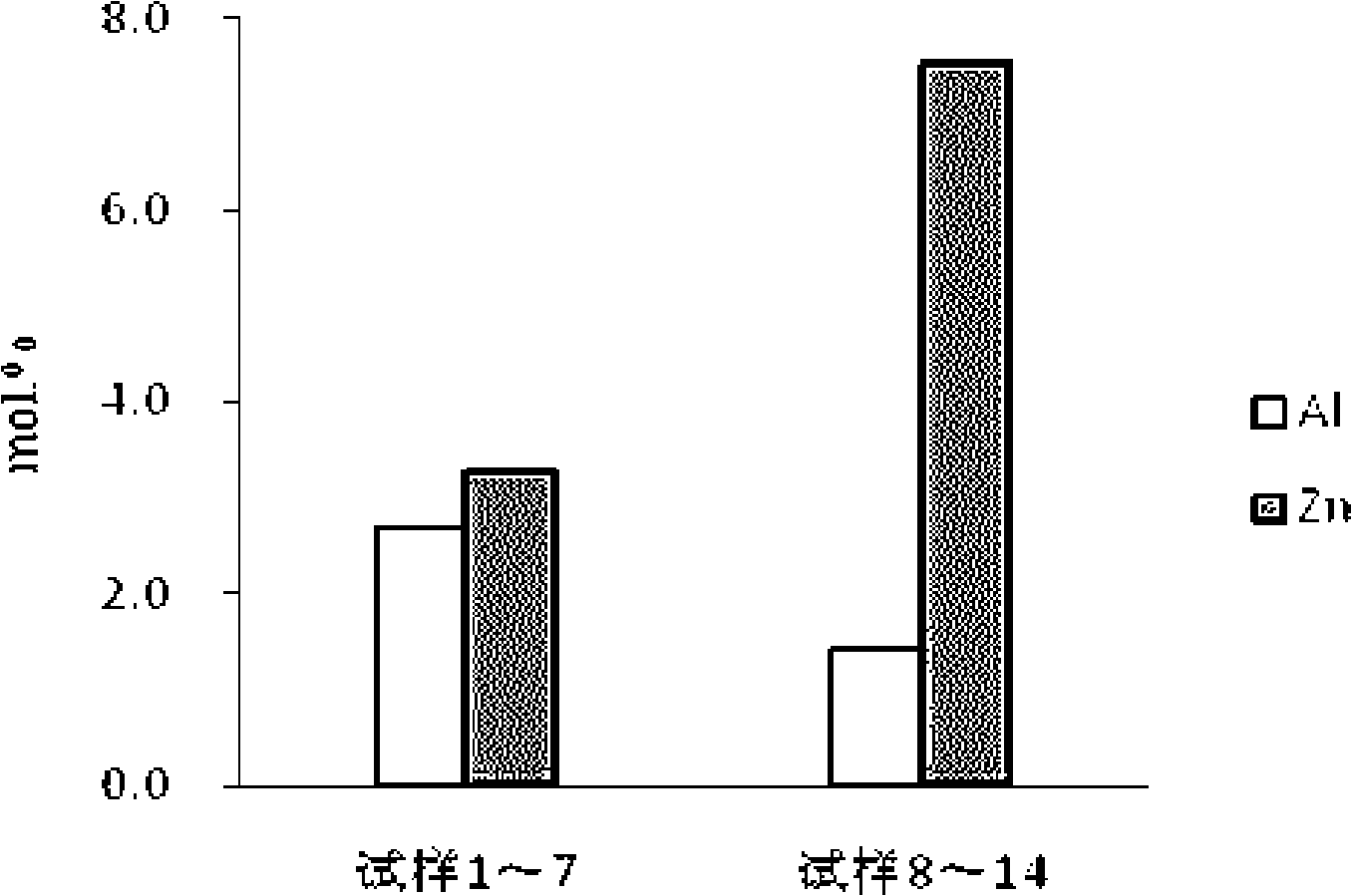

Galvanizing method of hot dip galvanizing steel plate

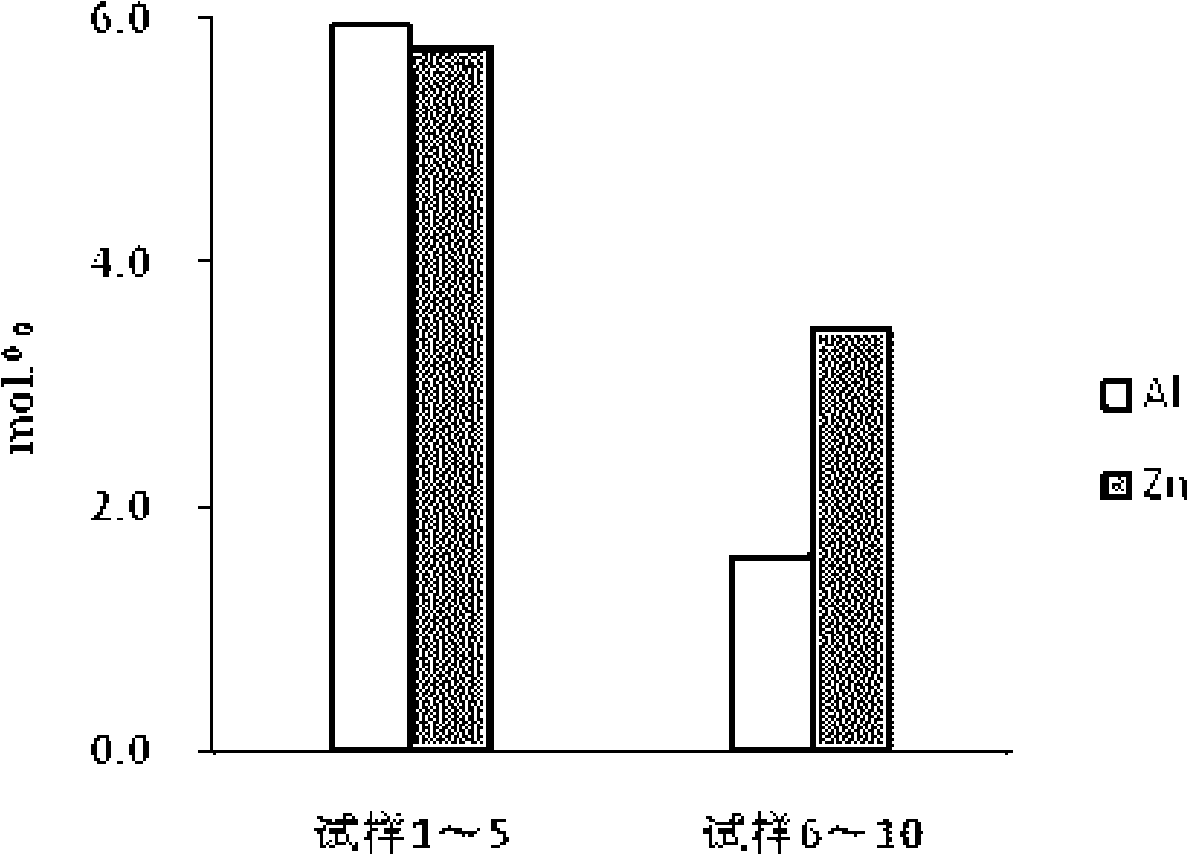

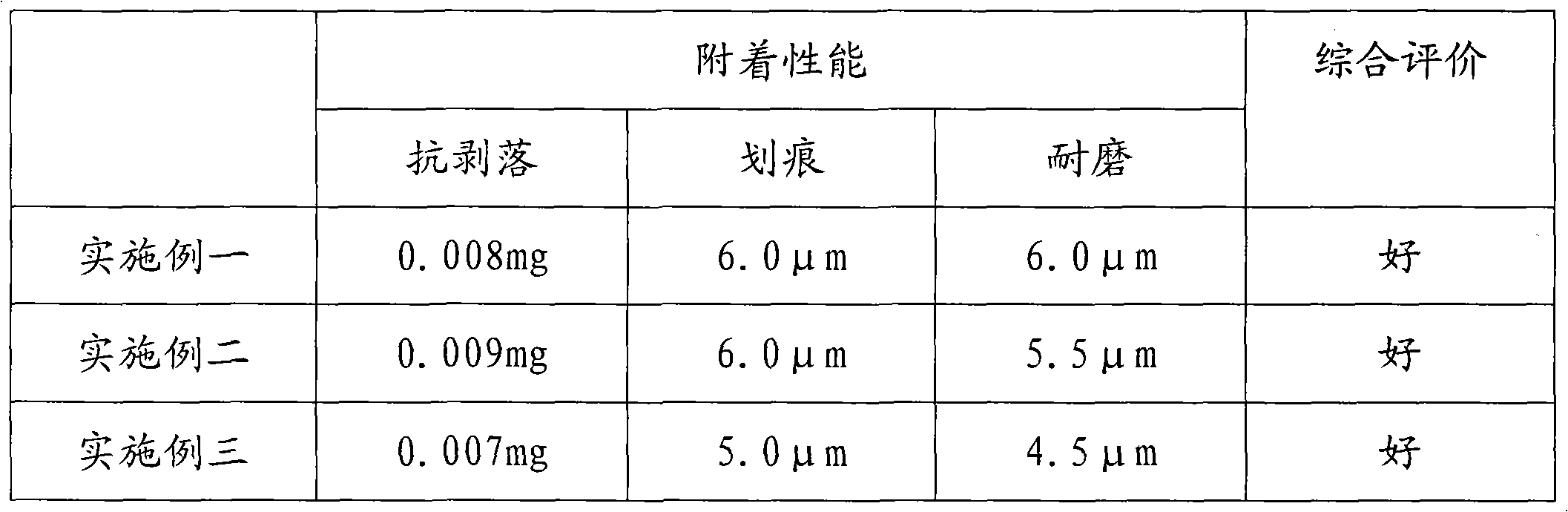

InactiveCN101323941AReduce formationGood adhesionHot-dipping/immersion processesSheet steelWear resistance

The invention pertains to the field of hot-dip galvanized steel sheet manufacturing; the technical problem to be solved is to provide a production method of a hot-dip galvanized steel sheet. The production method specifically comprises the steps that: a steel plate is pickled and annealed, and hot-dip galvanizing operation is carried out; during the operation, the temperature of starting to the plate is 455 to 465 DEG C; the plating temperature in the zinc pot is 450 to 460 DEG C; Fe content in plating bath is less than 0.03 percent; Al content in plating bath is 0.21 to 0.25 percent; the speed of machine unit is 100 to 110m / min; the cooling speed of the steel sheet is 0 percent; depth to span temperature is 235 to 245 DEG C. By adopting the technical conditions, the ratio Al / Zn of atomic concentration of Al and Zn in Fe-Al intermediate layer is larger than 0.9; and the circumstances that Gamma phase and Delta phase are relatively thin and Xi phase is small can not be formed in plating layer, and the most part of the plating layer is made up of Eta phase, and the crystal grain Zn (002) with optimized orientation is formed, thus causing the performance of attachment, scratch resistance, wear resistance to be greatly improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

A continuous hot-dip galvanizing process for strip steel

The invention discloses a continuous hot dip galvanizing process for strip steel. Based on a large number of experiments, the components of plating coat melting liquid are determined and are as follows in parts by weight: 90-92 parts of zinc ingot, 5-8 parts of aluminium ingot, 3-5 parts of pure iron, 0.8-1.2 parts of copper ingot and 0.3-0.8 part of magnesium ingot. Advantageous combination is realized through optimizing hot galvanizing process conditions and parameters, a majority of plating coats of the hot dip galvanizing strip steel is comprised by eta, plating coat grain orientation is optimized, and the scratch resistance, the abrasion resistance and the adhesion property of the plating layer are obviously improved.

