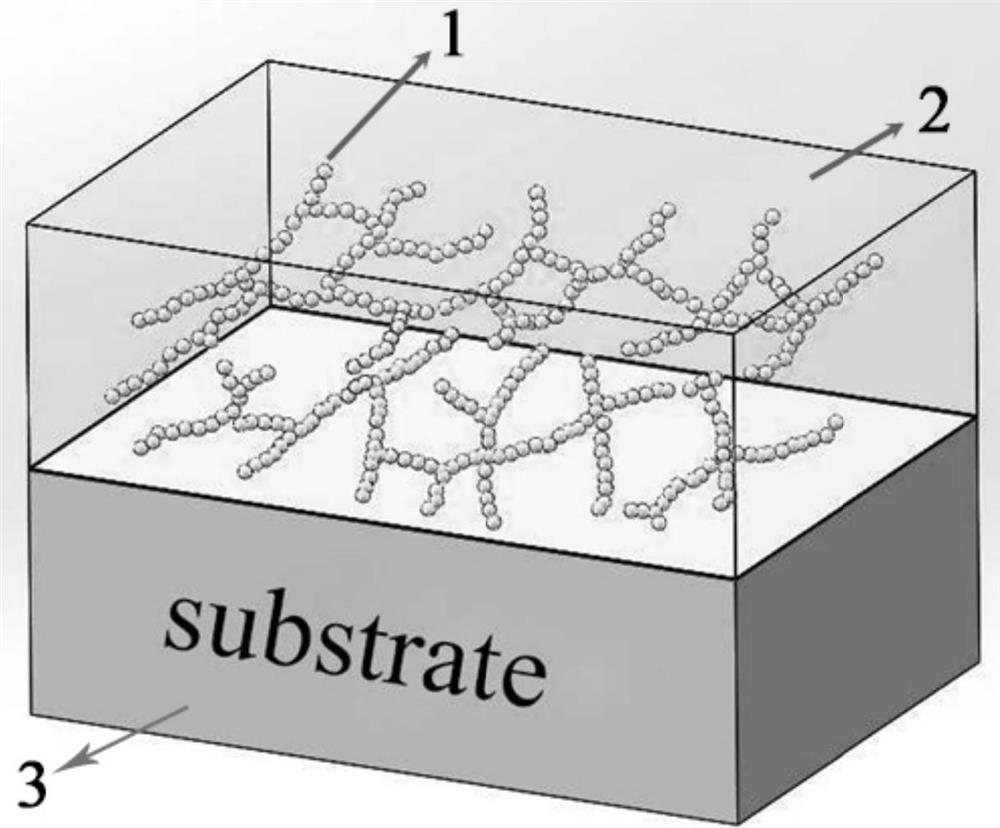

Magnetoelectric composite material composed of magnetic nanofiber ferroelectric thin film and preparation method thereof

