Preparation method of interface strong metallurgical bonding metal layered composite material

A technology of metallurgical bonding and composite materials, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of unstable composite interface bonding quality, increase raw material cost, reduce production efficiency, etc., and achieve improved composite interface bonding. quality, improve the pass reduction rate, and achieve the effect of strong metallurgical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

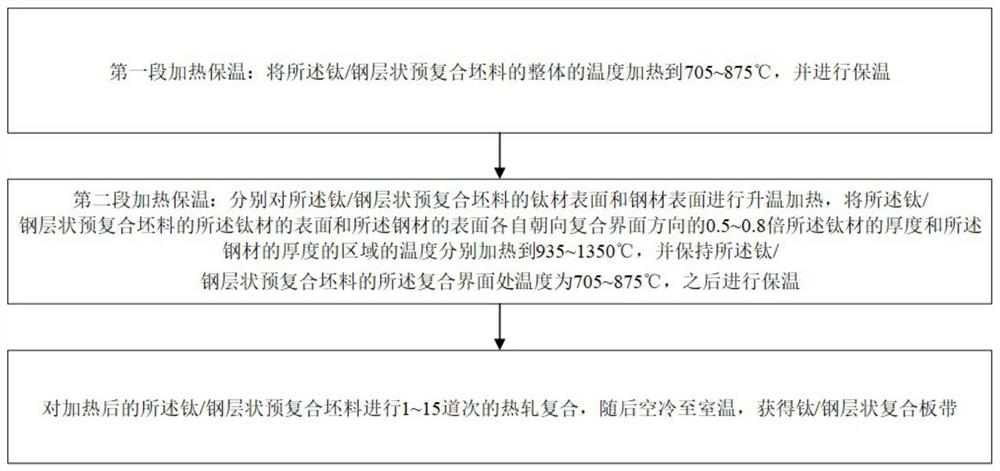

Method used

Image

Examples

Embodiment 1

[0034] The titanium material is TA2 pure titanium plate with an initial thickness of 2.0mm; the steel material is Q235 low-carbon steel plate with an initial thickness of 2.0mm. Firstly, the titanium and steel are annealed and pickled to remove the oxide skin on the surface of the titanium and steel; then the surface of the titanium and steel to be composited is continuously machined online with a broach to obtain the corresponding concave-convex structure along the titanium and steel. The surface to be compounded with the trapezoidal concave-convex structure of the steel horizontally arranged, the depth of the cross-sectional shape of the concave-convex structure is 0.5mm, and the top width is 2mm; then the surface to be composited is degreased and polished; finally the reduction rate A titanium / steel layered pre-composite billet was prepared for 48% single-pass cold-rolling composite.

[0035] The titanium / steel layered pre-composite billet is placed in an induction heating ...

Embodiment 2

[0038] The titanium material is a TA1 pure titanium plate with an initial thickness of 2.0 mm; the steel material is a 304 stainless steel plate with an initial thickness of 4.0 mm. Firstly, the titanium and steel are annealed and pickled to remove the oxide skin on the surface of the titanium and steel; then the surface of the titanium and steel to be compounded is continuously machined on-line with a parallel combination milling cutter to obtain the corresponding concave-convex structure. The concave-convex structure of the concave-convex structure that is horizontally arranged on the material and the steel is the surface to be compounded, the depth of the cross-sectional profile of the concave-convex structure is 0.5mm, and the top width is 3.0mm; then the surface to be composited is degreased and polished; Finally, a single-pass hot-rolling composite with a reduction ratio of 52% was carried out to prepare a titanium / steel layered pre-composite billet.

[0039] The titaniu...

Embodiment 3

[0042] The titanium material is a TA2 pure titanium plate with an initial thickness of 5.0 mm; the steel material is a Q345 low-alloy steel plate with an initial thickness of 10.0 mm. Firstly, use parallel combined hobs to continuously machine the uneven structure corresponding to the surface of titanium and steel to be compounded on-line, and obtain the surface to be compounded with a W-shaped appearance along the transverse direction of titanium and steel, and the concave-convex structure The depth of the cross-sectional morphology is 1.0 mm, and the width of the top is 5.0 mm; then the surface to be compounded is degreased and polished; and then explosive compounding is prepared to obtain a titanium / steel layered pre-composite billet.

[0043] The titanium / steel layered pre-composite billet was placed in a flame heating furnace and kept at 750°C for 80 minutes to form a TiC layer with a thickness of about 450nm at the composite interface of titanium and steel. Then the tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com