Patents

Literature

75results about How to "Improve production flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

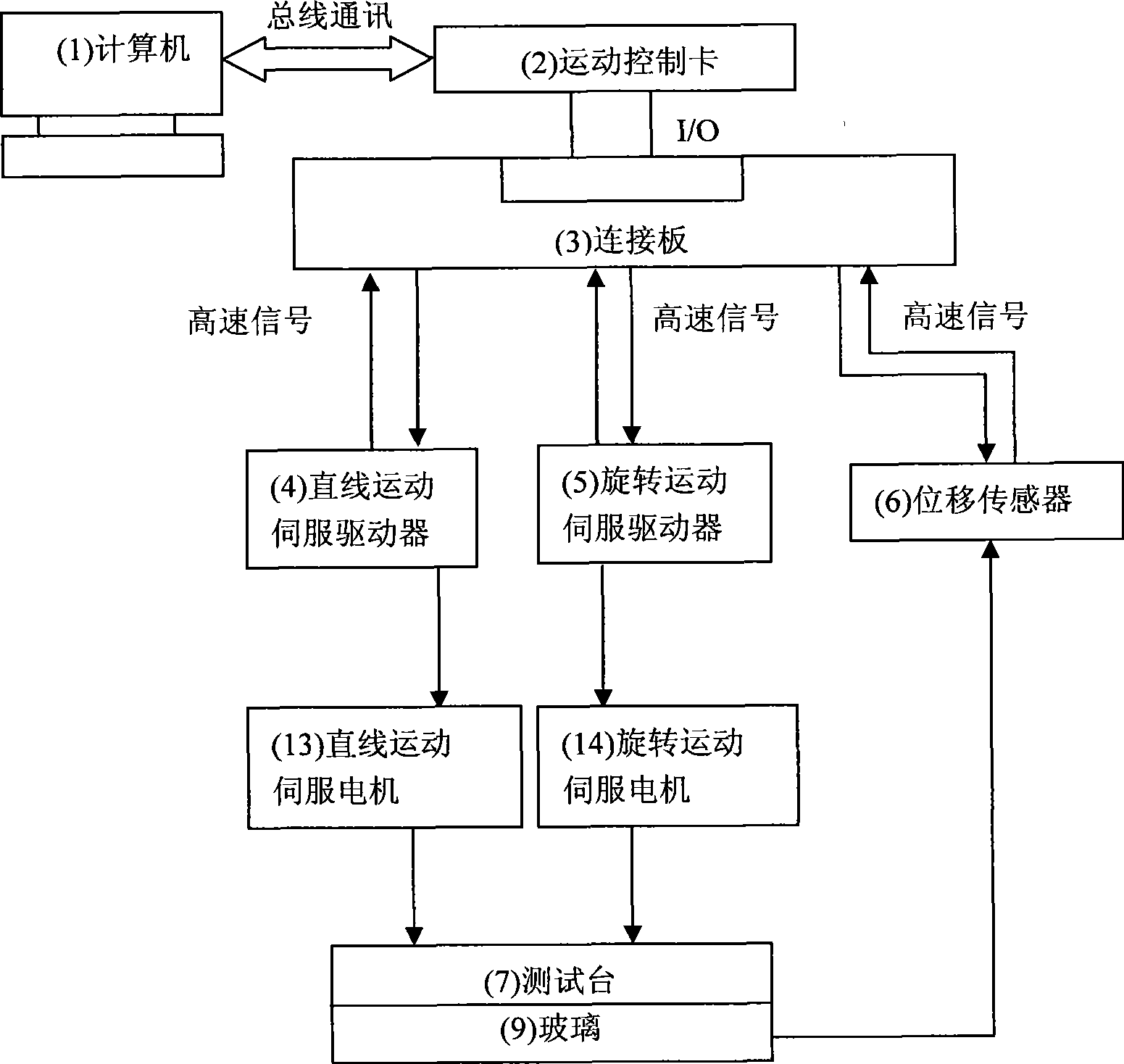

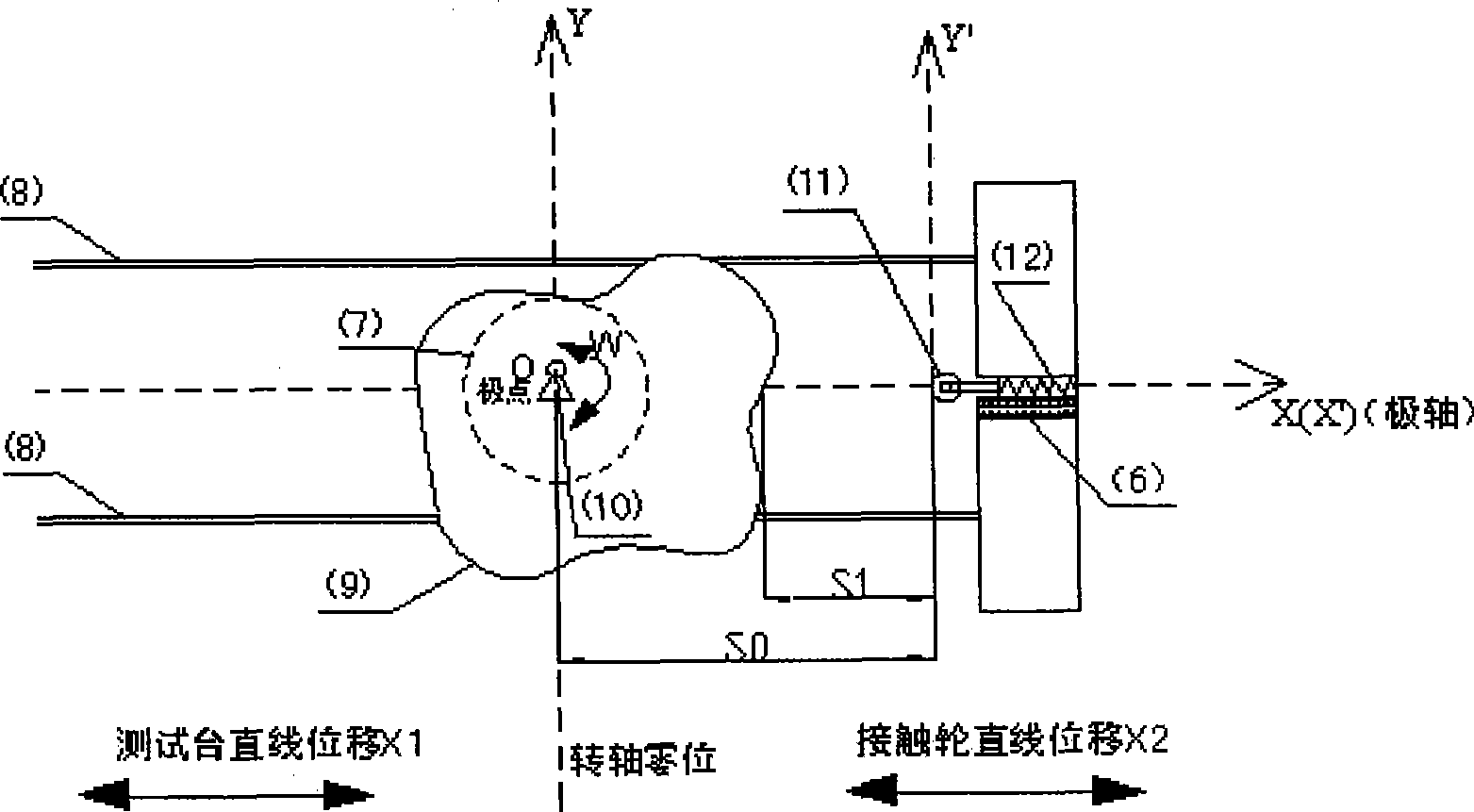

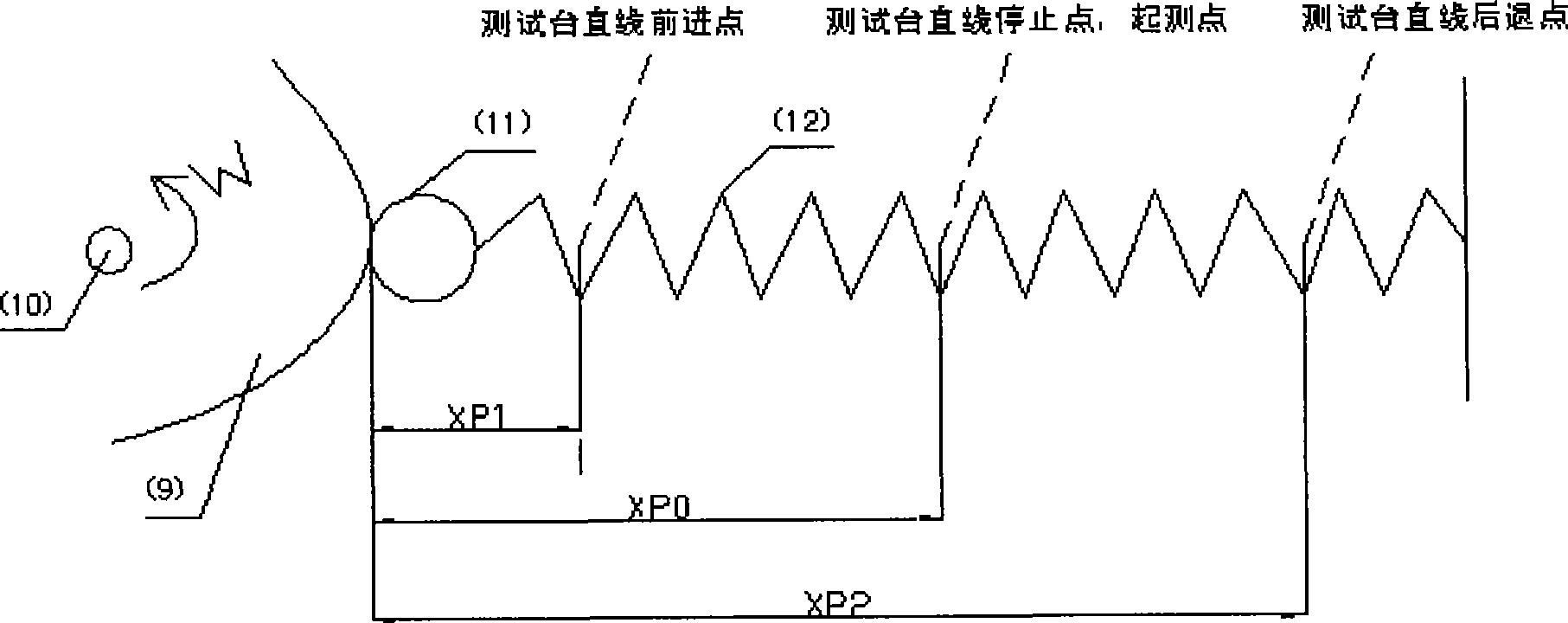

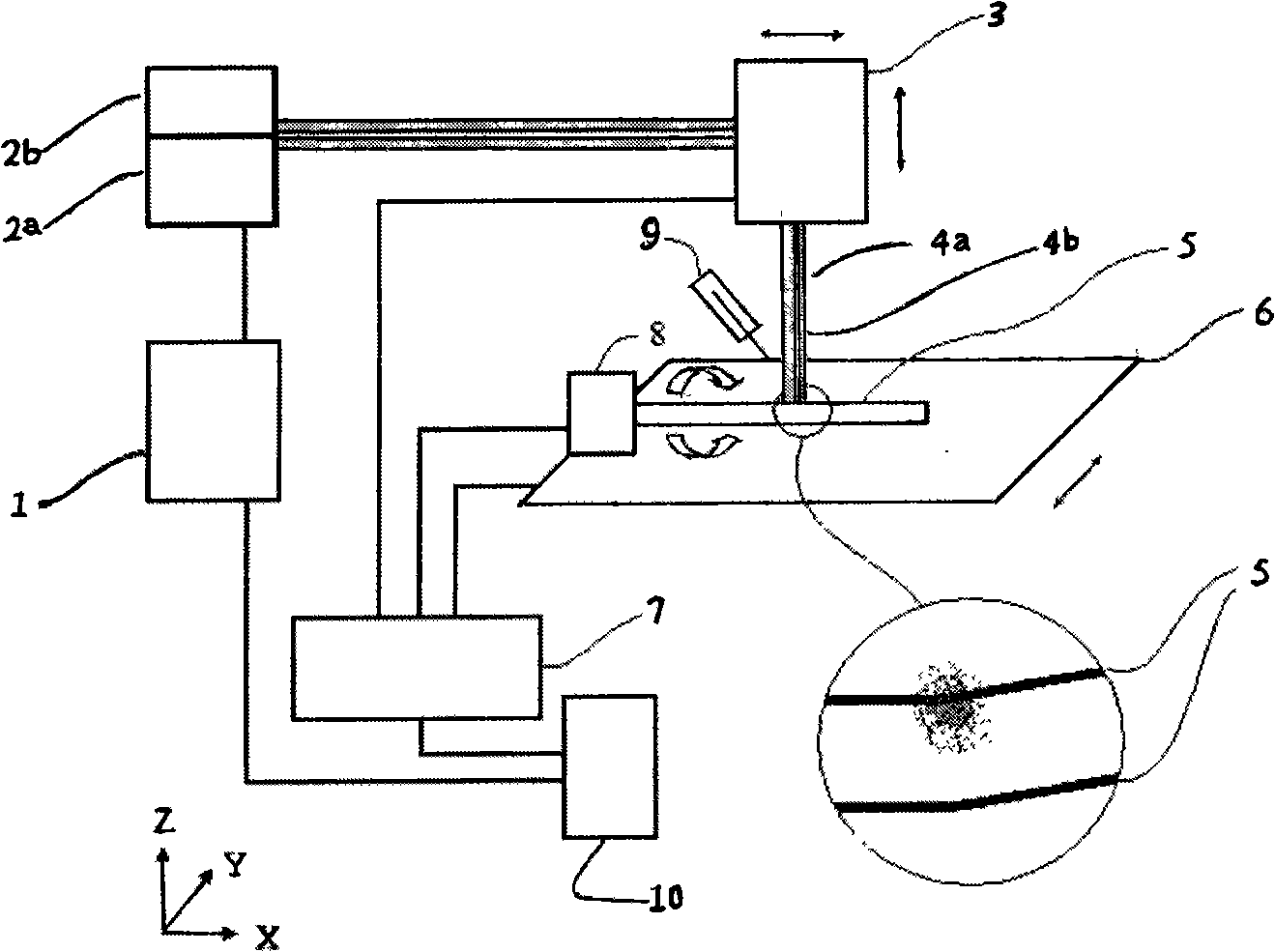

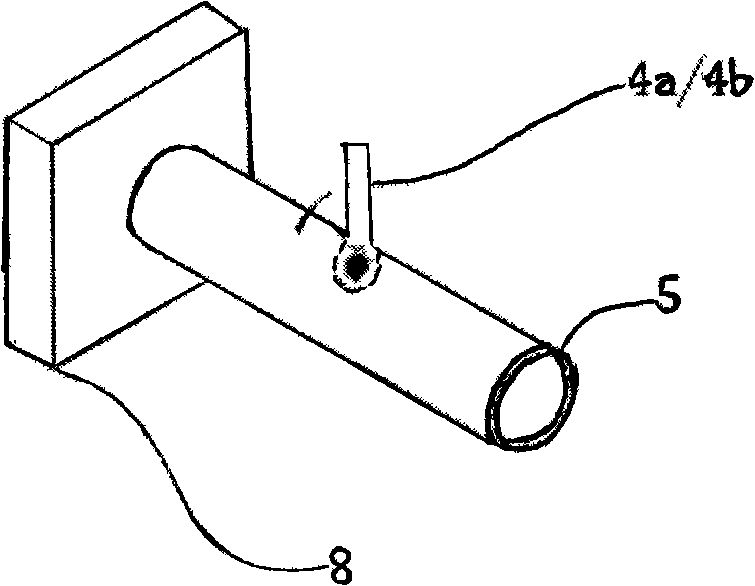

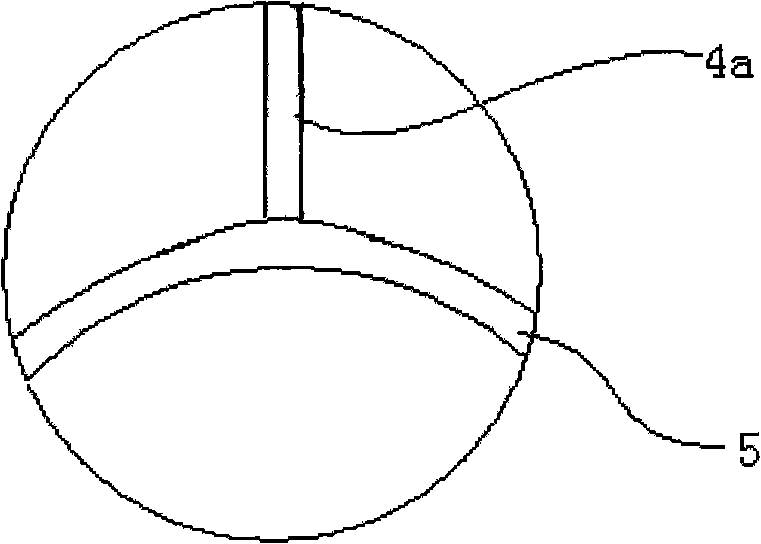

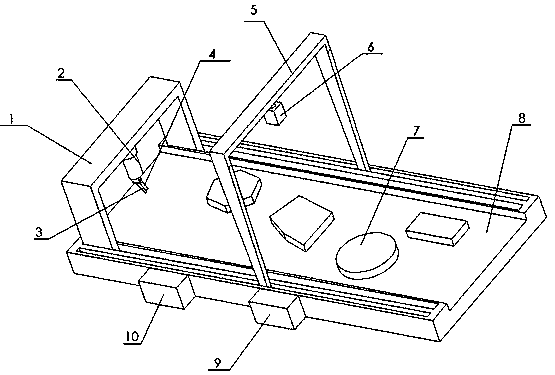

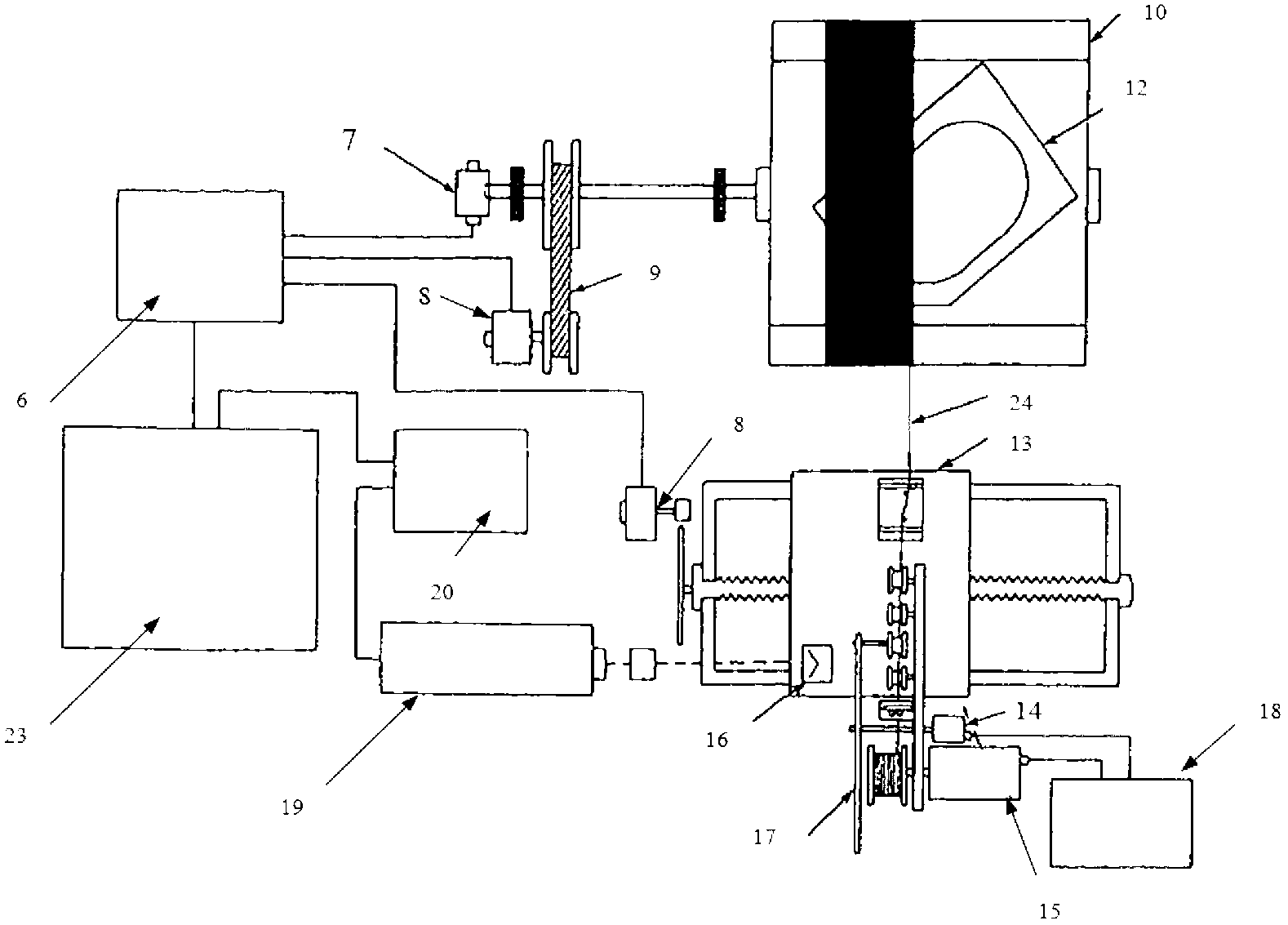

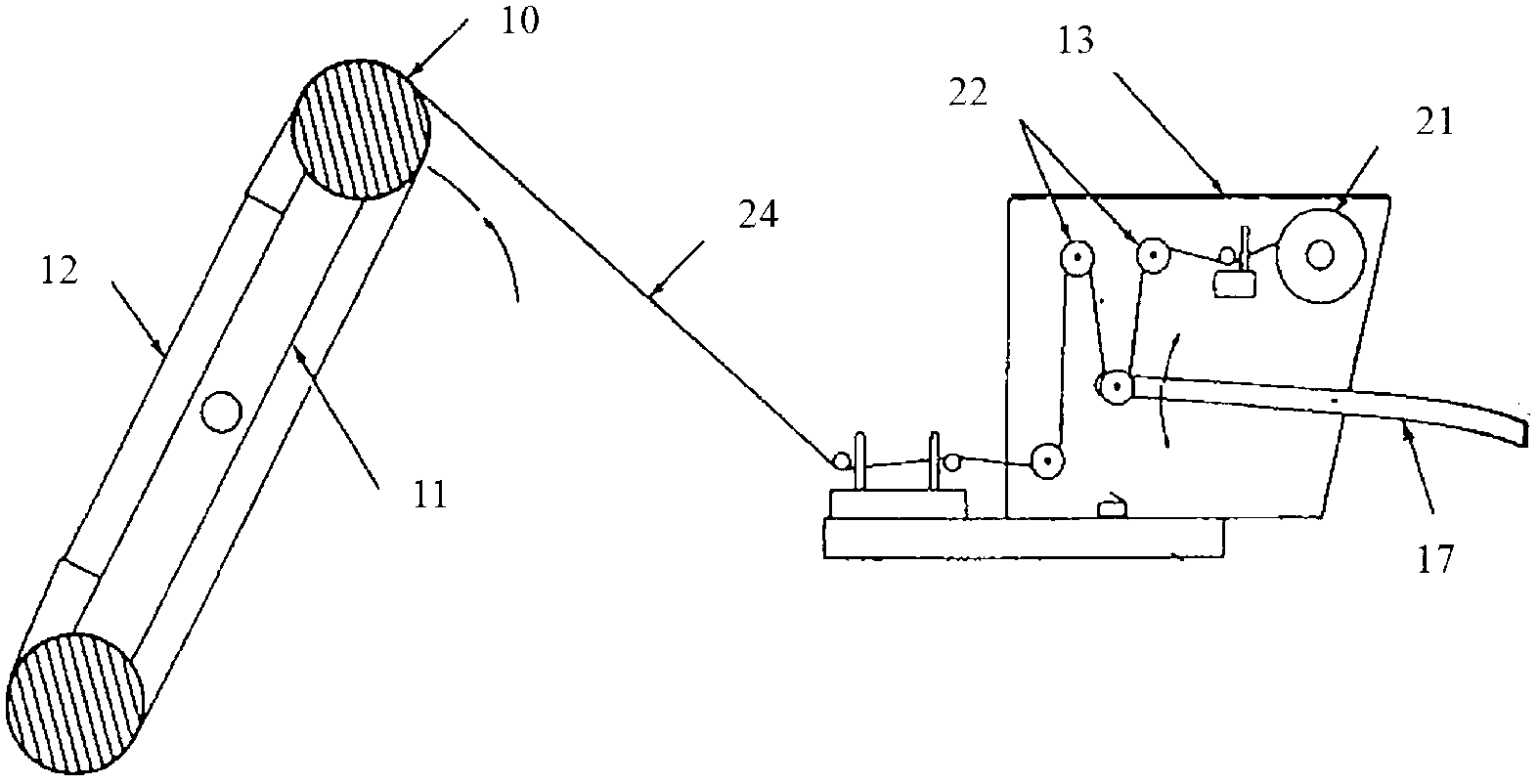

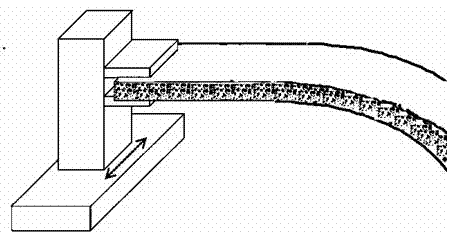

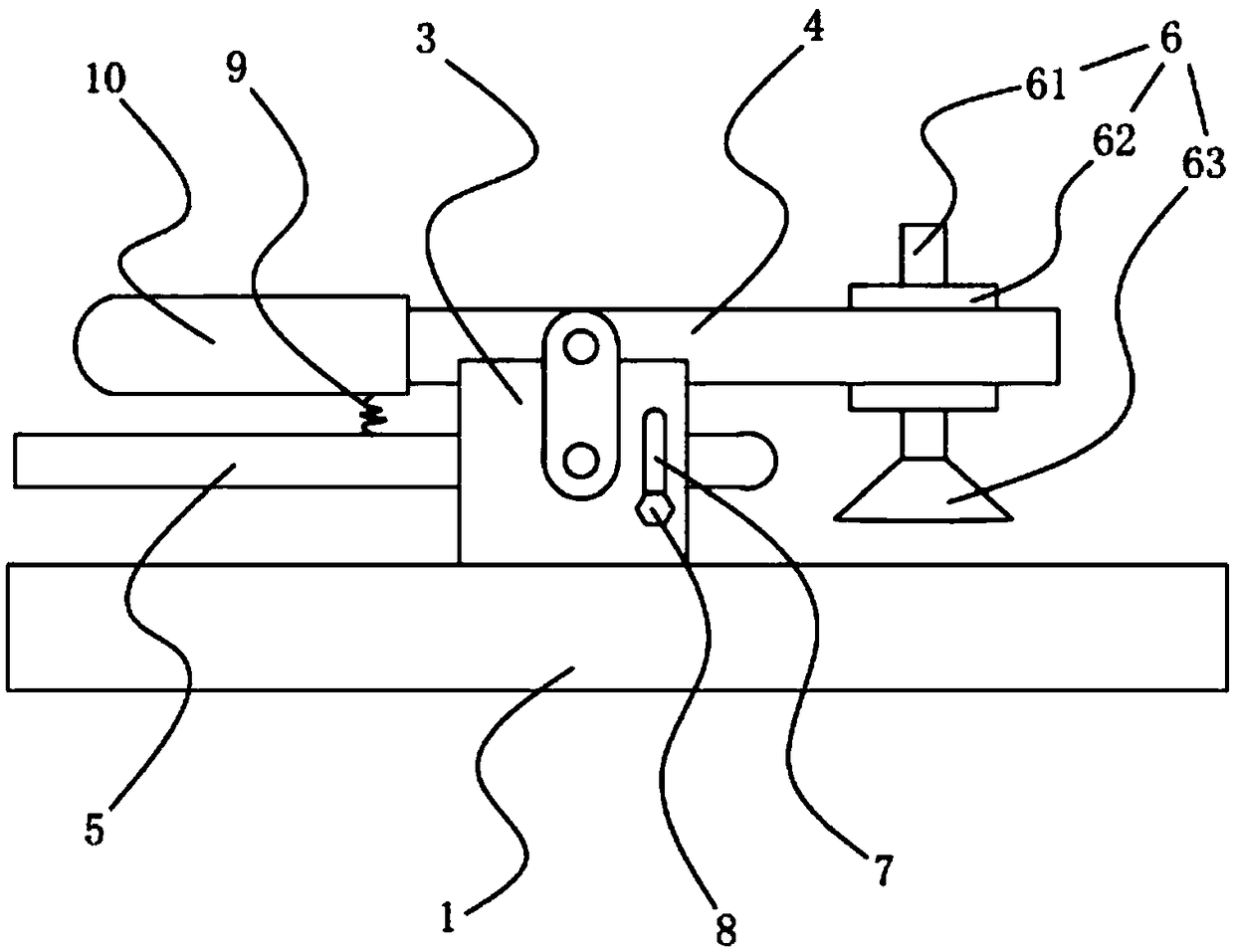

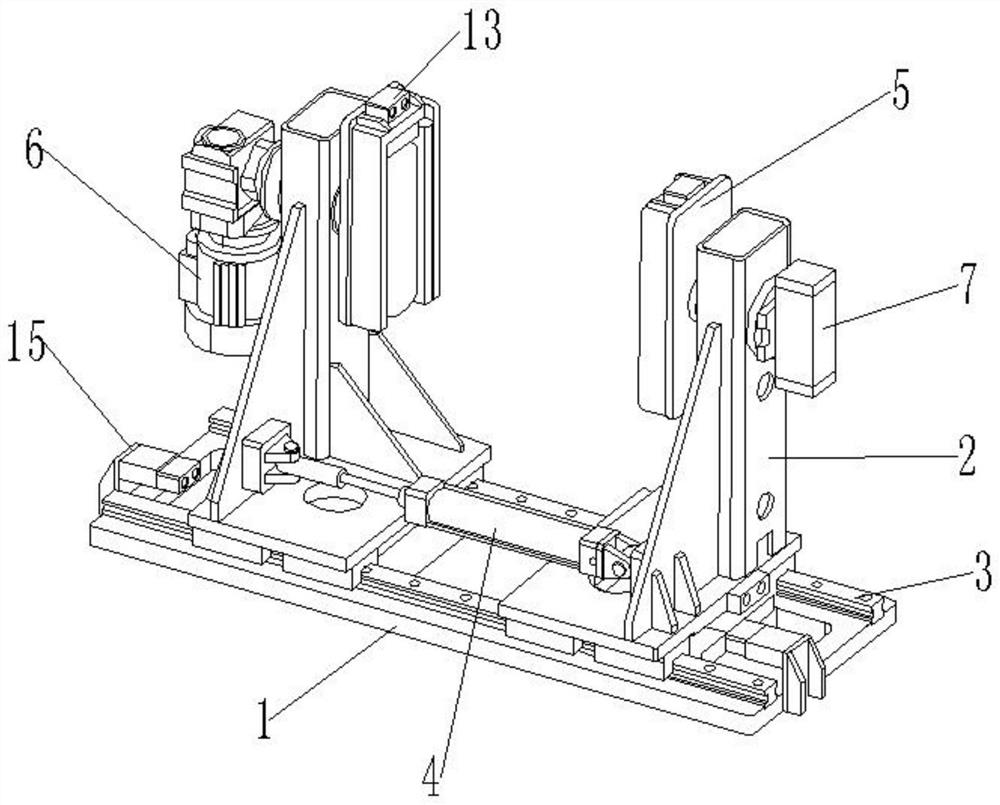

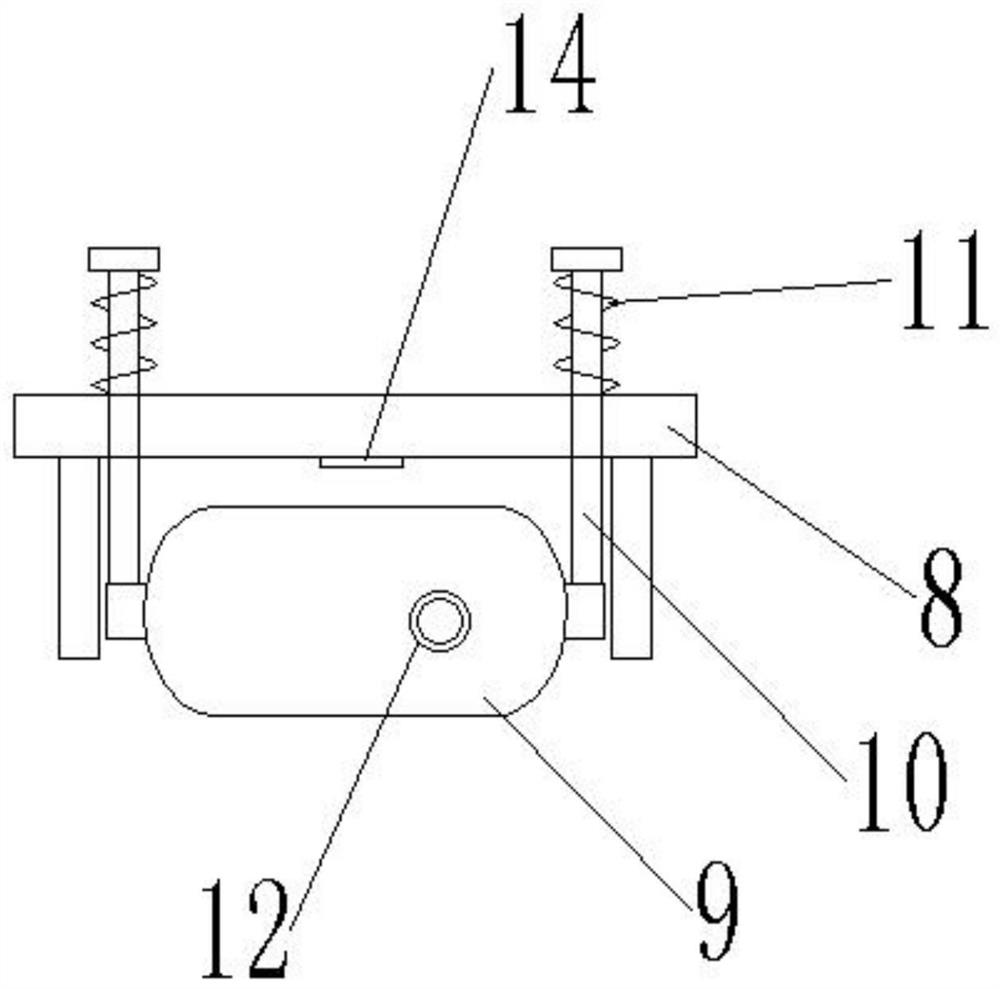

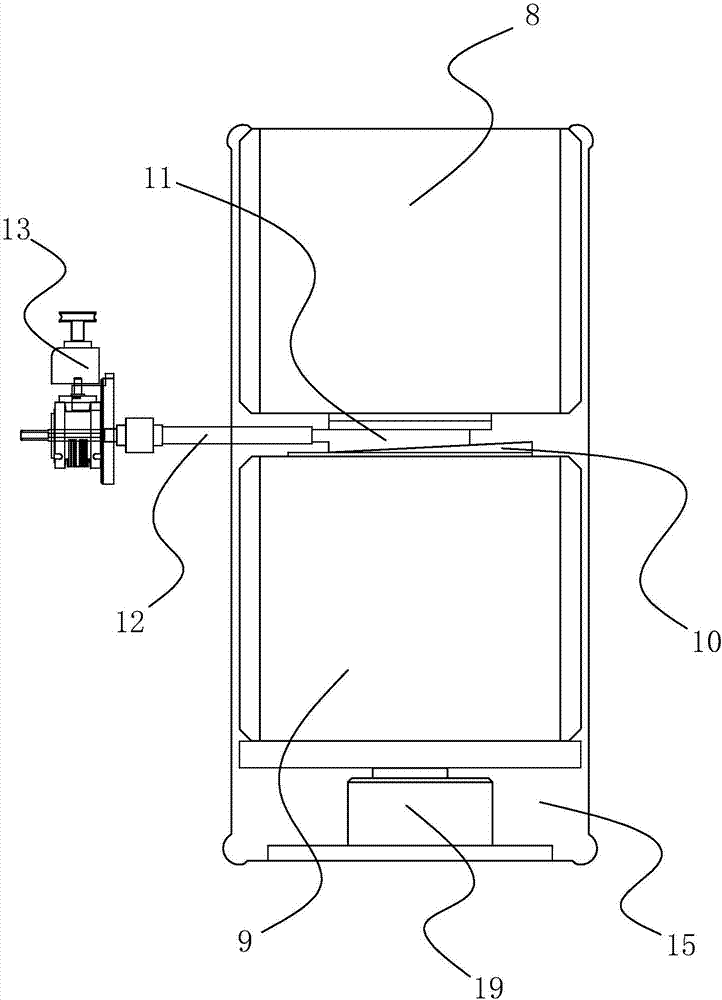

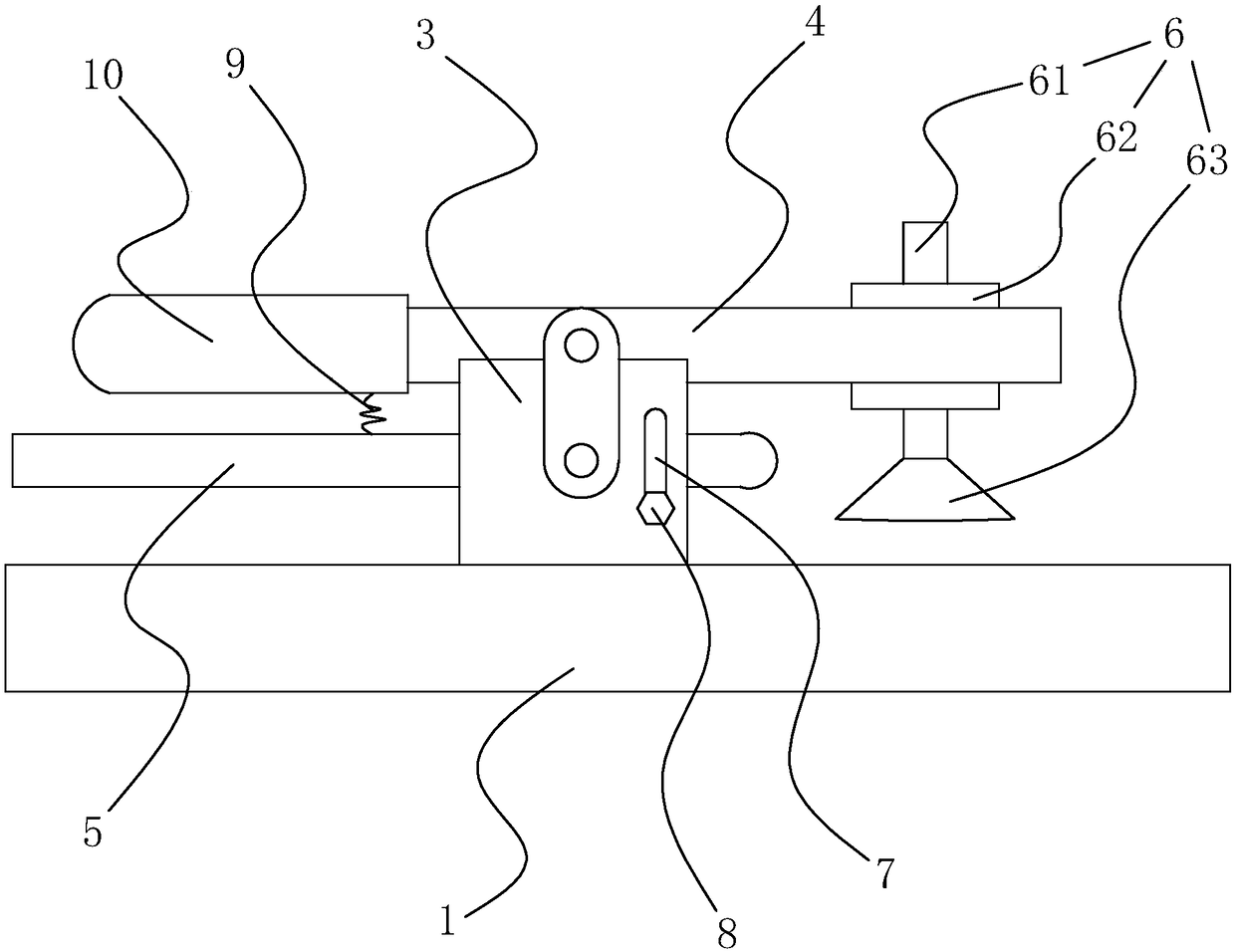

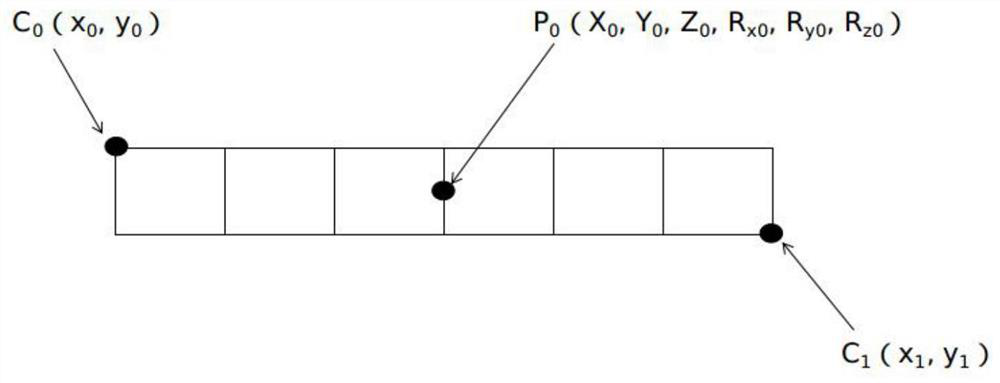

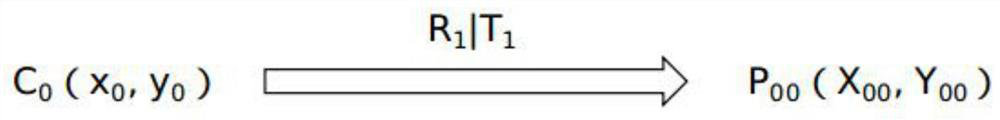

Device and method for detecting contact type large-scale special-shaped glass outline based on rotating-rectilinear movements

ActiveCN101377418ASmall footprintImprove production flexibilityMeasurement devicesDriving testMotion control

The invention relates to a contact type large heterotypic glass gabarit detection device and a method based on rotary-straight line motion. The device comprises a computer and a test desk which is used for arranging detected heterotypic glass and can do straight line motion and rotary motion. The computer is connected with a motion control card through a bus line. The motion control card is connected with a connection board through an I / O interface. The connected board is connected with a straight line motion servo driver, a rotary motion servo driver and a displacement sensor. The straight line motion servo driver is connected with a first servo motor which does carry out the straight line motion on the driving test desk. The rotary motion servo driver is connected with a second servo motor which does the rotary motion on the driving test desk. The displacement sensor is used to detect the displacement of a contact wheel which maintains contact with the heterotypic