A continuous hot-dip galvanizing process for strip steel

A technology of hot-dip galvanizing and strip steel, applied in hot-dip galvanizing process, metal material coating process, coating and other directions, can solve the problems of poor adhesion of zinc layer, decrease of Al percentage, and no effect. , to achieve the effect of improved wear resistance and adhesion, optimized grain orientation of the coating, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

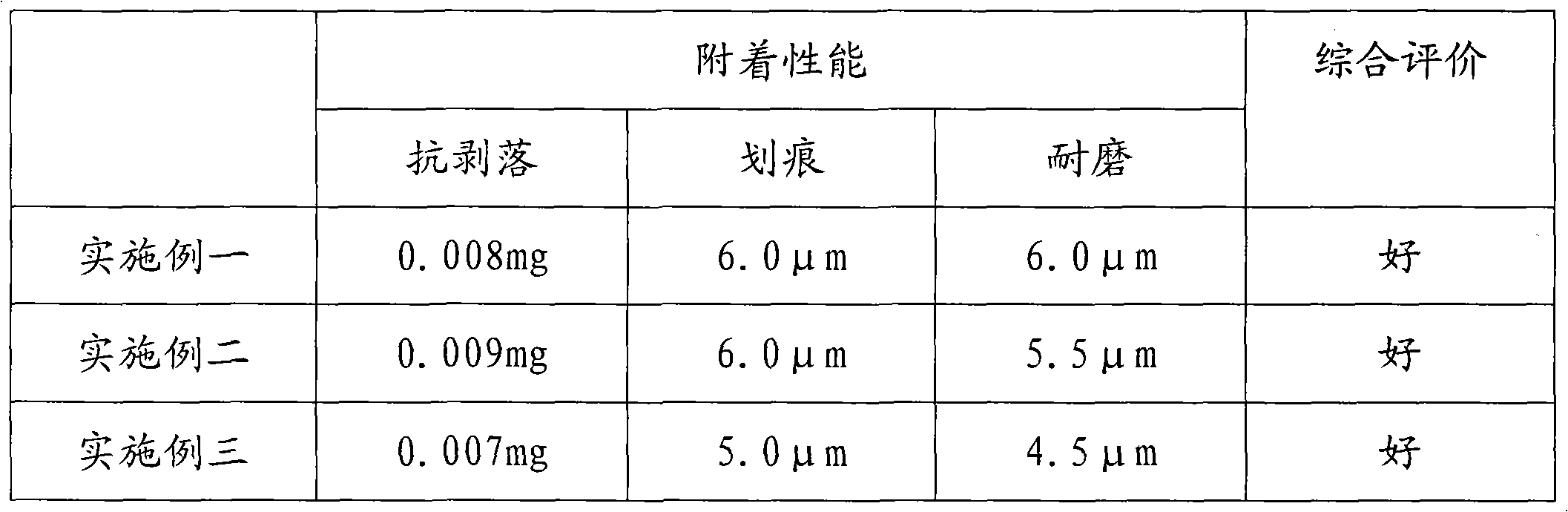

Examples

Embodiment 1

[0023] A strip steel continuous hot-dip galvanizing process, the process comprises the steps of:

[0024] (1) The configuration of the coating melt: take 90 parts of zinc ingots, 8 parts of aluminum ingots, 3 parts of pure iron, 1.2 parts of copper ingots, and 0.3 parts of magnesium ingots and put them in an induction heating furnace for melting. The melting heating temperature is 730°C. After homogenization, control the temperature of the coating melt to 650°C for use;

[0025] (2) strip steel degreasing pre-treatment: after the strip steel is uncoiled, it enters the chemical degreasing treatment solution tank for chemical degreasing, puts water and solid alkali in the solution tank to make a water-alkali solution, and the weight percentage of solid alkali in the water-alkali solution Concentration: 2.5%, solution temperature: 90°C; then enter the first clear water tank for cleaning; then enter the electrolytic degreasing solution tank for electrolytic degreasing, put water a...

Embodiment 2

[0031] A strip steel continuous hot-dip galvanizing process, the process comprises the steps of:

[0032] (1) Configuration of the coating melt: take 92 parts of zinc ingots, 5 parts of aluminum ingots, 5 parts of pure iron, 0.8 parts of copper ingots, and 0.8 parts of magnesium ingots and put them in an induction heating furnace to melt, melting and heating temperature: 710 ° C, uniform After melting, control the temperature of the coating melt to 670°C for use;

[0033] (2) strip steel degreasing pre-treatment: after the strip steel is uncoiled, it enters the chemical degreasing treatment solution tank for chemical degreasing, puts water and solid alkali in the solution tank to make a water-alkali solution, and the weight percentage of solid alkali in the water-alkali solution Concentration: 3.5%, solution temperature: 70°C; then enter the first clear water tank for cleaning; then enter the electrolytic degreasing solution tank for electrolytic degreasing, put water and soli...

Embodiment 3

[0039] A strip steel continuous hot-dip galvanizing process, the process comprises the steps of:

[0040] (1) Configuration of coating melt: Take 91 parts of zinc ingots, 6 parts of aluminum ingots, 4 parts of pure iron, 1.0 parts of copper ingots, and 0.5 parts of magnesium ingots and melt them in an induction heating furnace. After melting, control the temperature of the coating melt to 660°C for use;

[0041] (2) strip steel degreasing pre-treatment: after the strip steel is uncoiled, it enters the chemical degreasing treatment solution tank for chemical degreasing, puts water and solid alkali in the solution tank to make a water-alkali solution, and the weight percentage of solid alkali in the water-alkali solution Concentration: 3.0%, solution temperature: 80°C; then enter the first clear water tank for cleaning; then enter the electrolytic degreasing solution tank for electrolytic degreasing, put water and solid alkali into the solution tank to make a water-alkali soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com