Owner:WUXI GUANGRUN METAL PROD CO LTD

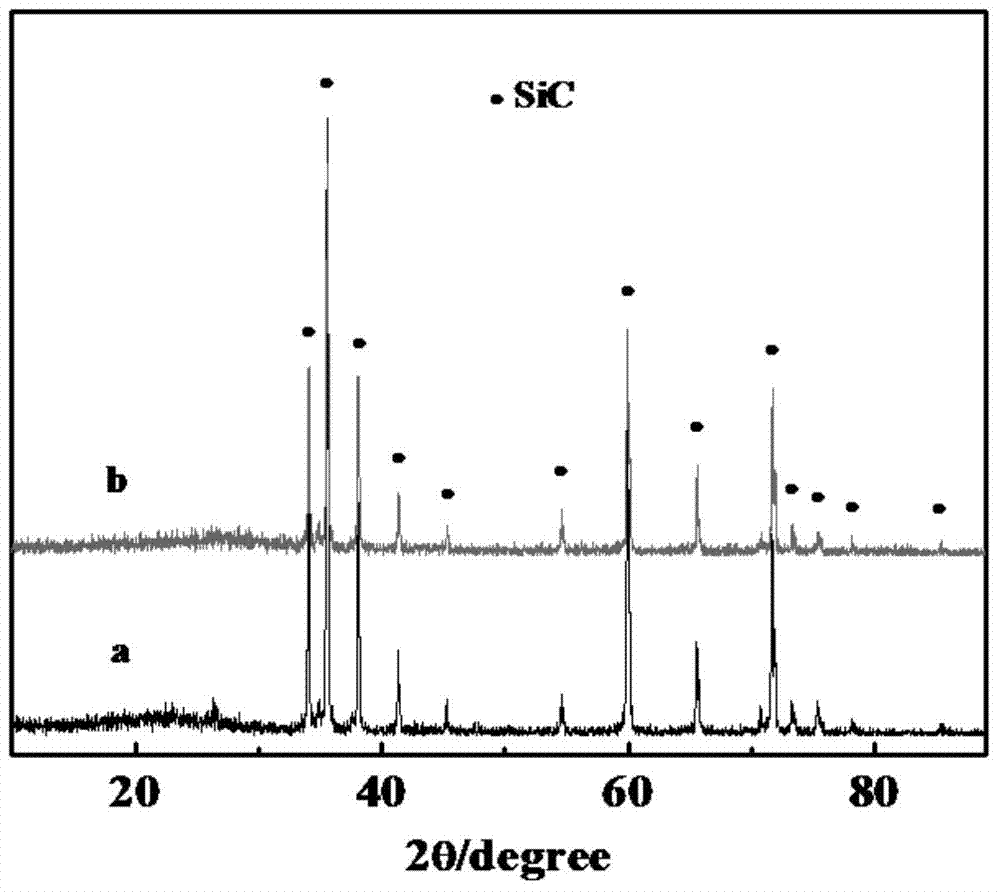

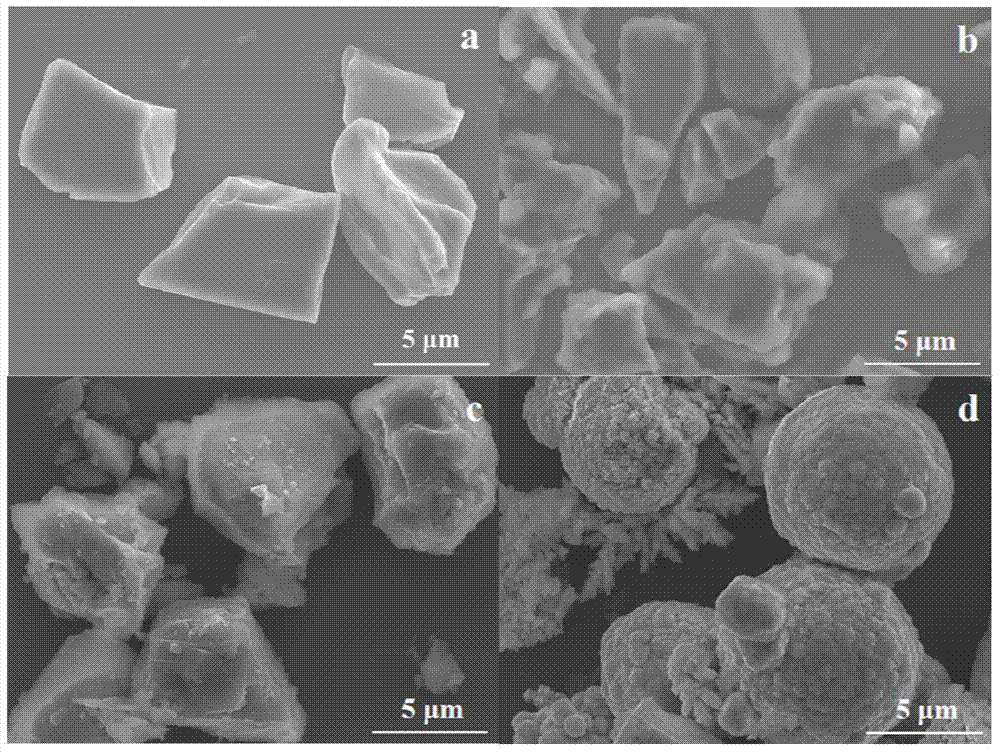

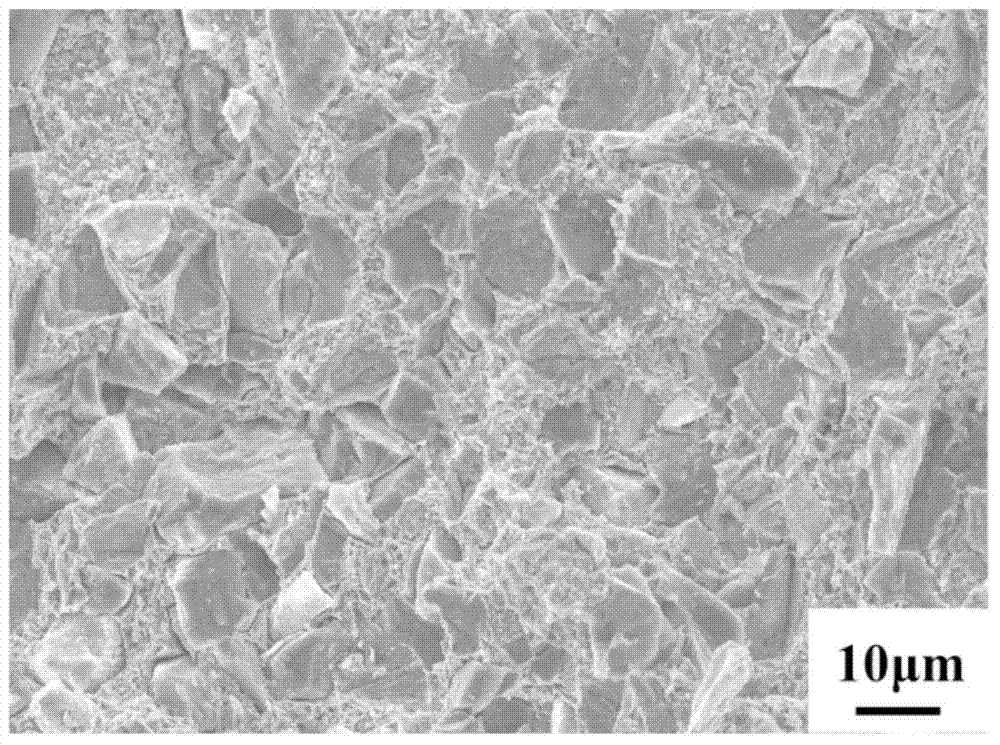

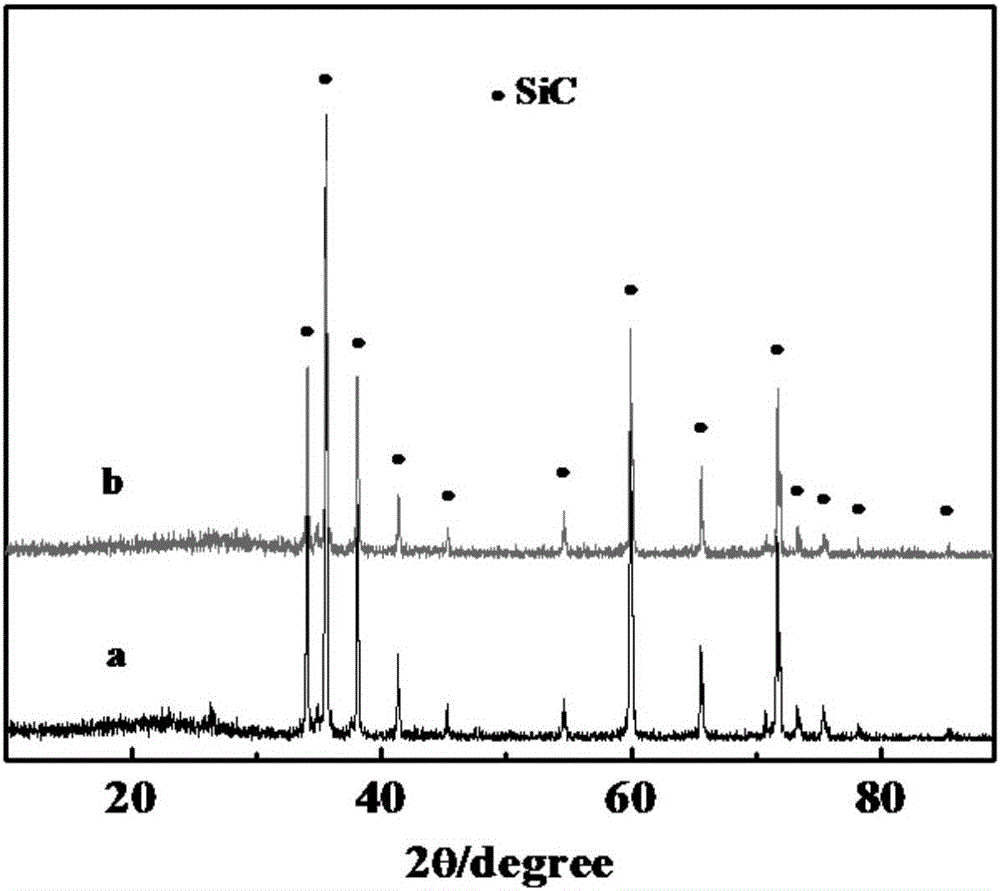

Low temperature glass phase enhanced SiCp/Cu composite material and preparation method thereof