glass gabarit. The device utilizes the contact wheel to collect the information of the glass gabarit, considers the motion states of the test desk and the contact wheel, combines the real time positions of sampling points gained from the rotary motion and straight line motion, calculates and fits the data in computer, and gets the gabarit curve of the heterotypic glass. The device does not need template, takes up small space, has simple structure and low cost, and is convenient to be used.

Owner:NANTONG XIANGYANG OPTICAL ELEMENT

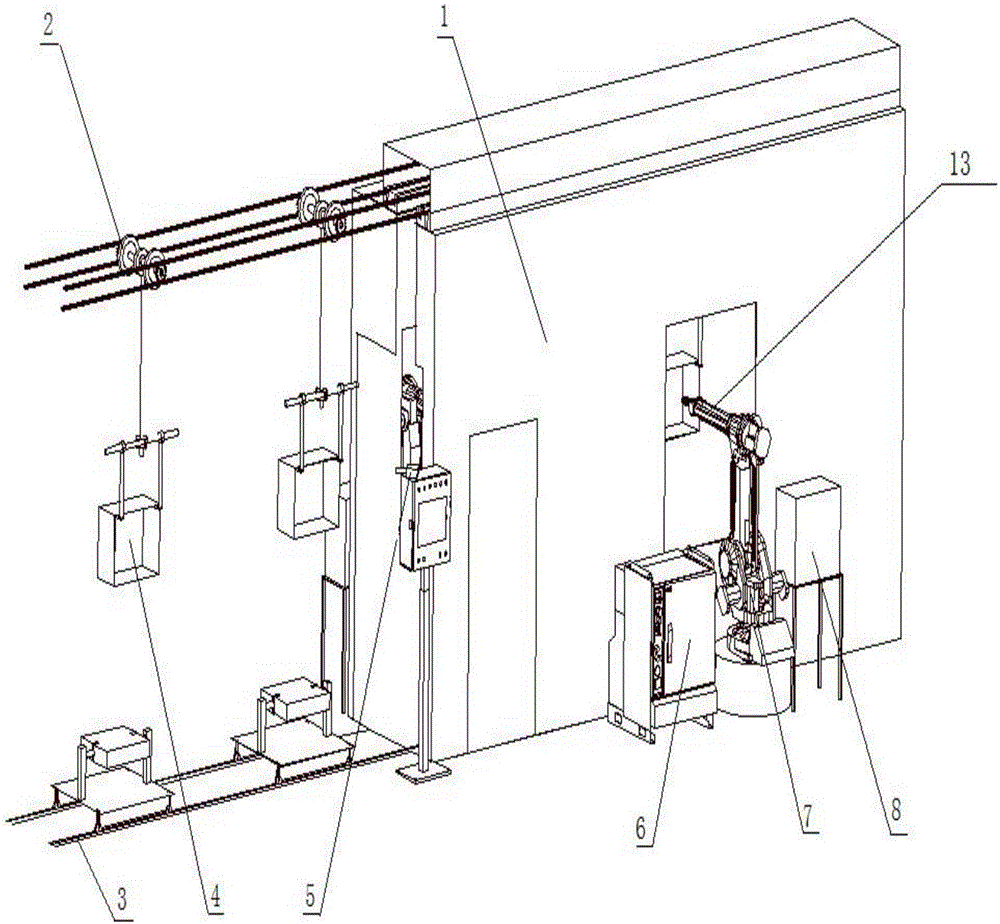

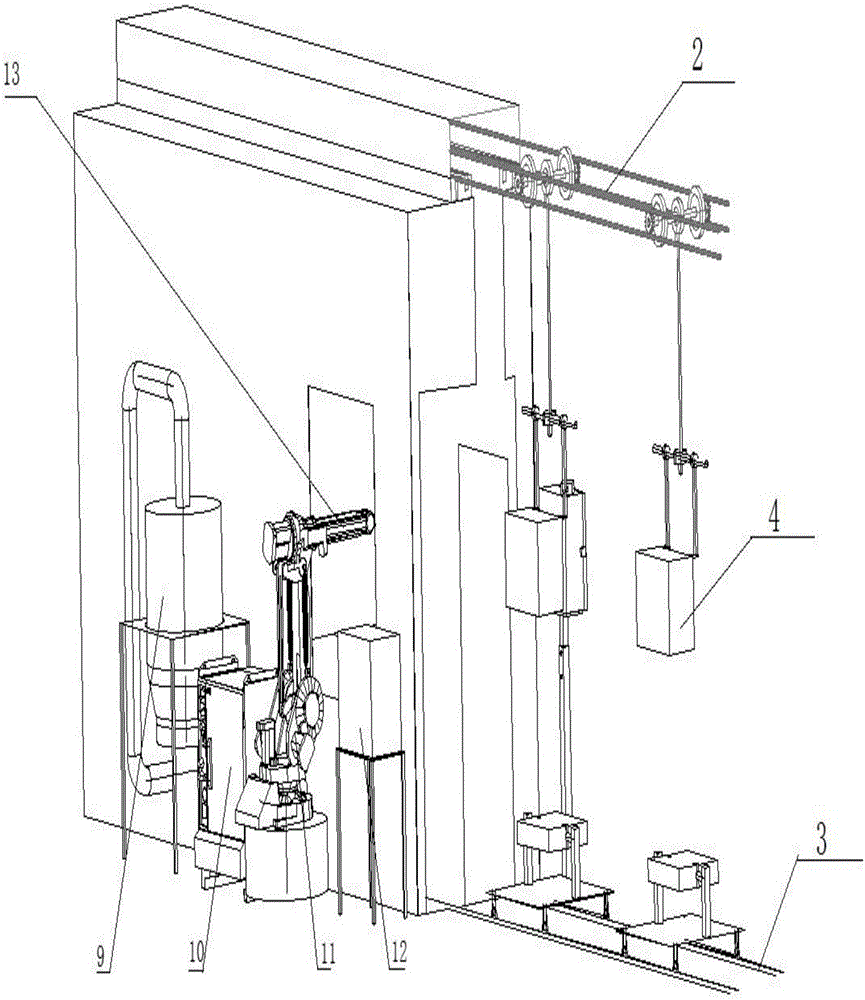

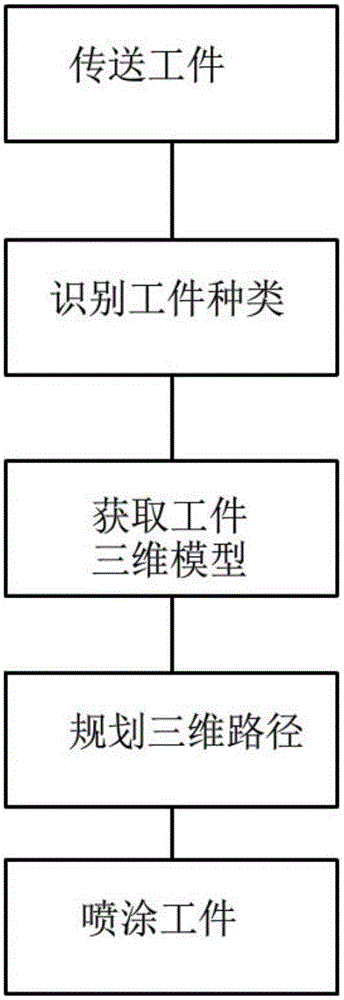

Spraying robot based on visual identification and control method thereof

PendingCN106733379AImprove adaptabilityImprove production flexibilityLiquid surface applicatorsCoatingsVision basedManipulator

The invention discloses a spraying robot based on visual identification and a control method thereof, and comprises the spraying robot based on visual identification and the control method of the spraying robot based on visual identification. The spraying robot based on visual identification comprises a spraying room, and an upper conveying chain, a lower conveying chain, a visual identification system, a control box 1, a manipulator 1, a computer control terminal 1, a powder recoverer, a control box 2, a manipulator 2 and a computer control terminal 2 arranged on the spraying room. The control method of the spraying robot based on visual identification comprises the steps of: (1) conveying of workpieces into the spraying room; (2) identification of the types of the workpieces; (3) obtaining of three-dimensional models of the workpieces; (4) planning of a spraying path; and (5) spraying of the workpieces. The spraying robot based on visual identification enables the spraying to be not only for one workpiece, but for one type of workpieces, and performs parametric programming for the same type of workpieces to improve the adaptability of the sprayed workpieces.

