Method for preparing 0-3 magnetic-electricity composite ceramic through low-temperature sintering realized by induction of nanometer sintering additive through self-propagating

A nano-sintering aid and magnetoelectric composite technology, applied in the field of magnetoelectric composite materials, can solve the problems of difficult polarization of ceramics, unsatisfactory magnetoelectric properties, large dielectric loss of granular magnetoelectric composite ceramics, etc., and achieve high magnetoelectricity Coupling effect, large magnetoelectric coupling coefficient, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

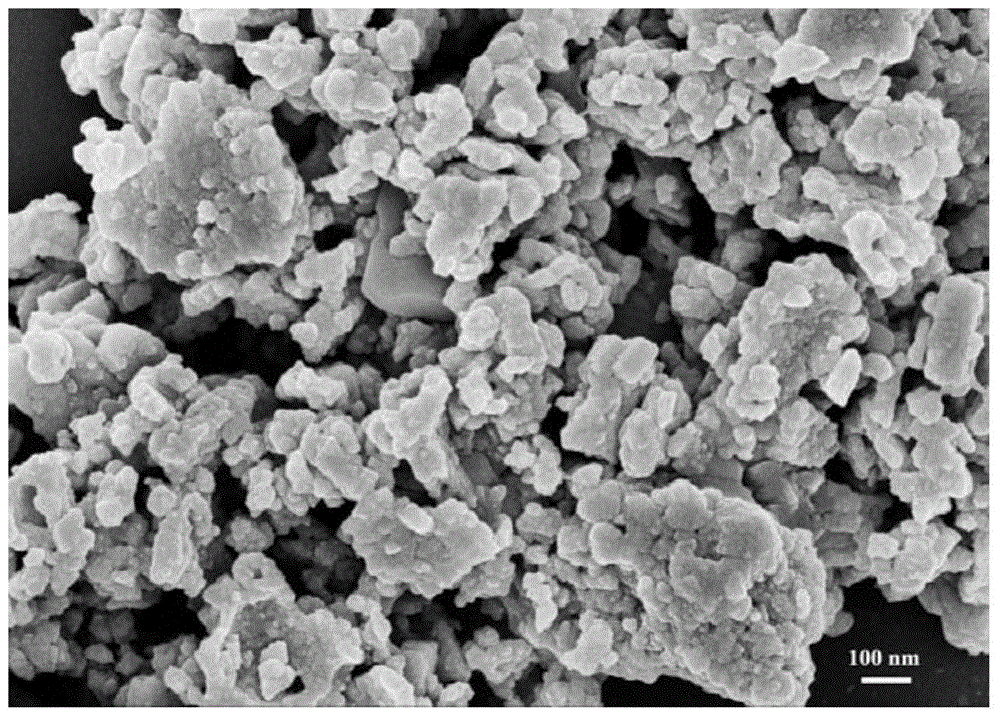

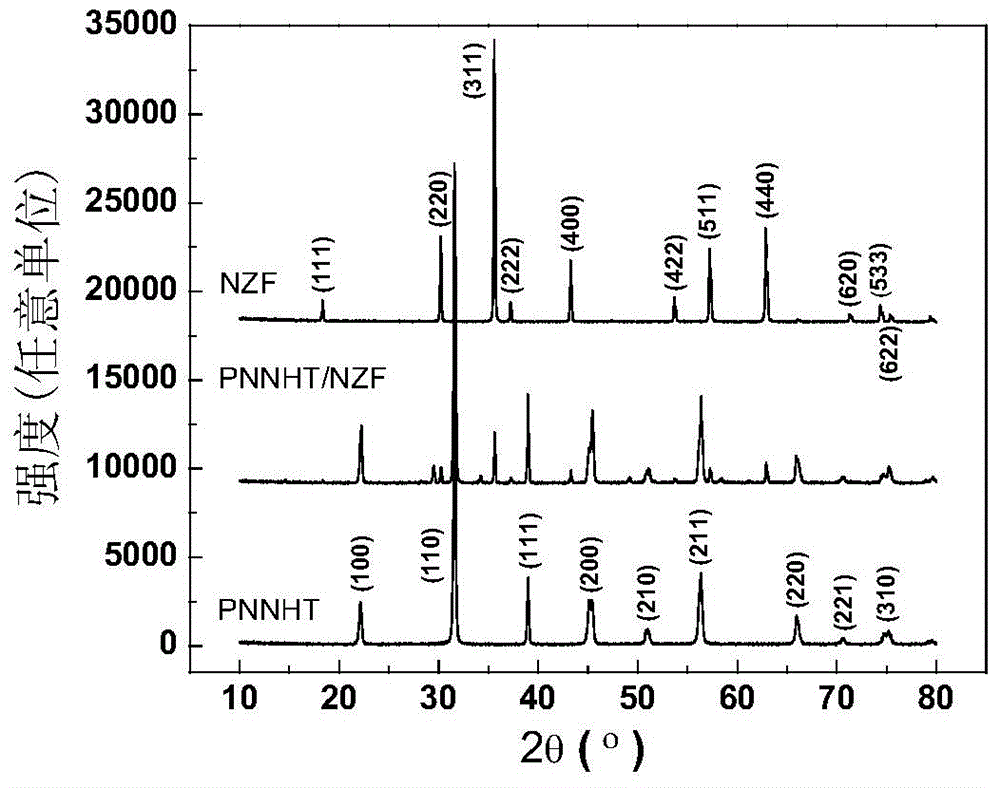

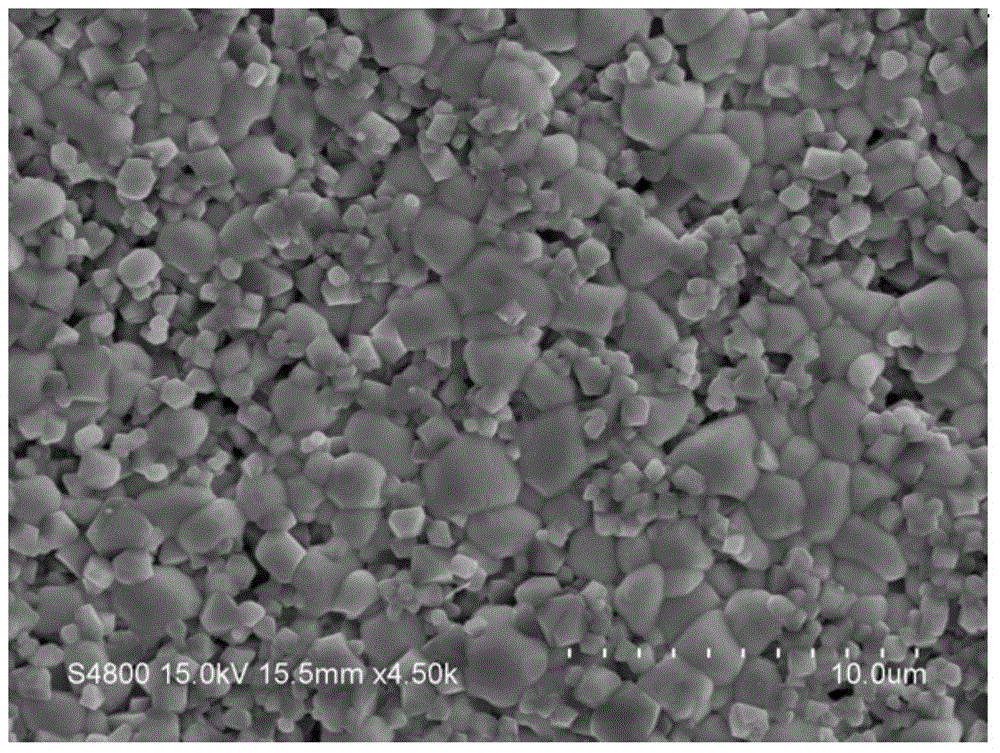

[0028] (1) According to the stoichiometric ratio of 0.55Pb(Ni 1 / 3 Nb 2 / 3 )O 3 -0.05PbHfO 3 -0.4PbTiO 3 (PNNHT), weigh B-site oxides NiO, Nb 2 o 5 , HfO 2 and TiO 2 , grind and mix evenly, pre-calcine at 1100°C for 4h; the calcined product is crushed and ground, add stoichiometric PbO, grind and mix evenly, and calcined at 850°C for 4h to obtain ferroelectric phase PNNHT. According to the stoichiometric Ni 0.875 Zn 0.125 Fe 2 o 4 (NZF), weigh NiO, ZnO and Fe 2 o 3 , ground and mixed evenly, and calcined at 1150°C for 4 hours to obtain ferromagnetic phase NZF.