ActiveCN104294071AImprove mechanical propertiesAvoid direct surface contactMaterials preparationMetal matrix composite

The invention discloses a low temperature glass phase enhanced SiCp / Cu composite material and a preparation method thereof, and belongs to the technical field of ceramic enhanced metal-based composite material preparation. SiC particles coated by a glass phase are dispersed in Cu matrix of the SiCp / Cu composite material; and the glass phase comprises SiO2 and K2O, wherein a molar ratio of SiO2 to K2O is 2-6 and a volume ratio of SiC to SiO2 and Cu in the glass phase is 1:(0.2-1.2):(2-4). On one hand, the low temperature glass phase has good interface wettability with the SiC particles in melting, a certain amount of Cu2O is formed on the Cu-based particle surfaces during a sintering process of the composite material, and Cu2O participates in formation of interface glass phase, so that the Cu matrix has good adhesion with the glass phase. On the other hand, the introduction of the interface glass phase can prevent direct surface contact of a plurality of SiC particles in aggregation and prevent mutual diffusion of reactant atoms in an interface solid-phase reaction, thereby effectively inhibiting formation of interface solid-phase reaction products and enabling the composite material to gain excellent comprehensive mechanical properties.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

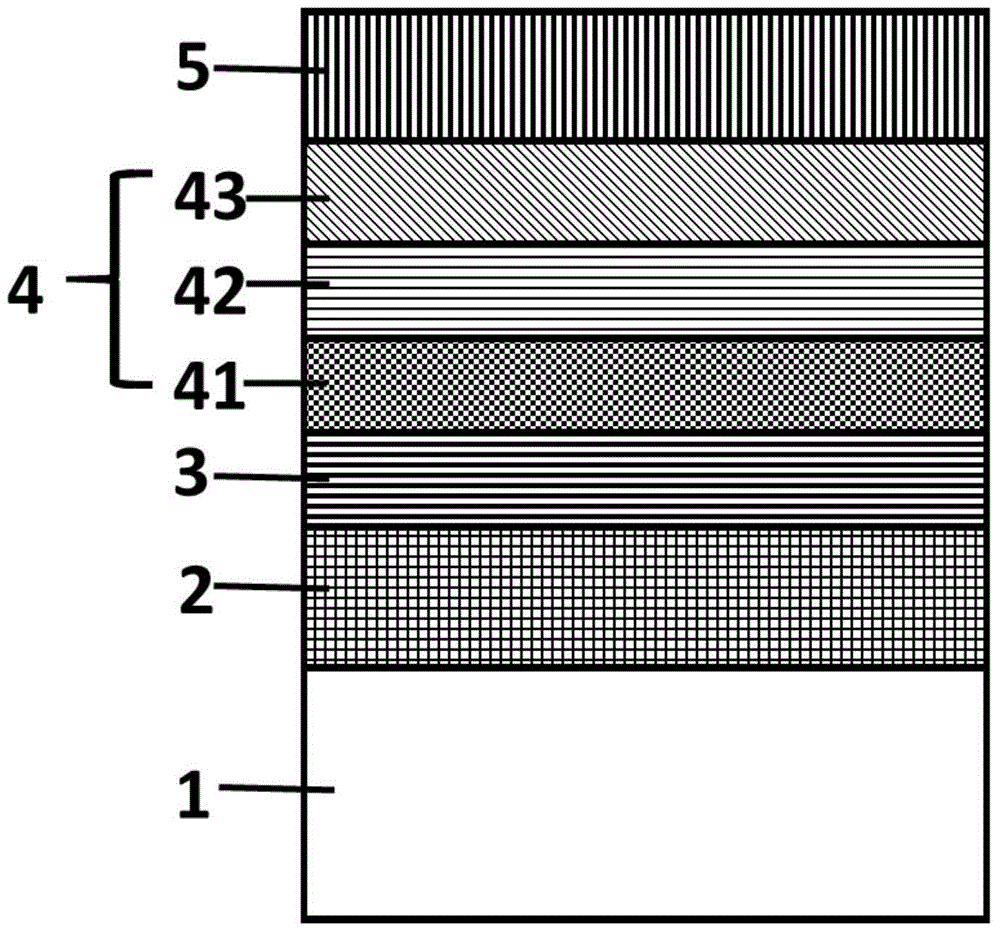

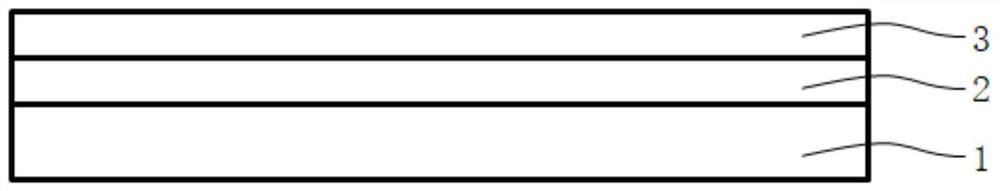

Solar selective absorbing coating and preparation method thereof

ActiveCN105091377AImprove thermal stabilityImprove absorption rateSolar heat devicesVacuum evaporation coatingRadianceThermal stability

The invention provides a solar selective absorbing coating. The solar selective absorbing coating is sequentially provided with a substrate, an infrared reflection layer, a transition layer, a composite absorbing layer and an antireflection layer from the bottom layer to the surface. Besides, the transition layer is arranged to be made of one or more of CrNx, yCrN*(1-y)Cr2O3, ySi3N4*(1-y)SiO2, yAlN*(1-y)Al2O3 and yTi3N4*(1-y)TiO2, wherein x is larger than 1 and smaller than 1.5, and y is larger than 0 and smaller than 1. Thus, the coating can effectively prevent mutual diffusion between the infrared reflection layer and the absorbing layer, and mutual diffusion among the infrared reflection layer, a diffusion impervious layer and the absorbing layer in the solar selective absorbing coating comprising the diffusion impervious layer The thermal stability of the solar selective absorbing coating is improved, so that the solar selective absorbing coating still has high solar spectral absorptivity and low infrared radiance under the atmospheric condition of 400 DEG C. The solar selective absorbing coating has the good thermal stability and excellent spectral selectivity.

Owner:CHINA BUILDING MATERIALS ACAD

Production method of hot dip galvanizing steel plate

The invention pertains to the field of hot-dip galvanized steel sheet manufacturing; the technical problem to be solved is to provide a production method of a hot-dip galvanized steel sheet. The production method specifically comprises the steps that: the steel plate is pickled and annealed, and hot-dip galvanizing operation is carried out; during the operation, the temperature of starting to plate is 475 to 485 DEG C; the plating temperature in the zinc pot is 450 to 460 DEG C; Fe content in plating bath is less than 0.03 percent; Al content in plating bath is 0.16 to 0.18 percent; the speed of machine unit is 100 to 110m / min; the cooling speed of the steel sheet is 0 percent; depth to span temperature is 235 to 245 DEG C. By adopting the technical conditions, the ratio Al / Zn of atomic concentration of Al and Zn in Fe-Al intermediate layer is larger than 0.9; and the circumstances that Gamma phase and Delta phase are relatively thin and Xi phase is small can not be formed in a plating layer, and the most part of the plating layer is made up of Eta phase, and the crystal grain Zn (002) with optimized orientation is formed, thus causing the performance of attachment, scratch resistance, wear resistance to be greatly improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

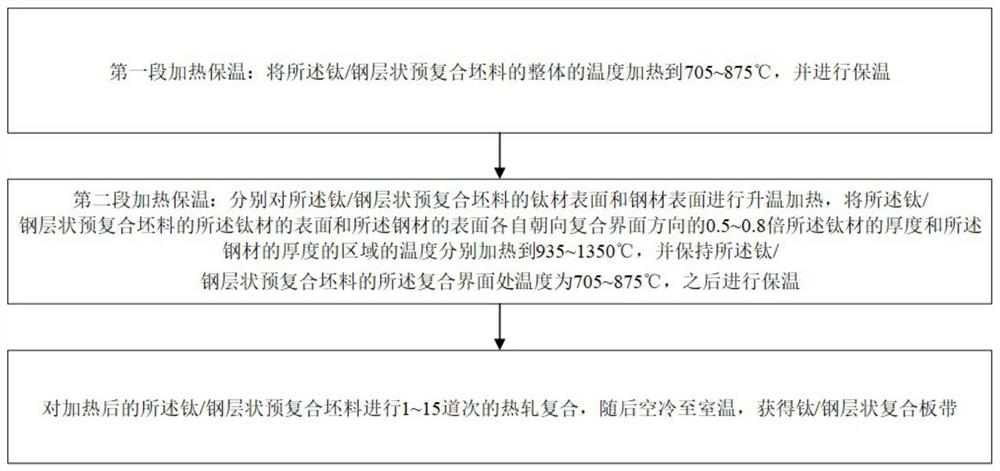

Preparation method of interface strong metallurgical bonding metal layered composite material

ActiveCN112108518AInterdiffusionSuppresses the formation of Fe-Ti phaseTemperature control deviceWork heating devicesTitaniumMaterials preparation

The invention discloses a preparation method of an interface strong metallurgical bonding metal layered composite material, and belongs to the technical field of metal layered composite material preparation. The method comprises the steps of heating to increase the temperature of a whole titanium / steel layered pre-composite blank to 705 to 875 DEG C, and conducting heat preservation; increasing temperature and heating the surface of a titanium material and the surface of a steel material of the titanium / steel layered pre-composite blank, respectively heating the areas, which are 0.5 to 0.8 time of the thickness of the titanium material and the thickness of the steel material, of the surface of the titanium material and the surface of the steel material towards the direction of a compositeinterface to 935 to 1350 DEG C, keeping the temperature of the composite interface at 705 to 875 DEG C, and then conducting heat preservation; and conducting 1 to 15 passes of hot rolling compoundingon the heated titanium / steel layered pre-composite blank, then conducting air cooling to the room temperature, and obtaining a titanium / steel layered composite plate strip. The method can be used forpreparing the titanium / steel layered composite plate strip with high interface bonding strength at low cost and high efficiency.

