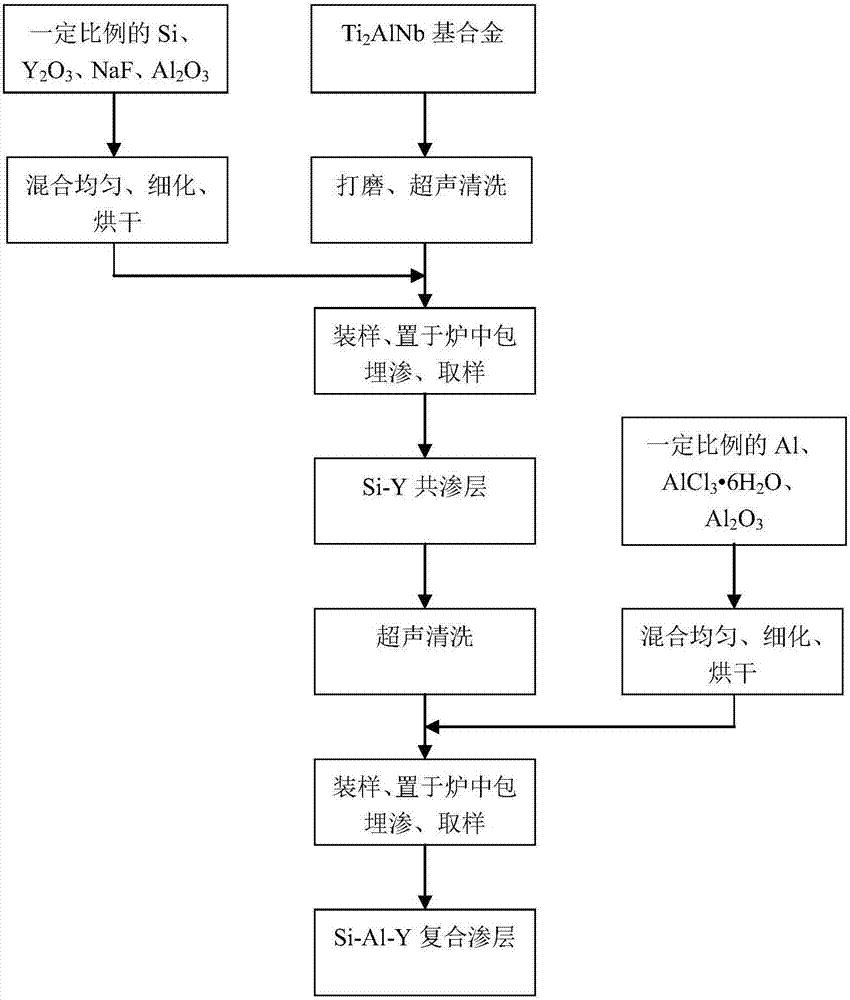

Method for preparing Si-Al-Y composite infiltrated layer on surface of Ti2AlNb alloy by two-step method

A compound infiltration and alloying technology, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of reduction, resource waste and benefit, and achieve the effect of low process cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The first step: preparation of Si-Y co-infiltration layer

[0051] (1) Put Ti 2 AlNb-based alloy samples are wire-cut into cuboid samples of 10mm×10mm×5mm, and each surface is cut with 80-1500 # Sand with SiC water sandpaper step by step, after ultrasonic cleaning in absolute ethanol for 10 minutes, dry it for later use; (2) prepare penetrating agent. The components of the penetrating agent are 15%Si-2%Y by weight percentage 2 o 3 -8%NaF-75%Al 2 o 3 , where Si powder and Y 2 o 3 The particle size of powder is 100 mesh, Al 2 o 3 The particle size of the powder is 200 mesh; (3) Put the prepared penetrating agent in a ball mill and grind it at 200r / min for 3 hours to make it fully mixed; (4) Put the penetrating agent in an oven with a temperature of 100°C to keep warm Dry for 1 hour; (5) Put half of the dried infiltration agent into the crucible and compact it, embed the cleaned and dried sample in the infiltration agent, cover with the other half of the infiltrat...

Embodiment 2

[0056] The first step: preparation of Si-Y co-infiltration layer

[0057] (1) Put Ti 2 AlNb-based alloy samples are wire-cut into cuboid samples of 10mm×10mm×5mm, and each surface is cut with 80-1500 # Sand with SiC water sandpaper step by step, after ultrasonic cleaning in absolute ethanol for 10 minutes, dry it for later use; (2) prepare penetrating agent. The components of the penetrating agent are 10%Si-3%Y by weight percentage 2 o 3 -8%NaF-79%Al 2 o 3 , where Si powder and Y 2 o 3 The particle size of powder is 100 mesh, Al 2 o 3 The particle size of the powder is 200 mesh; (3) Put the prepared penetrating agent in a ball mill and grind it at 200r / min for 3 hours to make it fully mixed; (4) Put the penetrating agent in an oven with a temperature of 100°C to keep warm Dry for 1 hour; (5) Put half of the dried infiltration agent into the crucible and compact it, embed the cleaned and dried sample in the infiltration agent, cover with the other half of the infiltrat...

Embodiment 3

[0062] The first step: preparation of Si-Y co-infiltration layer

[0063] (1) Put Ti 2 AlNb-based alloy samples are wire-cut into cuboid samples of 10mm×10mm×5mm, and each surface is cut with 80-1500 # Sand with SiC water sandpaper step by step, after ultrasonic cleaning in absolute ethanol for 10 minutes, dry it for later use; (2) prepare penetrating agent. The components of the penetrating agent are 15%Si-3%Y by weight percentage 2 o 3 -8%NaF-74%Al 2 o 3 , where Si powder and Y 2 o 3 The particle size of the powder is 100 mesh, Al 2 o 3 The particle size of the powder is 200 mesh; (3) Put the prepared penetrating agent in a ball mill and grind it at 200r / min for 3 hours to make it fully mixed; (4) Put the penetrating agent in an oven with a temperature of 100°C to keep warm Dry for 1 hour; (5) Put half of the dried infiltration agent into the crucible and compact it, embed the cleaned and dried sample in the infiltration agent, cover with the other half of the infil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com