Double-beam laser welding method of aluminum/steel dissimilar metals based on high-entropy alloy interlayer

A technology of high-entropy alloys and dissimilar metals, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of less research on high-entropy alloys, and achieve the effect of improving mechanical properties and inhibiting formation

Active Publication Date: 2022-05-31

JILIN UNIV

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, so far, high-entropy alloys have been poorly studied for laser welding dissimilar materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Login to View More

Abstract

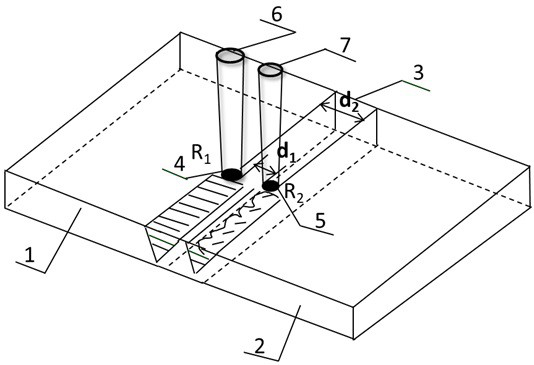

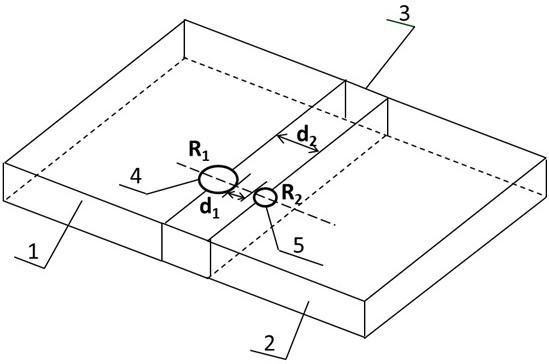

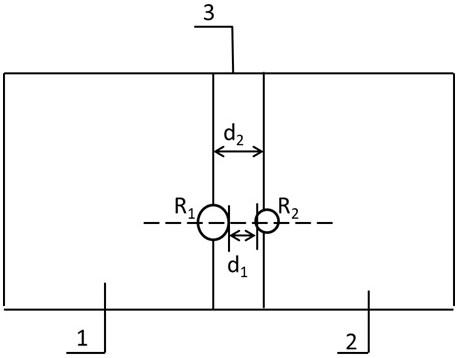

The invention relates to a double-beam laser welding method of aluminum / steel dissimilar metals based on a high-entropy alloy intermediate layer, and belongs to the technical field of material welding. Using Fe / Al-based high-entropy alloy metal sheet as the middle layer material, the power ratio of two side-by-side laser beams is precisely adjusted, so that the main beam spot is located on the steel plate side, and the auxiliary beam spot is located on the aluminum alloy plate side. By controlling the temperature field distribution, when the temperature of the high-power laser beam reaches above the liquidus temperature of the Fe / Al-based high-entropy alloy metal sheet and the steel plate, a molten weld is formed on the steel plate side. On the aluminum alloy plate side, a brazed weld is formed due to the low melting point of aluminum. A certain distance is reserved between the spots of the two laser beams. After welding, the part of the high-entropy alloy layer that is not irradiated by the laser is still in a solid state, which avoids the interdiffusion of Fe and Al elements and reduces the formation of Fe-Al intermetallic compounds. Generated, thereby improving the tensile strength of the weldment.

Description

Double-beam laser welding method of dissimilar metals based on high-entropy alloy interlayer aluminum / steel technical field The present invention relates to dissimilar material welding technical field, particularly a kind of aluminum alloy plate / steel plate dissimilar metal laser Welding method, especially a double beam laser welding method of dissimilar metals based on high-entropy alloy interlayer aluminum / steel. applied to steam Vehicles, rail vehicle manufacturing and other fields. Background technique [0002] The aluminum-steel composite structure not only has the low density of aluminum alloy, good corrosion resistance and plastic workability, but also has both It has the advantages of high steel strength and good impact resistance. The welded structure of dissimilar alloys is very important for vehicle weight reduction, energy consumption reduction and It is of great significance to reduce environmental pollution. However, due to aluminum alloy and steel, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K26/21B23K26/14B23K26/70B23K103/10B23K103/04

CPCB23K26/21B23K26/14B23K26/703B23K2103/10B23K2103/04

Inventor 谷晓鹏周贺徐国成董娟

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com