Galvanizing method of hot dip galvanizing steel plate

A hot-dip galvanized steel sheet, hot-dip galvanized technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc. Problems such as the decrease in the percentage of Al

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Preparation of hot-dip galvanized steel sheet experimental examples 1-5 and comparative examples 6-10

[0026] The thickness of DX1 cold-rolled steel plate is 0.8mm, the composition is C 0.03-0.07%, Mn 0.01-0.03%, Si 0.19-0.30%, P 0.006-0.019%, S 0.009-0.020%, Al 0.02-0.07%, and the rest is Fe and unavoidable impurities. After pickling and annealing, the DX1 cold-rolled steel sheet is hot-dip galvanized under the hot-dip galvanizing process conditions listed in Table 1. The initial temperature of the plating bath in the zinc pot is 450 ° C, and the Fe Al content 2 Left and right, the surface of the zinc layer passes through SiO 2 passivation treatment.

[0027] Table 1 hot-dip galvanizing process conditions

[0028]

Embodiment 2

[0029] Embodiment 2 Performance measurement of hot-dip galvanized steel sheet experimental examples 1-5 and comparative examples 6-10

[0030] The Fe-Al intermediate transition layer and coating structure of the coating, as well as the coating adhesion performance such as anti-shedding performance, scratch resistance, and wear resistance of the coating are evaluated by the following methods.