Owner:UNIV OF SCI & TECH BEIJING

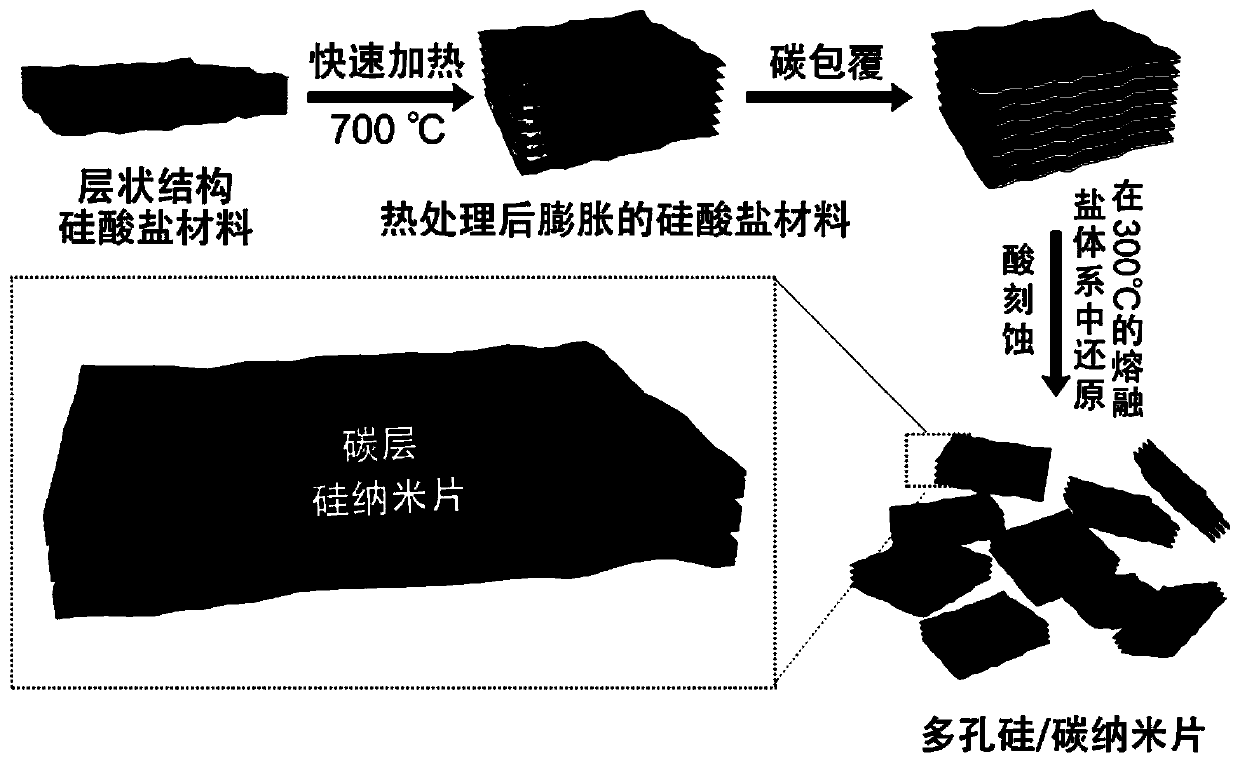

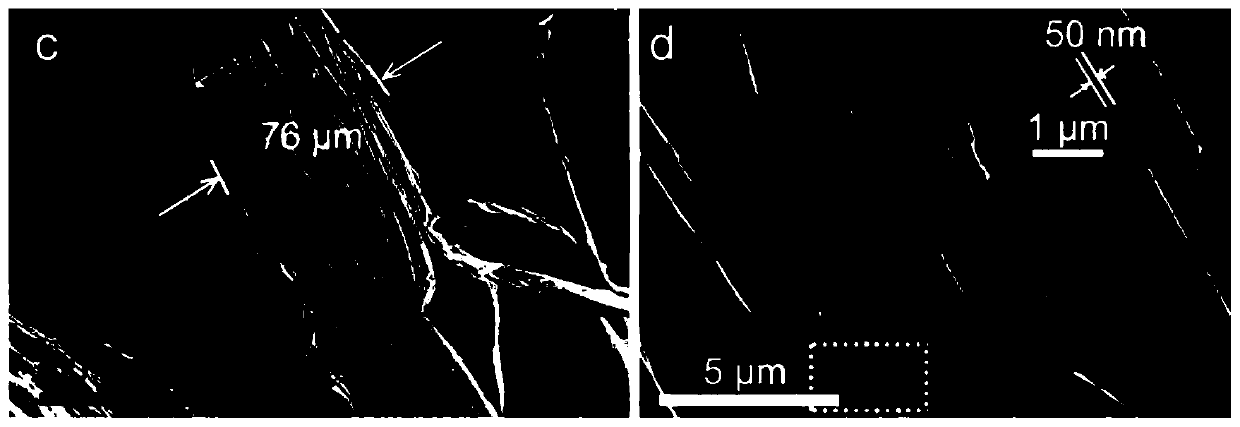

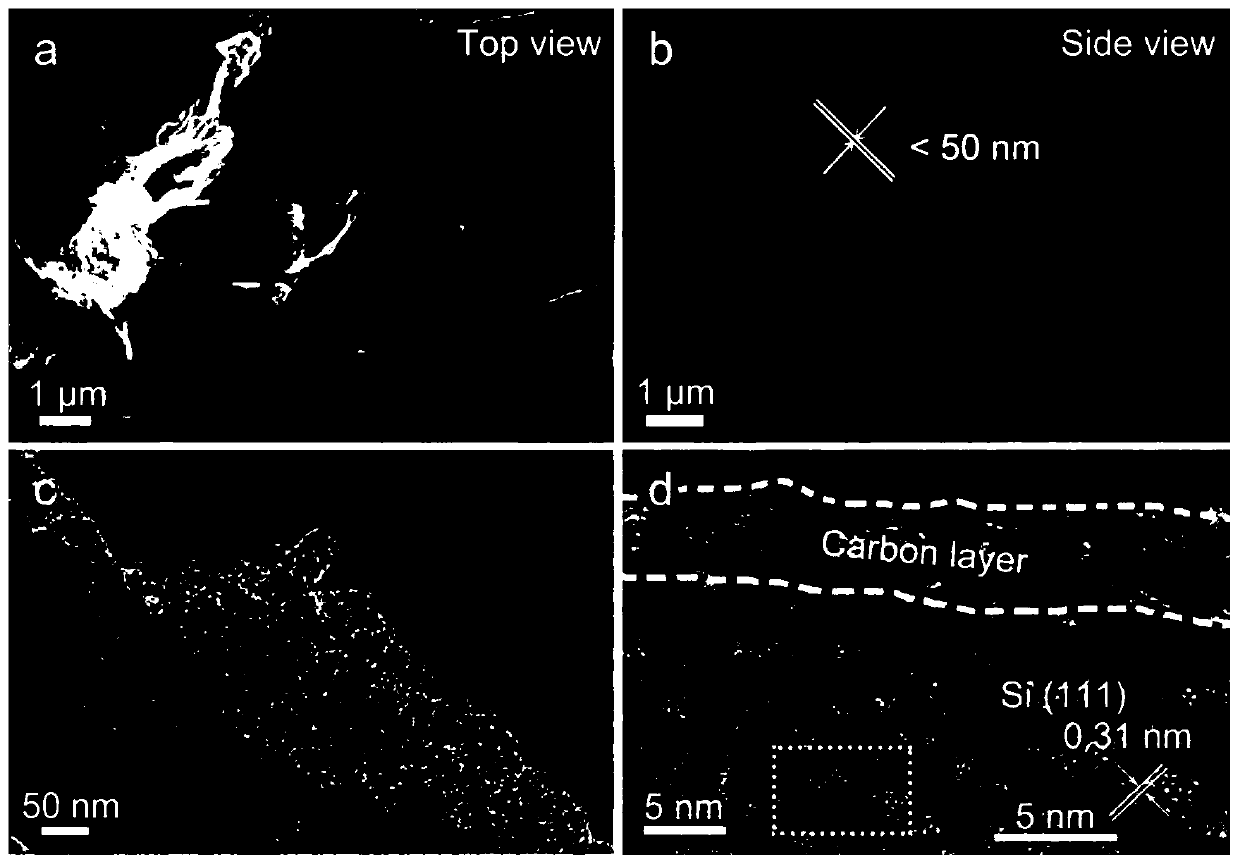

Silicon/carbon composite material and preparation method thereof and application of silicon/carbon composite material

The invention provides a silicon / carbon composite material and a preparation method thereof and application of a silicon / carbon composite material. The preparation method comprises the following stepsof: taking silicate with an aquifer-shaped structure as a silicon source; performing rapid heating treatment on the mixture in an inert atmosphere; uniformly coating a layer of nanocarbon on the surface of a silicon / carbon composite material by adopting a chemical vapor deposition method, reducing silicon oxide by a molten salt system after acid pickling and impurity removal, removing impuritiesby acid pickling, performing etching by hydrofluoric acid to remove molten salt and other oxides, and performing treating to obtain the silicon / carbon composite material. According to the composite material disclosed by the invention, holes between the layers and the internal portion of the composite material inhibit the volume expansion of silicon in a charging and discharging process and stabilizes the solid electrolyte interface film formed in the charging and discharging process, so that the rate capability and the cycle performance of the lithium ion battery are improved, the coating of the carbon layer is beneficial to improving the conductivity of the material, improving the charge transfer rate at the interface of the material and the electrolyte, inhibiting the polarization phenomenon in the cycle process and improving the electrochemical performance.