Owner:XIHUA UNIV

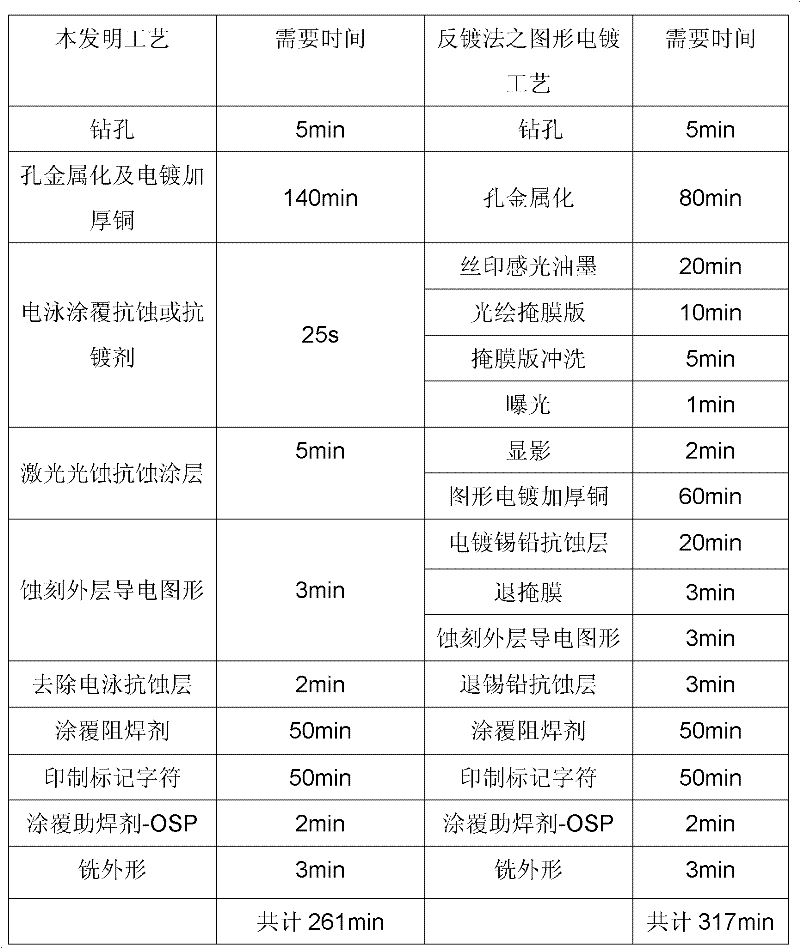

Method for producing anti-corrosion pattern in production of printed circuit board

ActiveCN102510671ASave processSave light paintingConductive material chemical/electrolytical removalResistEtching

The invention relates to a method for producing an anti-corrosion pattern in production of a printed circuit board, and the method comprises the steps of: drilling a hole, metalizing the hole, performing electrophoretic coating of a resist, producing the anti-corrosion pattern by laser, performing chemical etching and the like. The method with the electrophoretic coating of a resist and the production of the anti-corrosion pattern by the laser is adopted for replacing an existing tenting method process with the steps of hot-press lamination of an anti-corrosion photoinduced masking dry film, exposure, developing and the like or replacing the steps of pattern electroplating of an anti-corrosion metal layer and the like. According to the method disclosed by the invention, a process route for producing the anti-corrosion pattern is shortened, the operation steps are simplified, the operability is improved, the anti-corrosion coating is applied by electrophoresis, materials are easy to obtain, the operation is simple and easy, and the formed anti-corrosion coating is thin in thickness, uniform and reliable; and the anti-corrosion pattern formed by direct photoetching through the laser method is high in precision, good in an environment and great in production flexibility. The method disclosed by the invention is suitable for sample, small-batch, multi-variety and higher-precision production of the circuit boards, and is also suitable for production of ordinary circuit boards.

Owner:德中(天津)技术发展股份有限公司

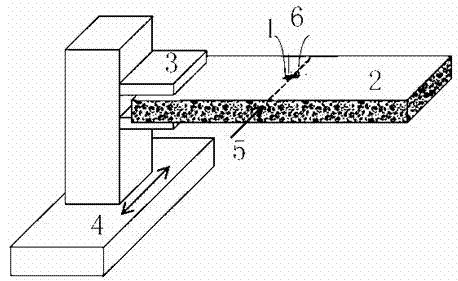

Laser bending shaping method and device of light-wall conduit

InactiveCN101332536AImprove fatigue lifeSmall bending radiusLaser beam welding apparatusControl systemTitanium

The invention discloses a laser bending forming method of a thin-walled tube and a special device used for realizing the method. The method adopts two laser beams to act on the thin-walled tube, wherein one laser beam is used for heating the thin-walled tube to soften the thin-walled tube and producing thermal stress along the thickness direction of the tube wall so as to cause the tube to bend and deform; the other laser beam forms a plasma on the surface of the tube, and further bends the thin-walled tube by the shock action produced by the plasma to obtain a fine grain structure. The special device for realizing the laser bending forming method of the thin-walled tube is composed of a laser generator system, a laser head system, a workbench system and a motion control system. By adopting the method, metal and alloy tubes made from steel, aluminum, copper, titanium and the like can be machined, which is a high-flexibility dieless forming technology.

Owner:SHANDONG UNIV

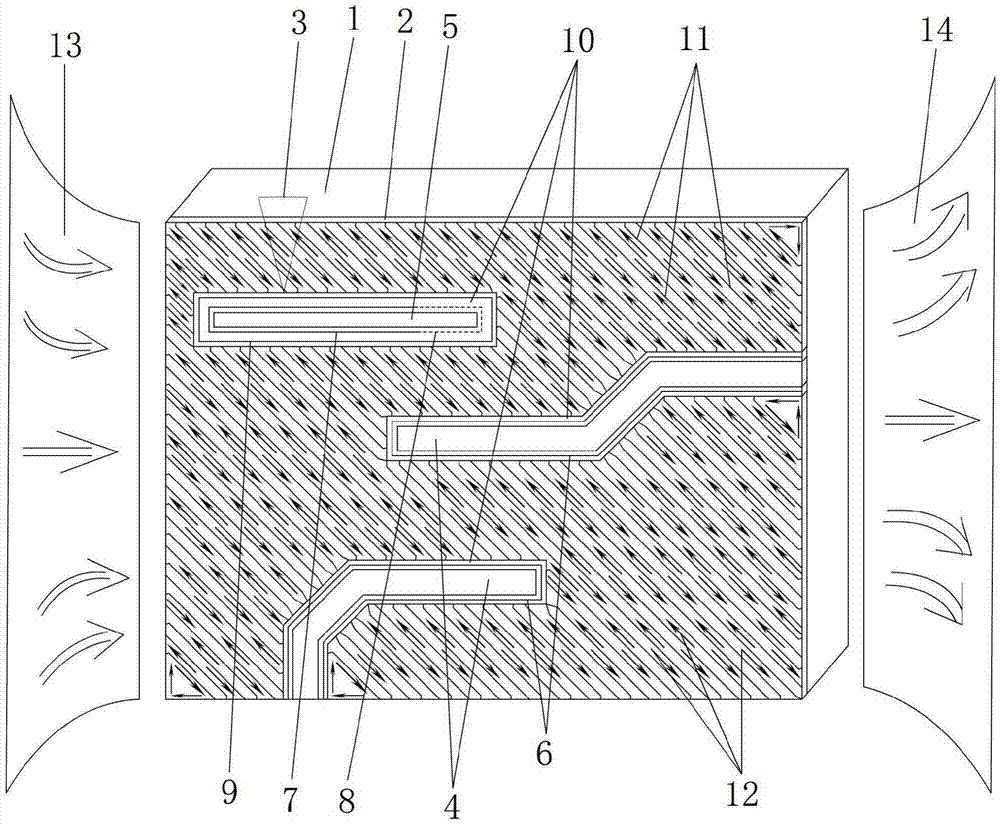

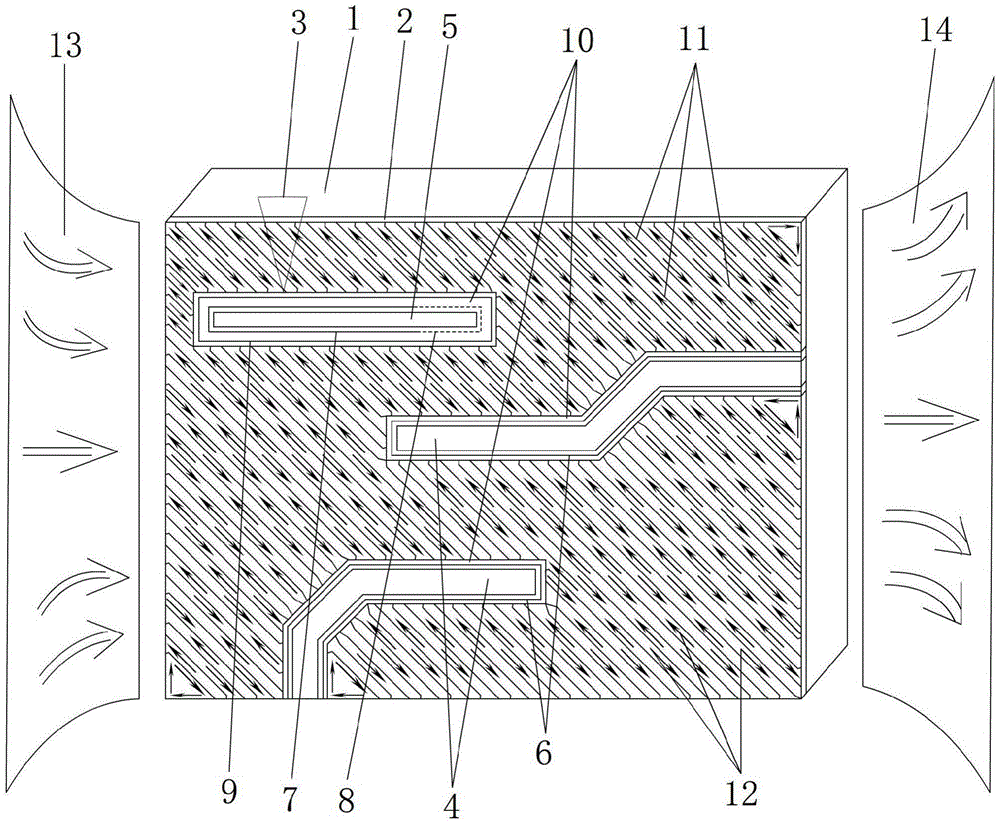

Method for selectively removing conductive layer on baseplate material

The invention relates to a method for selectively removing a conductive layer on a baseplate material. The method comprises the following steps: processing to manufacture an insulated enveloping channel on the periphery of a to-be-reserved conductive layer, wherein an isolated wire with over-narrow width is processed twice or more than twice; subdividing a to-be-removed conductive layer into a plurality of insulated small blocks, wherein the adjacent insulated small blocks are of complementary shapes such as inverted quadrangle, trapezoid or triangle; projecting electromagnetic waves onto the subdivided insulated small blocks so as to ensure that the subdivided insulated small blocks are separated from the baseplate material to be removed, wherein during heating, the projected laser moves from the narrower end of each small block of the conductive layer to the wider end of each small block. According to the method, the projecting parameter, projecting path and projecting environment of the laser are regulated and the conductive layer on the substrate material is removed, so that a preset conductive structure is formed, and the method can be used for replacing a corresponding technical process adopted in the process of manufacturing a conductive structure by virtue of an existing chemical method, an existing physical method and an existing laser method.

Owner:德中(天津)技术发展股份有限公司

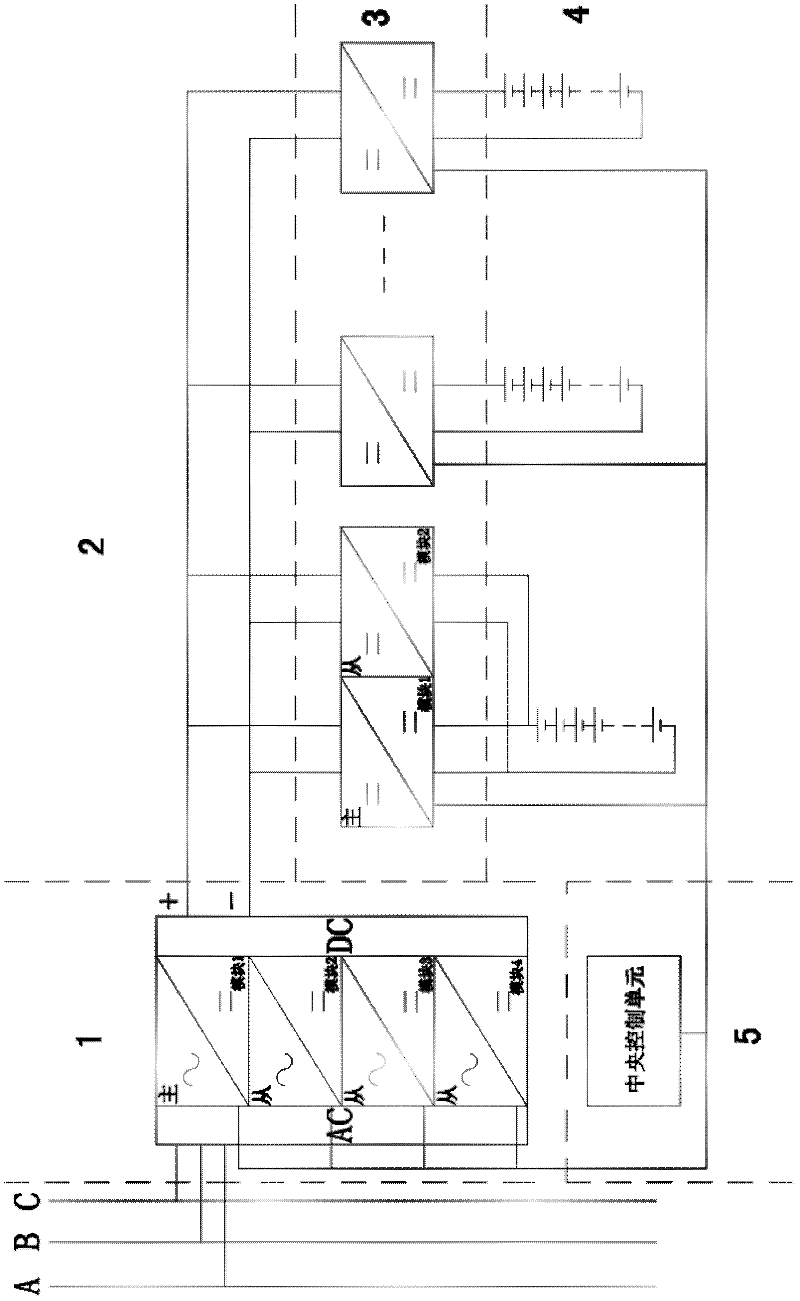

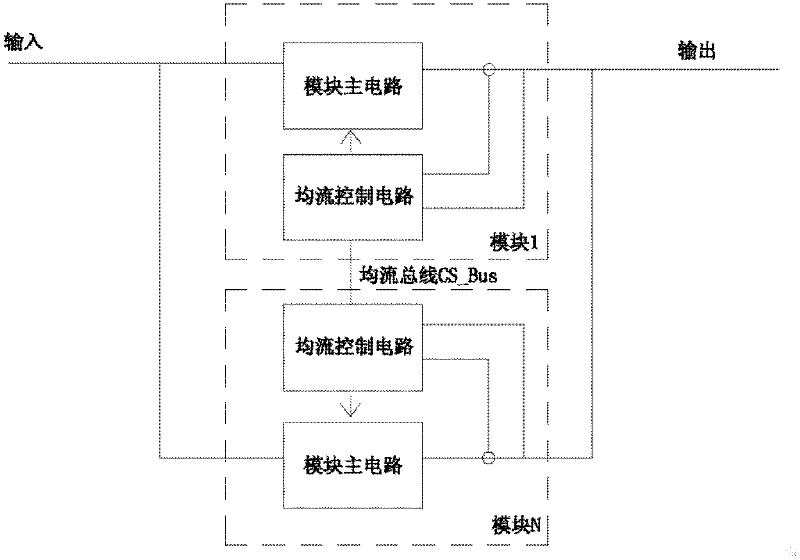

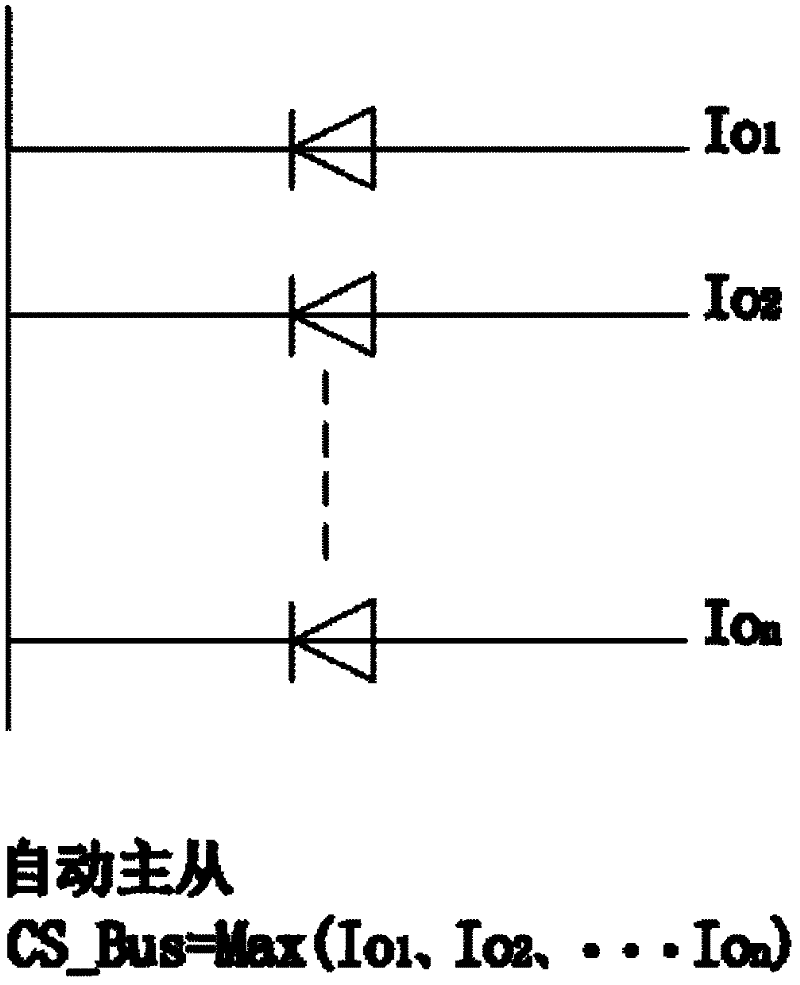

High-power modular lead-acid battery formation charging/discharging system

InactiveCN102340040AWith automatic sleep functionImprove system efficiencyFinal product manufactureLead-acid accumulators constructionSystem capacityData acquisition

The invention discloses a high-power modular battery formation charging / discharging system, belonging to the field of battery formation charge / discharge. The system comprises an invertible DC (direct current) power module, a DC bus, a conversion charging / discharging module and a central control unit. The invertible DC power module adopts an automatic master-slave current sharing technology, can automatically configure the module number according to the system capacity, realizes automatic current sharing among the modules, and can inversion-feed the redundant electric energy back to the power grid so as to realize master-slave redundant invertible DC power module design; the DC bus transmits electric energy in the system; the conversion charging / discharging module is directly connected with the DC bus; by adopting the automatic master-slave current sharing technology, each module can form a loop independently for production, or multiple modules are freely connected in parallel to form a loop for production; and the central control unit is connected with the invertible DC power module and the conversion charging / discharging module through the bus, and can realize the functions of operation data acquisition, system resource allocation, module alternation coordination, system capacity reduction protection and the like.

Owner:SHANDONG SACRED SUN POWER SOURCES

Method for rolling large-sized aluminum alloy ring piece and performing solid solution treatment by using electric furnace

InactiveCN102409270AIncrease furnace capacityImprove production flexibilityElectrical resistance and conductanceElectric arc furnace

The invention relates to a process method for rolling and molding a large-sized aluminum alloy ring piece and performing solid solution treatment by using an electric furnace, and belongs to the field of manufacturing of non-ferrous alloys. The method comprises the following steps of: determining the aluminum ingot rolling specification and the rolling process upsetting deformation ratio of an aluminum alloy ring piece blank and heating temperatures and temperature preservation time process parameters during solid solution aging treatment of the electric furnace through the rolling and molding ingot specification and the rolling process parameter of an aluminum alloy, wherein in the determined process, the upsetting deformation ratio of the rolled and molded aluminum ingot with the specification of phi 410*1,000mm is 85 to 88 percent; performing a solid solution process at the temperature of between 475+ / -5 DEG C for 500 minutes in a resistance furnace; performing water quenching at the temperature of 65 DEG C, wherein the straightening cold deformation amount is 3 to 4 percent; and performing aging treatment by using the electric furnace at the temperature of 130+ / -5 DEG C for 7 hours, and raising the temperature to 170+ / -5 DEG C for 8 hours. By the novel process method for rolling and molding a large-sized aluminum alloy and producing a blank through solid solution thermal treatment of the electric furnace, feeding amount is reduced by 38 percent, and the efficiency is improved by 30 percent; and the method has the characteristics of short production period, high quality stability and the like, is safe, energy-saving and environment-friendly, has obvious economic benefits and is positioned in a leading level in China.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

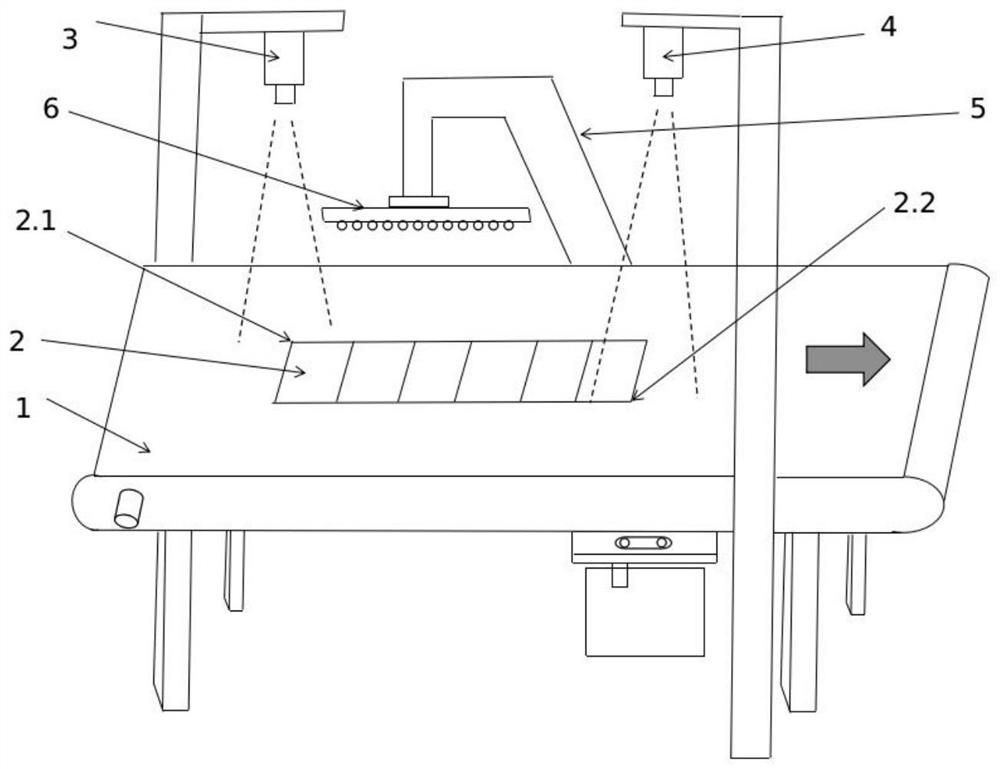

Steel plate groove cutting method based on visual recognition

ActiveCN109702290AImprove machining accuracyImprove production flexibilityGas flame welding apparatusSteel platesEngineering

The invention discloses a steel plate groove cutting method based on visual recognition, and relates to the technical field of numerical control machining. The steel plate groove cutting method refersto a working conveying platform for conveying workpieces, a first visual device, a first visual support, a cutting torch motion execution device, a numerical control cutter controller, an image processor, a cutting torch bracket and a second visual device. Multi-part online recognition and edge extraction are achieved, the machining path is planned through a planning algorithm, the part edges areobtained in real time by combining with an on-line visual tracking technology, numerical control machining is conducted through an error compensation method, the purpose of groove autonomous cuttingis achieved, and the machining accuracy of numerical control machining based on image positioning is improved.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

