Two-layer textured vectolite-lead zirconate titanate multiferroic composite film material and preparation method thereof

A technology of cobalt ferrite and lead zirconate titanate, which is applied in the field of composite magnetoelectric multiferroic materials, can solve the problems of large leakage current, small effective coupling area of ferroelectric/ferromagnetic phase, etc., and improve the magnetoelectric coupling effect , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

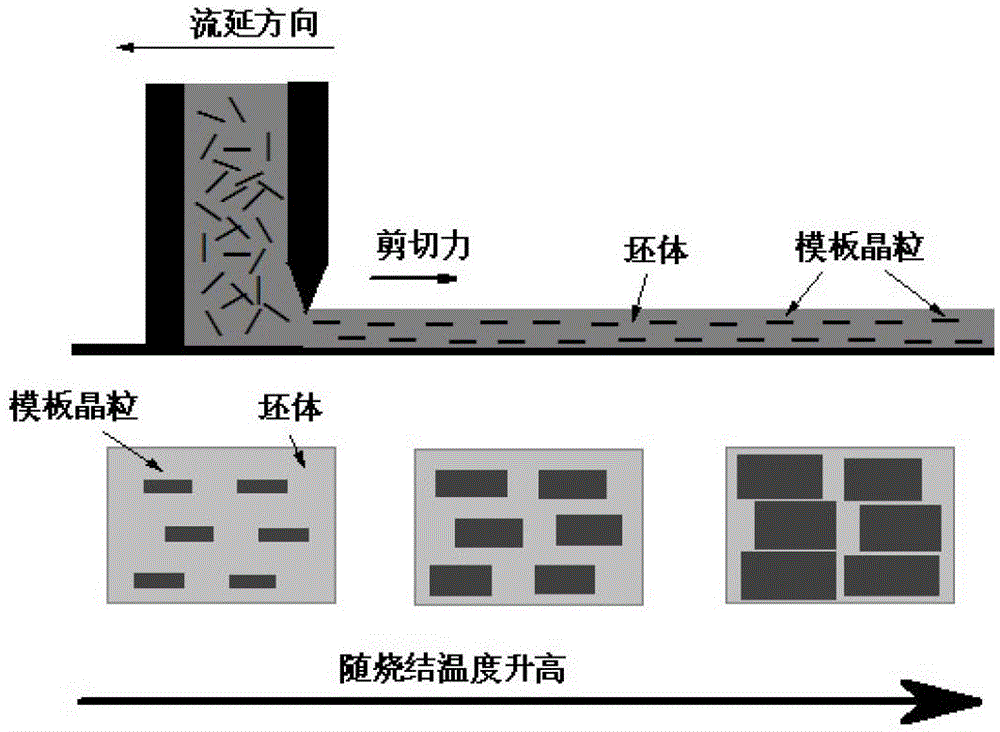

Method used

Image

Examples

Embodiment 1

[0035] When x=0.52, double-layer CoFe is obtained 2 o 4 -Pb(Zr 0.52 Ti 0.48 )O 3 Textured composite multiferroic film

[0036] 1) Slurry configuration:

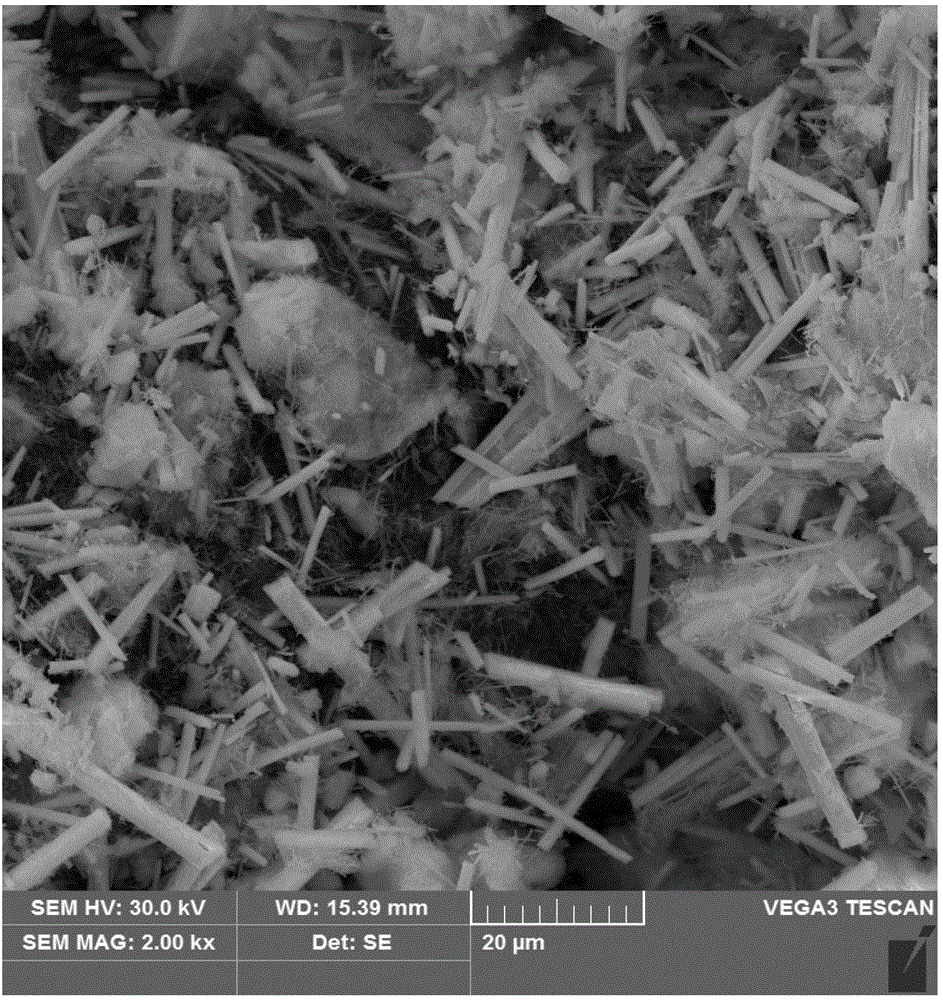

[0037] Weigh CoFe 2 o 4 Powder, adding organic solvent, dispersant and defoamer, planetary ball milling for 4 hours, adding binder to it, and secondary ball milling for 3 hours to obtain CoFe 2 o 4 Casting precursor slurry, solid content is 45wt%; Adding molar ratio to it is 5% CoFe 2 o 4 Rod-shaped crystals, stirred by magnetic force for 0.5h, and left to defoam for 0.5h to obtain CoFe 2 o 4 Ferromagnetic phase mixed slurry;