Owner:TONGJI UNIV +1

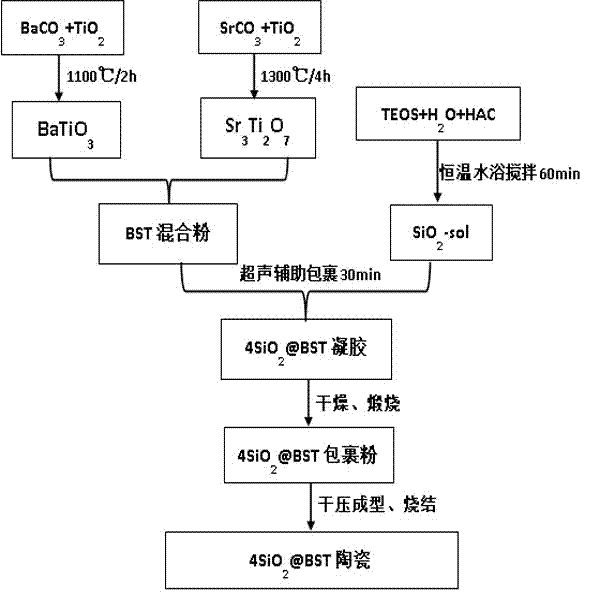

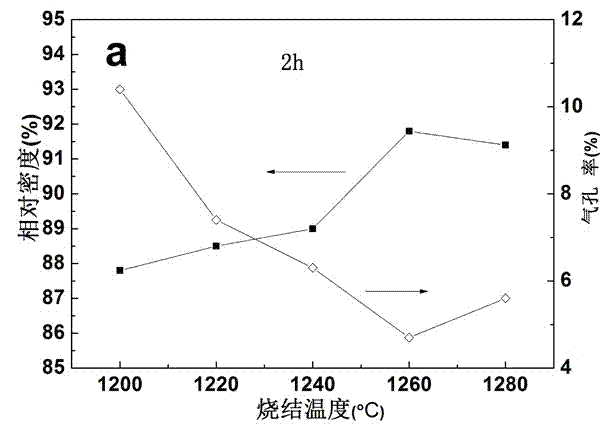

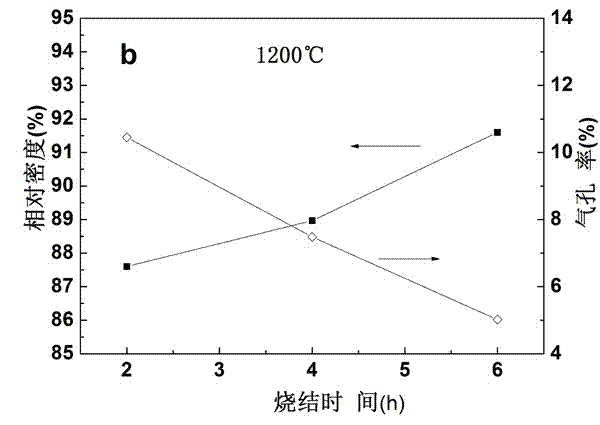

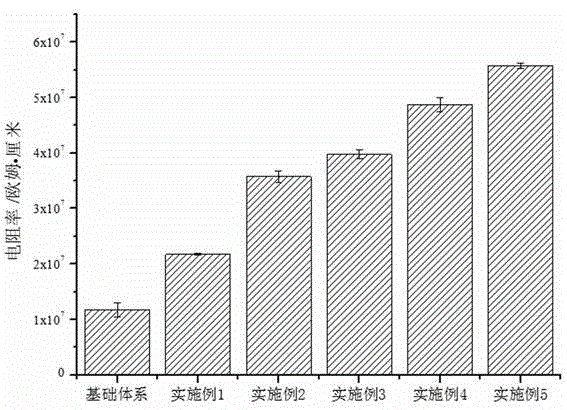

Preparation method of low-temperature sintering high-tunability barium strontium titanate ceramic

InactiveCN103922733AHigh tuning rateLower sintering temperatureStrontium titanateBarium strontium titanate

The invention relates to a preparation method of low-temperature sintering high-tunability barium strontium titanate ceramic. The preparation method comprises the following steps: synthesizing BaTiO3 powder and Sr3Ti2O7 powder through a solid phase reaction method by adopting BaCO3, TiO2 and SrCO3 as raw materials, and then mixing and carrying out ball milling on BaTiO3 powder and Sr3Ti2O7 powder in weight ratio of 80:20 to prepare an even mixed material; stirring tetraethoxysilane, glacial acetic acid and deionized water through thermostatic water bath to prepare SiO2 sol; then pouring the ball-milled mixed material into the SiO2 sol and ultrasonically stirring at normal temperature for 30 minutes, then drying the product in a constant temperature oven at a temperature of 120 DEG C, and roasting at a temperature of 800 DEG C for 2 hours to acquire mixed powder of 80wt% of BaTiO3 and 20wt% of Sr3Ti2O7 wrapped by a SiO2 layer; finally, preparing biscuit by dry-pressing molding, and sintering for 2-6 hours at a temperature of 1200-1800 DEG C. The material prepared through the method is suitable for the field of microwave tuning and has the advantages of high tunability, high temperature stability, proper dielectric constant and low dielectric loss.

Owner:SHANGHAI UNIV

Rare earth-doped BaTiO3 nanotube array photocatalyst and preparation method thereof

ActiveCN106390982APrevent collapseAvoid breakingMetal/metal-oxides/metal-hydroxide catalystsMischmetalBarium titanate

The invention discloses a rare earth-doped BaTiO3 nanotube array photocatalyst and a preparation method thereof. According to the method, a rare earth-doped BaTiO3 nanotube array is prepared from two-way porous anodic alumina as a template and silver nitrate as a Ti(OC4H9)4 stabilizer. The barium titanate nanotube array structure broadens the diffusion path of a charge carrier and reduces photo-generated electron and hole recombination. Through compounding of rare earth metal and barium titanate, the rare earth-doped BaTiO3 nanotube array heterogeneous photocatalytic material is constructed and the separation efficiency of photo-generated electrons and holes is improved.

Owner:CHANGZHOU UNIV

Method for rolling nickel interlayer titanium steel composite board through large rolling reduction

The invention relates to the field of titanium steel composite board preparation and machining, in particular to a method for rolling a nickel interlayer titanium steel composite board through the large rolling reduction. According to the technical scheme, the method includes the following steps that symmetric assembling is conducted according to the steel plate / titanium plate / nickel foil / steel plate sequence, the periphery of a blank is welded, the interior of the blank is vacuumized, and then a combined blank is acquired; the combined blank is heated for 120 min to 360 min, wherein the heating temperature ranges from 940 DEG C to 1000 DEG C; the heated combined blank is rolled, and then the titanium steel composite board is obtained. The titanium steel composite board obtained through the method is good in plate cut, no significant defect is formed on the surface, no titanium / iron compound is generated on a bonding interface, the bonding effect is good, and the bonding strength is larger than 230 MPa and is far larger than that of similar titanium steel composite board in the national standard.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Method for making hot dip galvanizing steel plate

InactiveCN101323943AReduce formationReduce sheddingHot-dipping/immersion processesSheet steelWear resistance

The invention pertains to the field of hot-dip galvanized steel sheet manufacturing; the technical problem to be solved is to provide a production method of a hot-dip galvanized steel sheet. The production method specifically comprises the steps that: the steel plate is pickled and annealed, and hot-dip galvanizing operation is carried out; during the operation, the temperature of starting to plate is 455 to 465 DEG C; the plating temperature in the zinc pot is 450 to 460 DEG C; Fe content in plating bath is less than 0.03 percent; Al content in plating bath is 0.16 to 0.18 percent; the speed of machine unit is 100 to 110m / min; the cooling speed of steel sheet is 0 percent; depth to span temperature in cooling section is 210 to 220 DEG C. By adopting the technical conditions, the ratio Al / Zn of atomic concentration of Al and Zn in Fe-Al intermediate layer is larger than 0.75; and the circumstances that Gamma phase and Delta phase are relatively thin and Xi phase is small can not be formed in a plating layer, and the most part of the plating layer is made up of Eta phase, and the crystal grain Zn (002) with optimized orientation is formed, thus causing the performance of attachment, scratch resistance, wear resistance to be greatly improved.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