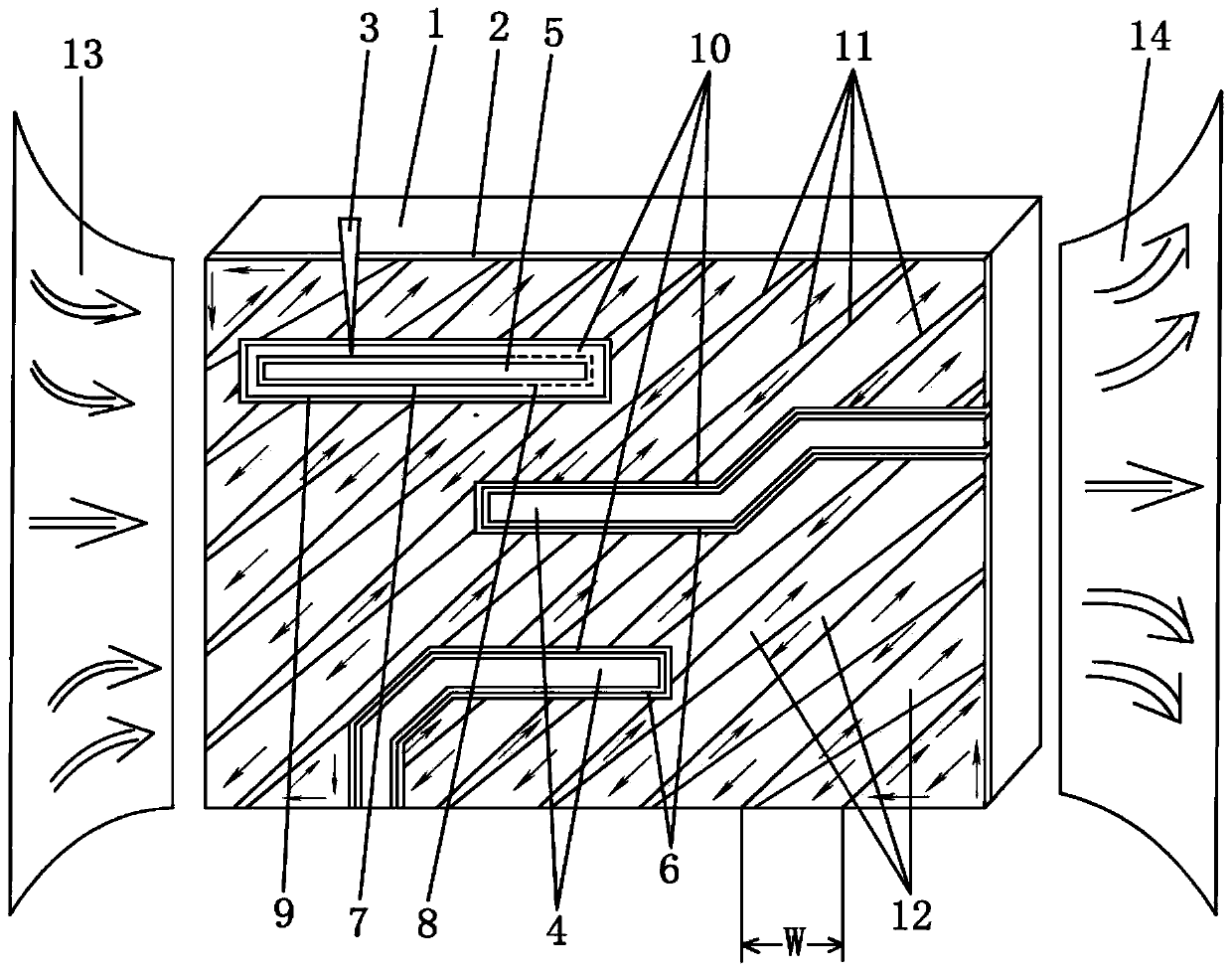

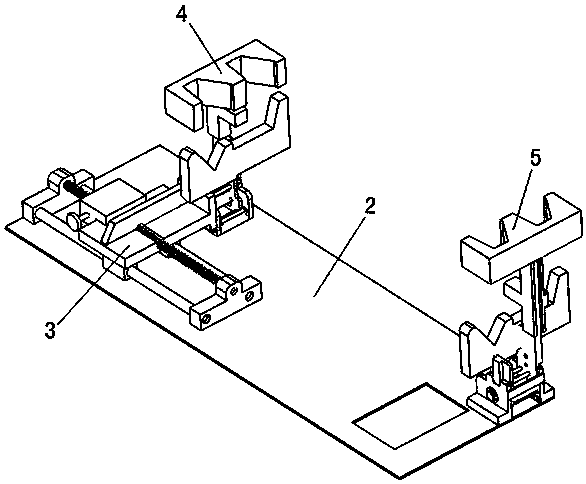

Manufacturing device and manufacturing method for supportless polarized separation grid at microwave band

InactiveCN103219594AReduce manufacturing costReduce manufacturing difficultyAntennasMicrowave bandManufacturing engineering

The invention relates to a manufacturing device and a manufacturing method for a supportless polarized separation grid at a microwave band. The manufacturing device comprises a support (1), a grid framework (3), a die (2) and a tensioning weight (5). On the basis of the application of the device disclosed by the invention, the invention further provides a manufacturing method for the supportless polarized separation grid at the microwave band. The method and device for manufacturing the polarized separation grid have the characteristics of low production cost, simple system components and production process, high precision of produced products, supportless manufacture, high reliability, convenience in maintenance and better production flexibility in production device; and the method and the device meet demands of the medium-small batch production and scientific application.

Owner:NAT SPACE SCI CENT CAS

Foamed aluminum sandwich board bend forming method

InactiveCN102873152AOptimizing Process ParametersPrecise control of temperature distributionLaser beam welding apparatusCompound aSandwich board

The invention discloses a foamed aluminum sandwich board bend forming method which is characterized by including steps of (1), compounding a layer of light absorption agents on the panel surface of a foamed aluminum sandwich board; (2), marking a machining straight line on the surface of the foamed aluminum sandwich board; (3), irradiating along the machining straight line on the surface of the foamed aluminum sandwich board by a laser with a scanning rate ranging from 3mm / s to 8mm / s, and heating the foamed aluminum sandwich board by accumulation of multiple irradiations to enable the same to generate thermal stress and generate trace bending deformation back to a laser beam; and (4) repeating the step of (3) until the bending requirements are met. By the foamed aluminum sandwich board bending method, any bending parts, special-shaped parts, other complicated parts with three-dimensional curved surfaces and the like can be formed. The foamed aluminum sandwich board bend forming method has the advantages that forming precision is high, production cycle is short, the formed parts are high in flexibility, and a wide application foundation is provided for further application of the foamed aluminum sandwich board.

Owner:SUZHOU UNIV

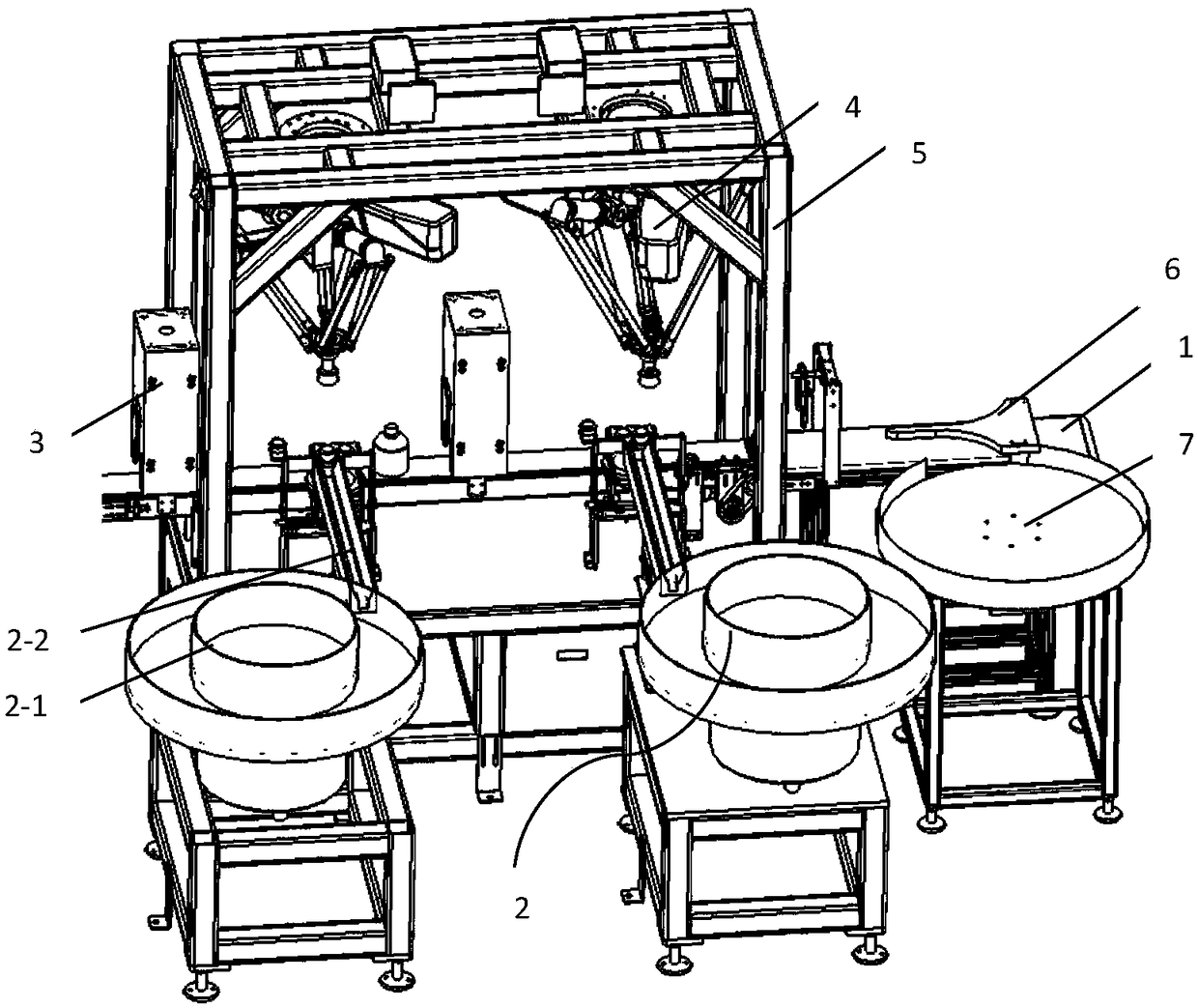

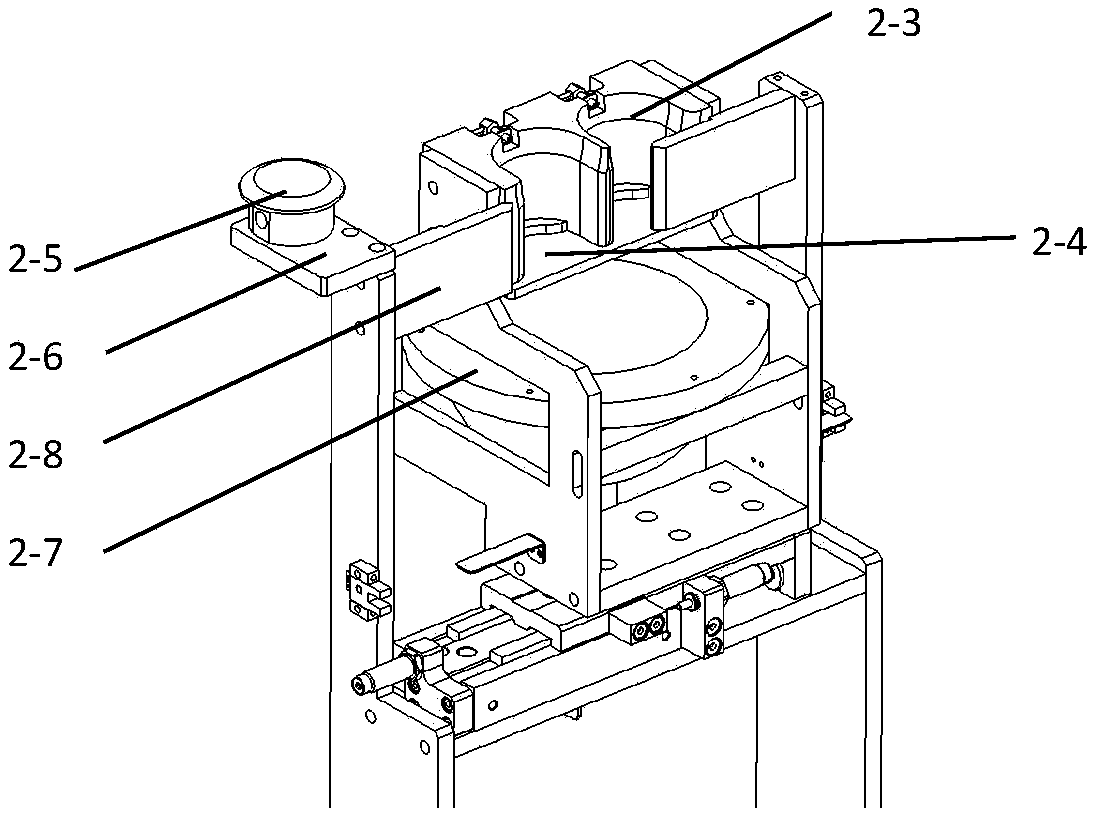

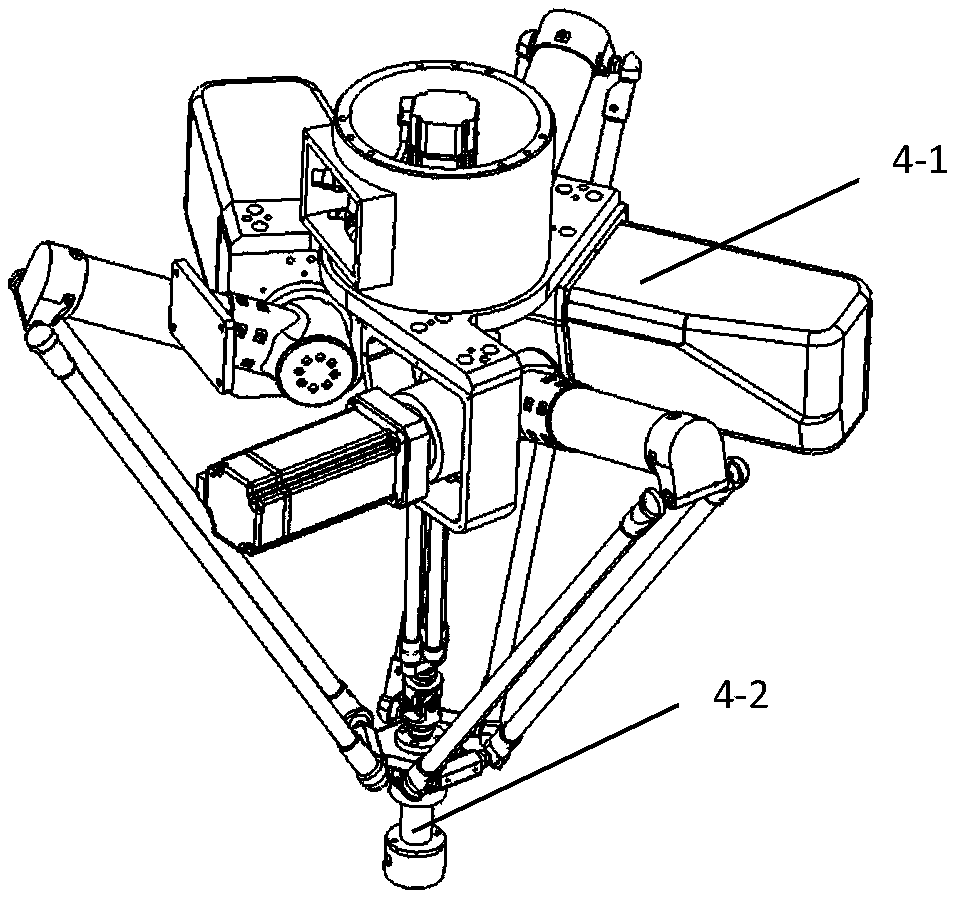

Automatic wine bottle cover putting device

PendingCN109179286AImprove production flexibilityIncrease the output speedConveyorsFlanged caps applicationWine bottleVisual inspection

The invention discloses an automatic wine bottle cover putting device, and belongs to the technical field of automatic white wine production equipment. The automatic wine bottle cover putting device comprises a first conveying line and a wine bottle cover putting unit; the wine bottle cover putting unit comprises a posture adjustment unit, a first visual inspection mechanism and a carrying robot;the first visual inspection mechanism and the carrying robot are sequentially arranged above the first conveying line in the movement direction of the first conveying line; the posture adjustment unitis arranged on one side of the carrying robot and comprises a vibration plate; the output end of the vibration plate is connected with the input end of a linear feeder; a receiving groove rightly faces the output end of the linear feeder; a wine bottle enters the receiving groove through the linear feeder; a light transmitting board is horizontally installed at the lower end of the receiving groove; a second visual inspection mechanism is arranged below the receiving groove and used for detecting the posture of a bottle cover in the receiving groove; and the carrying robot is used for carrying the bottle cover in the receiving groove to be put on a bottle mouth of the wine bottle. The automatic wine bottle cover putting device can put the special-shaped bottle cover on the wine bottle.