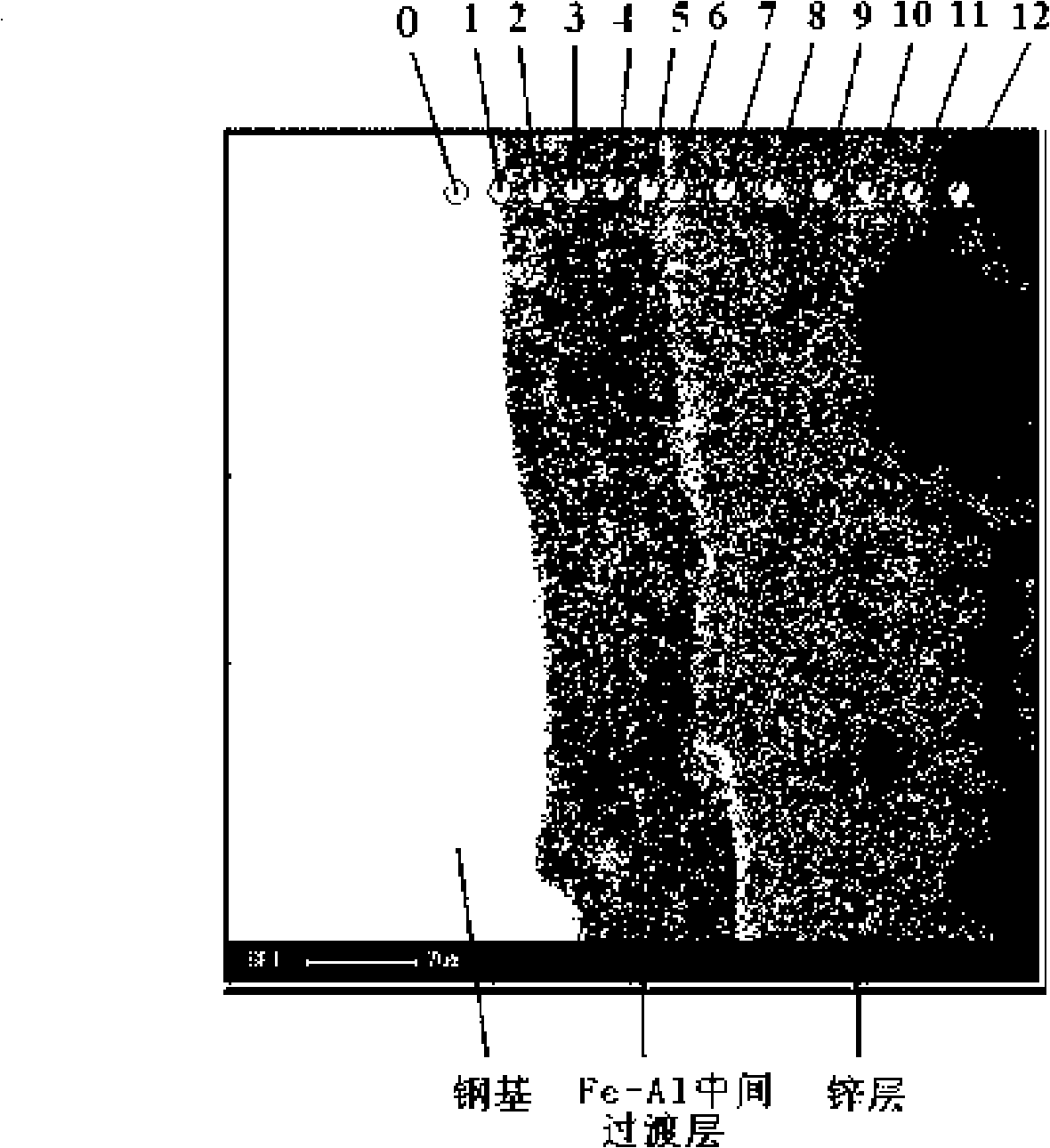

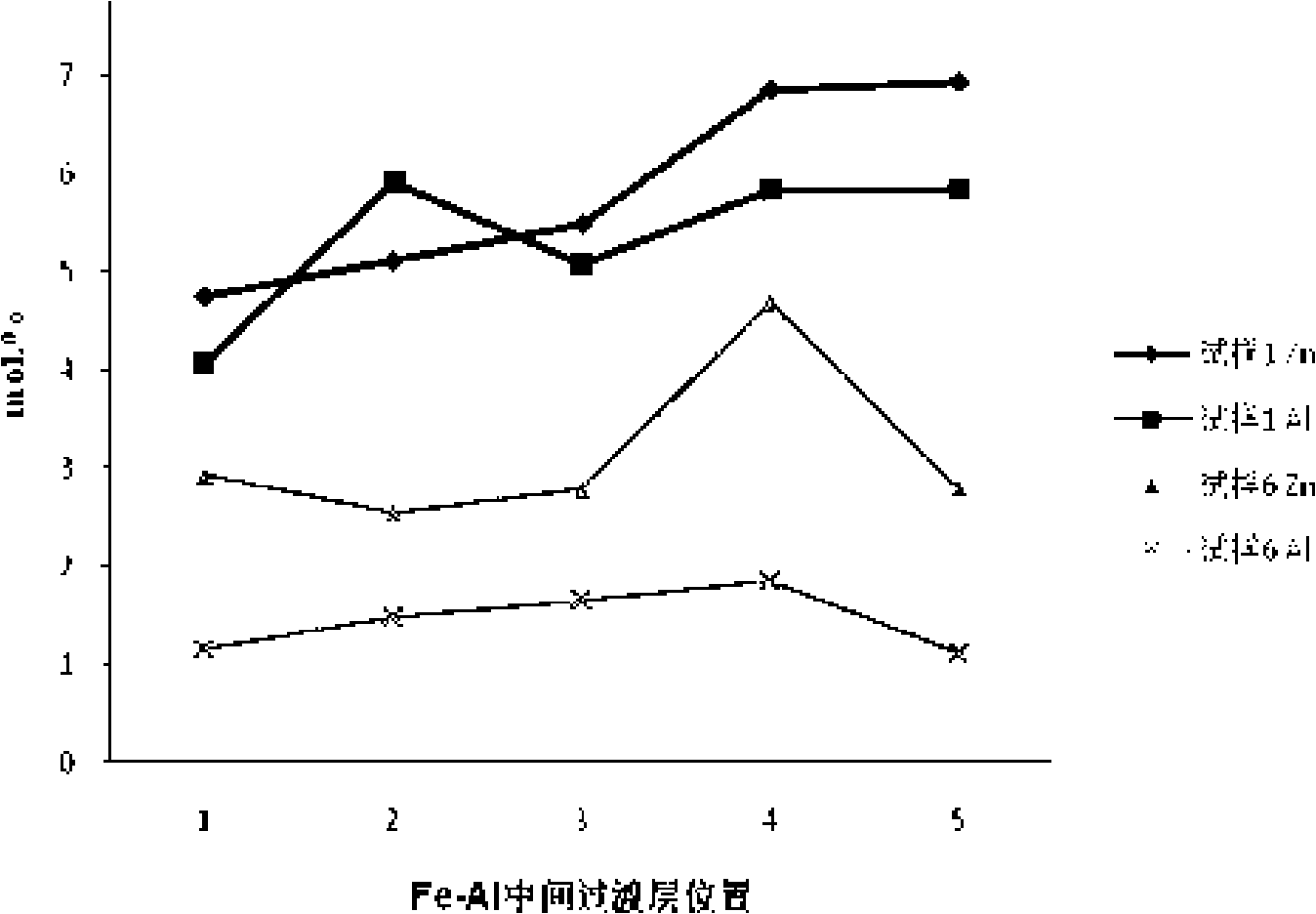

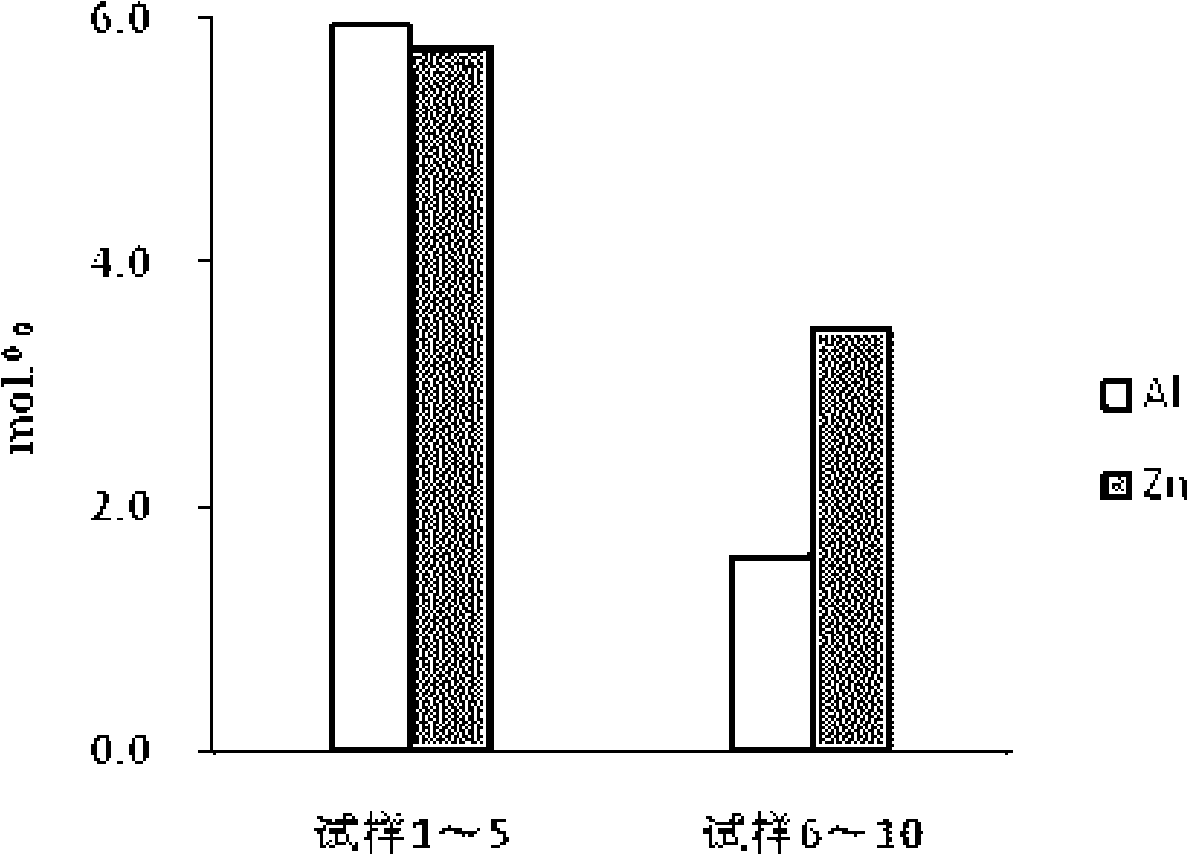

[0031] (1) Coating Fe-Al intermediate transition layer and structure

[0032] Since the thickness of the Fe-Al intermediate transition layer is between tens and hundreds of nanometers, it is difficult to display this intermediate layer by conventional metallographic sample preparation methods. The metallographic sample preparation of the present invention adopts oblique mounting, and the mounting material is bakelite powder. On the hot mounting machine, 3 hot-dip galvanized steel samples are glued together with 502 strong glue, and placed side by side after grinding and polishing. The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com