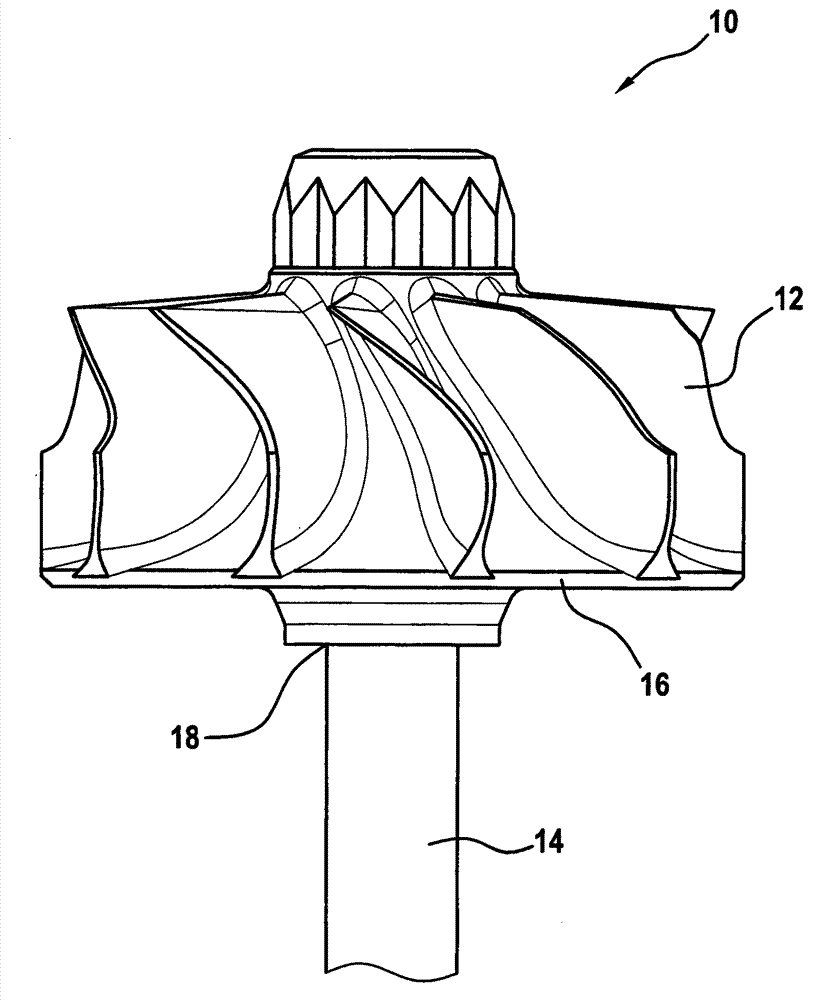

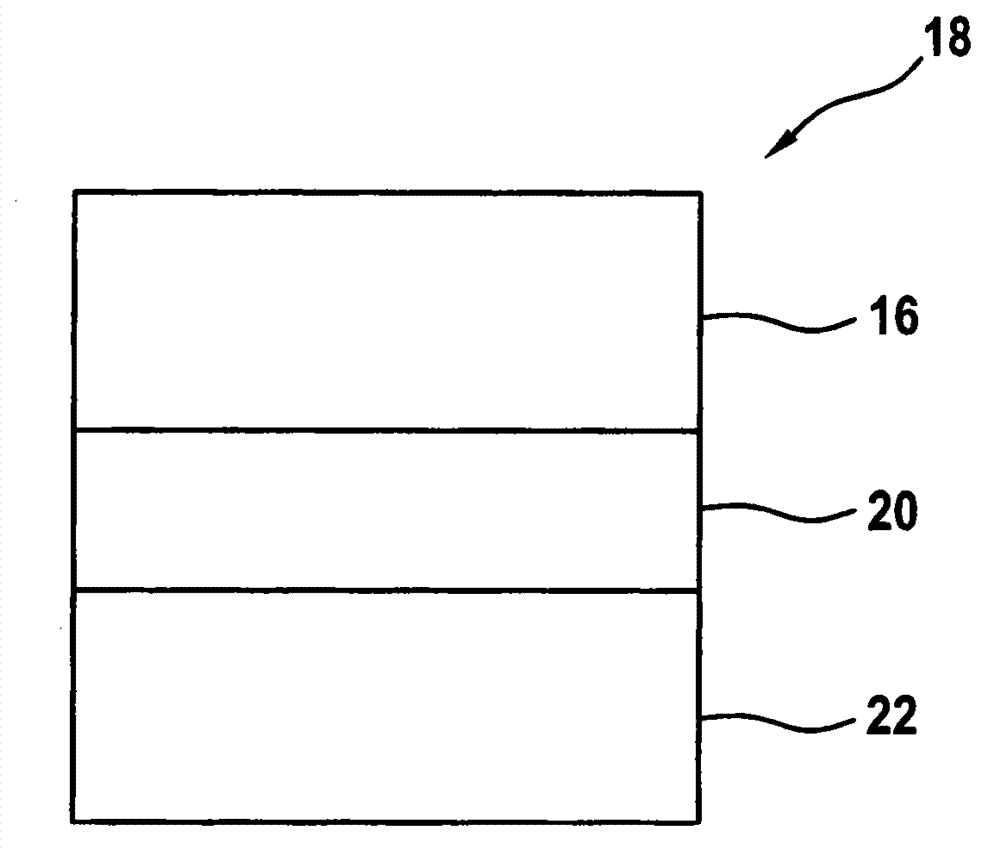

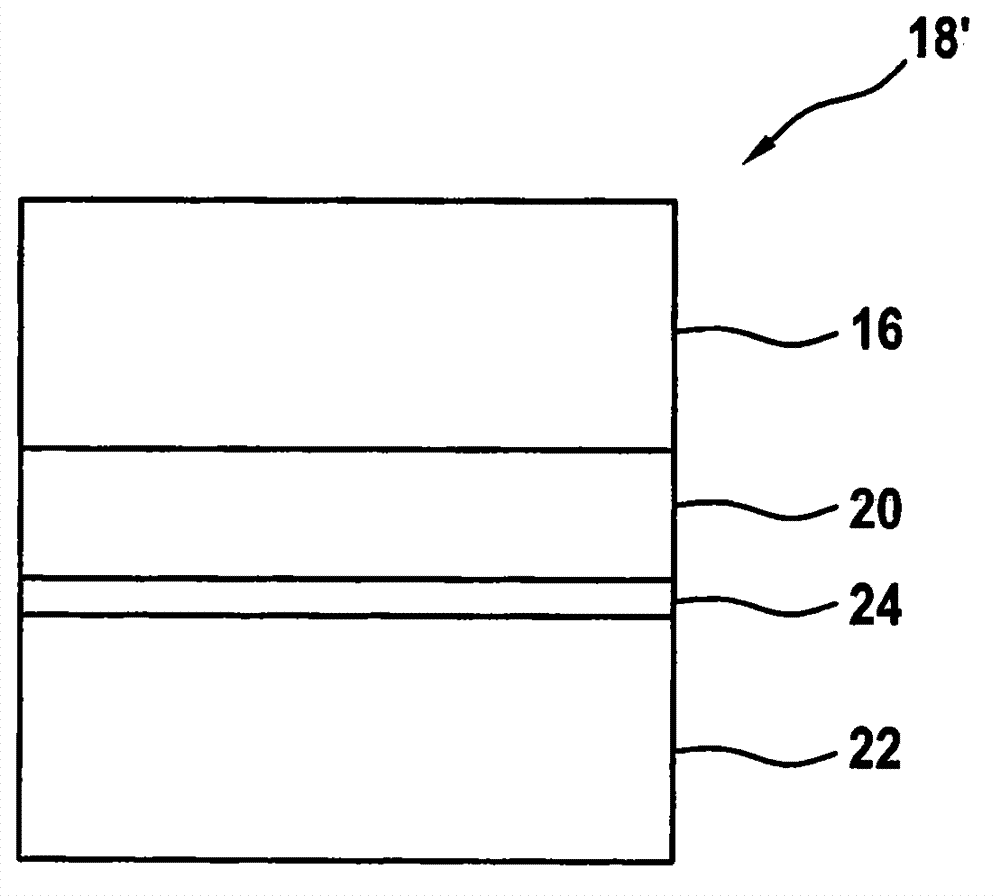

Method For Producing Rotor Wheel And Rotor

ActiveCN104722916ALow densityHigh specific strengthBlade accessoriesMachines/enginesThermal treatmentAlloy

A method for producing a component, in particular a rotor wheel, includes positioning a main body, a fusion-weldable attachment layer, and a barrier layer. The main body has a first alloy in an attachment region. The fusion-weldable attachment layer is positioned in the attachment region of the main body and has a second alloy which differs from the first alloy. The barrier layer is positioned between the main body and the fusion-weldable attachment layer. The barrier layer is configured to prevent a reaction of the first alloy of the main body with the second alloy of the fusion-weldable attachment layer during a thermal treatment. The method further includes heating the main body, the barrier layer, and the fusion-weldable attachment layer to connect the main body, the barrier layer, and the fusion-weldable attachment layer to one another.