Owner:ANHUI HISEED ROBOT CO LTD

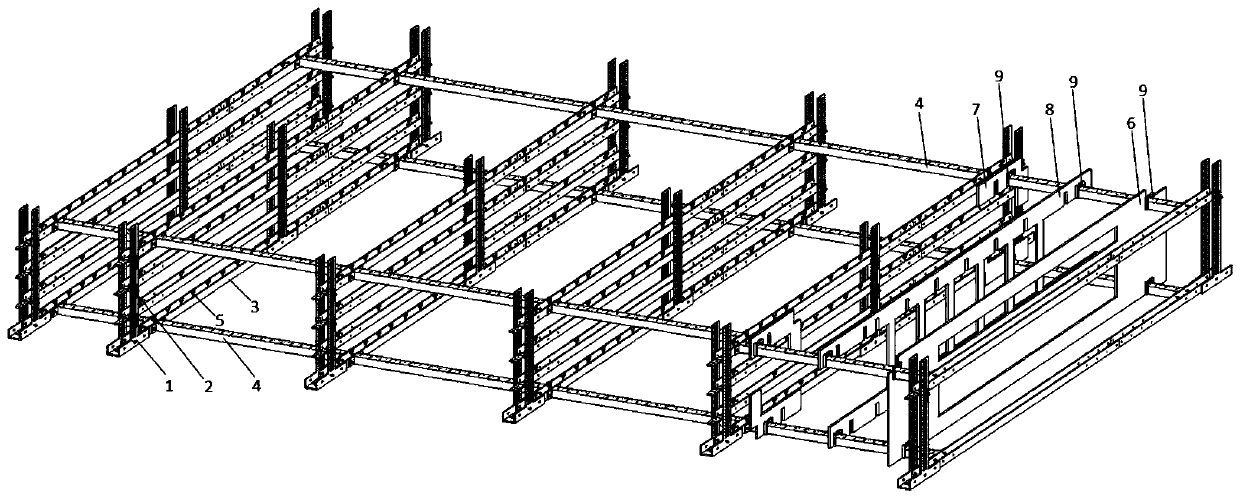

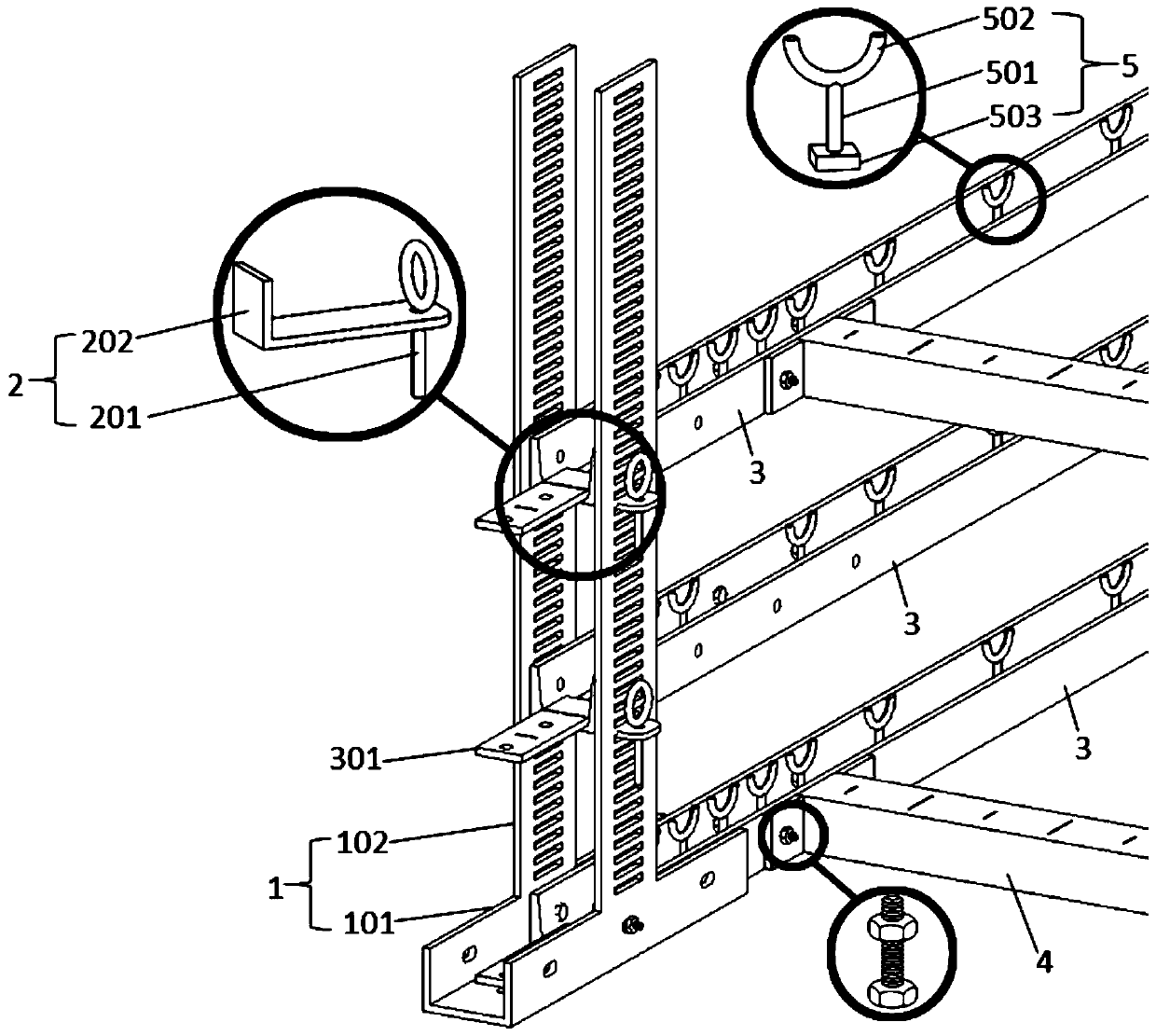

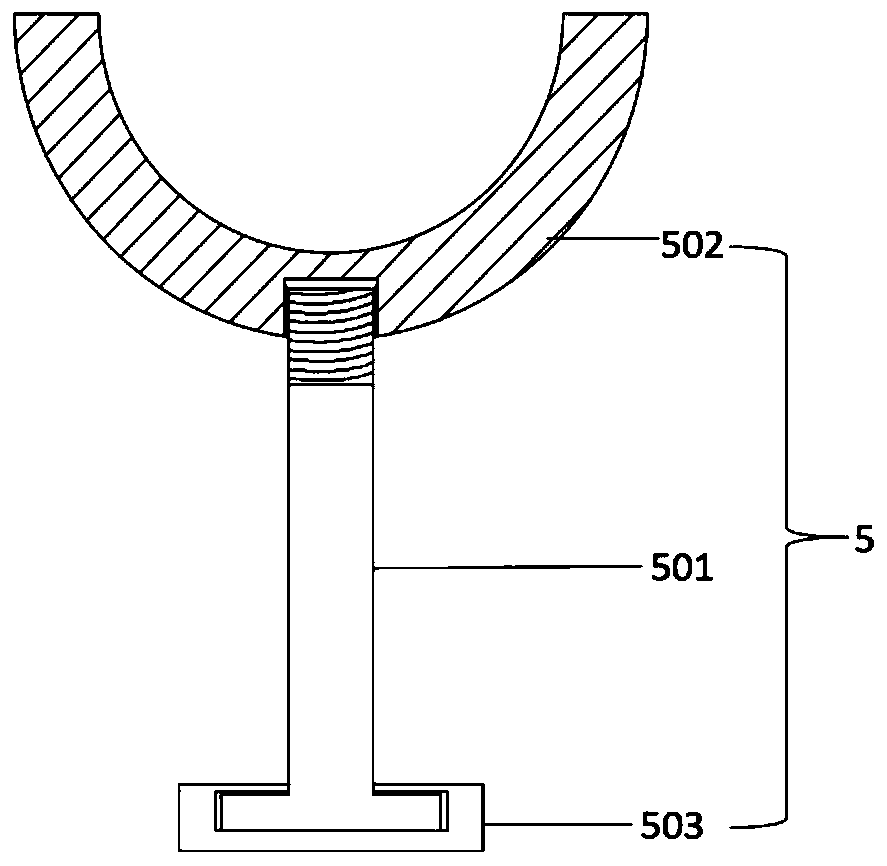

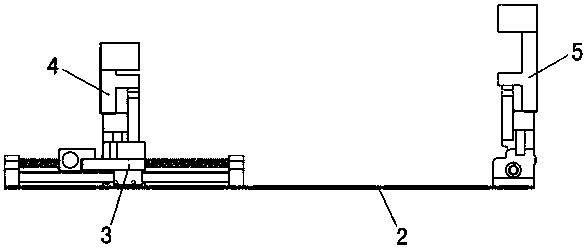

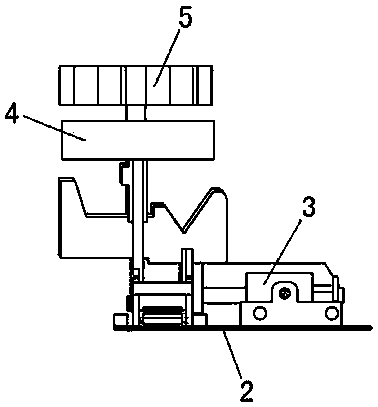

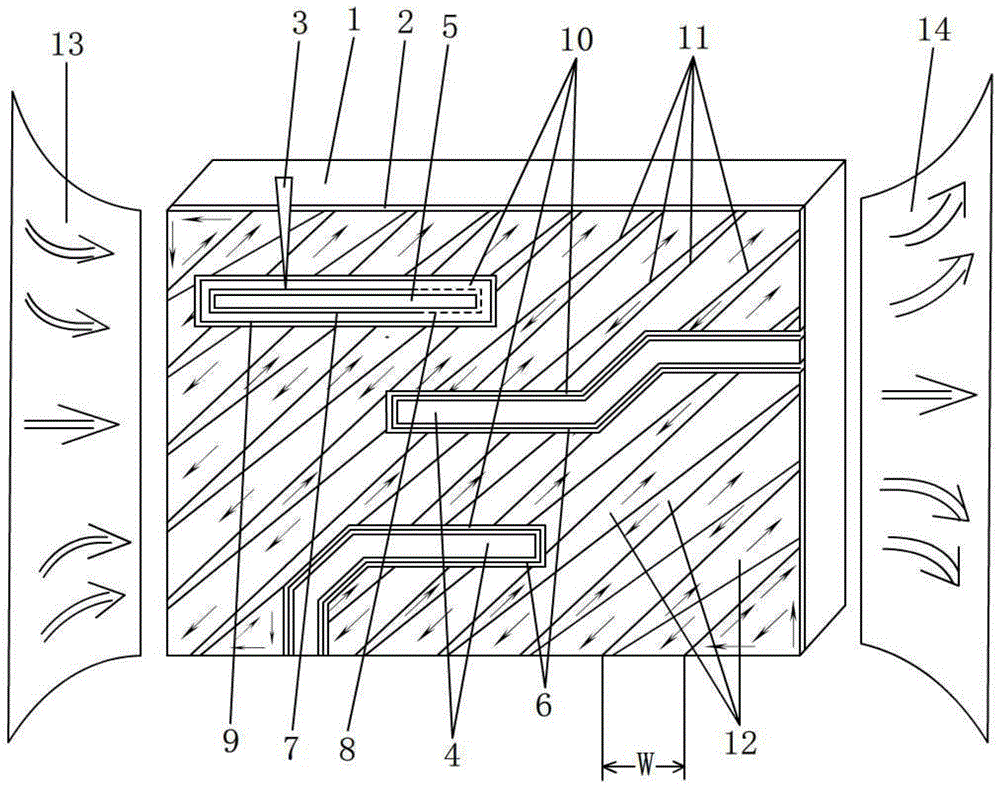

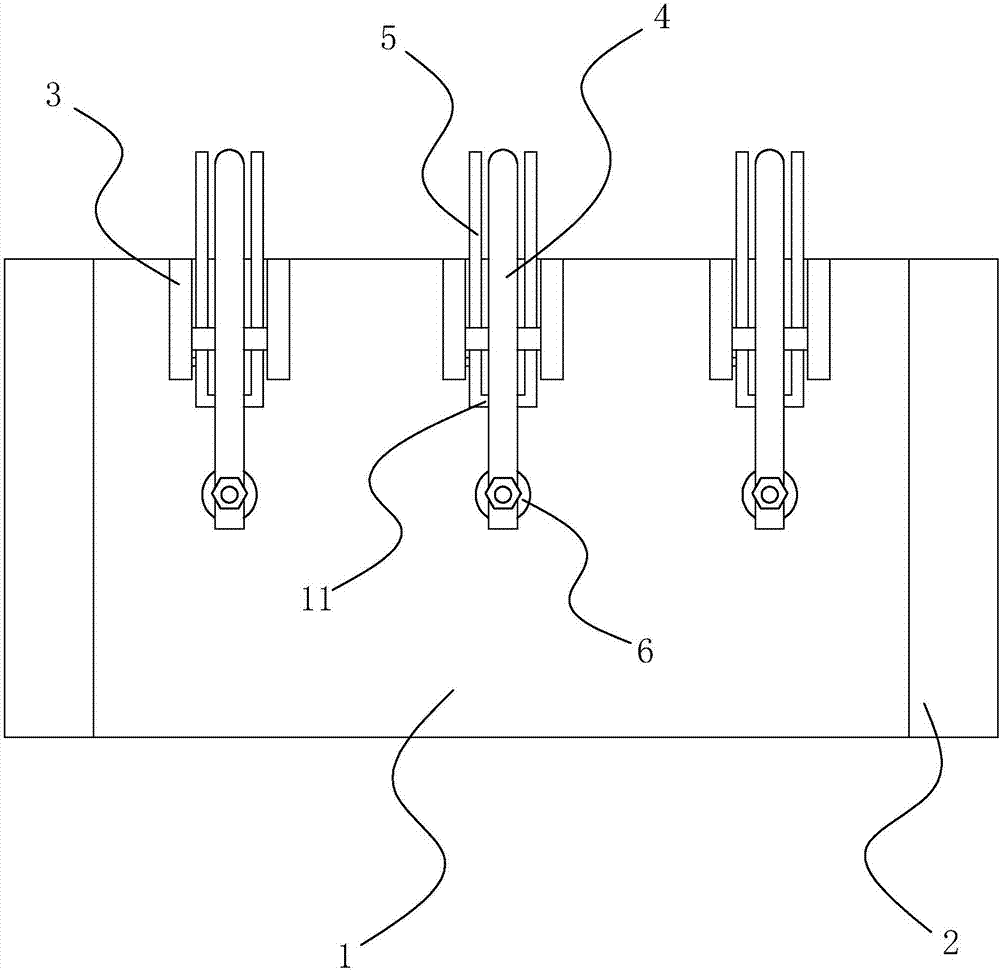

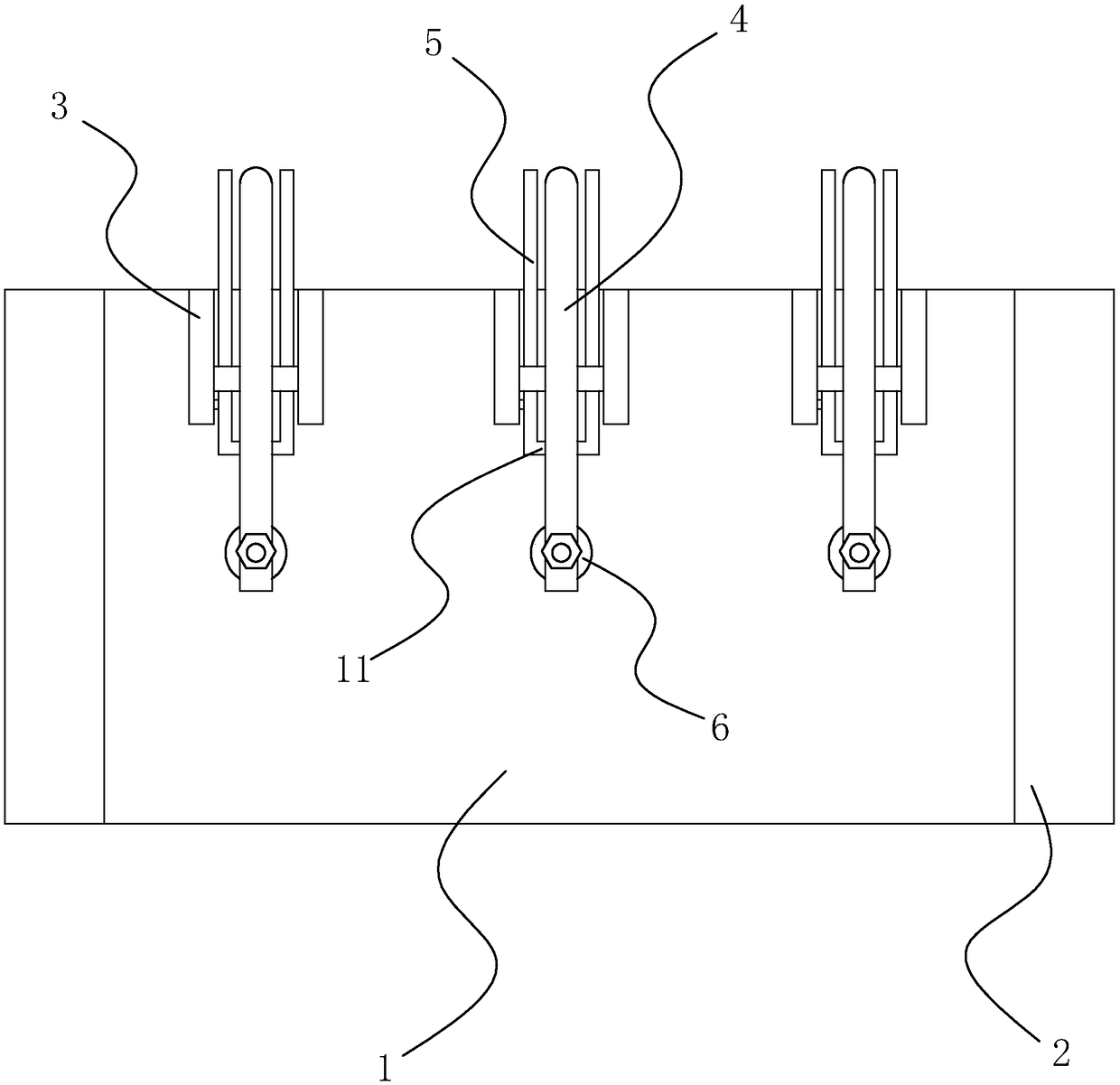

Size adjustability type multi-layer reinforcing mesh high-accuracy machining bed-jig and application method

PendingCN110586815AImprove production flexibilityReduce procurement costsWire networkEngineeringRebar

The invention discloses a size adjustability type multi-layer reinforcing mesh high-accuracy machining bed-jig and an application method. The size adjustability type multi-layer reinforcing mesh high-accuracy machining bed-jig and the application method are applied to the technical field of constructional engineering. The bed-jig structurally comprises multiple vertical supports, transverse beam supporting assemblies, transverse beams, longitudinal beams, longitudinal bar limiting devices, at least one long longitudinal bar limiting plate and at least one short longitudinal bar limiting plate.The purpose that a multi-layer reinforcing mesh with different longitudinal bar separation distances, horizontal bar separation distances, reinforcing mesh layer separation distances can be producedon the same bed-jig can be achieved, the production flexibility of the bed-jig is improved, the purchase cost and the resource waste caused by customized bed-jigs are reduced, the allocated expense isreduced, the purpose that the longitudinal bar separation distances and the reinforcing mesh layer separation distances of the machined multi-layer reinforcing mesh can be freely adjusted in a high-accuracy mode is achieved, and the success of the installation of the follow-up whole prefabricated reinforcing mesh is ensured. The installation of the bed-jig and the machining of the reinforcing mesh are conducted from bottom to top, the working procedure is reasonable, the technology is simple, and the on-site operation is easy.

Owner:SHANGHAI NO 4 CONSTR

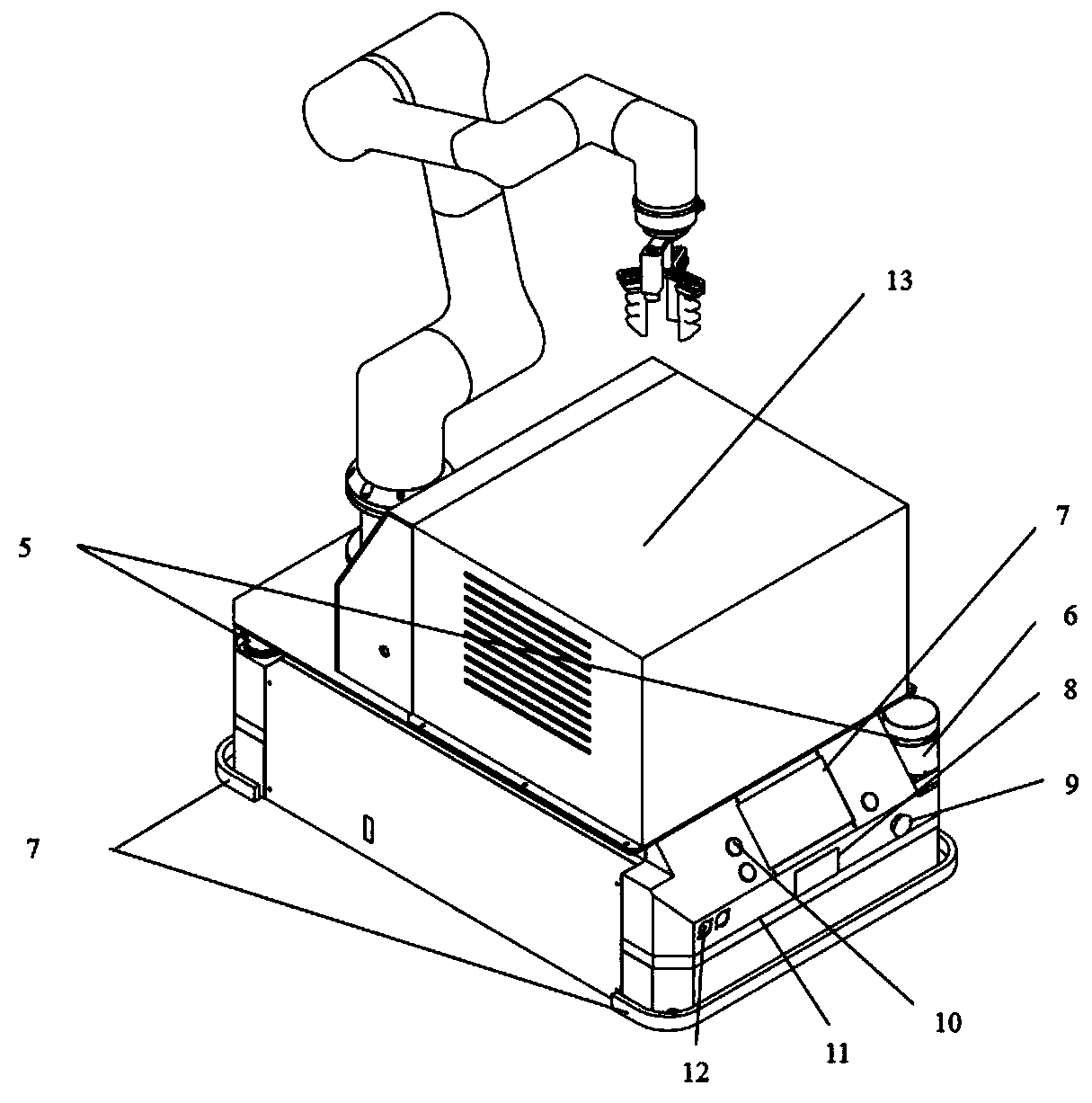

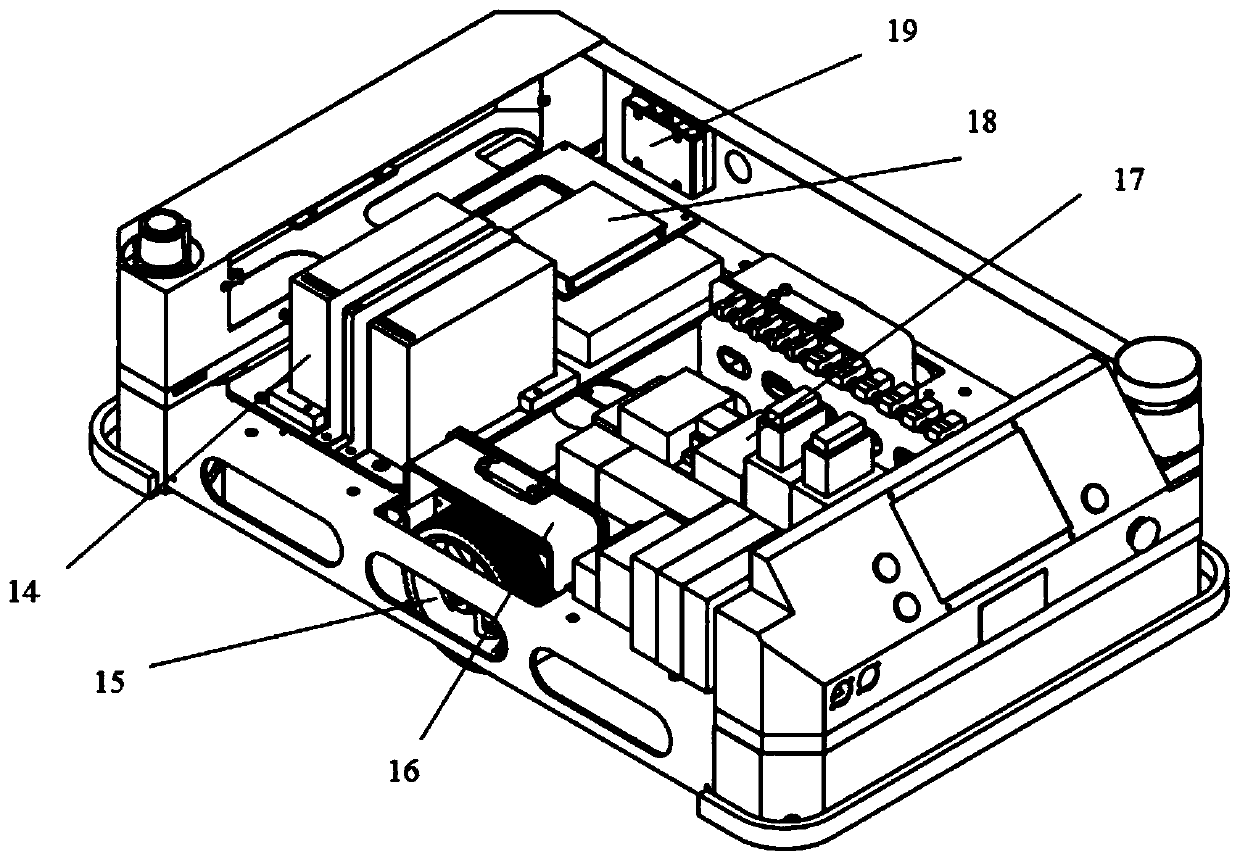

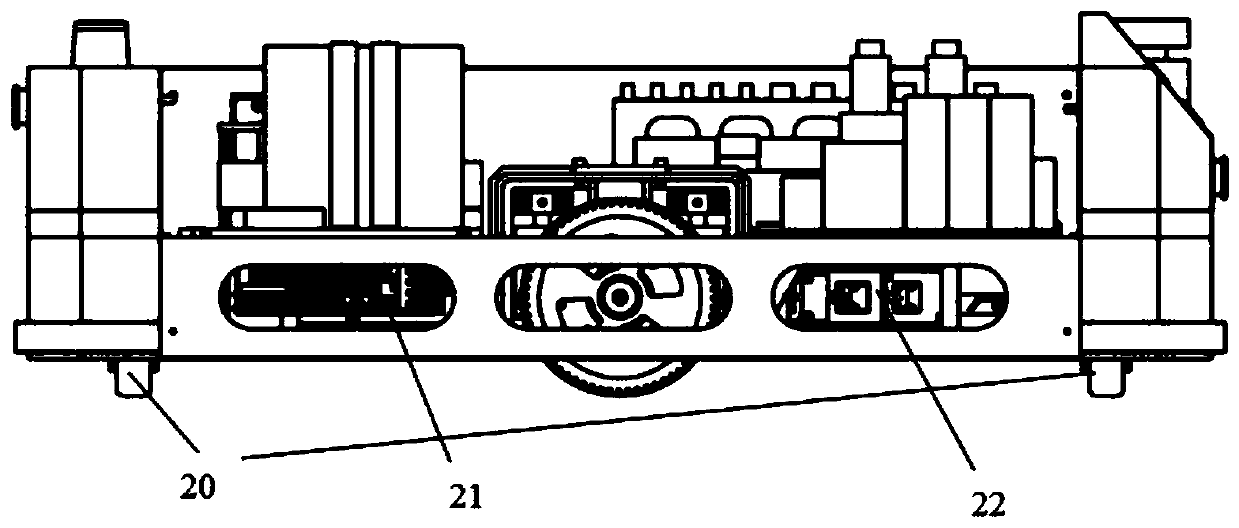

Intelligent mobile collaborative robot

PendingCN110977921ALow costMobility and production flexibilityManipulatorCollaborative roboticsRobot control system

The invention provides an intelligent mobile collaborative robot, which is characterized by comprising a mobile robot, a collaborative robot and an intelligent vision system, wherein the mobile robotcomprises a chassis and an upper cavity; the upper cavity is positioned above the chassis; the upper cavity comprises a power supply module, a mobile robot controller, a radar, a radar protective cover, an obstacle sensor and a collision sensor; the chassis comprises an elastic suspension system, a servo motor, a servo driver, walking driving wheels and universal wheels; the mobile robot comprisesa mechanical arm, a flexible claw, an air pump, an air pipe, a controller cover, a power supply system and a collaborative robot control system; the intelligent vision system comprises an intelligentcamera, a CCD sensor, a microprocessor and a communication interface; the intelligent camera is arranged at the flexible claw; and the CCD sensor is connected with the intelligent camera. The robot has the beneficial effects that the defects of high cost, no maneuverability and poor production flexibility of an industrial robot are overcome, and the mobility and good production flexibility can beachieved on the premise of low cost.

Owner:SHANGHAI SAGE INTELLIGENT TECH CO LTD

Method for making electric conduction patterns on metal-foil-clad insulating substrate

ActiveCN103769749AInhibit sheddingFinely craftedMetal working apparatusLaser beam welding apparatusMetal foilLaser beams

The invention relates to a method for making electric conduction patterns on a metal-foil-clad insulating substrate. The method comprises the steps that insulating envelope grooves are machined in the periphery of a conducting layer which needs to be reserved, and machining is conducted twice or more when excessively narrow isolated wires are encountered; a conducting layer which needs to be removed is subdivided into a plurality of strip-shaped heat-insulating small blocks, wherein one end of each small block is narrowed, the other end of each small block is widened, and the narrowed end of one metal foil layer small block and the widened end of another metal foil layer small block adjacent to the metal foil layer small block are arranged in a corresponding mode; next, laser beams are projected onto the heat-insulating small blocks obtained after subdivision, so that the small blocks are separated from the substrate material and removed. According to the method for making the electric conduction patterns on the metal foil-clad insulating substrate, by means of adjusting the projection parameters, a projection path and the projection environment of a laser, the conducting layer on the substrate material is removed, a predetermined electric conduction structure is formed, corresponding technological processes adopted for manufacturing the electric conduction structure through a chemical method, a physical method and a laser method in the prior art are replaced, the laser is directly used for forming and making the electric conduction patterns, as a result, multiple devices and materials are omitted, environmental friendliness is achieved, the process is short, the technology is simple and easy to implement, and the method is suitable for manufacturing multiple types of circuit board samples with higher accuracy in a small-batch mode and general circuit boards.