[0029] (2)①Weigh a certain mass of PNNHT ferroelectric phase. Weigh out the amount of PNNHT substance with 2.5 mol% Na 2 WO 4 2H 2 O, put into deionized water and heat and stir until completely dissolved. Weigh citric acid and CTAB, the mass ratio of citric acid to CTAB is 9:1, the mass ratio of CTAB to the sum of the mass of PNNHT and sodium tungstate dihydrate is 1:4, heat and stir in deionized water ...

Embodiment 2

[0037] Change the metering ratio of PNNHT material among the embodiment 1 to be 0.6Pb (Ni 1 / 3 Nb 2 / 3 )O 3 -0.05PbHfO 3 -0.35PbTiO 3 (PNNHT), change the metering ratio of NZF material among the embodiment 1 to be Ni 0.88 Zn 0.12 Fe 2 o 4 , using the same method as in Example 1 to prepare ferroelectric phase, ferromagnetic phase and PNNHT / NZF composite ceramics.

Embodiment 3

[0039] Change the stoichiometric ratio of PNNHT material in embodiment 1 to be 0.5Pb (Ni 1 / 3 Nb 2 / 3 )O 3 -0.05PbHfO 3 -0.45PbTiO 3 (PNNHT), change the metering ratio of NZF material among the embodiment 1 to be Ni 0.94 Zn 0.06 Fe 2 o 4 , using the same method as in Example 1 to prepare ferroelectric and ferromagnetic phases, and changing the ratio of ferroelectric and ferromagnetic phases to 90:10 and using the same method as in Example 1 to prepare PNNHT / NZF composite ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com