Owner:ROBERT BOSCH GMBH

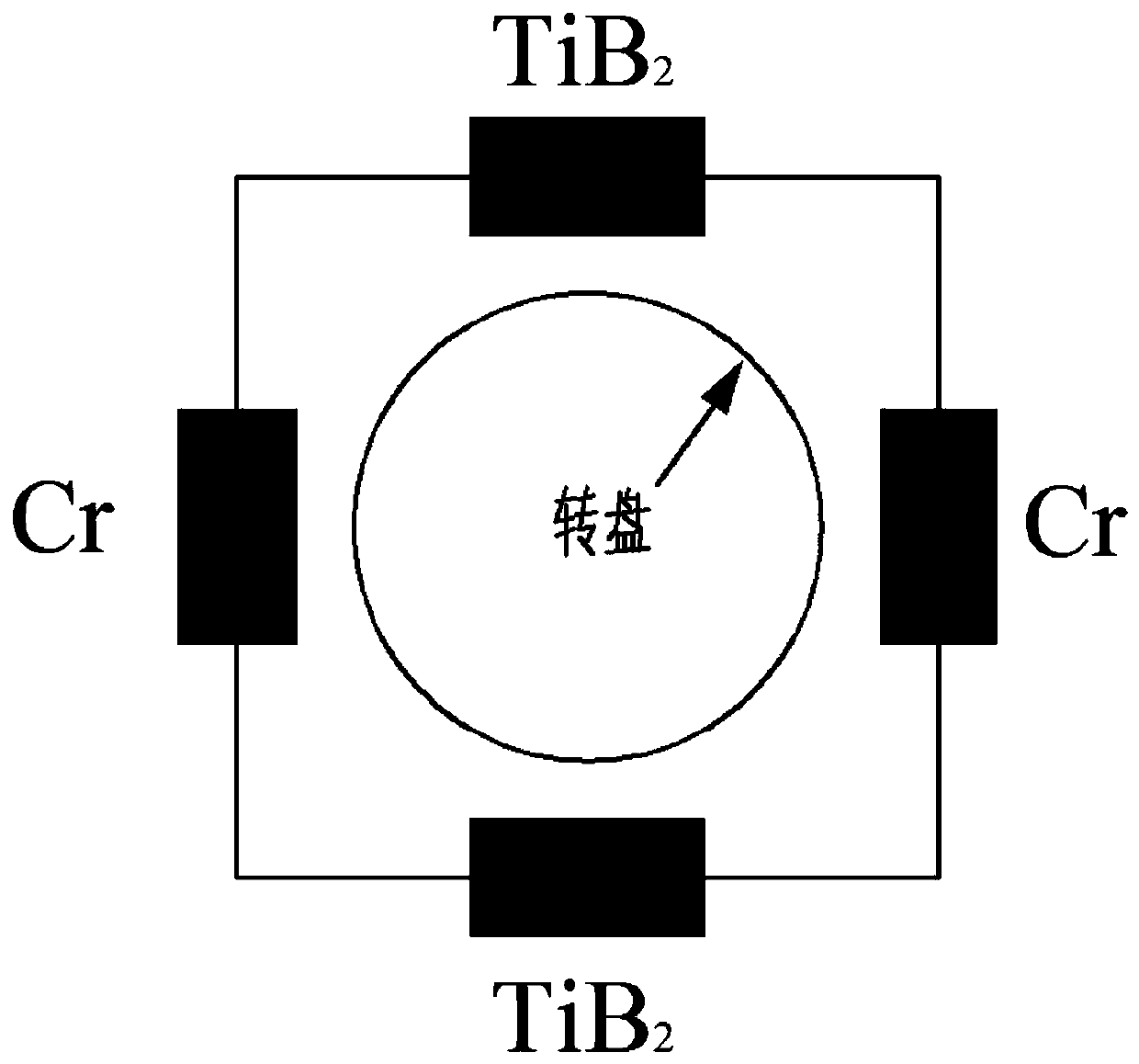

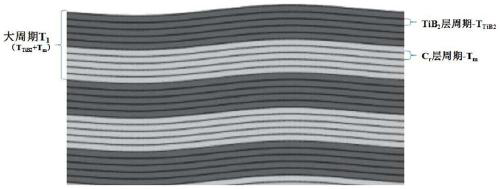

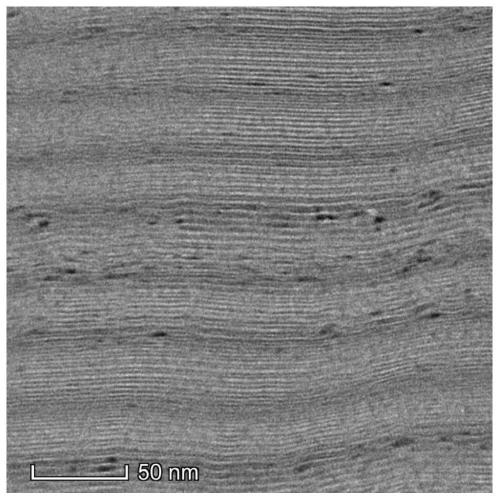

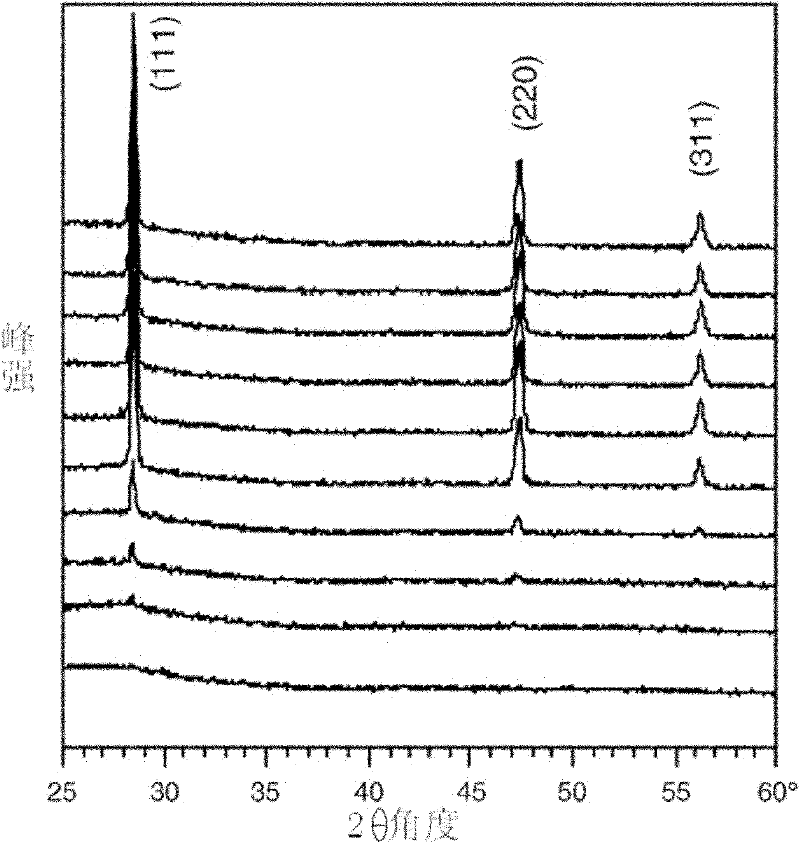

TiB2-based coating with multicycle structure and preparation method and application thereof

ActiveCN110042343AImprove high temperature oxidation resistancePrevent mobilityVacuum evaporation coatingSputtering coatingHardnessHigh intensity

The invention belongs to the technical field of surface protection, and discloses a TiB2-based coating with a multicycle structure and a preparation method thereof. The TiB2-based coating is formed bysputtering deposition on a substrate by taking a TiB2 target and a metal target as raw materials and adopting magnetron sputtering coating; and the TiB2-based coating is of a multicycle structure inwhich a TiB2 layer and an elemental metal layer are overlapped with each other, the adjacent TiB2 layer and the elemental metal layer are in a large period, meanwhile, periodic structures exist in theTiB2 layer and the elemental metal layer respectively, the period in the TiB2 layer is formed by alternately overlapping a TiB2-rich layer and a TiB2-poor layer, and the period in the elemental metallayer is formed by alternately overlapping a metal-rich layer and a metal-poor layer. The coating not only reduces the residual stress, but also integrates the characteristics of high hardness, highstrength, high high-temperature oxidation resistance and good bonding force of the single-layer TiB2, and is used for protecting the surfaces of products such as mechanical parts and knife molds.

Owner:GUANGDONG UNIV OF TECH

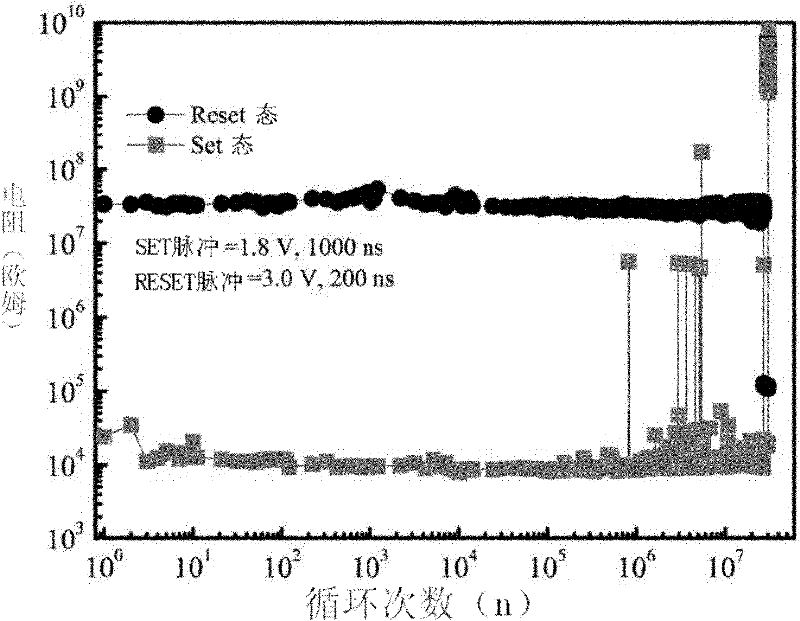

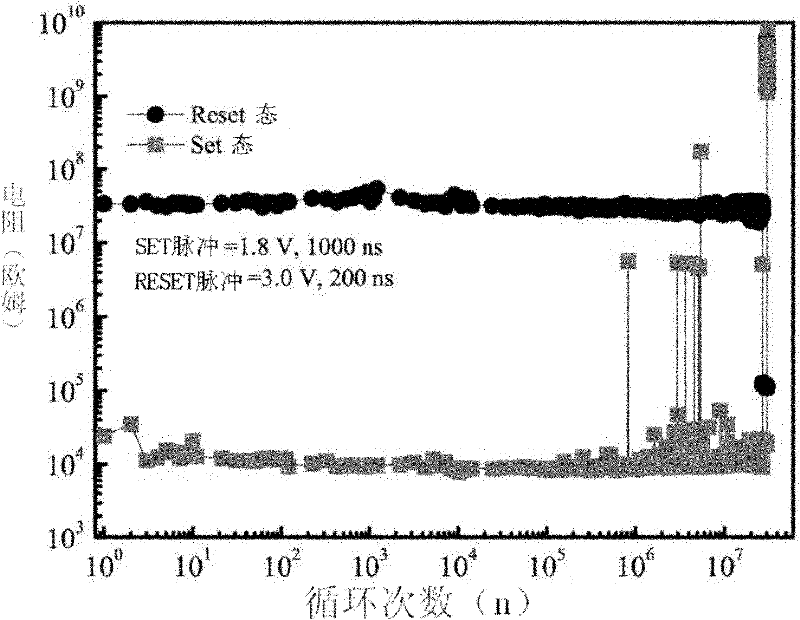

Microcrystalline Si-SbxTe1-x composite phase change material and preparation method thereof

ActiveCN102534479ADoes not affect phase transition propertiesImprove thermal stabilityElectrical apparatusVacuum evaporation coatingPhase-change memoryPower flow

The invention discloses a microcrystalline Si-SbxTe1-x composite phase change material and a preparation method thereof. The composite phase change material is formed by composition of microcrystalline-state Si and a phase change material SbxTe1-x, wherein x is not less than 0.1 and not more than 0.9. The preparation method comprises the steps of forming an amorphous Si-SbxTe1-x material by PVD (physical vapor deposition), then annealing in a hydrogen atmosphere to form the microcrystalline Si-SbxTe1-x composite phase change material, and finally heating and dehydrogenating to complete the preparation of the material. In the microcrystalline Si-SbxTe1-x composite phase change material disclosed by the invention, the existence of the microcrystalline Si can effectively inhibit oxidation, so that mutual diffusion of the Si and the SbxTe1-x can be hindered, and the microcrystalline Si-SbxTe1-x composite phase change material is more stable. Simultaneously, the microcrystalline-state Si can change the current distribution in phase change so as to be conductive to reducing power consumption, prolonging service life and improving operation stability of a phase change memory.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Galvanization method for steel plate

InactiveCN105296906AGrain Orientation OptimizationImprove scratch resistanceHot-dipping/immersion processesSheet steelAlloy

The invention discloses a galvanization method for a steel plate and belongs to the field of steel plate galvanization technology. The steel plate is subjected to hot galvanization operation after being subjected to acid pickling and annealing. The galvanization method is characterized in that during the process of the hot galvanization operation, the steel plate is at the temperature of 480 DEG C when being put into a plating bath, and the temperature of the plating bath in a zinc pot is 450 DEG C-460 DEG C; the content of Fe in the plating bath is smaller than 0.03%, and the content of Al in the plating bath is 0.26%; the speed of a machine set is 100-110 m / min, the cooling rate of the steel plate is 0-2%, and the high-span temperature is 246 DEG C-258 DEG C. According to the hot galvanization technological conditions of the galvanization method, interdiffusion between the Fe and Zn can be prevented by an Fe-Al intermediate transition layer between a substrate of the steel plate and a galvanization layer, so that formation of an Fe-Zn alloy layer is reduced, and the adhesiveness of a plating layer of the hot-galvanized steel plate is improved, and accordingly falling-off and stripping of zinc powder of the plating layer and other phenomena are reduced. Through the hot galvanization technological conditions of the galvanization method, the grain orientation of the plating layer of the hot-galvanized steel plate is optimized, and the scratch resistance, the abrasion resistance and the adhesiveness of the plating layer are significantly improved.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Ce and La codoped modified sealing-in microcrystalline glass

ActiveCN104876445AEnhanced network structureImprove insulation performanceHigh concentrationNetwork structure

The invention discloses Ce and La codoped modified sealing-in microcrystalline glass, which comprises the following ingredients through being metered by mole percentage: 0 to 10 percent of B2O3, 0 to 10 percent of Al2O3, 30 to 40 percent of SiO2, 20 to 40 percent of MO (one or several materials from MgO, CaO, SrO and BaO) and 15 to 40 percent of RO (CeO2 and La2O3). Through the design of invert glass, the sealing-in glass (greater than 15 mole percent) with high concentration Ce and La is obtained. Through the cooperated effect of the Ce and the La, the network structure of the glass can be obviously enhanced, and the insulation performance and the high-temperature chemical stability are effectively improved. The Ce and La codoped modified sealing-in microcrystalline glass has the advantages that preparing raw materials are simple and can be easily obtained, the process is stable, the cost is low, the process is simple and feasible, and the practical and industrialized conditions are reached.