Owner:德中(天津)技术发展股份有限公司

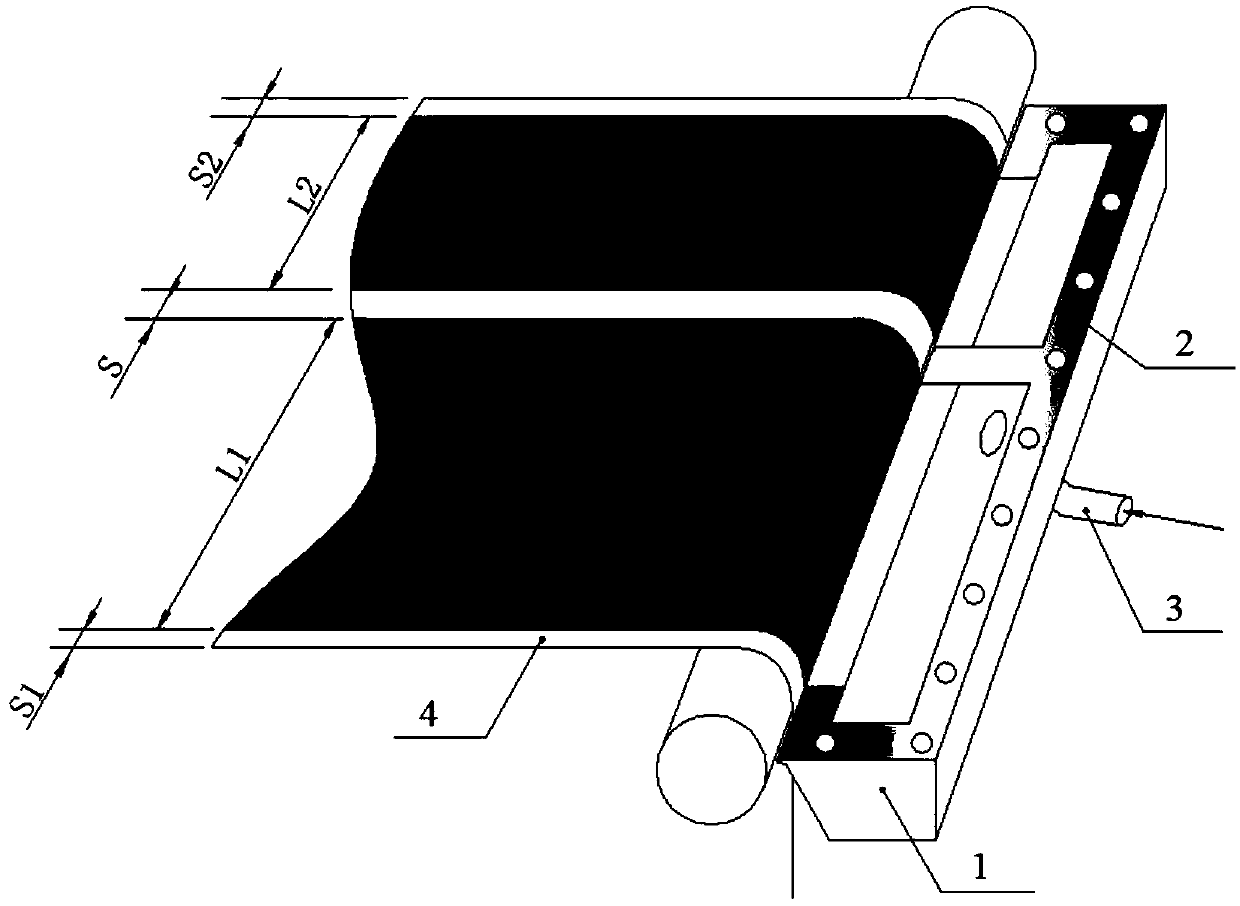

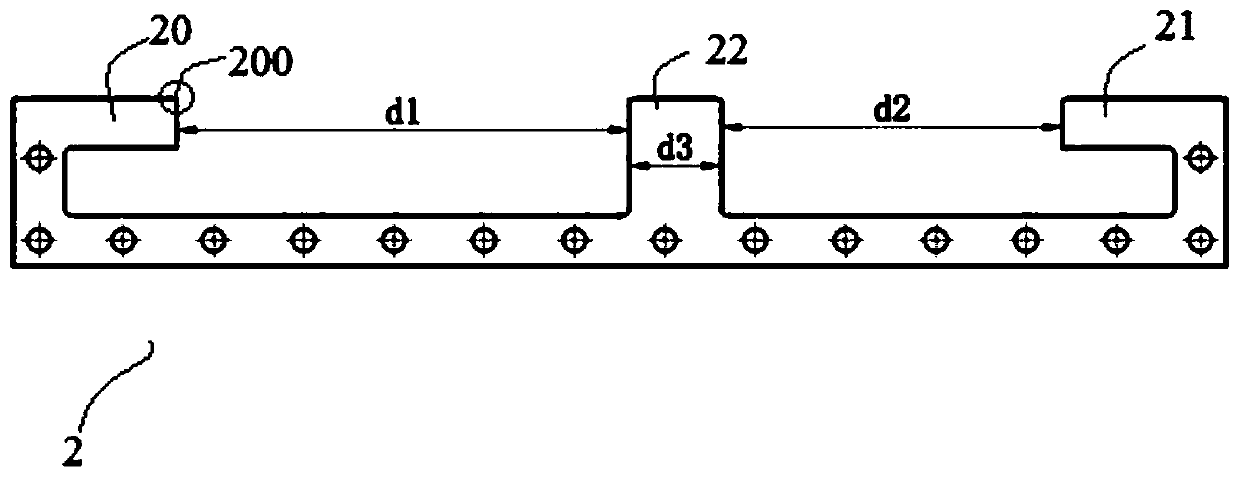

Effective elastic display transfer jig capable of folding and back flowing

ActiveCN103901645AElasticImprove production flexibilityNon-linear opticsProduction lineLiquid-crystal display

The invention relates to an effective elastic display transfer jig capable of folding and back flowing. The effective elastic display transfer jig comprises a base plate, a stepless adjustment module, a movable support handle, a fixed support handle and a collector plate. The stepless adjustment module and the fixed support handle are respectively installed on the left side and the right side of the collector plate which is fixedly arranged on the base plate. The stepless adjustment module comprises a lead screw, a slider and a positioning button, the positioning button is fixedly installed on the slider which is slidably installed on the lead screw and is locked through the positioning button, and the movable support handle is fixedly installed on the slider of the stepless adjustment module and is correspondingly matched with the fixed support handle to clamp a display. The effective elastic display transfer jig is applicable to production of LCD (liquid crystal display) below (including) 27 inches in dimension / crystal TV (television), adaptation of a line body of a production line and production efficiency can be improved, and labor can be saved.

Owner:L&T DISPLAY TECH FUJIAN

Method for simultaneously producing lithium ion battery pole pieces of multiple models and extrusion coating device

ActiveCN109585782AIncrease productivityImprove production flexibilityElectrode collector coatingElectrode extrusionElectrical batteryCurrent collector

The invention relates to a method for simultaneously producing lithium ion battery pole pieces of multiple models and an extrusion coating device. The method comprises the following steps of 1) according to different width coating requirements of battery pole pieces of different models, enabling coating slurry to be coated on the same current collector according to the different width coating requirements, after coating, performing drying and rolling to form at least two coating strips which are arranged at intervals along the direction perpendicular to the coating direction formed on the current collector, wherein a middle reserved blank area is formed between every two adjacent coating strips; and 2) cutting the middle reserved blank area along the coating direction to obtain pole stripsused for preparing the battery pole pieces of different models, wherein the pole strips are cut, and battery pole pieces of different models are obtained respectively. According to the method, the coating strips with different coating widths are coated on the current collector through an asymmetric zebra coating method, so that at least two different types of battery pole pieces can be produced on one production line, the production efficiency of the battery pole pieces of different models is improved, and the production flexibility of the coating production line is effectively improved.

Owner:中创新航科技股份有限公司

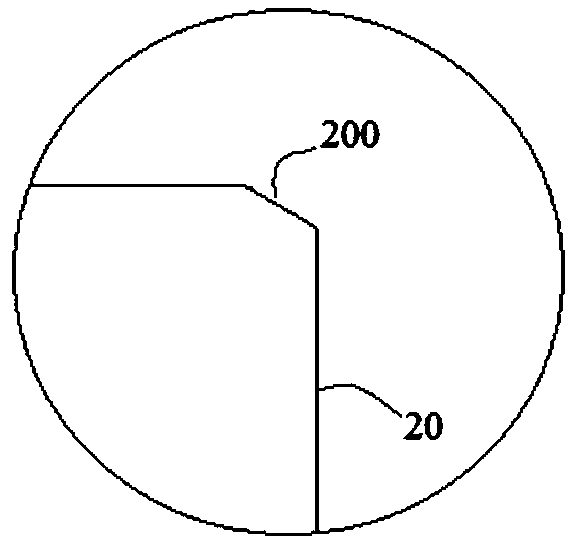

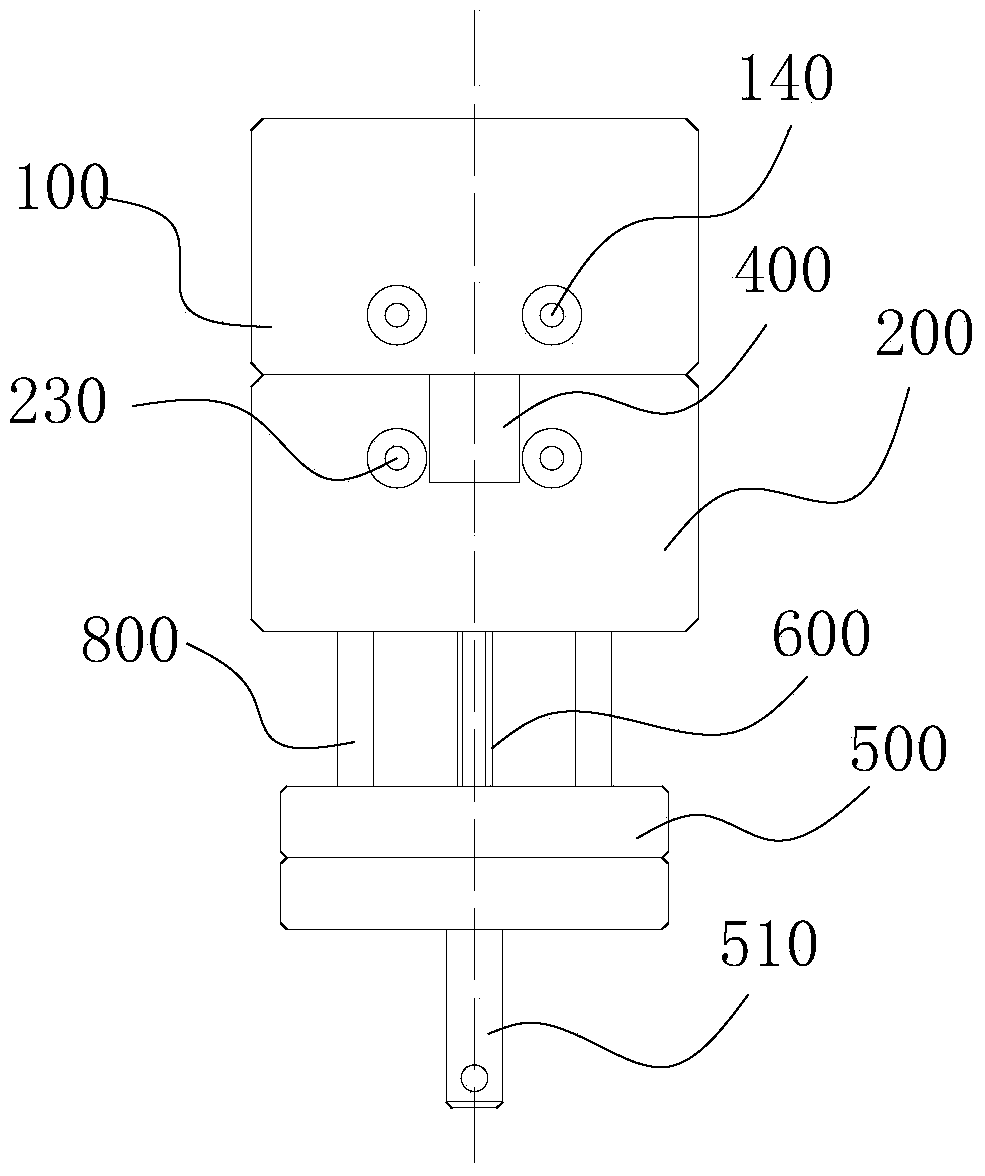

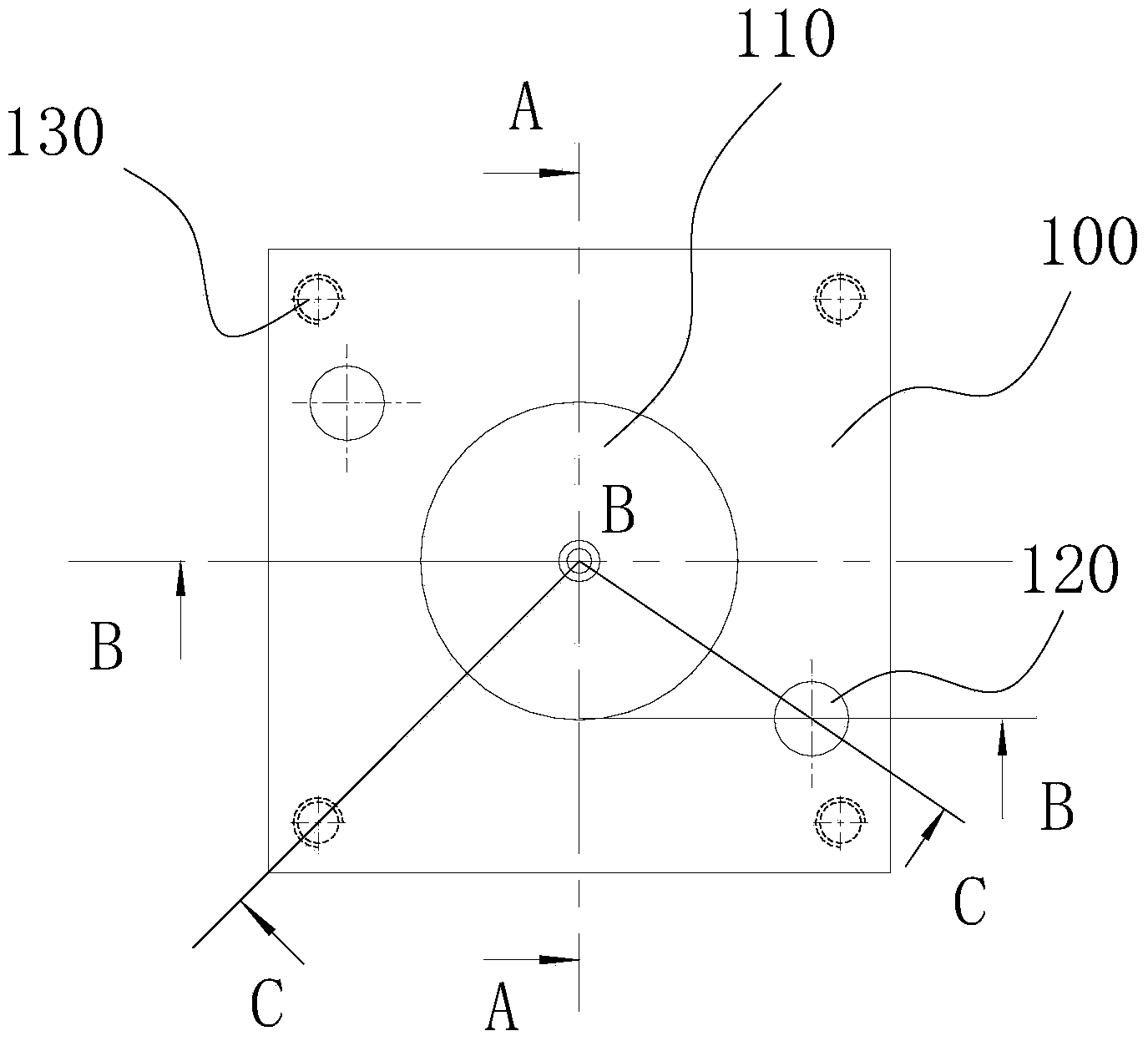

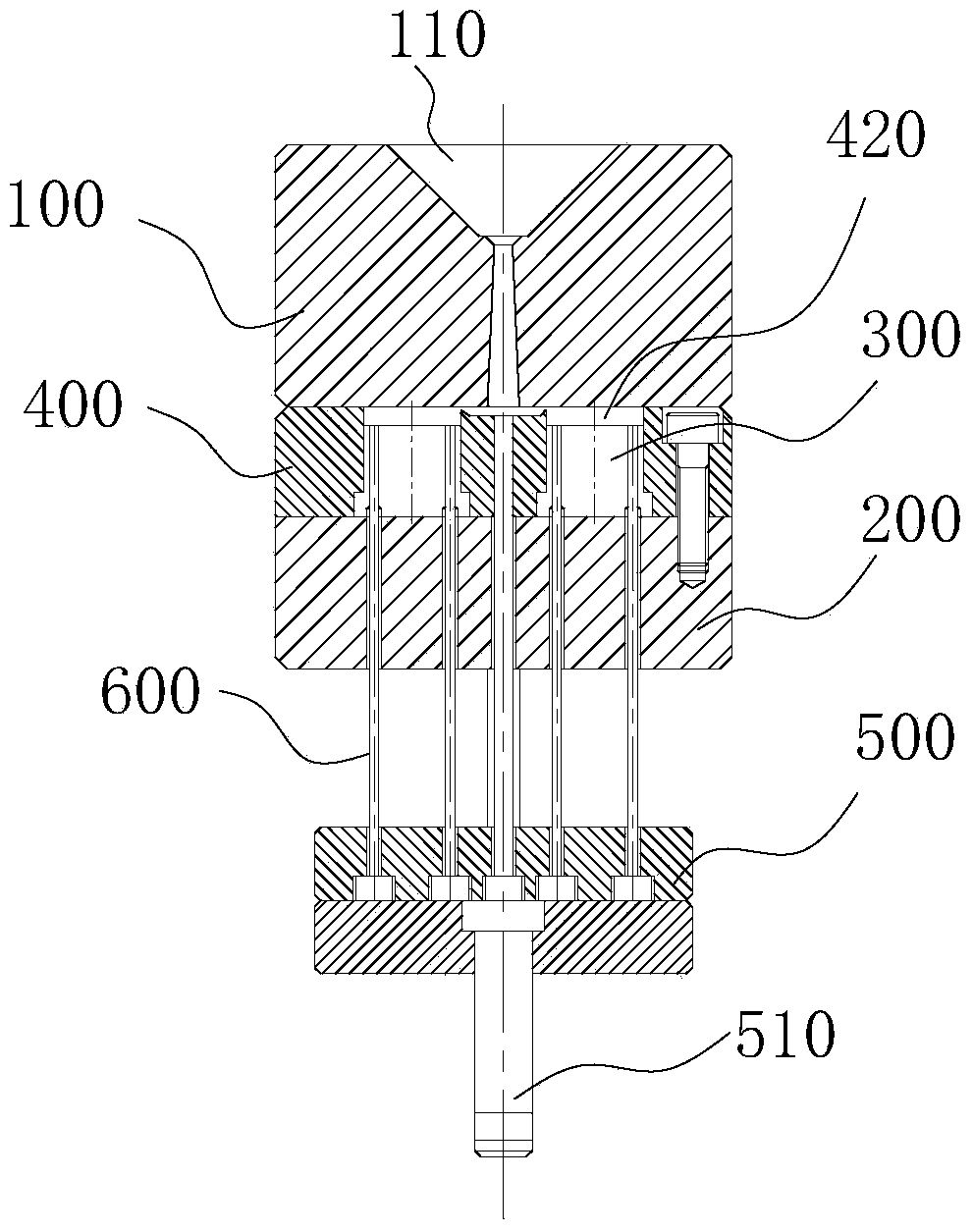

Injection mold of micro-molded dumbbell product

InactiveCN104325604AImprove production flexibilityQuality improvementEngineeringMechanical engineering

The invention discloses an injection mold of a micro-molded dumbbell product. The injection mold is simple in structure, and can realize flexible production and improve the quality of the product. The injection mold comprises a fixed mold, a movable mold, molding inserts and an insert, wherein a first guide hole, a pouring gate and a main runner communicated with the pouring gate are formed in the fixed mold; a mounting slot and a second guide hole are formed in the movable mold; the fixed mold is positioned above the movable mold; the movable mold and the fixed mold are guided by a guide column; a cavity for containing the dumbbell product is formed in the insert; a cold material well is arranged on the insert and is communicated with the cavity; the insert is mounted in the mounting slot; an outlet of the main runner in the fixed mold is positioned above the cold material well and is communicated with the cold material well; the molding inserts are mounted in the cavity and matched with the cavity; the upper surfaces of the molding inserts form the bottom surface of the cavity. The injection mold is high in production adaptability, and can realize flexible production, improve the working efficiency and lower the production cost.

Owner:ZHENGZHOU UNIV

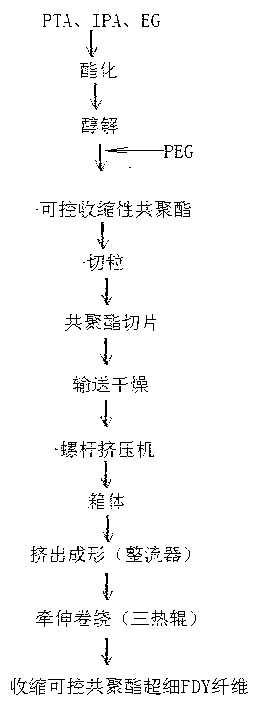

Method for preparing ultrafine contractible controllable copolyester fiber by adopting direct esterification polycondensation method

ActiveCN103290506ASimple processEasy to operateMonocomponent copolyesters artificial filamentPolymer scienceSpinning

The invention relates to a method for preparing ultrafine contractible controllable copolyester fiber by adopting a direct esterification polycondensation method. The method is characterized by comprising the steps of: adding terephthalic acid and isophthalic acid into ethylene glycol for esterification; copolymerizing the esterified product with ethylene glycol to prepare copolyester with different contraction percentages; precrystalizing and drying the copolyester, melting and extruding through a screw extruder, and drafting and winding by utilizing three-hot-roll 20-head high-speed spinning equipment. The product can be used for producing ultrafine fibers with total fiber number of 20-30dtex or filament number of 0.3-0.5dtex, and the contraction percentage can be adjusted within 15-70%.

Owner:苏州新民纺织有限公司 +1

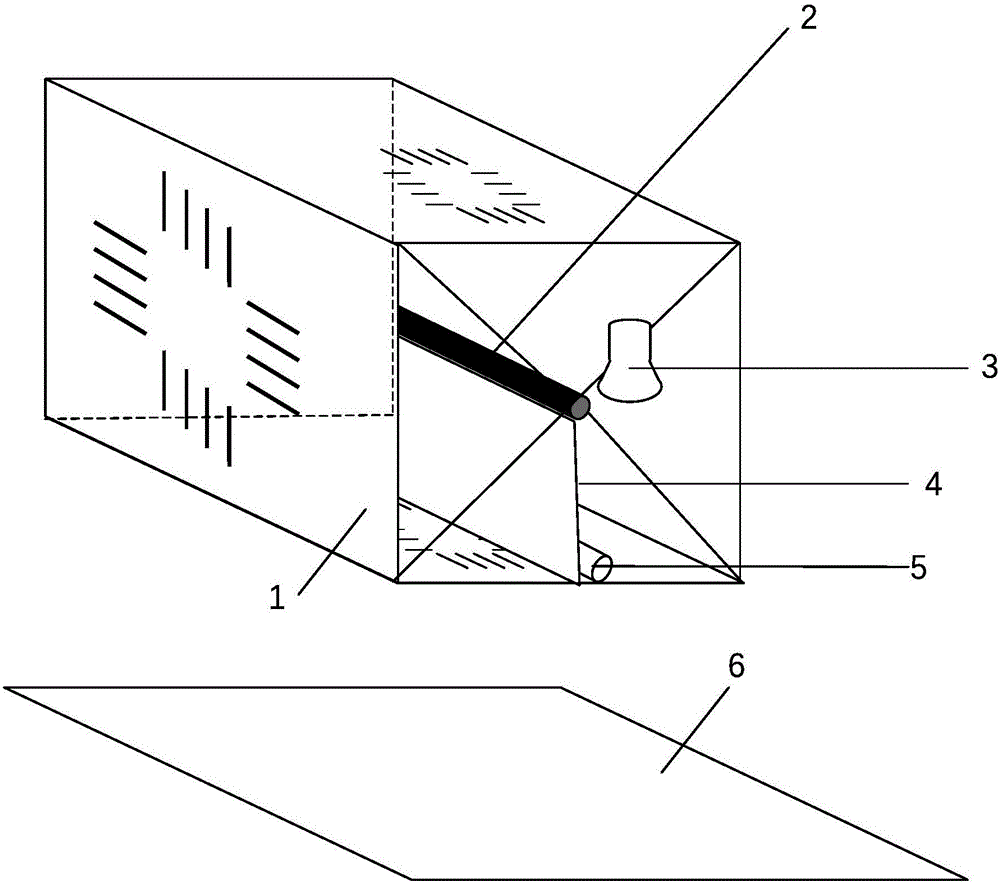

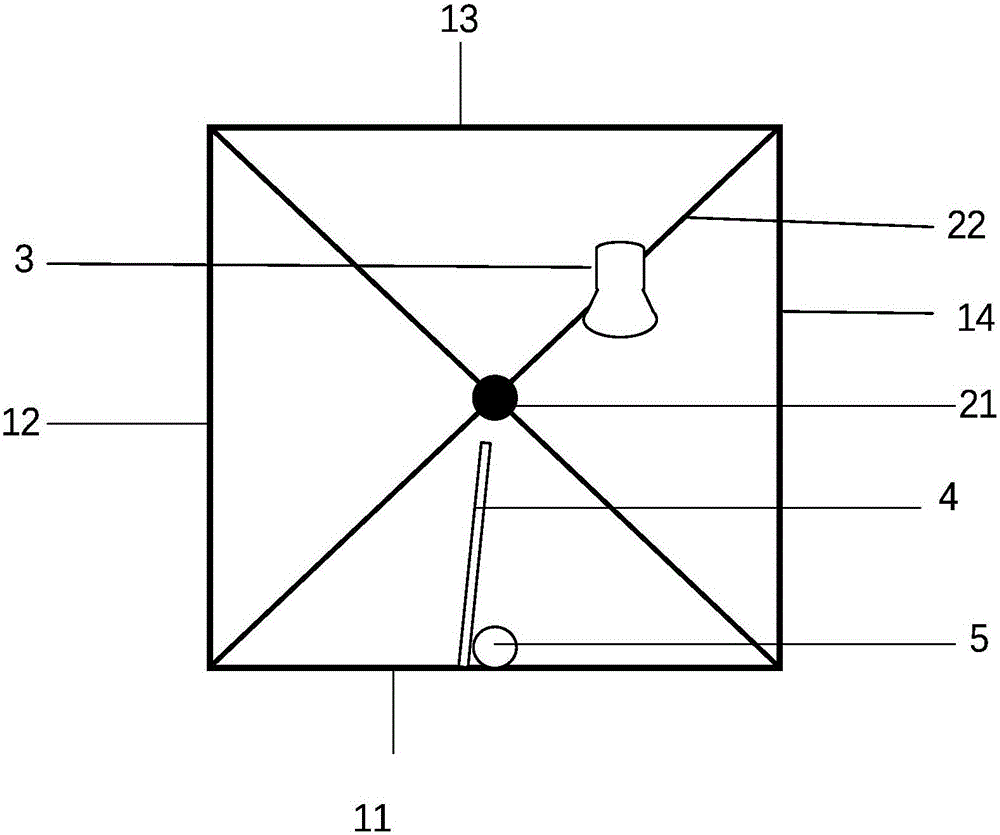

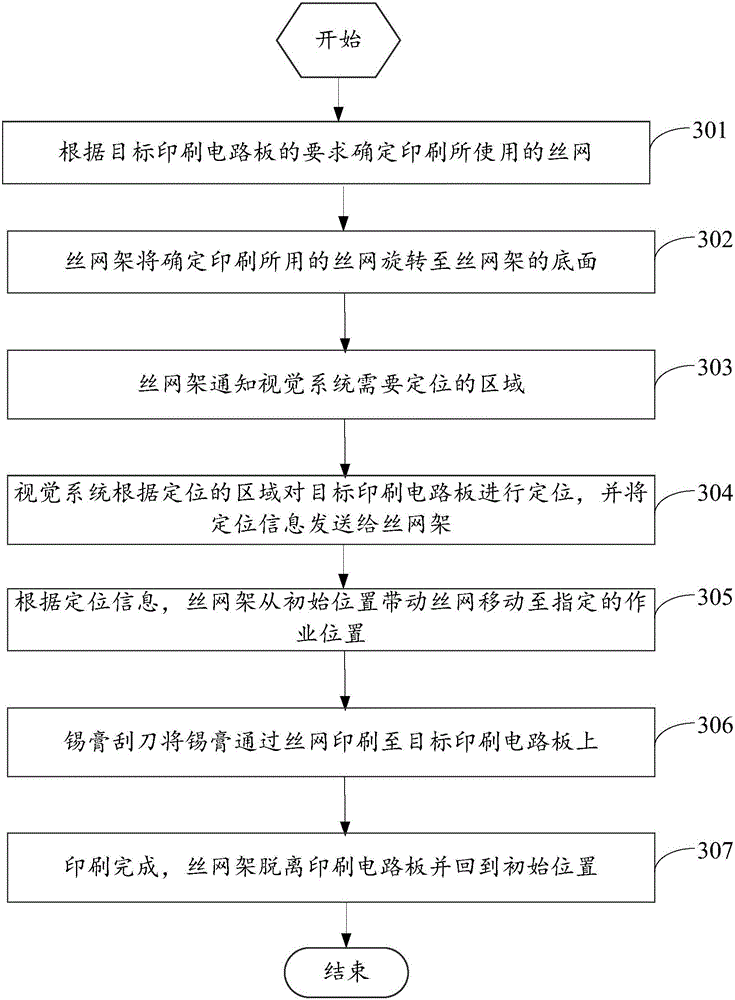

Solder paste printer and printing method thereof

ActiveCN106042613AEasy to replaceFacilitate local printing operationsScreen printersScreen printingPrinting press

The invention provides a solder paste printer and a printing method thereof, and belongs to the technical field of solder paste printing processes. The solder paste printer comprises a screen group, a screen frame, a visual system, a solder paste scraper, a solder paste and a printed circuit board, wherein the screen group comprises a plurality of screens, and the plurality of screens are distributed on a plurality of outer surfaces of the screen frame respectively; one of the screens is selected according to a breadth requirement of the printed circuit board, and is rotated to a working surface of the screen frame by the screen frame; the visual system is used for carrying out visual location on the screen group and the printed circuit board, and sending location information to the screen frame, so that the screen frame moves the screen to a working position needing printing; and the solder paste scraper is used for printing the solder paste onto the printed circuit board through the screen. The solder paste printer and the printing method thereof, which are provided by the invention, are applicable to local printing operation on large-dimension printed circuit boards and printed circuit boards of existing components, more convenient for replacing the screens, and capable of reducing manual intervention and improving production flexibility.

