Microcrystalline Si-SbxTe1-x composite phase change material and preparation method thereof

A technology of si-sbxte1-x and composite phase change materials, which is applied in metal material coating process, ion implantation plating, electrical components, etc., can solve problems such as material instability, achieve good thermal stability, and reduce power consumption , the effect of improving operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this example, by preparing microcrystalline Si-Sb 2 Te 3 Composite phase change material, and it is tested to further illustrate the technical solution of the present invention. Concrete preparation method is as follows:

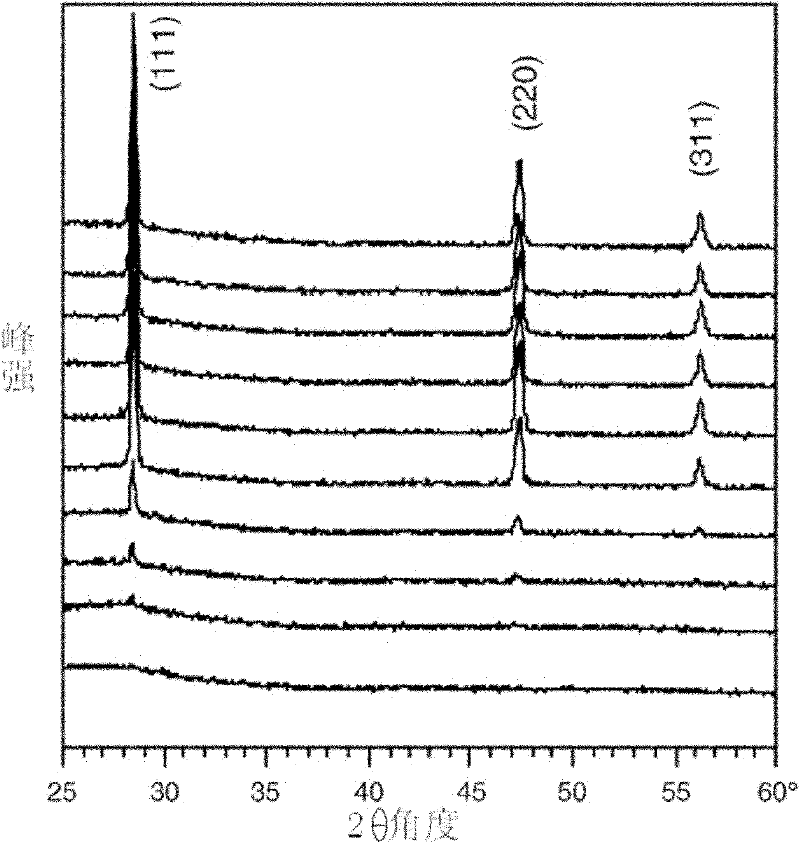

[0023] (1) Using PVD equipment to grow Si on a glass sheet 2 Sb 2 Te 3 Material. For example, methods such as magnetron sputtering can be used to obtain stoichiometric thin film materials by regulating process parameters (sputtering power, working pressure, etc.), wherein the technology of growing thin films by PVD technology is known to those skilled in the art, so in This will not be repeated. This embodiment preferably grows Si 2 Sb 2 Te 3 material, but the present invention is not limited thereto, it can also grow Si-Sb of other proportions x Te 1-x Material, 0.1≤x≤0.9. Si-Sb in PVD deposited state x Te 1-x Among the materials, Si exists in an amorphous form.

[0024] (2) the Si 2 Sb 2 Te 3 material placed in N 2 Annealed at ...

Embodiment 2

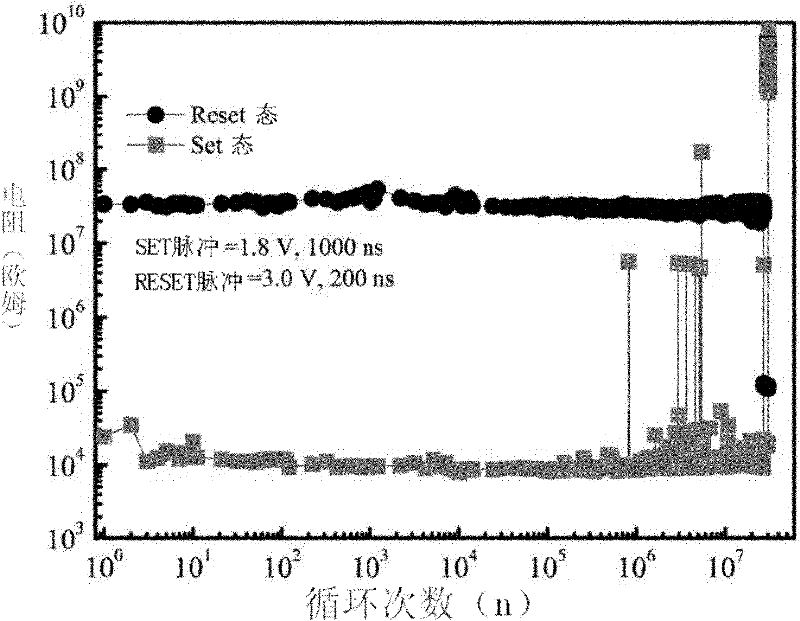

[0030] The microcrystalline Si-Sb prepared in embodiment one 2 Te 3 Composite phase change material is applied in phase change memory, and its performance is further analyzed.

[0031] (a) Using PVD equipment to Si 2 Sb 2 Te 3 The material is grown on a tapered substrate prepared with electrodes;

[0032] (b) repeat steps (2)-(4) in implementing one to form microcrystalline Si-Sb 2 Te 3 Composite phase change materials;

[0033] (c) Continue to complete the subsequent steps of tape-out, including growing TiN, etching, growing Al, etching, etc., to produce a complete phase-change memory unit;

[0034] (d) Perform write, erase, and read operations on the completed phase-change memory unit, and study the storage characteristics and fatigue characteristics of the material.

[0035] figure 2 For the test results, it can be seen that the microcrystalline Si-Sb 2 Te 3 Composite phase change materials are applied to phase change memory. The microcrystalline Si changes the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com