Owner:FUZHOU UNIV

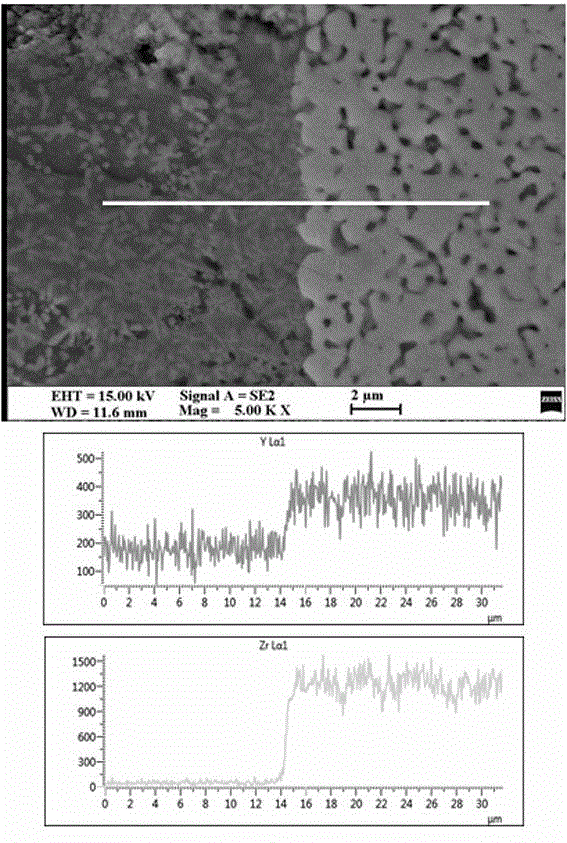

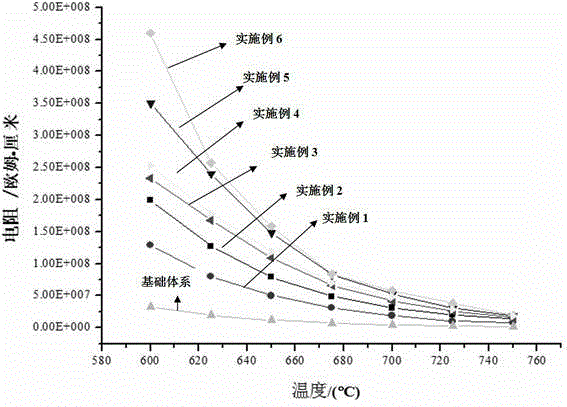

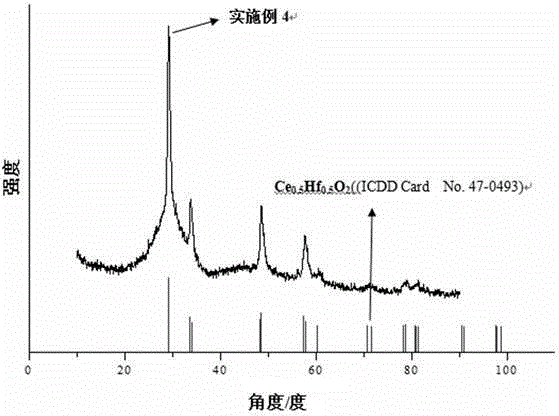

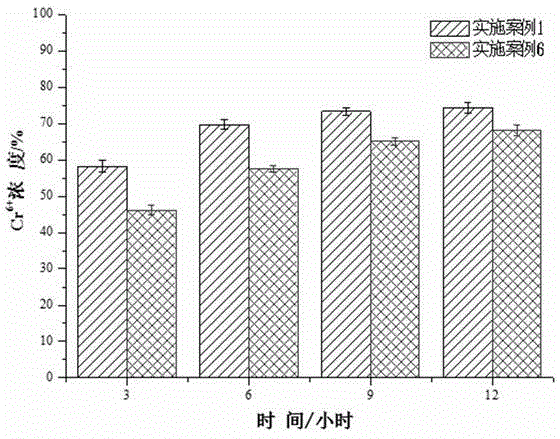

Ce and Hf co-doped modified sealing glass-ceramic

InactiveCN104926132AImprove high temperature insulationPromote oxidationMetallurgyChemical stability

The invention discloses a Ce and Hf co-doped modified sealing glass-ceramic. The Ce and Hf co-doped modified sealing glass-ceramic comprises the following raw materials in mole percentage by weight: 0-10% of B2O3, 0-10% of Al2O3, 25-40% of SiO2, 30-50% of MO ( one or more of MgO, CaO, SrO and BaO), and 5-30% of RO2 (CeO2 and HfO2). Through the co-doping of the CeO2 and HfO2, the generation of high-impedance-phase Ce0.5Hf0.5O2 is promoted, and the high temperature insulativity and the high temperature chemical stability of the sealing glass-ceramic are obviously improved. The preparation raw materials of the Ce and Hf co-doped modified sealing glass-ceramic are simple and easy to obtain, the process is stable, simple and feasible, the cost is low, and practical and industrial conditions can be met.

Owner:FUZHOU UNIV

Tunnel magnetoresistor and manufacturing method thereof

PendingCN112768603AImprove temperature stabilityAvoid driftingMagnetic-field-controlled resistorsGalvano-magnetic material selectionElectrical resistance and conductanceMagnetization curve

The invention provides a tunnel magnetoresistor and a manufacturing method thereof. The tunnel magnetoresistor comprises a first pinning layer, a free layer arranged opposite to the first pinning layer, a tunneling barrier layer located between the first pinning layer and the free layer, and a second pinning layer positioned on one side, back to the tunneling barrier layer, of the free layer. The second pinning layer can provide a weak exchange bias field for the free layer, and after an external environment temperature or an external magnetic field is removed, the exchange bias field can pin the free layer in the direction of an initial state. Therefore, the problem that a magnetization curve drifts due to a fact that the initial state of the tunnel magnetoresistor vortex magnetization is unstable and the external environment changes easily is solved, and the effects of stabilizing the free layer and improving the temperature stability of the free layer are achieved.

Owner:蚌埠希磁科技有限公司

A kind of SICP/CU composite material reinforced by low temperature glass phase and preparation method thereof

ActiveCN104294071BImprove mechanical propertiesAvoid direct surface contactMaterials preparationMetal matrix composite

The invention discloses a low temperature glass phase enhanced SiCp / Cu composite material and a preparation method thereof, and belongs to the technical field of ceramic enhanced metal-based composite material preparation. SiC particles coated by a glass phase are dispersed in Cu matrix of the SiCp / Cu composite material; and the glass phase comprises SiO2 and K2O, wherein a molar ratio of SiO2 to K2O is 2-6 and a volume ratio of SiC to SiO2 and Cu in the glass phase is 1:(0.2-1.2):(2-4). On one hand, the low temperature glass phase has good interface wettability with the SiC particles in melting, a certain amount of Cu2O is formed on the Cu-based particle surfaces during a sintering process of the composite material, and Cu2O participates in formation of interface glass phase, so that the Cu matrix has good adhesion with the glass phase. On the other hand, the introduction of the interface glass phase can prevent direct surface contact of a plurality of SiC particles in aggregation and prevent mutual diffusion of reactant atoms in an interface solid-phase reaction, thereby effectively inhibiting formation of interface solid-phase reaction products and enabling the composite material to gain excellent comprehensive mechanical properties.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Tunnel magnetoresistor and manufacturing method thereof

PendingCN112768604ALarge linear rangeAvoid disturbanceMagnetic-field-controlled resistorsGalvano-magnetic material selectionElectrical resistance and conductanceEngineering

The invention provides a tunnel magnetoresistor and a manufacturing method thereof. The tunnel magnetoresistor comprises a first pinning layer, a free layer arranged opposite to the first pinning layer, a tunneling barrier layer positioned between the first pinning layer and the free layer, a pinned layer located between the first pinning layer and the tunneling barrier layer, and a second pinning layer positioned on one side, opposite to the tunneling barrier layer, of the free layer. The first pinning layer and the pinned layer form a first pinning field, the second pinning layer and the free layer form a second pinning field, and the directions of the first pinning field and the second pinning field are parallel to the opposite surfaces of the first pinning layer and the second pinning layer; the included angle between the direction of the first pinning field and the direction of the second pinning field is 70-110 degrees; and a saturation field of the tunnel magnetoresistor is increased so that the linear range of the tunnel magnetoresistor is enlarged.

Owner:蚌埠希磁科技有限公司

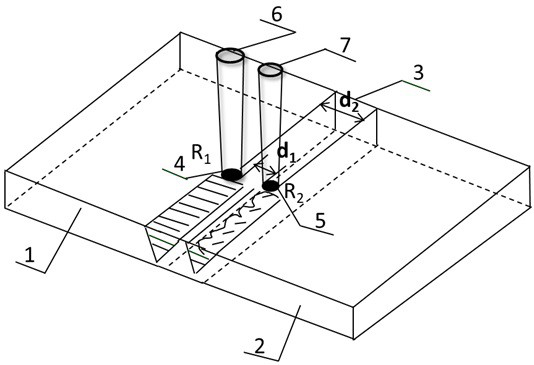

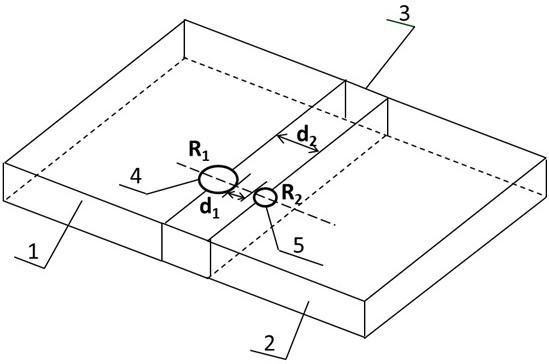

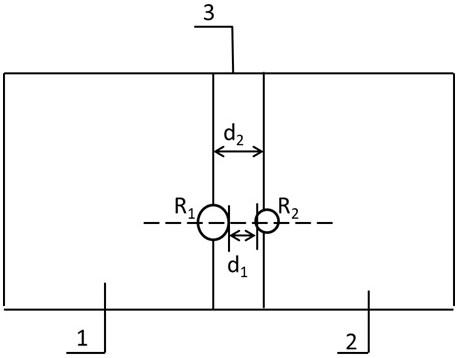

Double-beam laser welding method of aluminum/steel dissimilar metals based on high-entropy alloy interlayer

ActiveCN113500293BSuppress generationInterdiffusionWelding/soldering/cutting articlesLaser beam welding apparatusHigh entropy alloysWeld seam

The invention relates to a double-beam laser welding method of aluminum / steel dissimilar metals based on a high-entropy alloy intermediate layer, and belongs to the technical field of material welding. Using Fe / Al-based high-entropy alloy metal sheet as the middle layer material, the power ratio of two side-by-side laser beams is precisely adjusted, so that the main beam spot is located on the steel plate side, and the auxiliary beam spot is located on the aluminum alloy plate side. By controlling the temperature field distribution, when the temperature of the high-power laser beam reaches above the liquidus temperature of the Fe / Al-based high-entropy alloy metal sheet and the steel plate, a molten weld is formed on the steel plate side. On the aluminum alloy plate side, a brazed weld is formed due to the low melting point of aluminum. A certain distance is reserved between the spots of the two laser beams. After welding, the part of the high-entropy alloy layer that is not irradiated by the laser is still in a solid state, which avoids the interdiffusion of Fe and Al elements and reduces the formation of Fe-Al intermetallic compounds. Generated, thereby improving the tensile strength of the weldment.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com