Owner:易视智瞳科技(深圳)有限公司

A method of making conductive patterns on metal foil-clad insulating substrates

ActiveCN103769749BInhibit sheddingFinely craftedMetal working apparatusLaser beam welding apparatusMetal foilPhysical approach

The invention relates to a method for making electric conduction patterns on a metal-foil-clad insulating substrate. The method comprises the steps that insulating envelope grooves are machined in the periphery of a conducting layer which needs to be reserved, and machining is conducted twice or more when excessively narrow isolated wires are encountered; a conducting layer which needs to be removed is subdivided into a plurality of strip-shaped heat-insulating small blocks, wherein one end of each small block is narrowed, the other end of each small block is widened, and the narrowed end of one metal foil layer small block and the widened end of another metal foil layer small block adjacent to the metal foil layer small block are arranged in a corresponding mode; next, laser beams are projected onto the heat-insulating small blocks obtained after subdivision, so that the small blocks are separated from the substrate material and removed. According to the method for making the electric conduction patterns on the metal foil-clad insulating substrate, by means of adjusting the projection parameters, a projection path and the projection environment of a laser, the conducting layer on the substrate material is removed, a predetermined electric conduction structure is formed, corresponding technological processes adopted for manufacturing the electric conduction structure through a chemical method, a physical method and a laser method in the prior art are replaced, the laser is directly used for forming and making the electric conduction patterns, as a result, multiple devices and materials are omitted, environmental friendliness is achieved, the process is short, the technology is simple and easy to implement, and the method is suitable for manufacturing multiple types of circuit board samples with higher accuracy in a small-batch mode and general circuit boards.

Owner:德中(天津)技术发展股份有限公司

A method for selectively removing a conductive layer on a substrate material

ActiveCN103747626BInhibit sheddingFinely craftedPrinted circuit manufacturePhysicsElectrical and Electronics engineering

The invention relates to a method for selectively removing a conductive layer on a baseplate material. The method comprises the following steps: processing to manufacture an insulated enveloping channel on the periphery of a to-be-reserved conductive layer, wherein an isolated wire with over-narrow width is processed twice or more than twice; subdividing a to-be-removed conductive layer into a plurality of insulated small blocks, wherein the adjacent insulated small blocks are of complementary shapes such as inverted quadrangle, trapezoid or triangle; projecting electromagnetic waves onto the subdivided insulated small blocks so as to ensure that the subdivided insulated small blocks are separated from the baseplate material to be removed, wherein during heating, the projected laser moves from the narrower end of each small block of the conductive layer to the wider end of each small block. According to the method, the projecting parameter, projecting path and projecting environment of the laser are regulated and the conductive layer on the substrate material is removed, so that a preset conductive structure is formed, and the method can be used for replacing a corresponding technical process adopted in the process of manufacturing a conductive structure by virtue of an existing chemical method, an existing physical method and an existing laser method.

Owner:德中(天津)技术发展股份有限公司

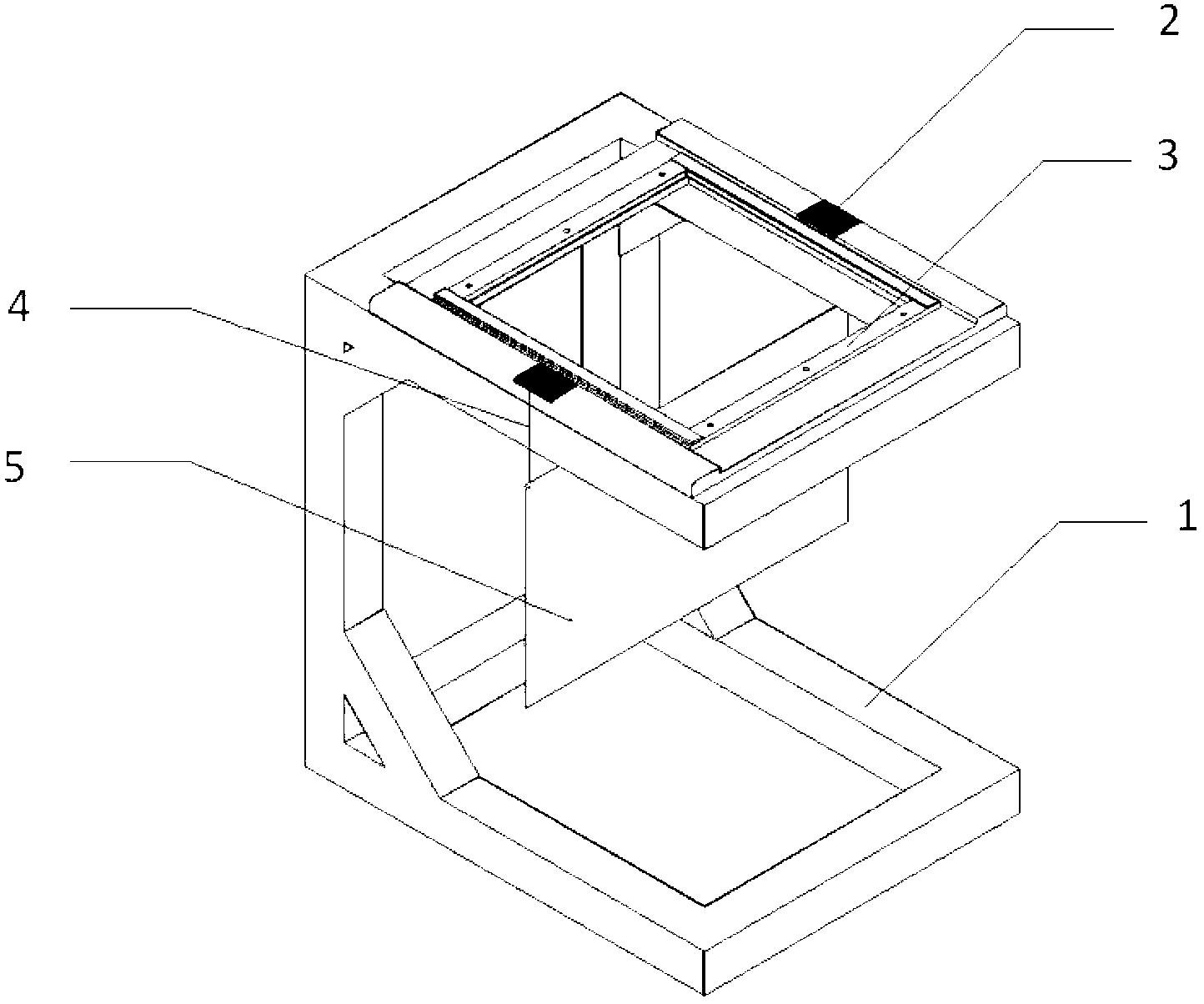

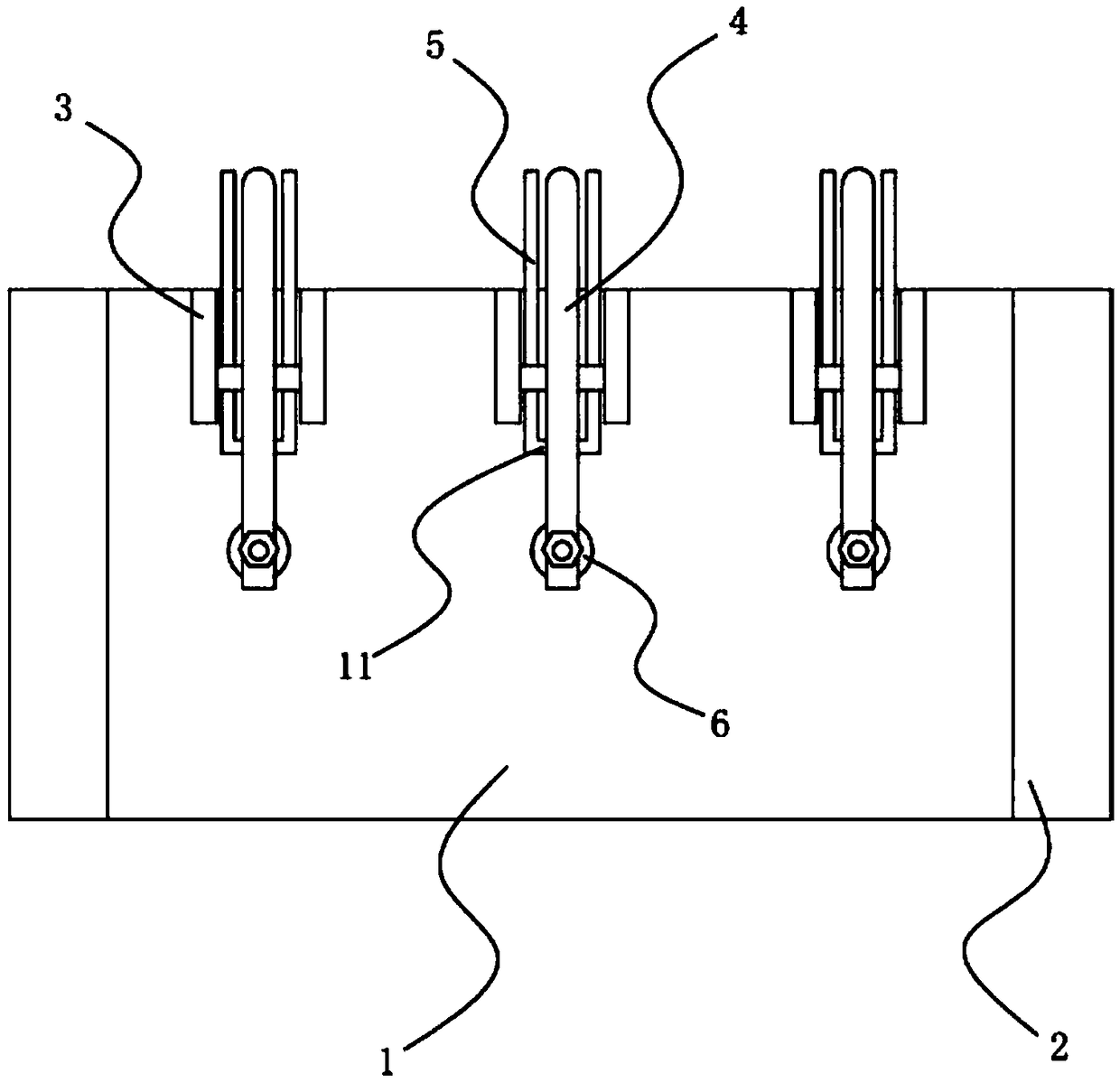

Tool clamp for pressing glass

The invention discloses a tool clamp for pressing glass. The tool clamp comprises a bottom plate, baffles and a clamping mechanism. The clamping mechanism comprises supports, pressing rods and ejectorrods are hinged to the supports, the pressing rods are located above the ejector rods, the ends of the pressing rods are provided with pressing parts located above the bottom plate, the ends, corresponding to the pressing parts, of the ejector rods can press the bottom of the pressing rods in a joint manner in the process that the ejector rods rotate relative to the supports, guide grooves are formed in the supports, bolts for pressing the bottoms of the ejector rods in a joint manner are arranged in the guide grooves in a sliding manner, the bolts can be locked in the guide grooves, the pressing parts comprise fixed bases fixed to the pressing rods, and fixed rods arranged on the fixed bases in a sleeving manner, and pressing blocks are arranged at the lower ends of the fixed rods. The rotating angles of the pressing rods and the ejector rods relative to the supports can be adjusted, the pressing rods and the ejector rods can be matched with the baffle plates on the two sides and thebottom plate to finish car glass clamping and fixing at the angles capable of pressing the car glass, subsequent machining is facilitated, production flexibility is high, and the production efficiency can be obviously improved.

Owner:鹤山市正大汽车玻璃有限公司

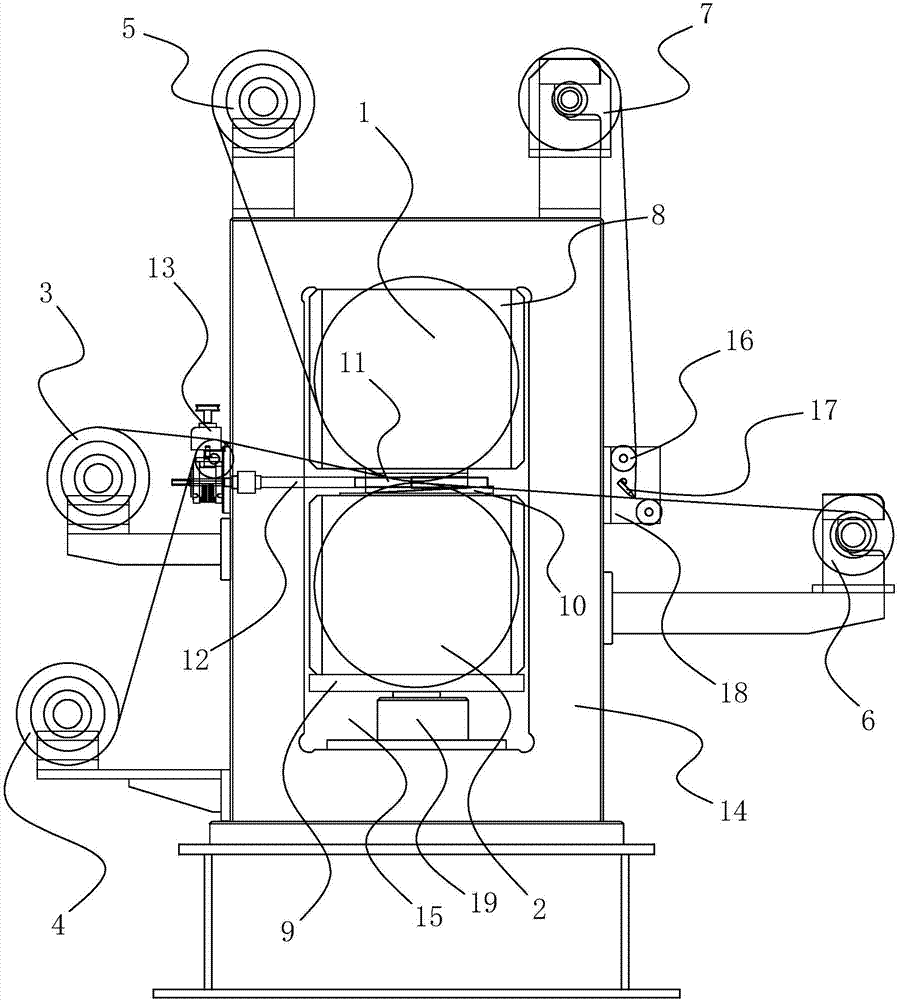

Flexible tooling fixture for automobile glass

InactiveCN112428175AUniform pressureAvoid force ruptureWork holdersElectric machineryStructural engineering

The invention discloses a flexible tooling fixture for automobile glass. The flexible tooling fixture for the automobile glass structurally comprises a base, two supports which are oppositely and symmetrically arranged are arranged at the top end of the base, the two supports both slide along a guide rail arranged at the top end of the base, an acting cylinder is connected between the two supports, the two ends of the acting cylinder are hinged to the bottoms of the inner sides of the two supports correspondingly, clamping devices are rotationally connected to the tops of the inner sides of the two supports correspondingly, a motor is arranged at the top of the left end of the support on the left side and is in transmission connection with the clamping device on the left side, an angle sensor is arranged at the top of the right end of the support on the right side, and the angle sensor is connected with the clamping device on the right side. According to the flexible tooling fixture for the automobile glass, traditional point location pressing is replaced with comprehensive pressing pushed by an air bag, so that pressure borne by glass is uniform; and meanwhile, force adjustment can be achieved through a pressure sensor, the glass is prevented from being broken due to stress, and therefore, subsequent machining is facilitated; the production flexibility is very high; and the production efficiency can also be obviously improved.

Owner:郭丽云

Gap-adjustable automatic calendering device for graphite heat-dissipation film

PendingCN107498975AQuality improvementGuaranteed to be smooth and cleanLamination ancillary operationsLaminationComposite filmGraphite

The invention discloses a gap-adjustable automatic calendering device for a graphite heat-dissipation film. The device comprises a base, an upper press roller, a lower press roller, a first unwinding roller, a second unwinding roller, a third unwinding roller, a first winding roller and a second winding roller, wherein the upper press roller and the lower press roller are arranged on the base; a gap between the upper press roller and the lower press roller is adjusted by a position adjusting assembly; a stripping mechanism is arranged at the front end of the second winding roller. According to the calendering device, smooth and clean surfaces of the press rollers are guaranteed, raw materials are saved, equipment can operate stably for a long time, and product quality is improved; production flexibility of the equipment is improved, and the relative position of the upper press roller and the lower press roller can be adjusted in time to meet the required calendering standard; the stripping position is adjusted by the stripping mechanism according to speed difference of the first winding roller and the second winding roller, so that an assisting film and a composite film can be conveyed under better tensile force, quality of the graphite heat-dissipation film is better, and overall tensile strength and color distribution are more uniform.

Owner:珠海市光环自动化科技有限公司

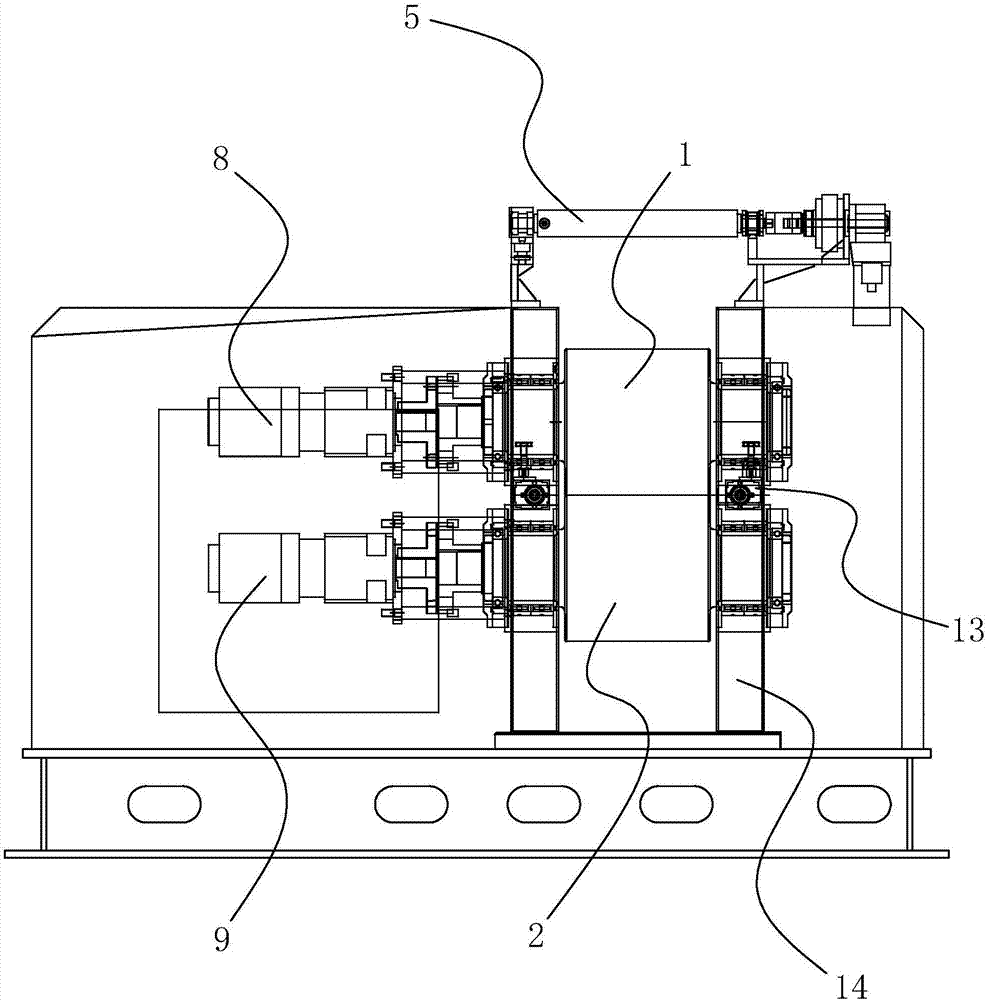

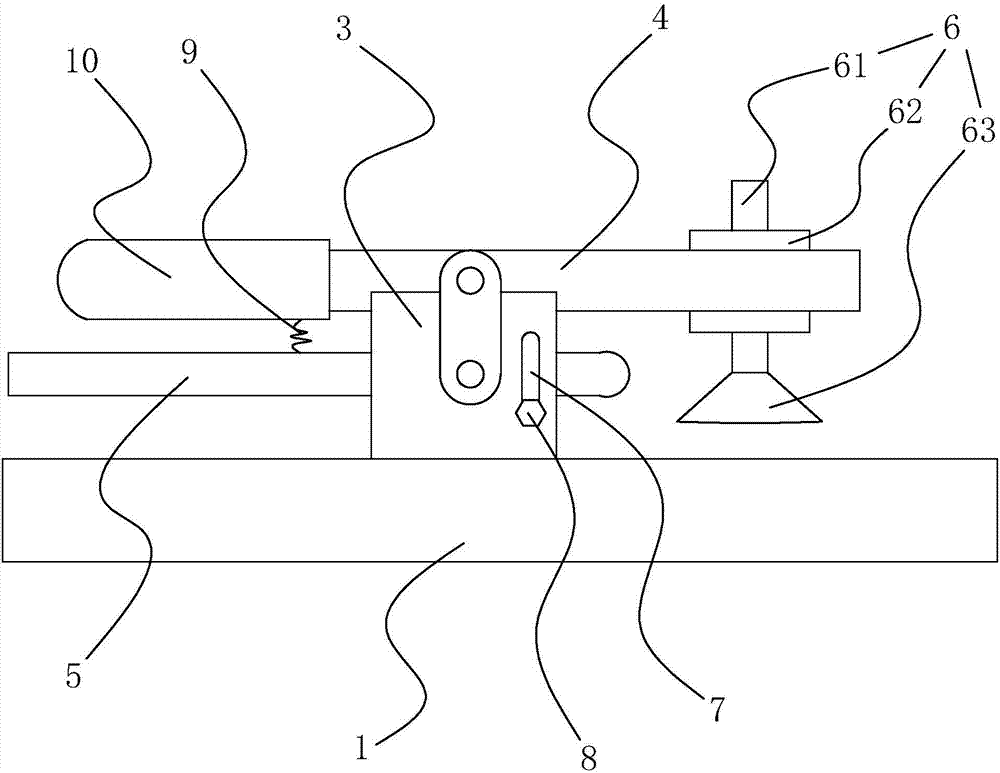

Flexible tool clamp for car glass

ActiveCN107953282AEasy to processImprove production flexibilityWork holdersMechanical engineeringEngineering

The invention discloses a flexible tool clamp for car glass. The flexible tool clamp comprises a bottom plate, baffles and a clamping mechanism. The clamping mechanism comprises a support. A pressingrod and an ejector rod are hinged to the support. The pressing rod is located above the ejector rod. The end portion of the pressing rod is provided with a pressing connection part located above the bottom plate. The end portion, corresponding to the pressing connection part, of the ejector rod can be connected to the bottom of the pressing rod in a pressing manner in the rotating process of the ejector rod relative to the support. The support is provided with a vertical sliding groove. A bolt capable of being connected with the bottom of the ejector rod in a pressing manner is arranged in thevertical sliding groove in a sliding manner. The bolt can be locked in the vertical sliding groove. According to the flexible tool clamp, by adjusting the rotating angle of the pressing rod and the ejector rod relative to the support, the pressing connection part can be connected with multiple types of car glass in a pressing manner, then the bolt is fixed to the corresponding positions of the vertical sliding groove, the pressing rod and the ejector rod can cooperate with the baffles on the two sides and the bottom plate at the angle capable of allowing the car glass to be pressed to complete clamping and fixing of the car glass, thus follow-up machining is facilitated, production flexibility is high, and the production efficiency can be improved remarkably.