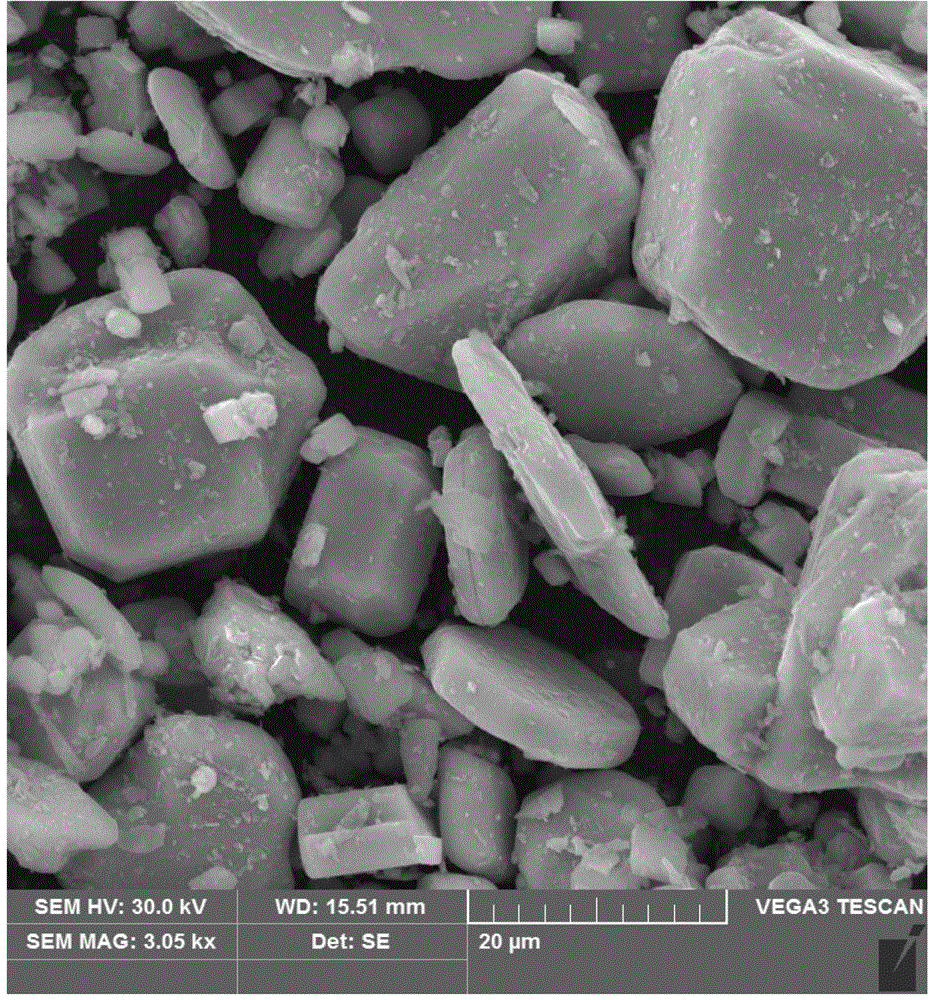

[0038] Weigh Pb(Zr 0.52 Ti 0.48 )O 3 Powder, adding organic solvent, dispersant and defoamer, planetary ball milling for 4 hours, adding binder to it, and secondary ball milling for 3 hours to obtain Pb(Zr x Ti 1-x )O 3 Casting precursor slurry with a solid content of 65wt%; adding a molar ratio of 5% flake SrTiO 3 single crystal, magnetically stirred for 0.5h, and left to defoam for...

Embodiment 2

[0043] When x=0, a double-layer CoFe is obtained 2 o 4 -PbTiO 3 Textured composite multiferroic film

[0044] 1) Slurry configuration:

[0045] Weigh CoFe 2 o 4 Powder, adding organic solvent, dispersant and defoamer, planetary ball milling for 5 hours, adding binder to it, and secondary ball milling for 4 hours to obtain CoFe 2 o 4 Casting precursor slurry, the solid content is 40wt%, and the molar ratio of 8% CoFe is added thereto 2 o 4 Rod-shaped crystals, stirred by magnetic force for 0.5h, and left to defoam for 0.5h to obtain CoFe 2 o 4 Ferromagnetic phase mixed slurry;

[0046] Weigh PbTiO 3 Powder, adding organic solvent, dispersant and defoamer, planetary ball milling for 5 hours, adding binder to it, and secondary ball milling for 4 hours to obtain PbTiO 3 Casting precursor slurry with a solid content of 70wt%, to which flaky SrTiO was added with a molar ratio of 8% 3 Single crystal, magnetic stirring for 0.5h, standing still for degassing for 0.5h, to o...

Embodiment 3

[0049] When x=0.3, double-layer CoFe is obtained 2 o 4 -PbZr 0.3 Ti 0.7 o 3 Textured composite multiferroic film

[0050] 1) Slurry configuration:

[0051] Weigh CoFe 2 o 4 Powder, add organic solvent, dispersant and defoamer, planetary ball mill for 4.5h, add binder to it, and ball mill for 3.5h twice to obtain precursor slurry with a solid content of 42wt%, adding a molar ratio of 7 %CoFe 2 o 4 Rod-shaped crystals, stirred by magnetic force for 0.5h, and left to defoam for 0.5h to obtain CoFe 2 o 4 Mix slurry.

[0052] Weigh Pb(Zr 0.3 Ti 0.7 )O 3 Powder, add organic solvent, dispersant and defoamer, planetary ball mill for 4.5 hours, add binder to it, and ball mill for 3.5 hours twice to obtain precursor slurry with a solid content of 68wt%, and add a molar ratio of 7 % flake SrTiO 3 single crystal, magnetically stirred for 0.5h, and left to defoam for 0.5h to obtain Pb(Zr 0.3 Ti 0.7 )O 3 Mix slurry.

[0053] 2) Using the oriented grain growth technology,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com