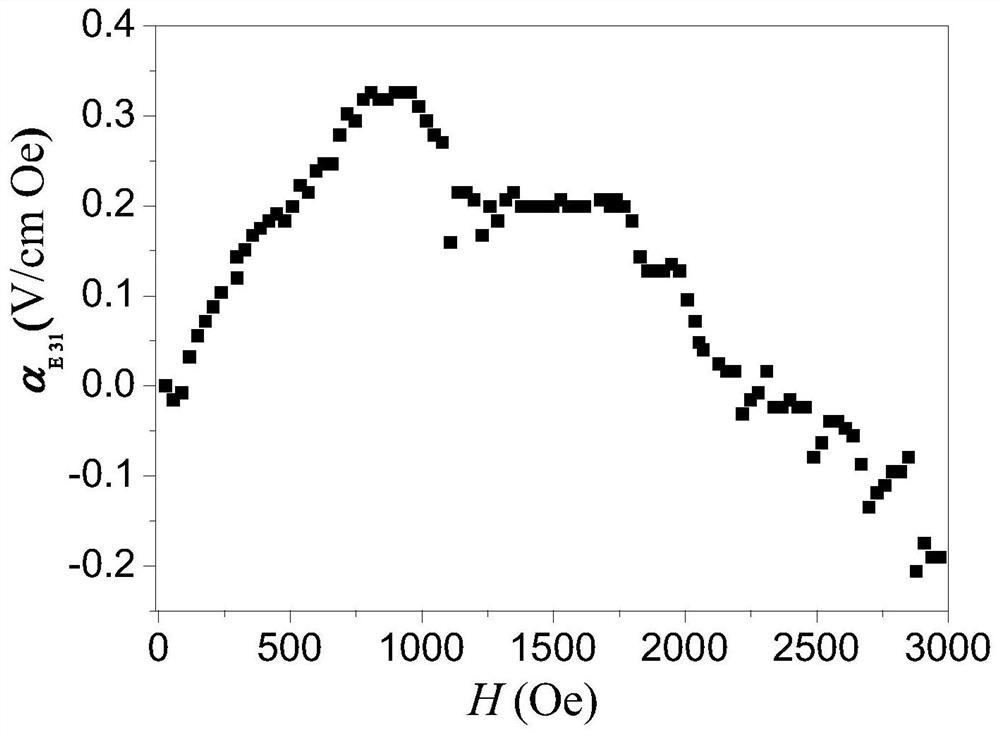

A magnetoelectric composite material and magnetic nanotechnology, applied in the application of magnetic film to substrate, inductance/transformer/magnet manufacturing, nanostructure application, etc., can solve the problem of limited, leakage, ferromagnetic phase volume fraction, and preparation difficulty Large and other problems, to achieve the effect of improving the magnetoelectric coupling performance, increasing the strain transfer area, and high magnetoelectric coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

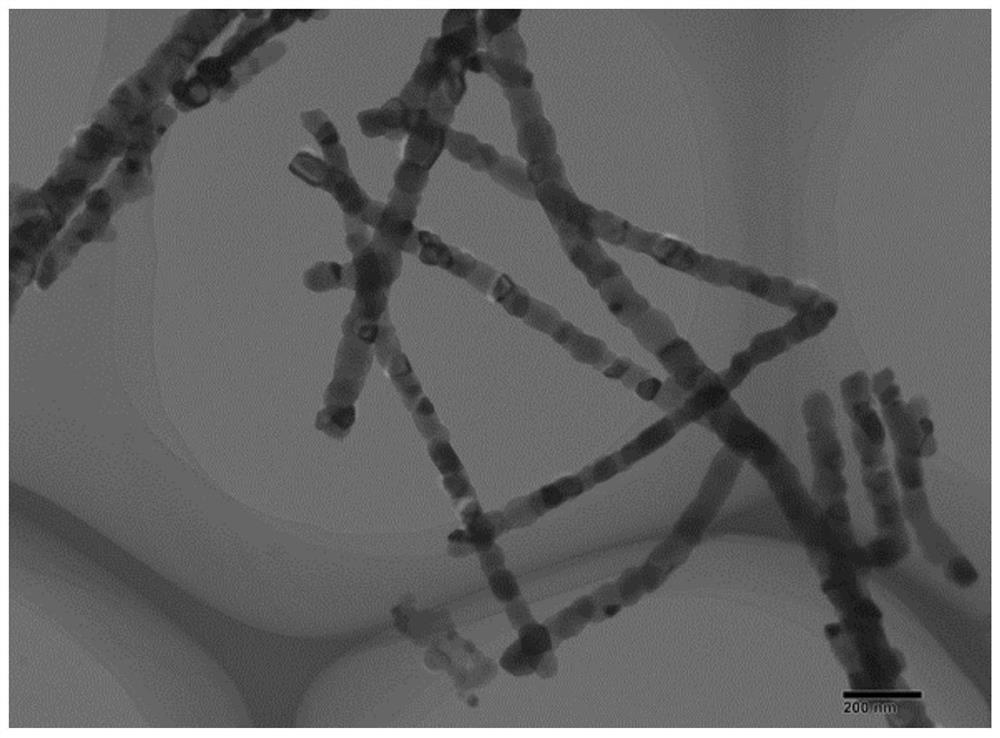

[0042] 1. Configure CoFe 2 o 4 (CFO) precursor solution

[0043] The solvent is N,N-dimethylformamide and ethanol, and N,N-dimethylformamide and ethanol are carried out according to five different ratios of 1:1, 1:1.4, 1:2, 1.4:1, and 2:1. Mix, weigh a certain amount of cobalt nitrate and ferric nitrate, Co 2+ with Fe 3+ The molar ratio is 1:2. Dissolve the weighed ferric nitrate and cobalt nitrate in mixed solutions of ethanol and N,N-dimethylformamide in different proportions, and then put them on a stirrer at room temperature and stir until they are completely dissolved. After it is completely dissolved, add 0.8g polymer PVP, continue to stir at room temperature, and stir for 5-6h until the polymer is completely dissolved. Then put the solution in an ultrasonic machine for 20 minutes to make it evenly dispersed. After taking it out, let it stand for 1 day to get a relatively uniform and stable solution.

[0044] 2. Clean the substrate

[0045] The substrate is select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com