Owner:鹤山市正大汽车玻璃有限公司

A flexible fixture for automotive glass

ActiveCN107953282BEasy to processImprove production flexibilityWork holdersPositioning apparatusEngineeringMechanical engineering

The invention discloses a flexible tool clamp for car glass. The flexible tool clamp comprises a bottom plate, baffles and a clamping mechanism. The clamping mechanism comprises a support. A pressingrod and an ejector rod are hinged to the support. The pressing rod is located above the ejector rod. The end portion of the pressing rod is provided with a pressing connection part located above the bottom plate. The end portion, corresponding to the pressing connection part, of the ejector rod can be connected to the bottom of the pressing rod in a pressing manner in the rotating process of the ejector rod relative to the support. The support is provided with a vertical sliding groove. A bolt capable of being connected with the bottom of the ejector rod in a pressing manner is arranged in thevertical sliding groove in a sliding manner. The bolt can be locked in the vertical sliding groove. According to the flexible tool clamp, by adjusting the rotating angle of the pressing rod and the ejector rod relative to the support, the pressing connection part can be connected with multiple types of car glass in a pressing manner, then the bolt is fixed to the corresponding positions of the vertical sliding groove, the pressing rod and the ejector rod can cooperate with the baffles on the two sides and the bottom plate at the angle capable of allowing the car glass to be pressed to complete clamping and fixing of the car glass, thus follow-up machining is facilitated, production flexibility is high, and the production efficiency can be improved remarkably.

Owner:鹤山市正大汽车玻璃有限公司

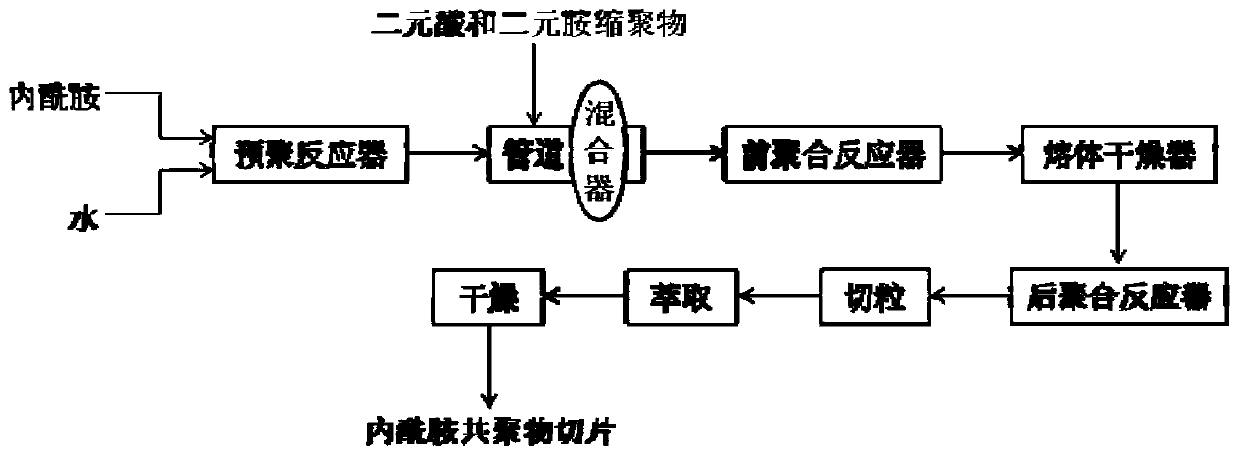

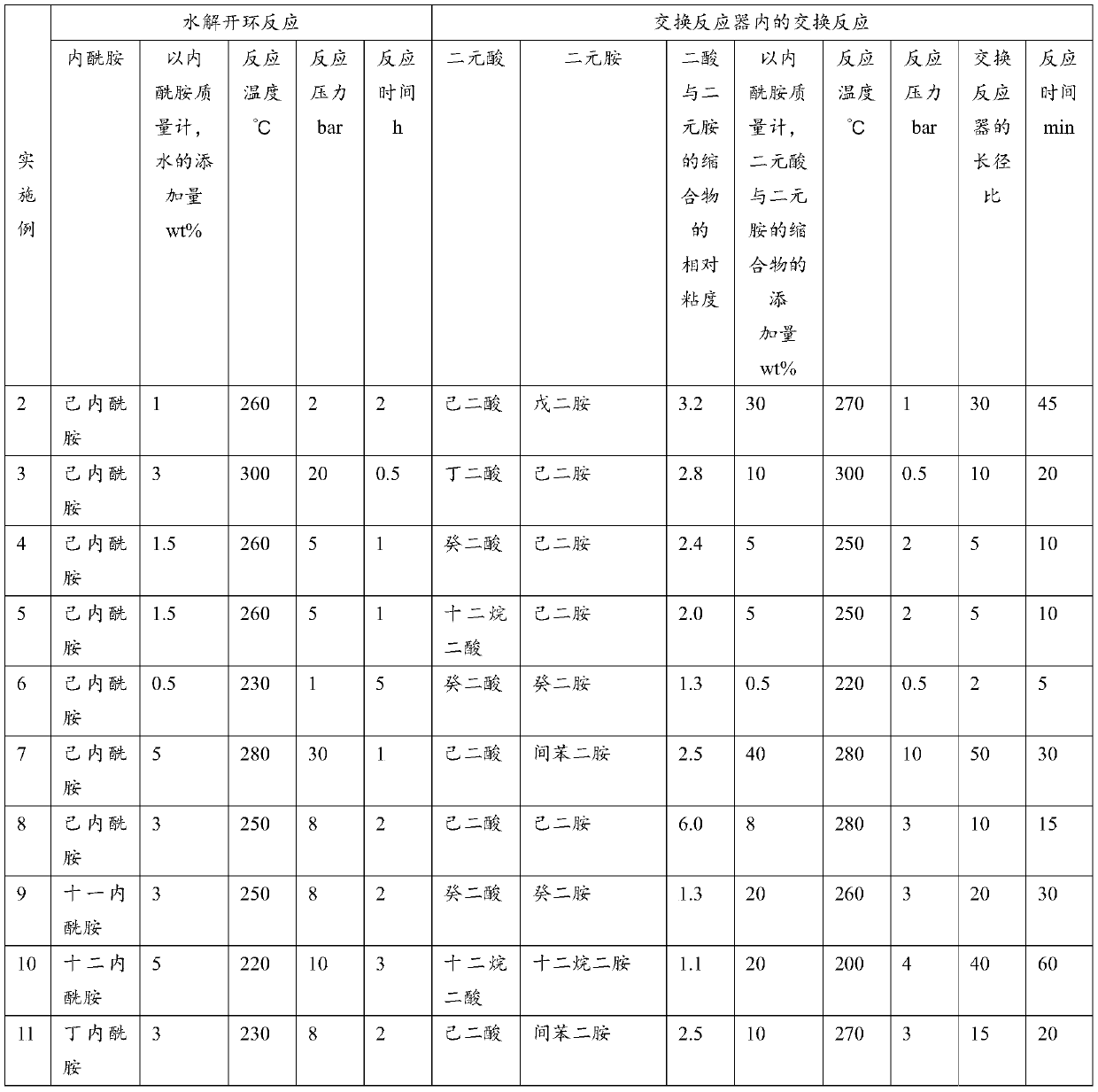

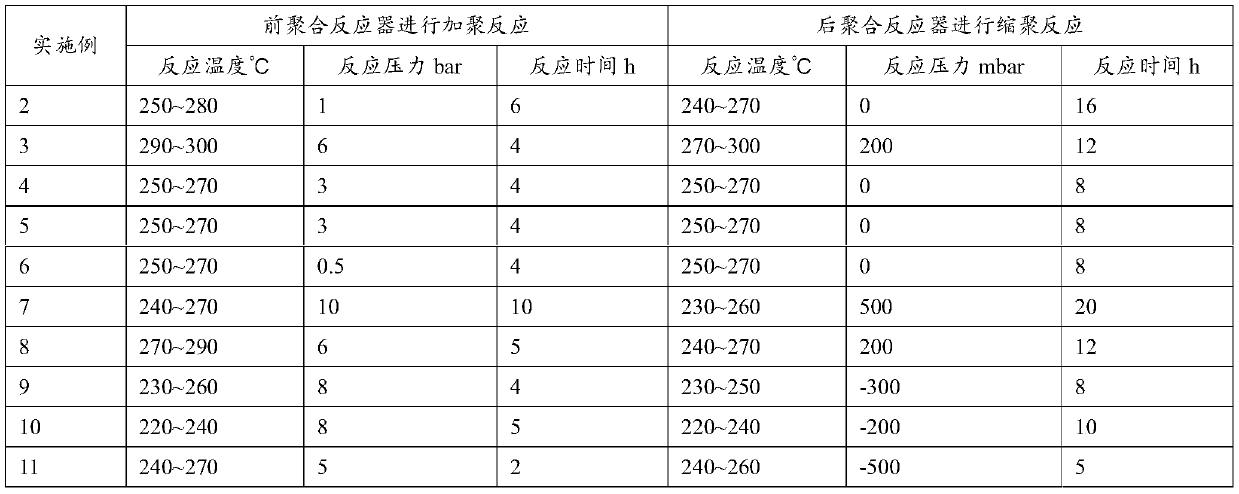

Method for continuously producing lactam copolymer

A method for continuously producing the lactam copolymer comprises the following steps: A1, uniformly mixing a lactam melt with water, and then feeding the mixture into a pre-polymerization reactor for hydrolysis ring-opening reaction to obtain a lactam oligomer; A2, uniformly mixing the lactam oligomer prepared in the step A1 with a condensation polymer of binary acid and diamine which are addedon line, and then enabling the mixture to enter an exchange reactor for exchange reaction to obtain an oligomer melt of a lactam copolymer; A3, enabling the oligomer melt prepared in the step A2 to enter a pre-polymerization reactor for addition polymerization, so as to obtain the prepolymer melt of the lactam copolymer; A4, removing residual moisture from the prepolymer melt prepared in the stepA3 through a melt dryer, and then enabling the prepolymer melt to enter a post-polymerization reactor for polycondensation reaction, so as to obtain a lactam copolymer melt; and A5, sequentially granulating, extracting and drying the lactam copolymer melt prepared in the step A4 to obtain lactam copolymer slices. The regularity of the molecular structure of the produced copolymer can be improved.

Owner:CHINESE TEXTILE ACAD +1

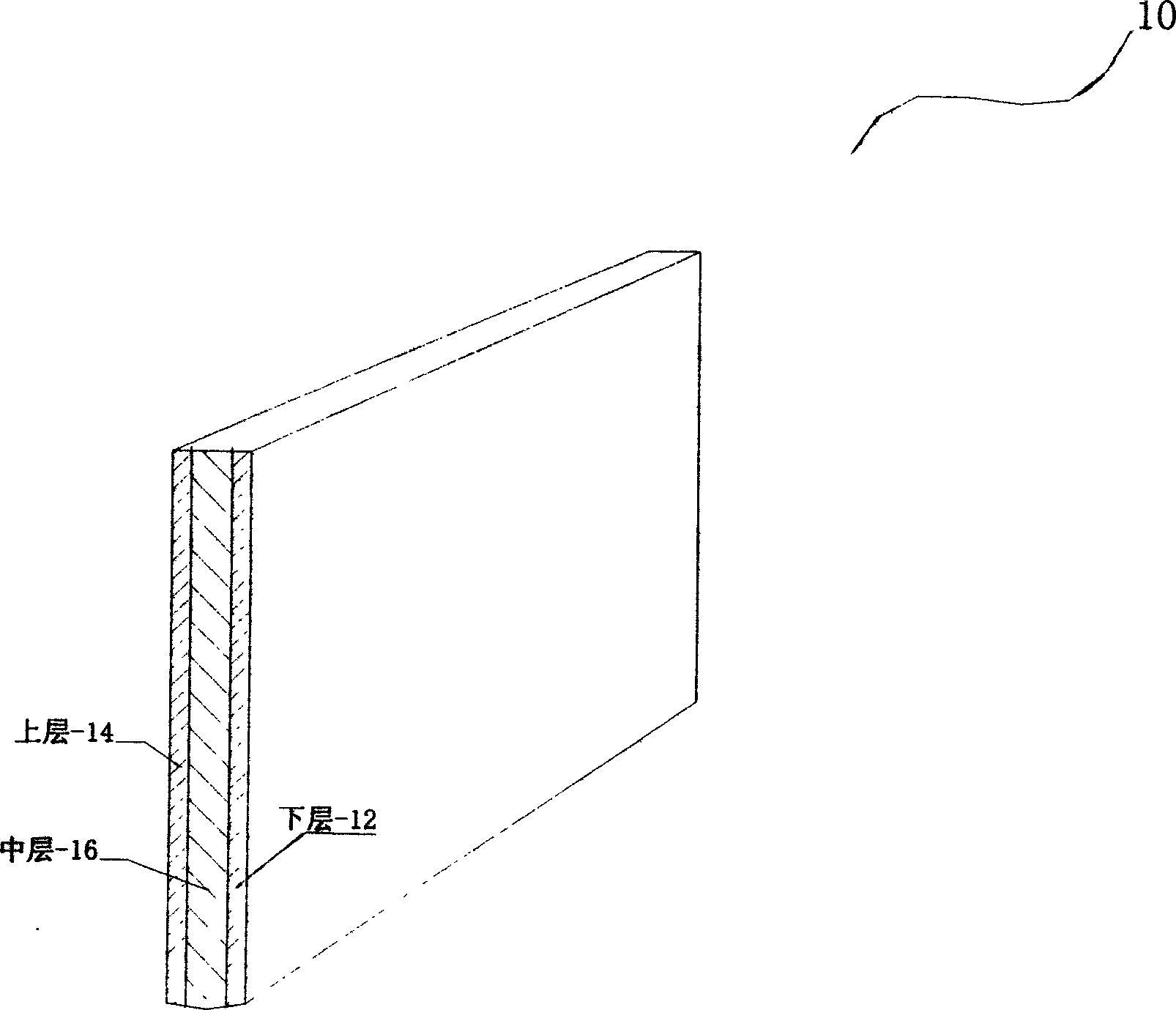

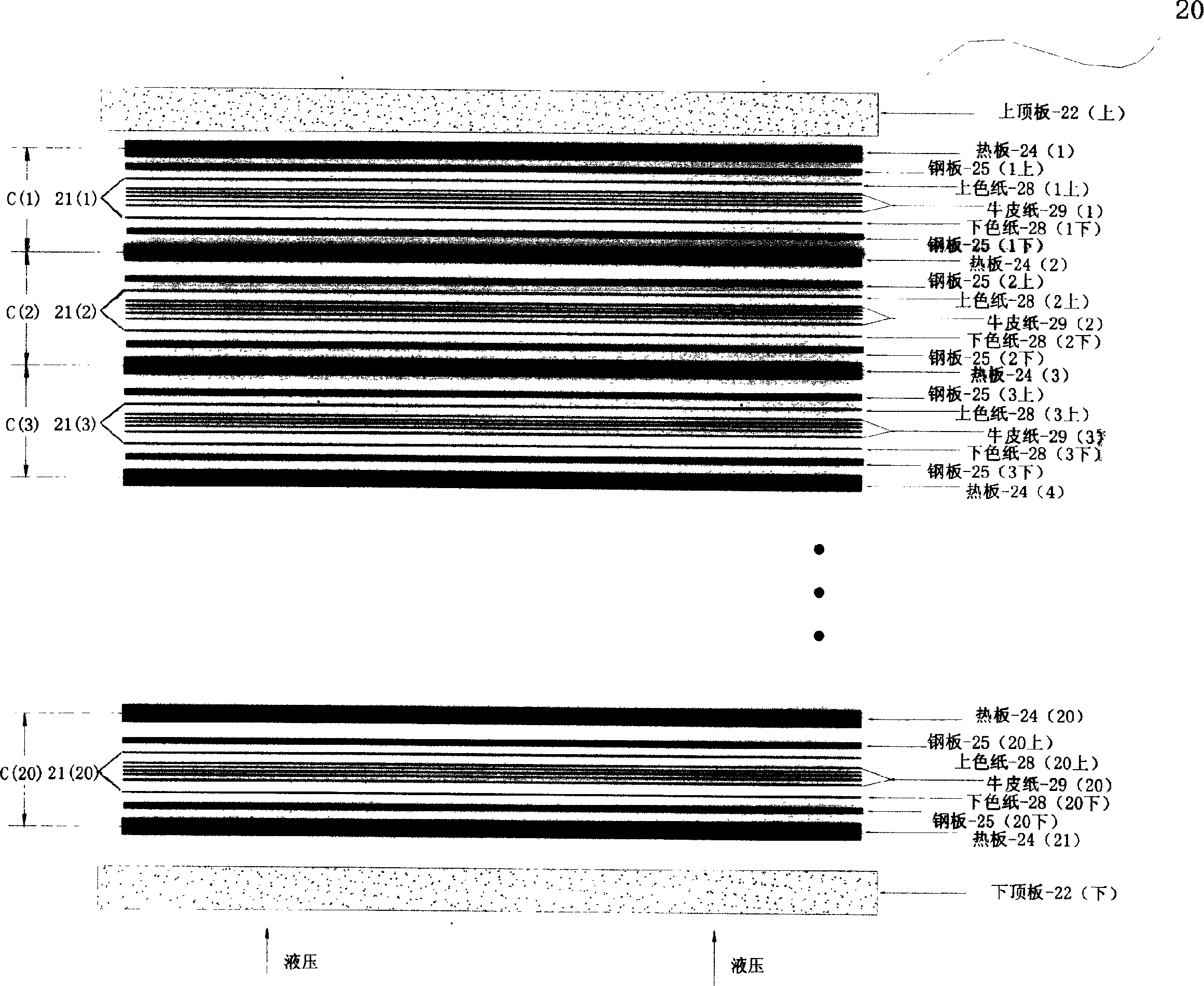

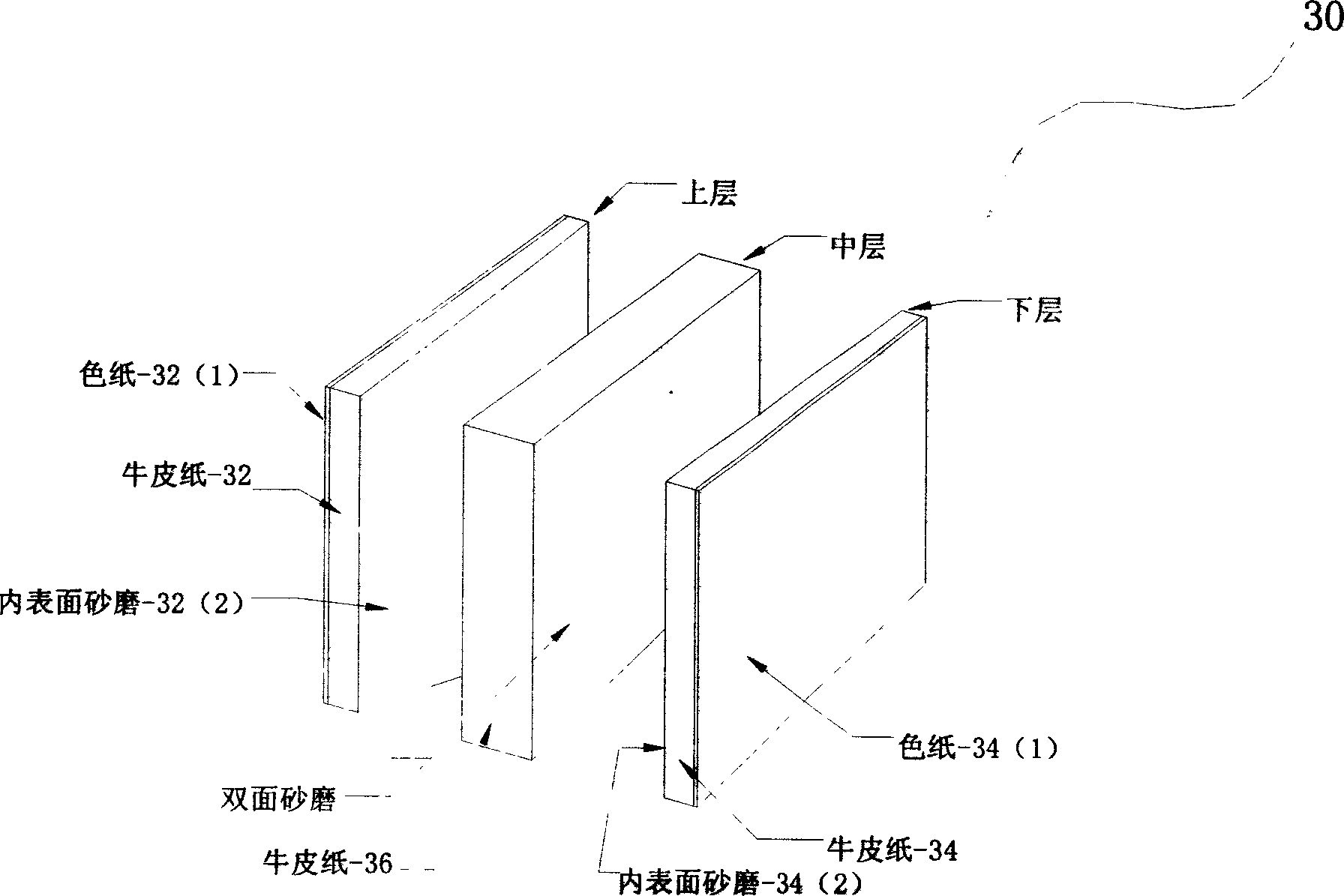

Double-resistance plate and its manufacturing method

InactiveCN1814443AIncrease productionImprove production flexibilitySynthetic resin layered productsPaper/cardboard layered productsInternal layerHeat press

The invention discloses a three layer structure endurable board that includes the first outside layer, internal layer, the second outside layer. The internal layer is made up of thick solid core board; and the first and second outside layer is thin board body. The benefit effect of the invention is that under the circumstance of certain thermal pressing machine resource, the yield of endurable board and elasticity of production would be improved.

Owner:WILSONART SHANGHAI

Photovoltaic cell string positioning method based on robot

ActiveCN113043334AResolve size inconsistenciesImprove production flexibilityProgramme-controlled manipulatorEngineeringMechanical engineering

The invention relates to the field of photovoltaic cell string positioning of a robot, in particular to a photovoltaic cell string positioning method base on the robot. The photovoltaic cell string positioning method comprises the following specific steps of: S1, building an implementation platform; S2, calibrating a relation between hands and eyes; S3, putting a photovoltaic cell string on a conveying belt, and regarding the photovoltaic cell string as a standard photovoltaic cell string; S4, determining an angular point position; S5, setting a standard grabbing pose; S6, calculating the grabbing pose of the robot according to the data in the step S5; S7, obtaining a deviation formula; S8, obtaining an angular point position formula. Compared with the prior art, the two opposite angles of the photovoltaic cell string correspond to the view field of a camera I and the view field of a camera II respectively, and any hardware facility and software parameters are not changed, so that the robot can position and grab the photovoltaic cell string, therefore the production flexibility is improved, and the problem of size inconsistency during photovoltaic production is solved.

Owner:上海埃奇机器人技术有限公司 +1

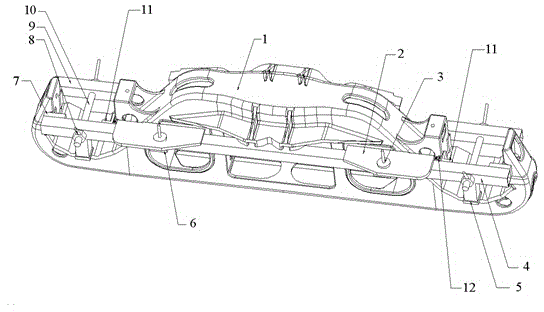

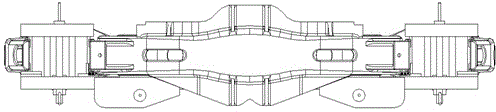

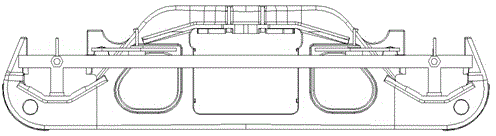

A ZOCT type bogie side frame cross-bearing installing base assembly welding tool

ActiveCN104889640AEnsure left and right symmetryNo displacementWelding/cutting auxillary devicesAuxillary welding devicesBogieCross bracing

The invention provides a ZOCT type bogie side frame cross-bearing installing base assembly welding tool comprising a tool body (4) with a square tube structure. Two locating and clamping bases (6) are arranged on the tool body (4). Each locating and clamping base (6) is provided with a locating pin (3) which fixes a support base plate (2) of a ZOCT type side frame (1) on the corresponding locating and clamping base (6). The tool body (4) is also provided with first locating bases (5) used for determining the distance between the support base plates (2) and the top surface of the side frame, second locating bases (11) used for location and centering, and third locating bases (7) used for location assisting. The assembly welding tool restrains several crucial dimensions of cross-bearing installing bases, thereby guaranteeing that the position and the dimensions of the cross-bearing installing base meet the requirement of drawings. The tool structure is simplified and the operation is simpler. The location is direct and adjustable location.

Owner:CRRC GUIYANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com