Novel aluminum heating ring and manufacturing method thereof

A manufacturing method and technology of heating rings, applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of loss of commercial value of manufacturing cost components, heavy processing workload of cast aluminum heating rings, pollution of casting process, etc., to achieve cost Low cost, large production flexibility and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

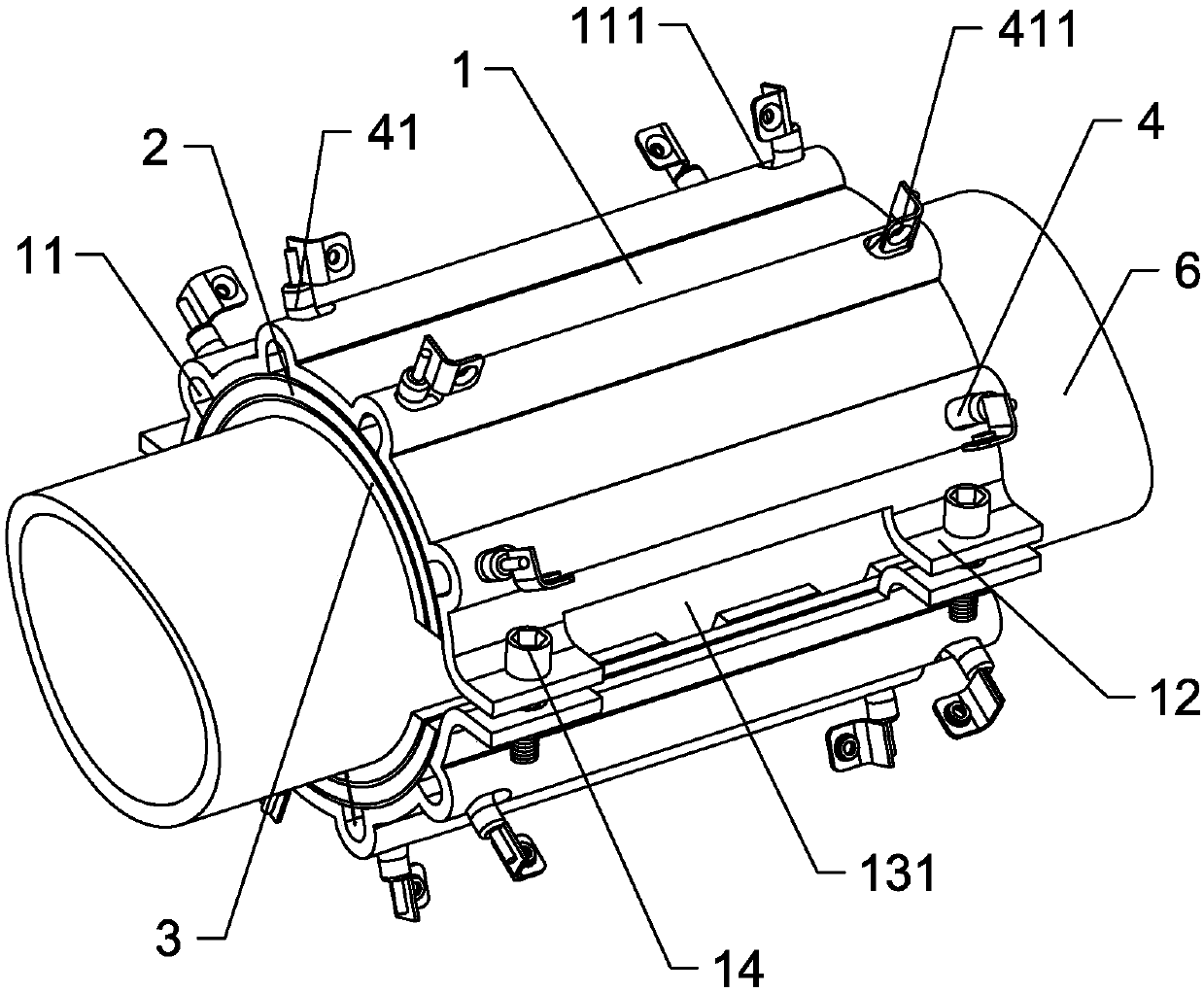

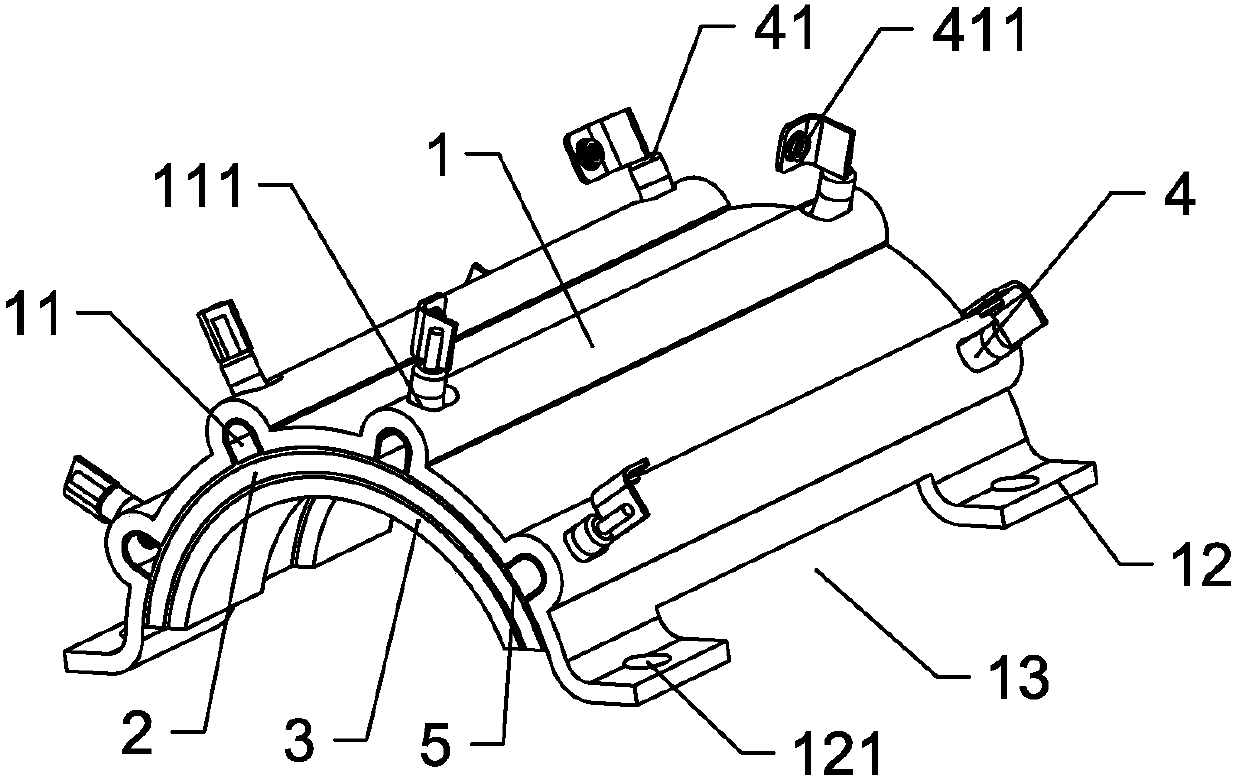

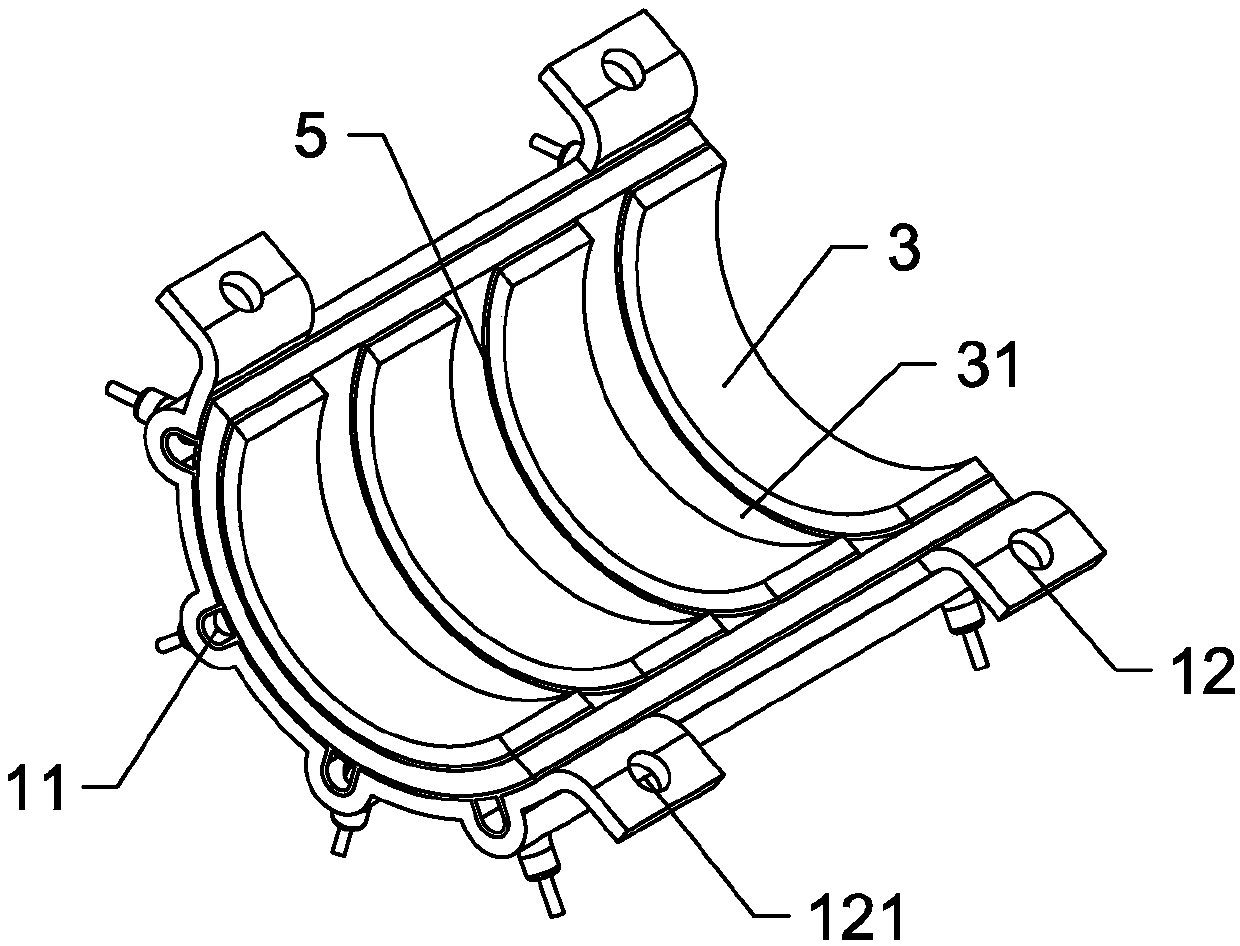

[0037] Such as Figure 1 to Figure 3 As shown, a new type of aluminum heating ring matched with the heated pipeline 6 includes a heating tube 4 and two semi-circular heating rings of the same structure. The outer ring 1, the inner ring 2 and several heat conduction rings 3, the outer ring 1, the inner ring 2 and the heat conduction ring 3 are all made of aluminum rolled plate, and the inner surface of the outer ring 1 is provided with several edge The outwardly protruding groove 11 extending in the axial direction, the heating tube 4 is placed in the groove 11, and each of the grooves 11 is respectively provided with A through hole 111 for the electrodes 41 of the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com